DYNISCO SC170 Manual

11

11

1

11

11

1

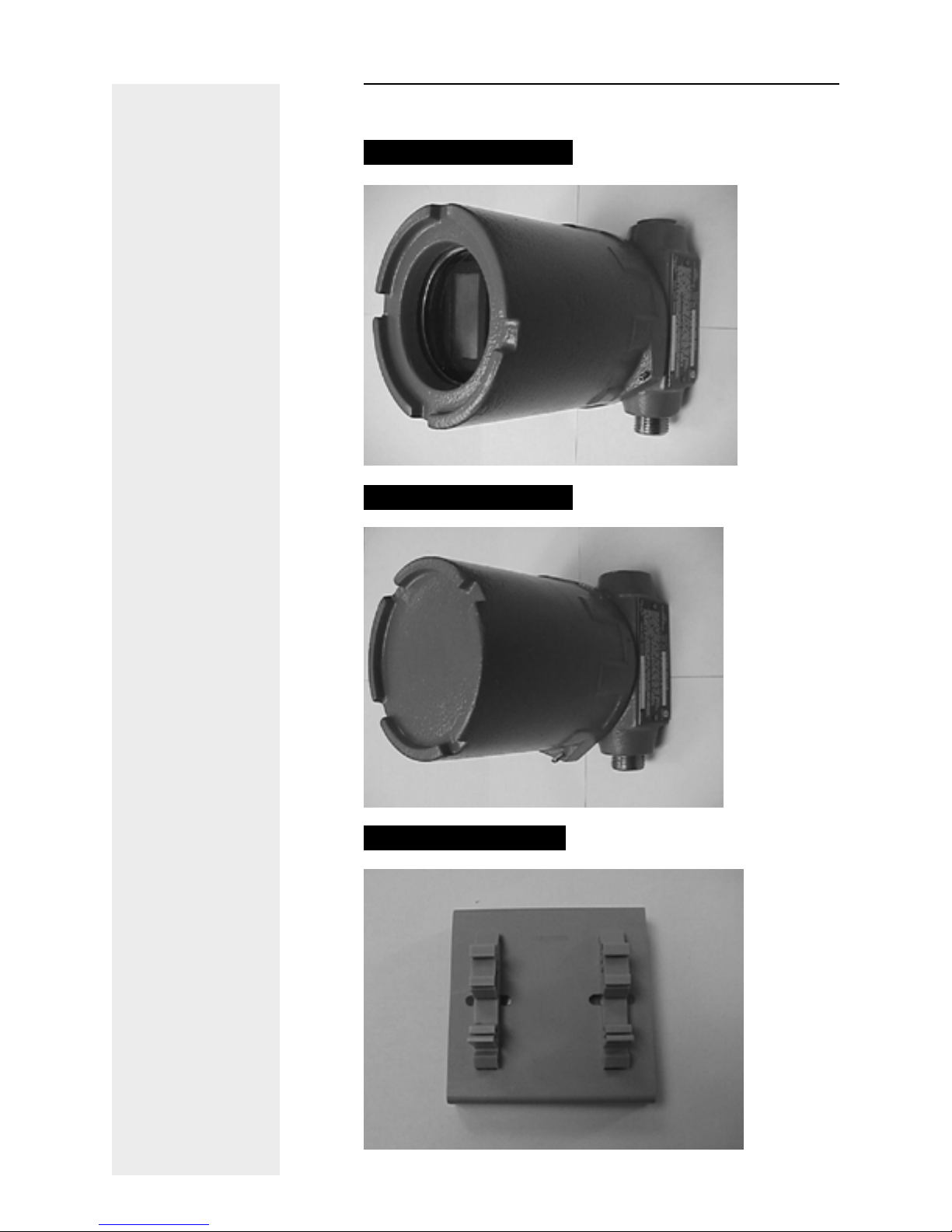

1.0 INTRODUCTION

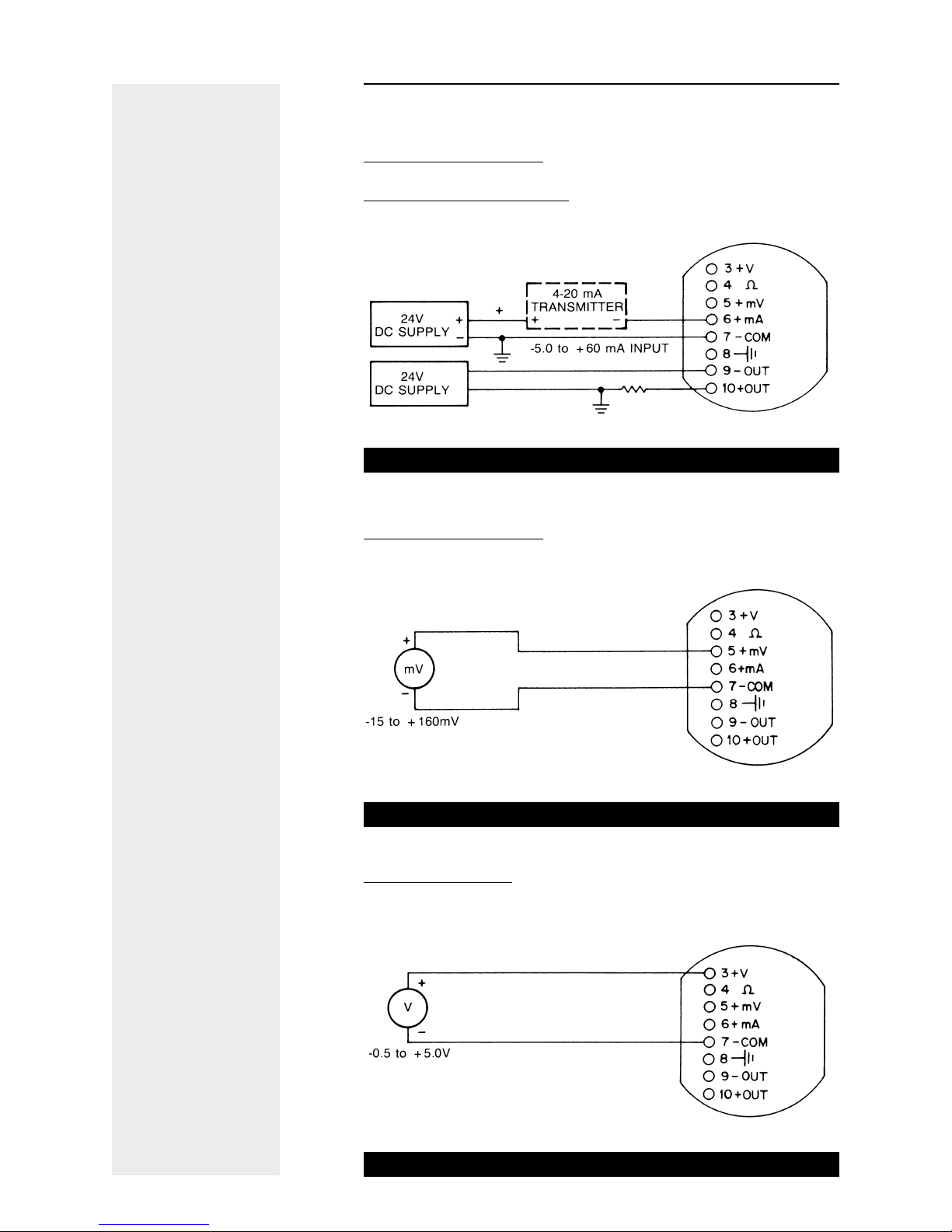

The SC170 is a programmable, two-wire, isolated signal conditioner

that accommodates DC milliamperes, DC millivolts, DC volts,

Potentiometer (slidewire), two and three wire resistance as inputs.

This instrument is exceptionally versatile and can be used when any

one or all of the following requirements exist:

• Signal isolation

• Conversion of signal types (e.g., Millivolt input to 4 to 20mA

output)

• User-tailored noise filter to eliminate noise without damping

• Local digital display in engineering units

• Bar graph display indicating percent of span

• Local configuration without external calibration sources

• NIST traceable calibration warranted for 24 months.

The SC170 achieves its performance through the use of digital signal

processing and microcontroller technologies. Many of the features,

such as the automatic self diagnostics and the exceptional temperature

stability, are transparent to the user.

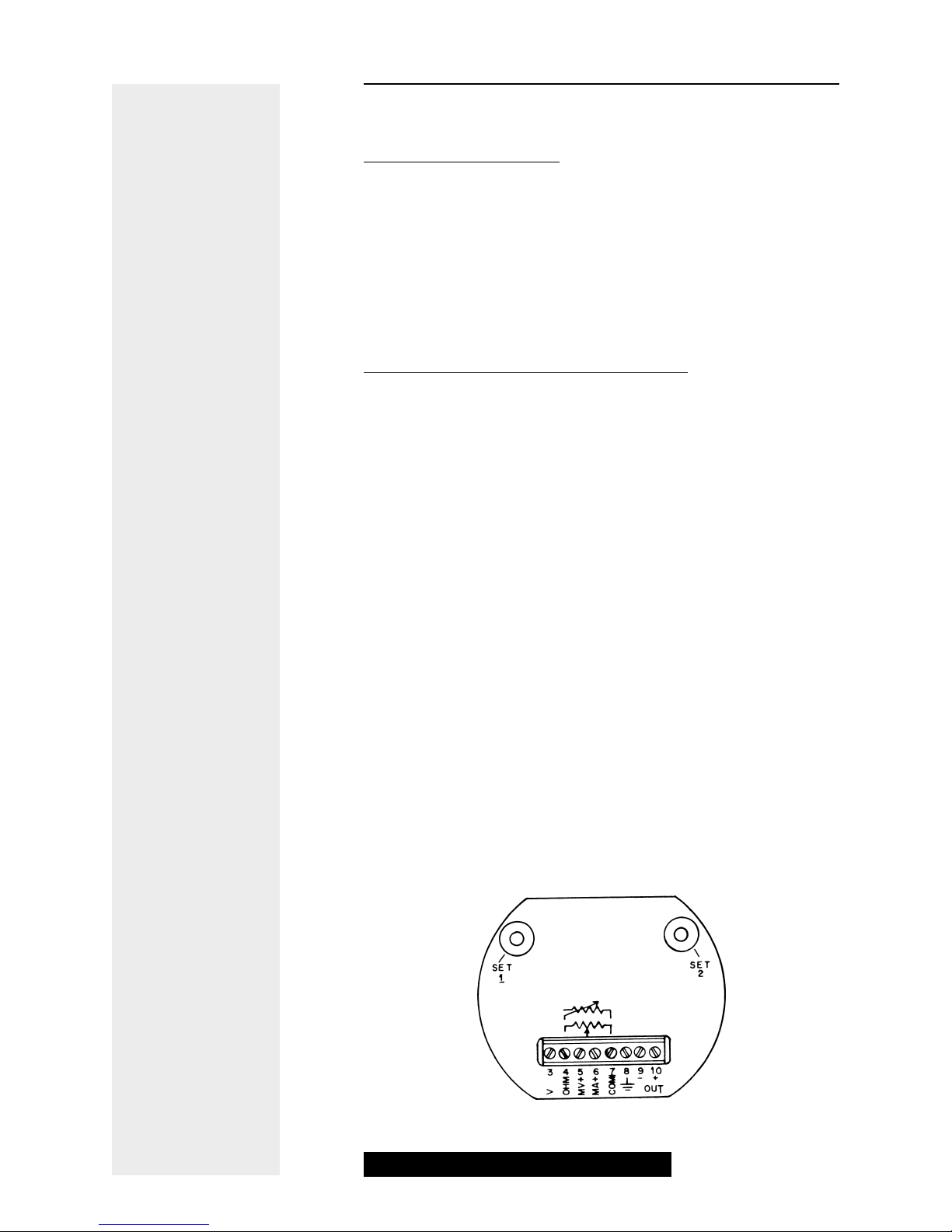

It is simple to setup and operate the SC170 signal conditioner. It can

be set up, with a smart local display, the LD-2, and a two-key

keyboard, the KB-2. These accessories facilitate local configuration

and ranging of the signal conditioner. In operation, the local LCD

display indicates the measured signal and units of measurement to six

digit resolution, an analog percent of range indication and also

provides a seven-character alphanumeric label or message indication.

The SC170 signal conditioner does not have any potentiometers or

switches to set, and there are no user-serviceable components inside

the enclosure. It has a two-year NIST traceable calibration warranty.

Opening the enclosure will void the manufacturer’s warranty.

This manual is divided into several main sections. Section One,

INTRODUCTION, describes briefly the signal conditioner and the

organization of this manual. Section Two, UNPACKING AND

INSTALLATION, contains much useful information for the first time

installer. Section Three, SIGNAL CONDITIONER OPERATION,

contains analog mode of operation. Section Four, CONFIGURATION,

THE DISPLAY MODE, explains display mode. Section Five,

APPLICATIONS INFORMATION, contains additional applications

information. Section Six, SPECIFICATIONS, deals with the signal

conditioner specification.