Dynon Avionics FlightDEK-D180 User manual

FlightDEK-D180

Installation Guide

This product is not approved for installation in type certificated aircraft

P/N 100600-000, Revision H

For use with firmware version 5.4

August, 2010

Copyright © 2003-2010 by Dynon Avionics, Inc.

Contact Information

Dynon Avionics, Inc.

19825 141st Place NE

Woodinville, WA 98072

Phone: (425) 402-0433 - 7:00 AM – 5:00 PM (Pacific Time) Monday - Friday

Fax: (425) 984-1751

Dynon Avionics offers online sales, extensive support, and continually-updated information on its products via its

Internet sites:

www.dynonavionics.com/support –Dynon Avionics primary web site; including:

docs.dynonavionics.com – Current and archival documentation.

downloads.dynonavionics.com – Software downloads.

support.dynonavionics.com – Support resources.

store.dynonavionics.com – Dynon’s secure online store for purchasing all Dynon products 24 hours a day.

wiki.dynonavionics.com – Dynon Avionics’ Documentation Wiki provides enhanced, extended,

continuously-updated online documentation contributed by Dynon employees and customers.

forum.dynonavionics.com – Dynon Avionics’ Internet forum where Dynon customers can interact and

receive Dynon technical support outside of telephone support hours. A key feature of the forum is that it

allows the exchange of diagrams, photos, and other types of files.

newsletter.dynonavionics.com – Dynon’s email newsletter.

blog.dynonavionics.com – Dynon’s blog where you can find new and interesting Dynon-related content.

Copyright

2003-2010 Dynon Avionics, Inc. All rights reserved. No part of this manual may be reproduced, copied, transmitted, disseminated or stored in

any storage medium, for any purpose without the express written permission of Dynon Avionics. Dynon Avionics hereby grants permission to

download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed for

personal use, provided that such electronic or printed copy of this manual or revision must contain the complete text of this copyright notice and

provided further that any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Information in this document is subject to change without notice. Dynon Avionics reserves the right to change or improve its products and to

make changes in the content without obligation to notify any person or organization of such changes. Visit the Dynon Avionics website

(www.dynonavionics.com) for current updates and supplemental information concerning the use and operation of this and other Dynon Avionics

products.

Limited Warranty

Dynon Avionics warrants this product to be free from defects in materials and workmanship for three years from date of shipment. Dynon

Avionics will, at its sole option, repair or replace any components that fail in normal use. Such repairs or replacement will be made at no charge

to the customer for parts or labor. The customer is, however, responsible for any transportation cost. This warranty does not cover failures due to

abuse, misuse, accident, improper installation or unauthorized alteration or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE, AND IN LIEU OF ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, INCLUDING ANY LIABILITY ARISING UNDER WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, WHICH

MAY VARY FROM STATE TO STATE.

IN NO EVENT SHALL DYNON AVIONICS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE OR INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN

THE PRODUCT. SOME STATES DO NOT ALLOW THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Dynon Avionics retains the exclusive right to repair or replace the instrument or firmware or offer a full refund of the purchase price at its sole

discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

These instruments are not intended for use in type certificated aircraft at this time. Dynon Avionics makes no claim as to the suitability of its

products in connection with FAR 91.205.

Dynon Avionics’ products incorporate a variety of precise, calibrated electronics. Except for replacing the optional internal backup battery in

EFIS-based products per the installation guide, our products do not contain any field/user-serviceable parts. Units that have been found to have

been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon Avionics unit is opened up, it will require calibration

and verification at our Woodinville, WA offices before it can be considered airworthy.

Table of Contents

Contact Information......................................................................................................................................................iii

Copyright......................................................................................................................................................................iii

Limited Warranty .........................................................................................................................................................iii

1. 1-1Introduction

OEM Installations...................................................................................................................................................... 1-1

Warning ..................................................................................................................................................................... 1-1

About this Guide........................................................................................................................................................ 1-2

Menu Descriptions..................................................................................................................................................... 1-2

2. 2-1Wiring Overview

Recommended Wiring Practices................................................................................................................................2-1

Power Requirements.................................................................................................................................................. 2-1

Grounding.................................................................................................................................................................. 2-2

+5V Excitation........................................................................................................................................................... 2-3

Thermocouple Harness Preparation........................................................................................................................... 2-3

Harness Mating.......................................................................................................................................................... 2-3

25-Pin Female EFIS Harness..................................................................................................................................... 2-4

37-Pin Female EMS Harness..................................................................................................................................... 2-7

25-Pin Male EMS Harness ........................................................................................................................................ 2-9

3. 3-1Transducer Installation

Tools and Equipment Required ................................................................................................................................. 3-1

Exhaust Gas Temperature (EGT) Probes................................................................................................................... 3-2

Cylinder Head Temperature (CHT) Probes ............................................................................................................... 3-3

Tachometer ................................................................................................................................................................ 3-4

Manifold Pressure Sensor.......................................................................................................................................... 3-5

Oil Pressure Sensor.................................................................................................................................................... 3-6

Oil Temperature Sensor............................................................................................................................................. 3-7

Fuel Pressure Sensor.................................................................................................................................................. 3-7

Fuel Flow Sensor....................................................................................................................................................... 3-9

Fuel Level Sensor .....................................................................................................................................................3-11

Ammeter Shunt.........................................................................................................................................................3-12

General Purpose Inputs.............................................................................................................................................3-13

Contacts ....................................................................................................................................................................3-18

General Purpose Thermocouple ...............................................................................................................................3-19

4. 4-1Instrument Installation

Selecting a Remote Compass Module Location ........................................................................................................ 4-1

EDC-D10A Communication Cable ........................................................................................................................... 4-2

Power Inputs.............................................................................................................................................................. 4-3

Serial Communication Cables ................................................................................................................................... 4-4

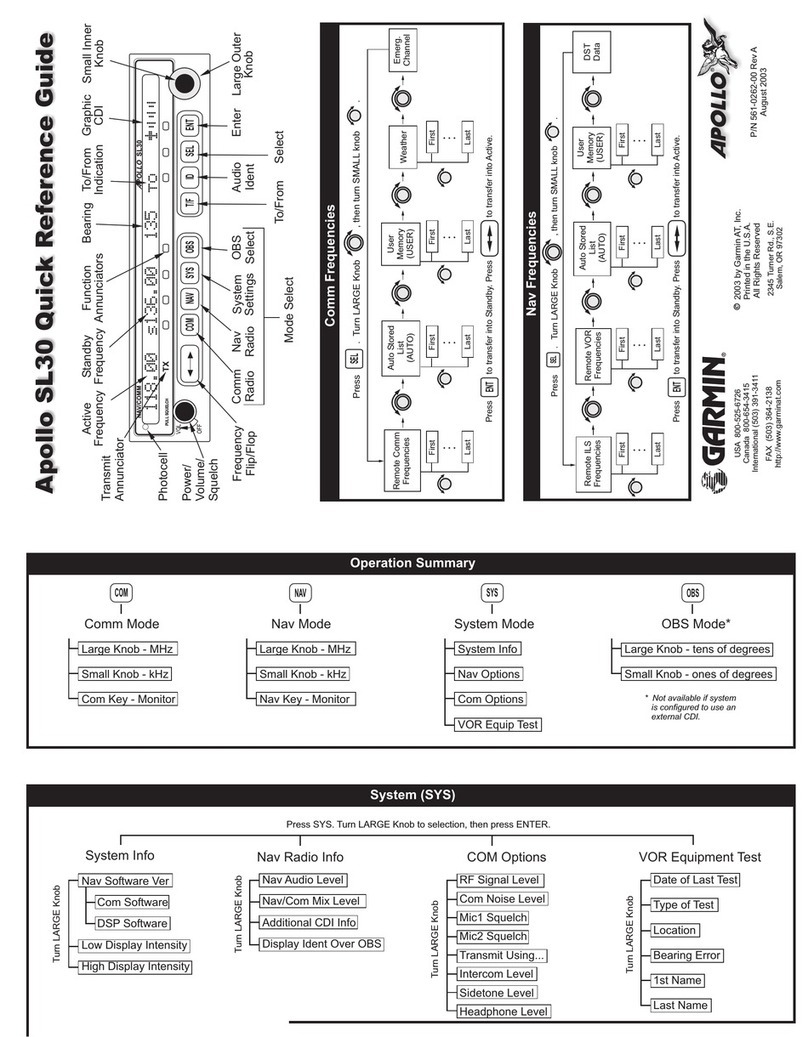

SL30 and/or GPS connection..................................................................................................................................... 4-6

Altitude Encoder Wiring ........................................................................................................................................... 4-8

External EMS Warning Light...................................................................................................................................4-10

Audio Alert Outputs .................................................................................................................................................4-10

Dynon Smart Avionics Bus (DSAB) Wiring............................................................................................................4-11

Panel Location and Mounting...................................................................................................................................4-13

Connecting Static & Pitot Lines ...............................................................................................................................4-14

5. 5-1EFIS Calibration and Configuration

Ensuring Proper Installation ...................................................................................................................................... 5-1

Setting Zero Pitch (In flight)...................................................................................................................................... 5-1

FlightDEK-D180 Installation Guide v

Table of Contents

vi FlightDEK-D180 Installation Guide

Compass Heading Calibration ................................................................................................................................... 5-1

Configure Airspeed Color Thresholds....................................................................................................................... 5-4

6. 6-1EMS Configuration

Full-Page Setup Menu Overview............................................................................................................................... 6-1

Alarm and Color Threshold Configuration................................................................................................................ 6-2

Global Parameters Setup ........................................................................................................................................... 6-3

Engine Type Configuration ....................................................................................................................................... 6-4

Fuel Level Calibration ............................................................................................................................................... 6-5

Trim Calibration ........................................................................................................................................................ 6-6

Flaps Calibration ....................................................................................................................................................... 6-7

Tachometer ................................................................................................................................................................ 6-8

Manifold Pressure...................................................................................................................................................... 6-8

Oil Pressure ............................................................................................................................................................... 6-9

Oil Temperature......................................................................................................................................................... 6-9

Exhaust Gas Temperature (EGT) .............................................................................................................................6-10

Cylinder Head Temperature (CHT)..........................................................................................................................6-11

Fuel Level.................................................................................................................................................................6-13

Fuel Pressure ............................................................................................................................................................6-13

Fuel Flow..................................................................................................................................................................6-14

Voltage .....................................................................................................................................................................6-15

Current......................................................................................................................................................................6-15

General Purpose Inputs.............................................................................................................................................6-16

Contacts ....................................................................................................................................................................6-18

General Purpose Thermocouple ...............................................................................................................................6-19

7. 7-1DSAB Configuration

Network Concepts ..................................................................................................................................................... 7-1

Example Networks .................................................................................................................................................... 7-2

Initial Setup ............................................................................................................................................................... 7-4

Brightness Configuration........................................................................................................................................... 7-5

Network Status .......................................................................................................................................................... 7-6

8. 8-1Autopilot Installation and Configuration

Additional Information and Updates ......................................................................................................................... 8-1

DSAB Firmware Compatibility................................................................................................................................. 8-2

Compass Calibration Critical For Certain AP Modes................................................................................................ 8-2

Autopilot System Electrical Installation .................................................................................................................... 8-3

Servo Mechanical Installation ................................................................................................................................... 8-6

AP74 Mechanical Installation...................................................................................................................................8-11

Firmware Upgrades Required For AP Functionality ................................................................................................8-13

AP Servo Configuration ...........................................................................................................................................8-14

AP74 Configuration..................................................................................................................................................8-30

9. 9-1Appendix

Appendix A: Ongoing Maintenance and Troubleshooting........................................................................................ 9-1

Appendix B: Dynon EFIS OAT Probe Installation and Usage.................................................................................. 9-7

Appendix C: HS34 Installation and Configuration...................................................................................................9-10

Appendix D: Dynon AOA/Pitot Installation and Calibration...................................................................................9-24

Appendix E: Encoder Serial-to-Gray Code Converter Installation...........................................................................9-32

Appendix F: Capacitance-to-Voltage Converter Installation....................................................................................9-35

Appendix G: Replacing the FlightDEK-D180 battery pack .....................................................................................9-36

Appendix H: Weights ...............................................................................................................................................9-36

Appendix I: FlightDEK-D180 Specifications...........................................................................................................9-38

1. INTRODUCTION

This manual provides information about the physical, electrical, and plumbing installation of the

FlightDEK-D180, EDC-D10A, optional AOA pitot probe, and all engine sensors purchased from

Dynon Avionics. Additionally, this guide deals with setting up the installation-dependant

firmware options. Because you may not have purchased all the components, you need only read

through the relevant sections of this guide. Information about the operation of this instrument

can be found in the FlightDEK-D180 Pilot’s User Guide.

The EFIS component of the FlightDEK-D180 uses solid-state sensor technology to give an

accurate and easy-to-understand display. To ensure accuracy in its readings, it is very important

that you install the instrument correctly and perform the specified calibration steps. This

installation guide helps you through that process.

OEM Installations

If your FlightDEK-D180 is installed by an OEM distributor, you may find that you are unable to

access some menus and settings. Some Dynon distributors customize various areas of the

FlightDEK-D180 firmware to maintain a consistent pilot experience and minimize integration

issues across a large number of installations. Currently, OEMs can customize access levels to the

following settings on Dynon systems: EMS GLOBAL setup menu, EMS SENSOR setup menu,

fuel calibration, trim calibration, flaps calibration, GPS/NAV setup menu, screen configurations,

data logging, and checklists/data panels. OEM distributors have the option of customizing some

or all of these areas. Please contact your aircraft’s manufacturer if you have any questions about

how your unit has been customized.

Warning

Dynon Avionics’ products incorporate a variety of precise, calibrated electronics. Except for

replacing the optional internal backup battery in EFIS-based products per the installation guide,

our products do not contain any field/user-serviceable parts. Units that have been found to have

been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon

Avionics unit is opened up, it will require calibration and verification at our Woodinville, WA

offices before it can be considered airworthy.

FlightDEK-D180 Installation Guide 1-1

Introduction

1-2 FlightDEK-D180 Installation Guide

About this Guide

In the electronic (.PDF) version of this manual, page and section references in the Table of

Contents and elsewhere act as hyperlinks taking you to the relevant location in the manual. The

latest version of this manual is available on the Dynon Avionics website at

docs.dynonavionics.com.

The following icons are used in this guide:

Any text following this icon describes functionality available only with the HS34 HSI

Expansion Module connected to your system.

Any text following this icon describes functionality available only with the AP74

Autopilot Interface Module connected to your system.

Any text following this icon describes functionality that is possible when multiple Dynon

Avionics products are networked together via the Dynon Smart Avionics Bus (DSAB).

Any text following this icon refers to a setting or situation which merits particularly close

attention.

Menu Descriptions

Throughout this guide, the “>“ character is used to indicate entering a deeper level of the menu

system. For example, “EFIS > INFO > LEFT” indicates entering the EFIS menu, pressing

MORE, then pressing INFO, and then pressing LEFT to enter the left info item menu. Note that

the MORE button is not shown in the sequence, since pressing MORE reveals more options in

the same level of the menu system.

2. WIRING OVERVIEW

Please follow these instructions explicitly as improper wiring can result in permanent damage to

your instrument and/or the accompanying sensors.

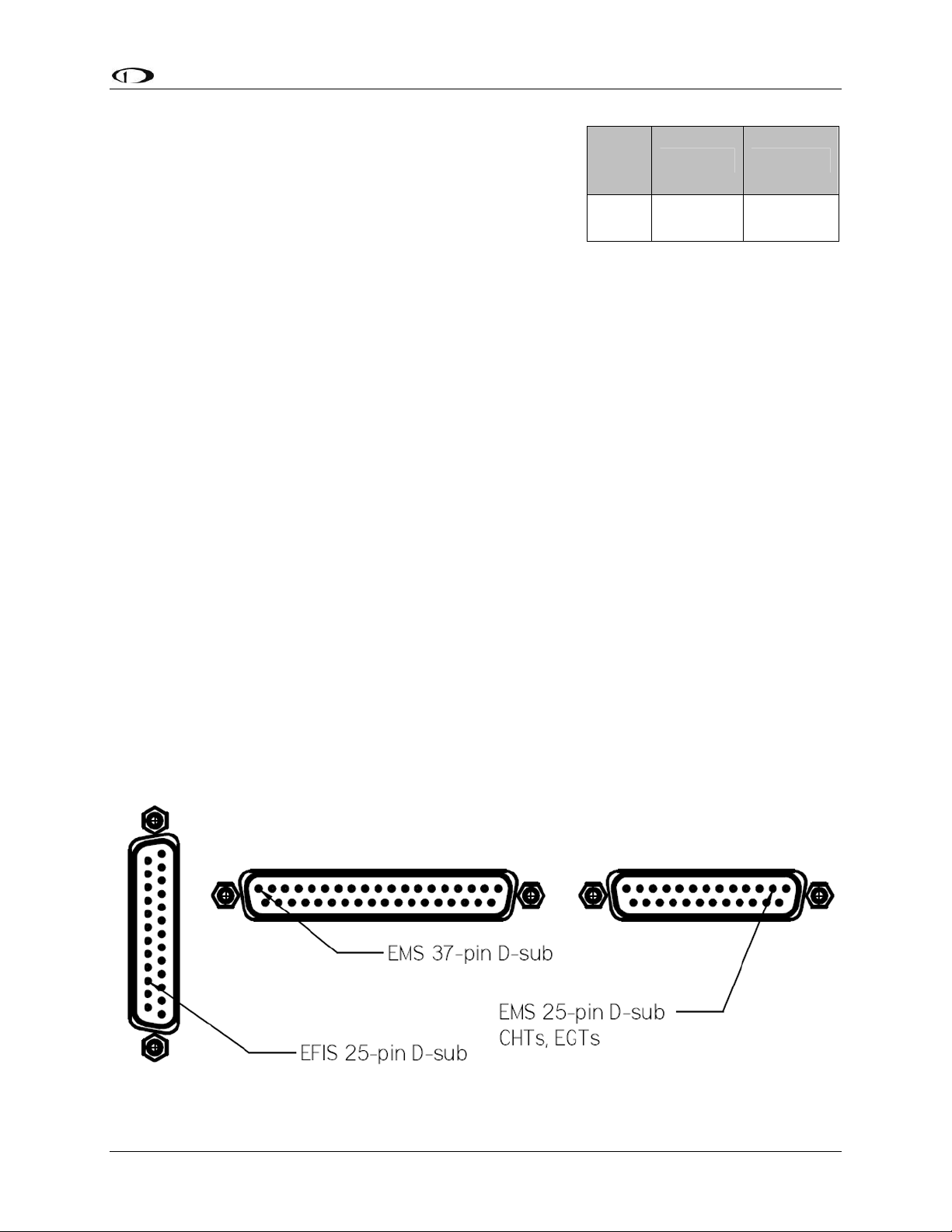

All electrical power and EFIS-specific lines interface with the FlightDEK-D180 via the female

25-pin D-sub connector on the back of the instrument. All EMS-related sensor inputs enter the

FlightDEK-D180 via the male 37-pin and female 25-pin D-sub connectors on the back of the

instrument. Ensure that the unit powers on and that all indicators display expected values before

completing the final physical assembly.

Recommended Wiring Practices

For all electrical connections, use correct wiring techniques, taking care to properly

insulate any exposed wire. A short circuit between any of the wires may cause damage to

the FlightDEK-D180 and/or your aircraft. Make all connections to your harness before

plugging it into any of the components of the system. Do not make connections while

power is applied at any point in the system.

Dynon Avionics sells wiring harnesses for all connections to the FlightDEK-D180. The

harnesses are made up of 22 AWG wire and – with the exception of the thermocouple harnesses

– meet Mil Standard MIL-W-22759/16 (Tefzel insulation). If you have opted not to purchase

these harnesses, please refer to the provided wiring diagrams for construction information. We

recommend that all wire you use also meets Mil Standard MIL-W-22759/16; all wire supplied by

Dynon Avionics (with the exception of thermocouple wire, which uses FEP insulation) meets

this specification.

When using any pre-manufactured harness, verify that each pin has continuity with the expected

wire on the wiring diagram. This test can be easily done with a multimeter. When verifying

harnesses, use the wiring charts and diagrams in this guide as your ultimate authority on pin

function (for any harness) and wire color (for harnesses purchased from Dynon Avionics).

Route all wiring through the engine compartment such that there are no spots where it could

chafe or break. Use appropriate strain relief at all junctions between wires and connectors. We

recommend that you secure all wires at regular intervals along wiring runs to accommodate

vibration effects.

In the sections below, many connections have an

associated legend, as shown at right. All connections on

the EMS male 25-pin harness route to thermocouples and

are color-coded to correspond to the thermocouple

coloring. All connections on the EFIS female 25-pin harness are described in the 25-Pin Female

EFIS Harness section on page 2-4.

Pin Color Function

# Color function

Power Requirements

22 AWG wire is normally sufficient for the power supply and ground lines, but we recommend

that you consult a wire sizing chart and determine the size required for the wire routing in your

particular aircraft. Ensure that the power lines include a circuit breaker or an appropriately sized

FlightDEK-D180 Installation Guide 2-1

Wiring Overview

fuse for the wire you select. Power is fed to the FlightDEK-D180 via pins in the female D-25

connector as shown on the 25-Pin Female EFIS Harness diagram on page 2-4.

The FlightDEK-D180 system-wide power requirement is 14 watts typical and 19 watts

maximum. On a 12-volt system, this translates to about 1.5 amps of maximum current draw. On

a 24-volt system, this translates to about 0.8 amps maximum current draw. Normally, a 3-amp

circuit breaker or fuse is sufficient.

Grounding

Many of the engine sensors require a connection to a

shared electrical ground with the FlightDEK-D180. There

are many places on an aircraft where you could connect

these sensors. However, the ideal location to ground these

sensors is near the FlightDEK-D180 to minimize voltage

differences between the sensor and instrument grounds.

Some sensors (e.g., oil pressure and oil temperature)

connect to ground via their cases’ contact with the engine

or aircraft body. There must be a solid connection between

this “case ground” and the FlightDEK-D180 ground. The oil temperature sensor is very

susceptible to voltage differences between the engine case and the negative terminal of the

battery. Ensure that solid, thick electrical connections exist between the engine and battery

ground. Other sensors (e.g., fuel pressure) do not have a grounded case and have two leads

instead. One lead must be connected to ground, the other to the sensing input of the FlightDEK-

D180. The FlightDEK-D180 has 3 pins on the 37-pin harness which may be used for connecting

such sensors to ground. More than one sensor’s ground may be connected to any of these three

grounds using a splice.

EMS

DB37

Pin

Color Function

5 Black Ground

16 Black Ground

17 Black Ground

The case of the FlightDEK-D180 is connected to its supply ground. If your panel is connected to

aircraft ground, the connection between the instrument’s case and the panel dramatically helps

minimize voltage differences between the instrument and sensor grounds. If your panel is not

metal, or is otherwise isolated from engine ground, connect a 14 AWG or larger wire to the

instrument case. The most convenient place to do this is at the back of the mounting tray.

Additionally, connect any unused EMS ground leads to a convenient ground. Keep all ground

leads as short as possible.

Because of the current drawn by the FlightDEK-D180, even very small resistances between

battery ground and instrument ground can cause voltage differences which adversely affect

engine sensor readings. An easy way to test the quality of the instrument’s ground is to measure

voltage between the ground pin at the FlightDEK-D180 and the ground lead at your aircraft’s

battery. With the FlightDEK-D180 powered on, connect one lead of your voltmeter to a free

ground lead coming from the FlightDEK-D180. Connect the other lead of your voltmeter to the

ground terminal of your battery. The voltage between these two points should measure very

close to 0 mV (within 5 mV). If it does not, you must improve the ground connection between

the ground of your battery and that of your avionics bus.

2-2 FlightDEK-D180 Installation Guide

Wiring Overview

+5V Excitation EMS

DB37

Pin Color Function

18 White/red +5V

excitation

Some of the sensors require either a direct connection, or

connection via a resistor, to the +5V excitation circuit. We

recommend that you allow for more than one splice into

this line.

Thermocouple Harness Preparation

Refer to the 25-Pin Male EMS Harness section on page 2-9 during this procedure. Strip 1” of

brown outer insulation off each thermocouple wire pair on the supplied 25-pin thermocouple

harness. Strip ¼” of insulation from each of the thermocouple wires inside. Crimp the supplied

male Fastons onto each wire on the thermocouple harness. These will later be inserted into the

female Fastons on each thermocouple.

Do not connect the Fastons on the harness with those on the thermocouples until you have routed

the wires and mounted the thermocouples at the desired location.

The thermocouple wires can be cut to a desired length if your application requires. If you need to

extend the length of the thermocouple, you must use the correct type (J or K) thermocouple wire

to accomplish this. It is acceptable to use non-thermocouple fasteners to join two pieces of

thermocouple pair wire, provided the junction does not extend very far or have large temperature

differences across it. Please contact Dynon Avionics to order extension wire.

Harness Mating

The following diagram shows the 3 electrical connectors on the back of the FlightDEK-D180.

The two horizontal connectors are used for the EMS portion of the product; the vertical

connector is used for the EFIS portion. The main EMS harness (for all connections except EGT

& CHT thermocouples) should terminate in a 37-pin female D-sub connector. The EGT/CHT

thermocouple harness should terminate in a 25-pin male D-sub connector. The EFIS harness

(also used to provide power to the instrument) should terminate in a 25-pin female D-sub

connector. The following pages provide wiring diagrams and details for each of these harnesses.

FlightDEK-D180 Installation Guide 2-3

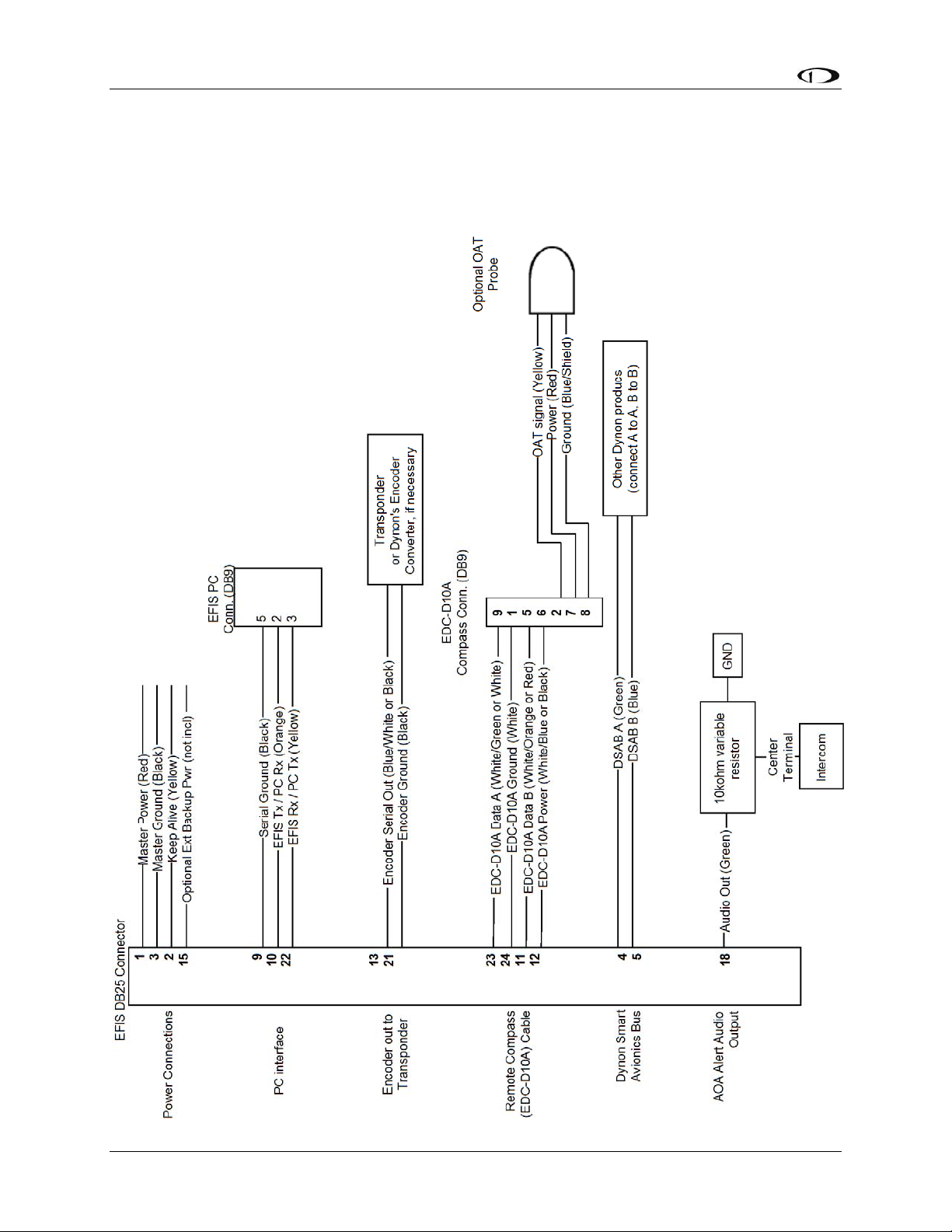

25-Pin Female EFIS Harness

Below is the wiring diagram of the EFIS 25-pin female harness. If you purchased your harness

from Dynon Avionics, it is color coded according to the chart on the following page. Unless

noted otherwise, all wires are 3 feet long on the Dynon-provided harness.

2-4 FlightDEK-D180 Installation Guide

FlightDEK-D180 Installation Guide 2-5

The pin assignments for the female 25-pin harness are repeated below. Note that the pin numbers

are labeled on the face of both the female and male connector. Each connection on the harness

supplied by Dynon is color-coded. These colors are listed in the following chart.

Female

DB25

Pin#

Dynon Harness

Wire Color Function Details

1 Red Master Power (10-30 volts) Page 4-2

2 Yellow Keep Alive Power (10-30 volts, always on) Page 4-2

3 Black Master Ground Page 4-2

4 Green DSAB-A Page 4-11

5 Blue DSAB-B Page 4-11

6 N/A No Connect

7 N/A No Connect

8 N/A No Connect

9 Black (bundled) PC Serial Ground – EFIS logging only Page 4-5

10 Orange (bundled)

FlightDEK-D180 Transmit / PC Serial

Receive (RS-232) – EFIS logging only

Page 4-4

11 White/Orange (Red

on some harnesses) EDC-D10A Data B Page 4-2

12 White/Blue (Black

on some harnesses) EDC-D10A Power (12V) Page 4-2

13 Blue/White (black

on some harnesses) Serial Encoder Transmit (RS-232) Page 9-32

14 N/A No Connect

15 N/A External Backup Power Page 4-2

16 Black Ground

17 N/A No Connect

18 Green Audio Alert Out Page 4-10

19 N/A No Connect

20 N/A No Connect

21 White (Bundled in

Encoder cable) Serial Encoder Ground Page 9-32

22 Yellow (Bundled)

FlightDEK-D180 Receive / PC Serial

Transmit (RS-232) – EFIS logging

Page 4-5

23 White/Green (Green

on some harnesses) EDC-D10A Data A Page 4-2

24 White EDC-D10A GND Page 4-2

25 N/A No Connect

Wiring Overview

WIRING SYSTEM OVERVIEW

The following block diagram depicts the basic layout of the EFIS DB25 electrical connections

and is for reference only. Read the specific instructions for each connection prior to installation.

The colors shown refer to the Dynon-supplied EFIS harness.

2-6 FlightDEK-D180 Installation Guide

Wiring Overview

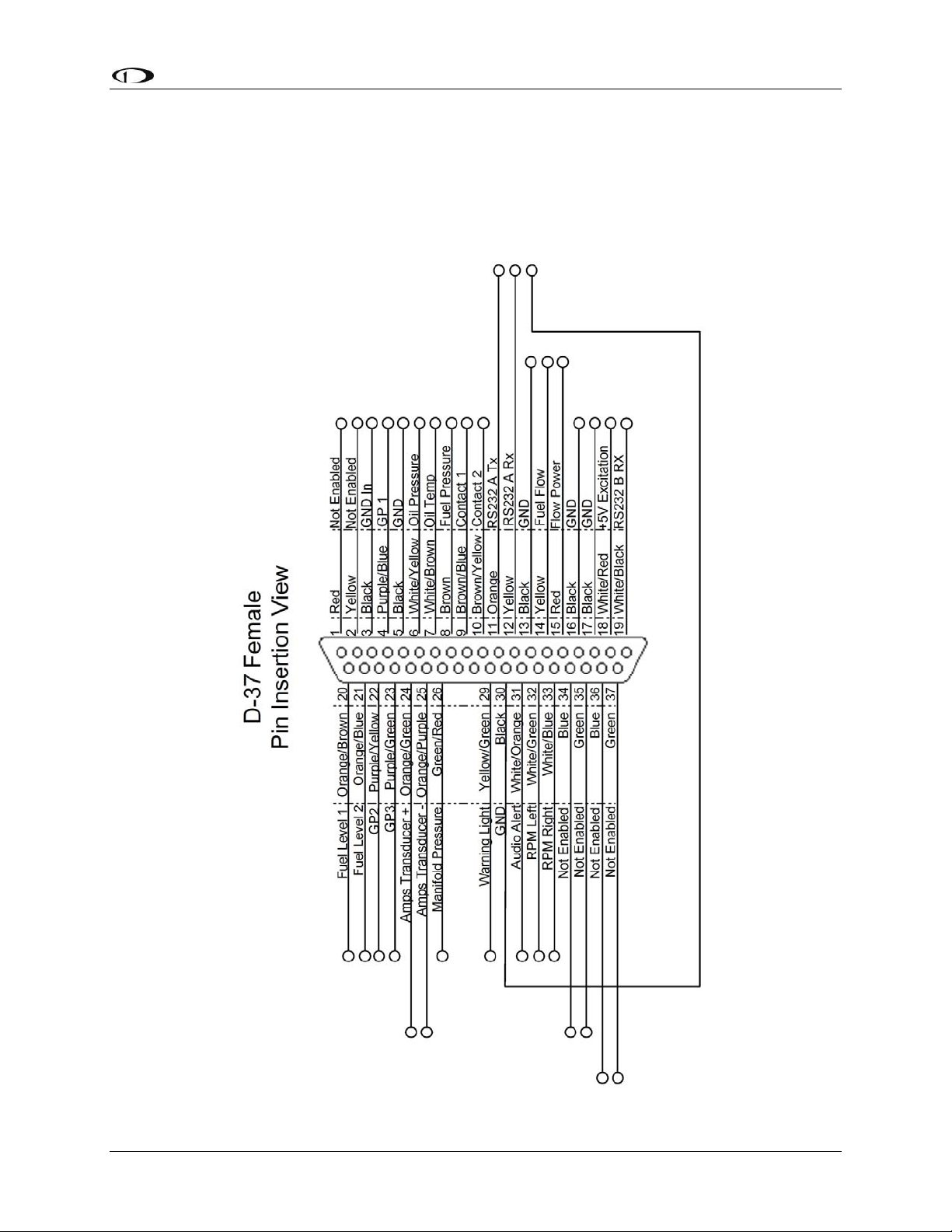

37-Pin Female EMS Harness

Below is the wiring diagram of the EMS 37-pin female harness. If you purchased your harness

from Dynon Avionics, pins 1, 2, 34, 35, 36, and 37 have wires inserted, but are not used. You

may clip the wires or remove the pins as needed. Refer to the following page for detailed pin out

descriptions.

FlightDEK-D180 Installation Guide 2-7

Wiring Overview

2-8 FlightDEK-D180 Installation Guide

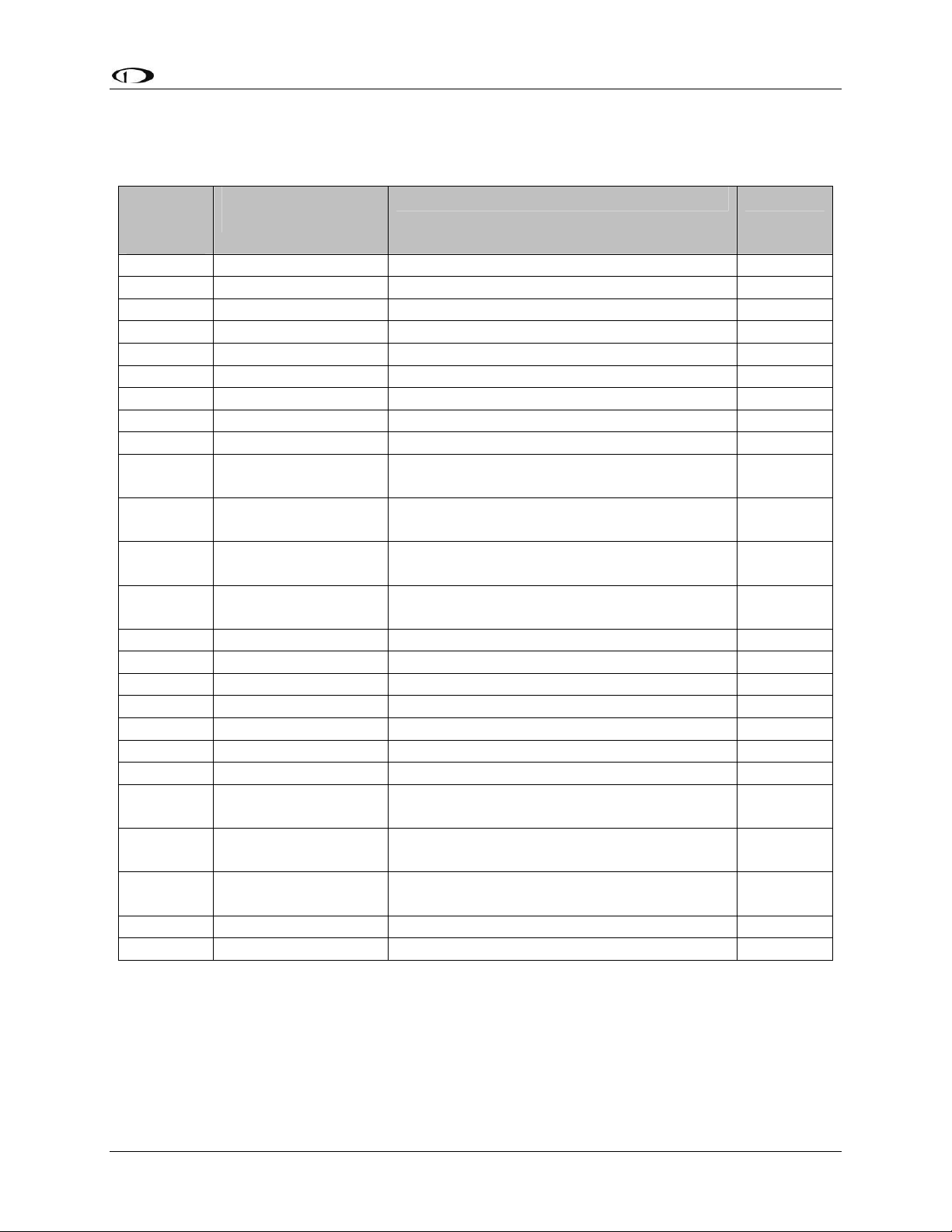

The pin assignments for the female 37-pin harness are repeated below. Note that the pin numbers

are labeled on the face of both the female and male connector. Each connection on the harness

supplied by Dynon is color-coded. These colors are listed in the following chart.

DB37 harness

Pin# Dynon Harness

Wire color Function Details

1 Red Do not connect

2 Yellow Do not connect

3 Black Ground Page 2-2

4 Purple/blue GP 1 (general purpose resistive) Page 3-13

5 Black Ground Page 2-2

6 White/yellow Oil pressure Page 3-6

7 White/brown Oil temperature Page 3-7

8 Brown Fuel pressure Page 3-7

9 Brown/blue Contact 1 Page 3-18

10 Brown/yellow Contact 2 Page 3-18

11

Orange FlightDEK-D180 Transmit / PC Serial

Receive (RS-232) – EMS logging only

Page 4-5

12

Yellow FlightDEK-D180 Receive / PC Serial

Transmit (RS-232) – EMS logging only

Page 4-5

13 Black Ground (Fuel Flow) Page 3-9

14 Yellow Fuel flow input Page 3-9

15 Red Fuel flow power (12V) Page 3-9

16 Black Ground Page 2-2

17 Black Ground Page 2-2

18 White/red 5V excitation circuit Page 2-3

19 White/black Auxiliary Serial Receive (RS-232) Page 4-6

20 Orange/brown Fuel level 1 Page 3-11

21 Orange/blue Fuel level 2 Page 3-11

22 Purple/yellow GP 2 (General Purpose Resistive) Page 3-13

23 Purple/green GP 3 (General Purpose Resistive) Page 3-13

24 Orange/green Amps High Page 3-12

25 Orange/purple Amps Low Page 3-12

26 Green/red Manifold pressure Page 3-5

27 Not supplied General purpose thermocouple (J or K-type) Page 3-19

28 Not supplied General purpose thermocouple (J or K-type) Page 3-19

29 Yellow/green External warning light Page 4-10

30 Black PC Serial ground – EMS logging only Page 4-5

31 White/orange Intercom audio alert Page 4-10

32 White/green RPM left Page 3-4

33 White/blue RPM right Page 3-4

34 Blue Do not connect

35 Green Do not connect

36 Blue Do not connect

37 Green Do not connect

Wiring Overview

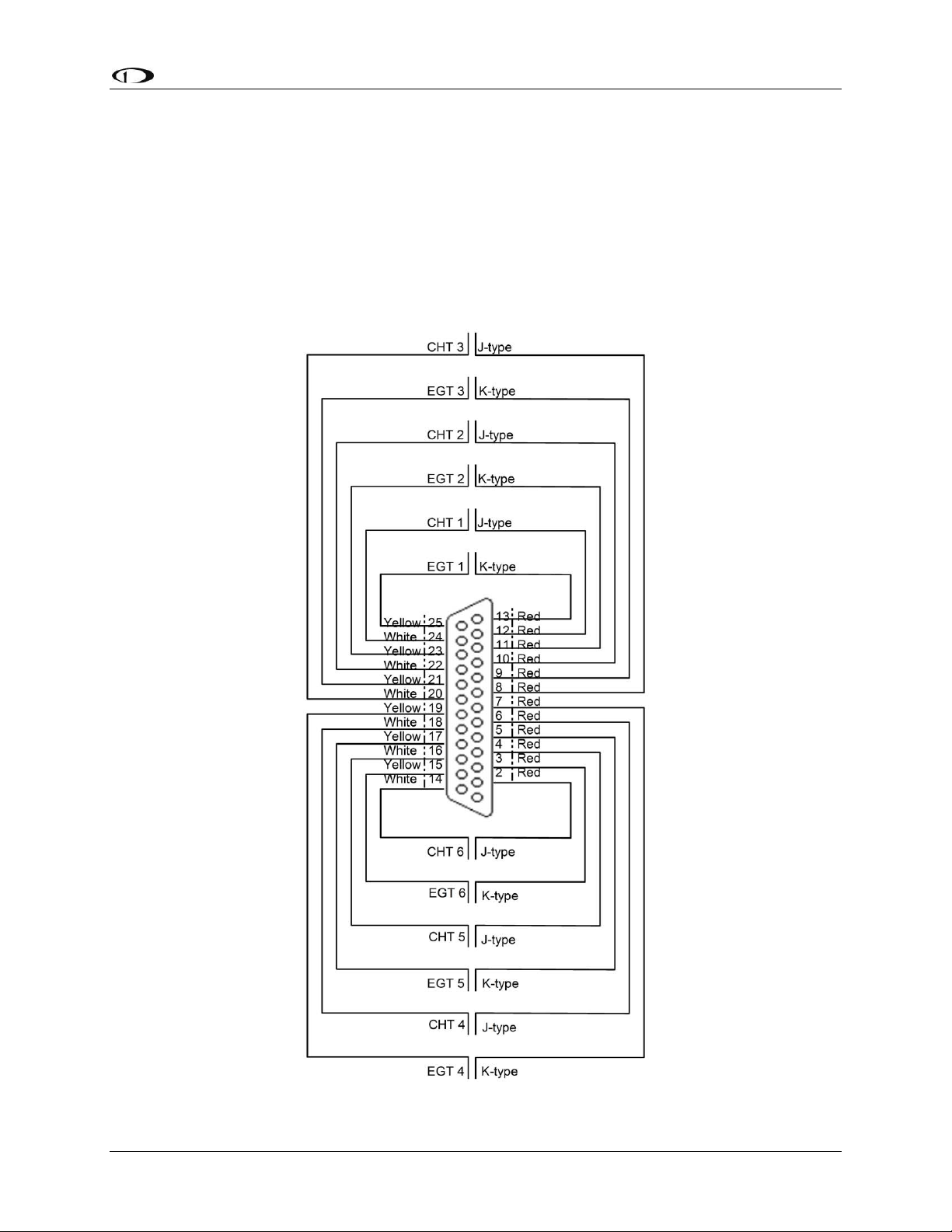

25-Pin Male EMS Harness

Below is the EMS 25-pin harness wiring diagram. The 4-cylinder harness only has EGTs 1

through 4 and CHTs 1 through 4 wired. The Rotax harness only has EGTs 1 and 2 wired, as the

EMS measures the Rotax-supplied resistive CHTs through its GP inputs. On the supplied

harness, each pair of wires is encased in brown insulation and labeled with corresponding

cylinder number. Inside the outer insulations, each wire in the pair has the color listed on the

diagram below. If you are making your own harness, utilize J & K type thermocouple wire as

indicated in the diagram.

FlightDEK-D180 Installation Guide 2-9

3. TRANSDUCER INSTALLATION

This section explains the steps required to install and connect all transducers supplied by Dynon

Avionics. Additionally, connection instructions are given for some transducers that Dynon

Avionics does not sell, like the tachometer, fuel level, flaps, trim, and contacts.

Tools and Equipment Required

The following list contains commonly used tools and equipment; however some of the tools or

equipment listed below may not apply to your installation.

Wire strippers

22 AWG wire (if harness not purchased or extending harness beyond 6 feet)

D-sub pin crimper

Faston/ring terminal crimp tool

oAvailable from www.bandcspecialty.com – (316) 283-8000 – part number RCT-1

Weather Pack crimp tool (common slip joint pliers will also work)

oAvailable from www.whiteproducts.com/tools.shtml

#2 Phillips screwdriver

Flathead screwdriver

¼” ID tubes, any necessary adapters, and clamps for routing manifold pressure to the

sensor.

Drill and 1/8” bit

FlightDEK-D180 Installation Guide 3-1

Transducer Installation

3-2 FlightDEK-D180 Installation Guide

Exhaust Gas Temperature (EGT) Probes

Correct placement of EGT probes on the exhaust manifold is critical to obtaining accurate

readings. Placement differs between engine types, and even specific models. Consult your

specific engine’s manual for proper EGT locations.

ROTAX ENGINES

For Rotax 912 engines, only two of the four cylinders are typically monitored for EGT. Unlike

the CHT probes which are mounted on diagonal cylinders, the EGT probes should be mounted

on the two rear cylinders’ exhaust manifolds. It is critical that the EGT probes be mounted to

parallel cylinders’ exhaust manifolds for proper temperature comparison.

ALL ENGINES

Once you have determined the appropriate EGT locations for your engine, drill 1/8” diameter

holes at the specified positions in the exhaust manifold. Usually, this spot is 2 to 8 inches from

the cylinder. This spot should be on a straight portion of the exhaust manifold, as this provides a

better fit for the hose clamps. For best results, mount all probes the same distance from each

cylinder.

1. Make sure the hole is placed to ensure that the probe does not interfere with the cowl or

spark plug. Also, when making holes, keep in mind that the probe could inhibit the ability

to perform routine maintenance if placed incorrectly.

2. Place probe in exhaust manifold, and secure it by tightening the clamp with a flathead

screwdriver. Make sure the clamp is tight and provides a secure fit, but do not over-tighten

such that visible stress is put on the pipe.

Now, plug each thermocouple wire into its corresponding wire on the thermocouple harness.

Ensure that you match the wire color pairs on the harness to those on the thermocouple. All

thermocouple harnesses supplied by Dynon have each function (e.g., CHT1, EGT1) labeled on

each thermocouple pair.

A loose probe could allow exhaust to leak. This can lead to carbon monoxide poisoning

in the cabin and/or a potential fire. Have a knowledgeable mechanic inspect the

installation.

The probe can come lose during flight, and could potentially come in contact with

rotating engine parts or the propeller. We suggest a safety wire to keep the probe in place.

Other manuals for FlightDEK-D180

1

Table of contents

Other Dynon Avionics GPS manuals

Dynon Avionics

Dynon Avionics SkyView SE User guide

Dynon Avionics

Dynon Avionics EMS-D120 User manual

Dynon Avionics

Dynon Avionics EFIS-D100 User manual

Dynon Avionics

Dynon Avionics SkyView User manual

Dynon Avionics

Dynon Avionics EMS-D10 User manual

Dynon Avionics

Dynon Avionics FlightDEK-D180 User manual

Dynon Avionics

Dynon Avionics EMS-D10 User manual

Dynon Avionics

Dynon Avionics DX15 User manual

Dynon Avionics

Dynon Avionics EFIS-D100 User manual

Dynon Avionics

Dynon Avionics EFIS-D10A User manual