Introduction........................................................2

Precautions.........................................................3

Preparations.......................................................4

Required Items ..................................................4

Optional Items ..................................................4

Suggested Supplies ...........................................4

Building Notes ..................................................5

Types of Wood..................................................5

Metric Conversions............................................5

Die Patterns ...................................................6&7

Build the Tail Group ............................................8

Build the Fin......................................................8

Build the Rudder................................................8

Build the Stabilizer ............................................9

Build the Elevators.............................................9

Build the Wing....................................................9

Join the Wing Halves.......................................14

Build the Ailerons............................................16

Build the Fuselage.............................................16

Final Assembly .................................................20

Finishing ..........................................................24

Set the Control Throws......................................25

Balance the Model............................................26

Preflight ...........................................................26

At Home..........................................................26

At The Flying Site .............................................26

Engine Safety Precautions .................................27

Flight................................................................27

Find a Safe Place to Fly.....................................27

Takeoff................................................Back Cover

Flying .................................................Back Cover

Landing...............................................Back Cover

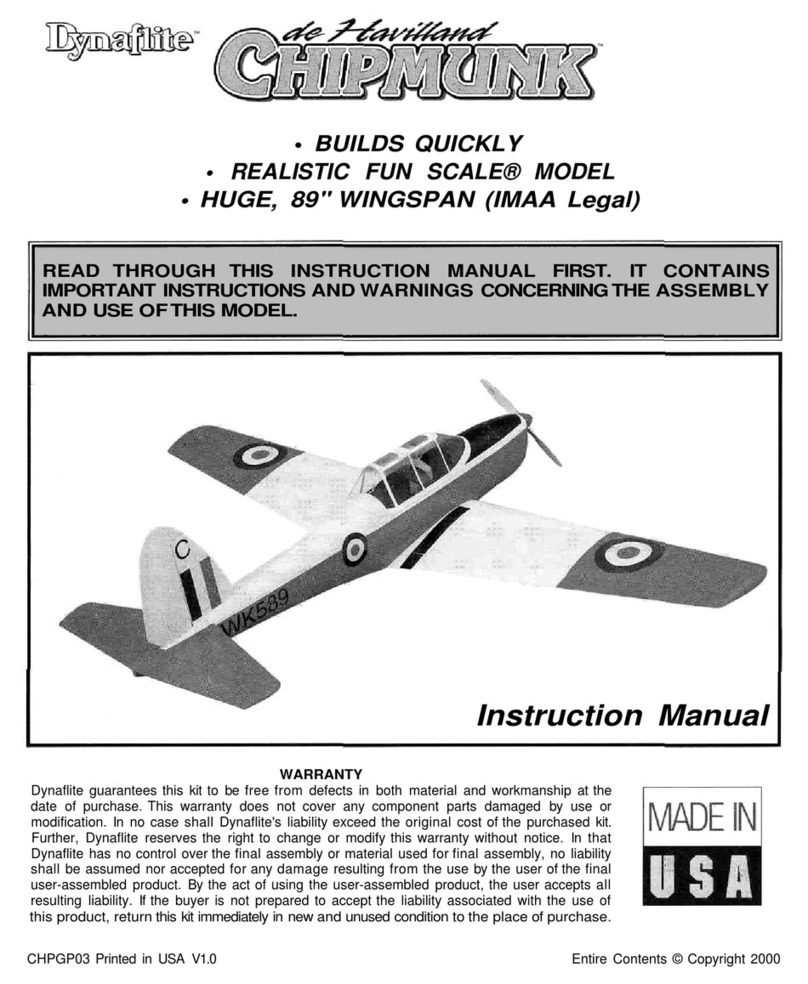

Congratulations on your choice of this kit for your

next project. The Fly Baby is a Fun Scale™model of

a true classic aircraft. It has the presence that only a

big model can carry off. The full scale Fly Baby was

actually derived from a model aircraft. This kit is a

model of that full scale aircraft.

The Dynaflite Fly Baby was designed to allow the

modeler a wide selection of power plants from a .75

two stroke to a 25 cc gas engine. With an airplane

this large and a power plant selection this broad,

there are a few problems that may come up. If you

use a light .75 two stroke you will need to add

weight to the nose. A .91 4 stroke will balance very

closely. With a gas motor like the US Engines 25cc

you will need to add weight in the tail.

At Dynaflite we take pride in offering kits that are

simple and straightforward to build and provide

value for your modeling dollar. Because of the size

and cost of this model, we assume you have built

several models and have a general working

knowledge of modeling and its terms.

If you HAVE NOT built and flown several kits, do

yourself a favor - back up and get some experience

before beginning this kit.

Please inventory and inspect all parts carefully

before starting to build! If any parts are missing,

broken or defective or if you have any questions

about building or flying this model, please call us at

(217) 398-8970 and we'll be glad to help. If you are

calling for replacement parts, please look up the

part numbers and have them ready when calling.

INTRODUCTIONTABLE OF CONTENTS

2