e-motion i3 Metal Motion User manual

ASSEMBLY INSTRUCTIONS

Documentation version 1.1.0

/ 2

Version 1.1.0

INTRODUCTION

/ 3

Version 1.1.0 Version 1.1.0

• Target :

Provide a visual guide of the various steps required to assemble the

«i3 Metal Motion» 3D printer.

• Designers of the i3 Metal Motion :

eMotion Tech : http://www.emotion-tech.com

Hugo FLYE

Mohamad KOUBAR

Tom LOPEZ

• Author of this document :

eMotion Tech : http://www.emotion-tech.com

Anthony BERNA

• Photographics credits :

Pictures and 3D representations made by eMotion Tech :

http://www.emotion-tech.com

• Sources :

http://reprap.org/wiki/reprap

• Licenses :

i3 Metal Motion : CC BY-NC-SA 4.0

This document : CC BY-NC-SA 4.0

http://creativecommons.org/licenses/by-nc-sa/4.0/

• Update :

Last update : 07/02/2018

• Useful links :

You can nd more informations on the following links :

eMotion Tech’s website : http://www.emotion-tech.com

RepRap community : http://reprap.org/wiki/reprap

INTRODUCTION

INTRODUCTION / 4

Version 1.1.0

INTRODUCTION 2

INTRODUCTION 3

SUMMARY 4

PRESENTATION OF THE I3 METAL MOTION 5

SAFETY INSTRUCTIONS 6

BILL OF MATERIAL 7

A. Metallic parts 7

B. Mechanical parts 7

C. Plastic parts 8

D. Hardware 8

E. Electronic parts 9

F. Extruder kit 9

G. Hexagon kit 10

H. Cables and extensions 10

I. Other 10

MECHANICAL ASSEMBLY 11

LCD screen 12

Electronic board 13

IEC connector 14

Reset button 16

Y axis (part 1) 17

Stabilized power supply 19

Y axis (part 2) 20

Y axis carriage 23

Y axis belt 25

Y Axis plate 27

Z Axis right side carrriage 32

Z Axis left side carriage 35

Print head 36

X axis carriage 38

Z axis assembly 46

X axis assembly 53

Auto-leveling probe assembly 65

ELECTRONIC ASSEMBLY 66

SUMMARY

/ 5

Version 1.1.0 Version 1.1.0

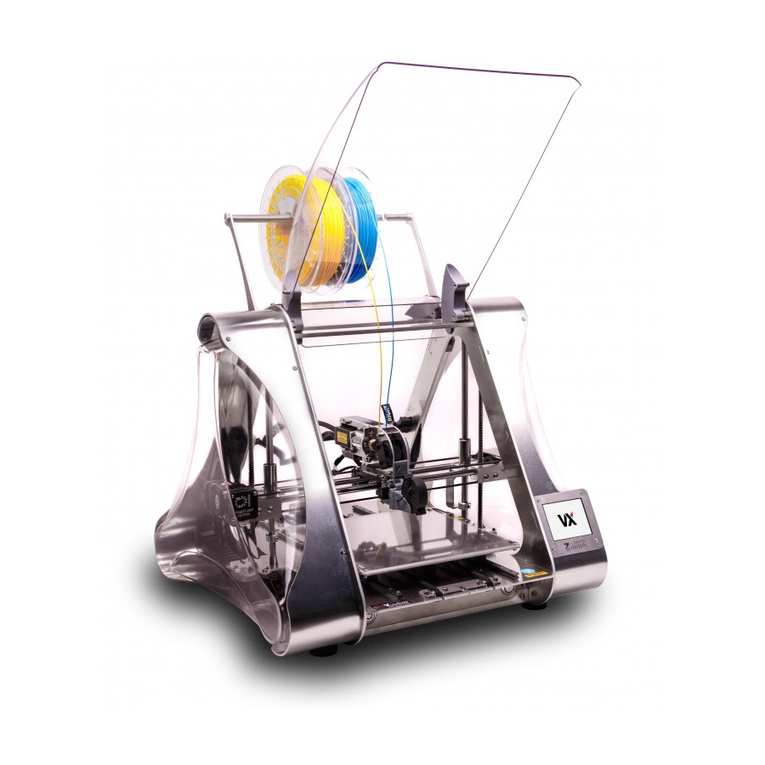

PRESENTATION OF THE I3 METAL MOTION

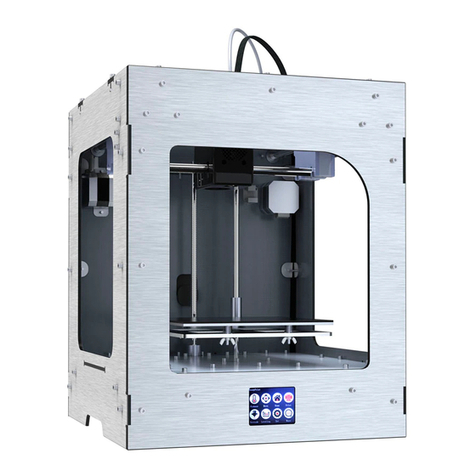

The latest creation of the eMotion Tech company, the I3 Metal Motion

promises stability and accuracy.

With all our knowledge and experience acquired with our previous

printers, we wanted to propose an elegant and reliable solution

to the problems encountered on many 3D printers on the market.

The I3 Metal Motion will seek to become a symbol of durability and

robustness, a precision tool at your disposal.

The I3 Metal Motion is, rst of all, a solid steel frame that makes it easy

to build in compare to any classic I3, with a low number of components.

We have searched to develop a heavy and solid structure, including

reinforcements in order to minimize vibrations and maximize the stability.

A sharper and reliable extrusion

The whole extrusion system is mounted on a steel carriage that

avoids the distortions that most of the plastic parts are victims. For

a higher ergonomics and quality, we have brought our solutions :

- a disengageable extruder to take o or engage the lament with a

simple ngers pressure.

- Manual extrusion of the lament made by a molded wheel to have a

very sharp ow.

- No clearances or empty space on the path of the lament, so it’s

possible to print with every kind of lament available on the market

(PLA, ABS, G-l, G-Carbon, eMotion Flex...)

Here are the features of the I3 Metal Motion :

• Dimensions : Height 440mm, Width 400mm, Depth 430mm

• Print volume : 200x200x200mm

• Thickness of the layers : from 100 to 350 microns

• Compatible laments : 1.75mm diameter, PLA, ABS, G-Fil, M-Fil, Flex

• Heating bed : yes, up to 110 ° C.

• Rated print speed : > 80mm / s

• Maximum movement speed : 200mm / s

• Nominal movement speed : 150mm / s

• Average accuracy (X, Y) : 100 microns

• Average accuracy (Z) : 50 microns

• Electronics type : eMotronic and TF card

• Microcontroller : LPC1768, 32-bit ARM Cortex-M3 at 100MHz

• Print with Hexagon 1.75mm extrusion head (interchangeable nozzles)

• Nozzle outlet : Ø 0.4 mm by default (modiable a posteriori)

• Operating System : Win XP, Vista, 7, 8, 10, Ubuntu 12+, Mac OS X

• USB connectivity

• Interfacing : LCD screen with TF card reader

• Power supply : 24 Volts / 320 Watts

The kit includes :

All the spare parts of the kit

A spool of 500 grams of PLA

INTRODUCTION / 6

Version 1.1.0

SAFETY INSTRUCTIONS

General safety instructions

The nozzle can reach 270°C, do not touch the nozzle while the printer is

working.

A supervisor is needed when the printer is used with young people.

KEEP PRINTER AWAY FROM CHILDREN AND ANIMALS

Operate in a ventilated room. Plastic vapors eets are not known. In

case of use in a closed room, we recommend the use of an extractor fan.

The addition of protections is your own responsibility. Safety can be

improved by :

• Housing protection

• Smoke detector

Electrical safety

The power supply provided is labelled CE. The power supply is protected

against short-circuit and do not need any modication. The I3 Metal

Motion operate at 24V and is not concerned by the low voltage directives.

Further informations

Informations above are not exhaustive.

We used sources of informations that we consider reliable. However, we

cannot guarantee that all these informations are true and complete.

We assume no liability for loses, injuries or damages due to assembly,

transporting, storage or removal of the product.

NEVER LEAVE THE PRINTER WORKING WITHOUT

SUPERVISOR.

INTRODUCTION / 7

Version 1.1.0 Version 1.1.0

BILLS OF MATERIAL

A. Metal parts

1 x Lower part

4 x Rod Ø 8 x 290 mm

2 x Rod Ø 8 x 360 mm

1 x Frame 2 x Reinforcement 1 x Y axis carriage 1 x Y axis plate

1 x Z axis carriage

right side

1 x Z axis carriage

left side

1 x X axis carriage

B. Mechanical parts

2 x Ø 8 mm lead screw

2 x Trapezoidal nut drive

2 x Coupling 3 x Linear bearing block 4 x Flanged linear

bearing

INTRODUCTION / 8

Version 1.1.0

D. Hardware

10 x M2,5 x 8 mm screw

5 x M2,5 x 12 mm screw

50 x M3 x 8 mm screw

30 x M3 x 12 mm screw

25 x M3 x 20 mm screw

4 x M3 x 22 mm screw

20 x M4 x 6 mm screw

15 x M3 nut

15 x Ø 3 mm x height 3 mm spacer

5 x Ø 3 mm x height 5 mm spacer

5 x Ø 3 mm x height 10 mm spacer

13 x Ø 3 mm washer

2 x GT2 pul-

ley

2 x GT2 belt 2 x Idler pulley kit

C. 3D printed parts

1 x Fan duct 1 x Y axis belt

holder

1 x X axis belt

holder

4 x Y axis rod

holder

4 x Z axis rod

holder

4 x X axis rod

holder

1 x Hexagon

bracket

1 x PTFE tube

1 x Leveling

sensor holder

1 x Filament

guide

INTRODUCTION / 9

Version 1.1.0 Version 1.1.0

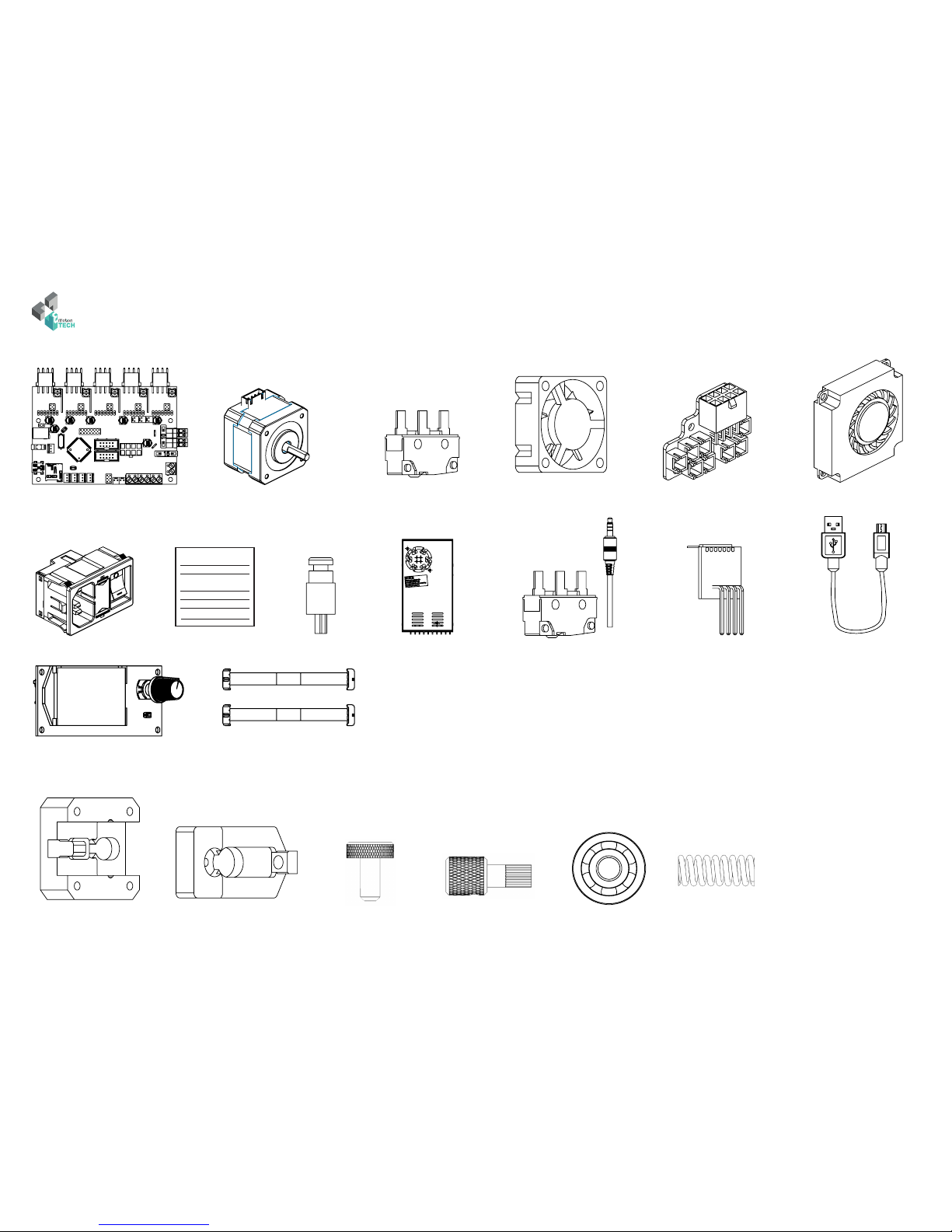

E. Electronic

F. Extruder kit

1 x eMotronic

1 x TF Card

5 x Nema 17 Motor 3 x Endstop

(colored connector)

1 x 3 cm fan

1 x Power supply

1 x EBoard

1 x IEC connector 1 x Reset button

1 x Body

extruder

1 x Mobile

extruder

1 x M5 x 12 mm

knurled screw

1 x Driving wheel 1 x 693zz

bearing

1 x Spring

1 x Calibration probe 1 x USB cable

1 x Blower fan

1 x Heating patch 1 x Motor driver

1 x LCD screen

and TF card reader

2 x Ribbon cable

INTRODUCTION / 10

Version 1.1.0

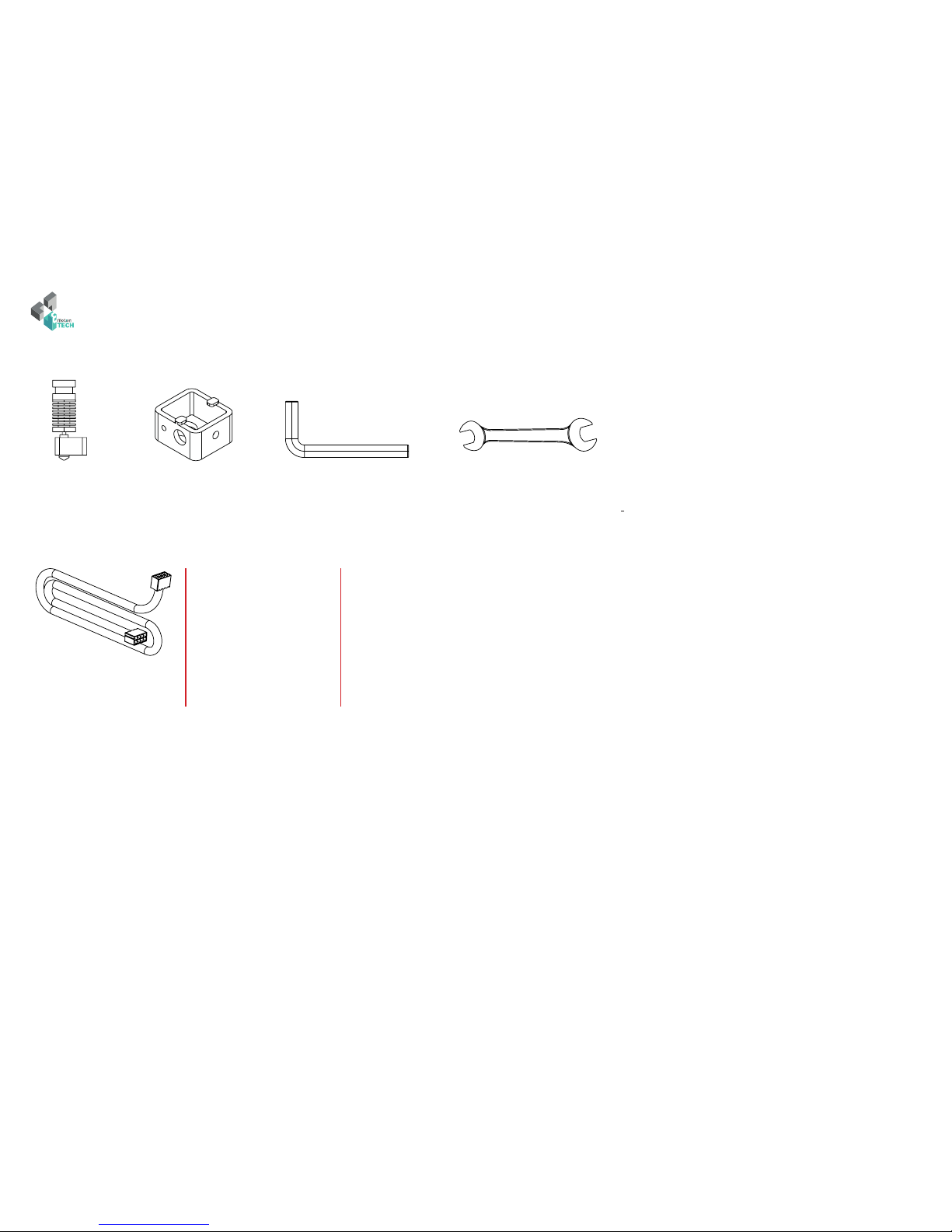

G. Hexagon kit (hotend)

1 x Hexagon hotend 1 x 3 Allen key 1 x 4.5 wrench1 x Silicon sleeve

H. Cables and extensions

I. Autres

• 1 x bag of grease

• 1 x bag of zip ties

1 x 20 mm motor’s cable

2 x 50 mm motor’s cable

1 x Thermistor

1 x Heater cartridge

1 x Blue endstop

4 x Power supply cable

1 x Reset button

2 x IEC On/O cable

1 x IEC VCC cable

1 x IEC GND cable

1 x IEC EARTH cable

1 x JACK endstop

1 x Extruder extension

1 x Z carriage extension

2 x endstop

1 x 220V power supply cable

1 x Mini USB cable

MECHANICAL ASSEMBLY / 11

Version 1.1.0 Version 1.1.0

MECHANICAL ASSEMBLY

MECHANICAL ASSEMBLY / 12

Version 1.1.0

ASSEMBLY OF THE LCD SCREEN

Target : mount the LCD screen on the lower part

Needed parts :

• Lower part

• LCD screen

• LCD button

• 4 x M3 x 12 mm screw

• 4 x Ø3 x H5 spacer

• 4 x M3 nut

M3 x 12 mm

Ø3 x H5 spacer

M3 nut

LCD screen

Lower part

Result

Result

LCD button

!

Do not tighten the

screws too much,

otherwise the LCD

screen may be

damaged

MECHANICAL ASSEMBLY / 13

Version 1.1.0 Version 1.1.0

ASSEMBLY OF THE ELECTRONIC BOARD

Target : mount the electronic board on the lower part

Needed parts :

• Lower part

• eMotronic board

• 4 x M3 x 8 mm screw

• 4 x Ø3 x H3 spacer

M3 x 8 mm screw

eMotronic board

Ø3 x H3 spacer

Result

MECHANICAL ASSEMBLY / 14

Version 1.1.0

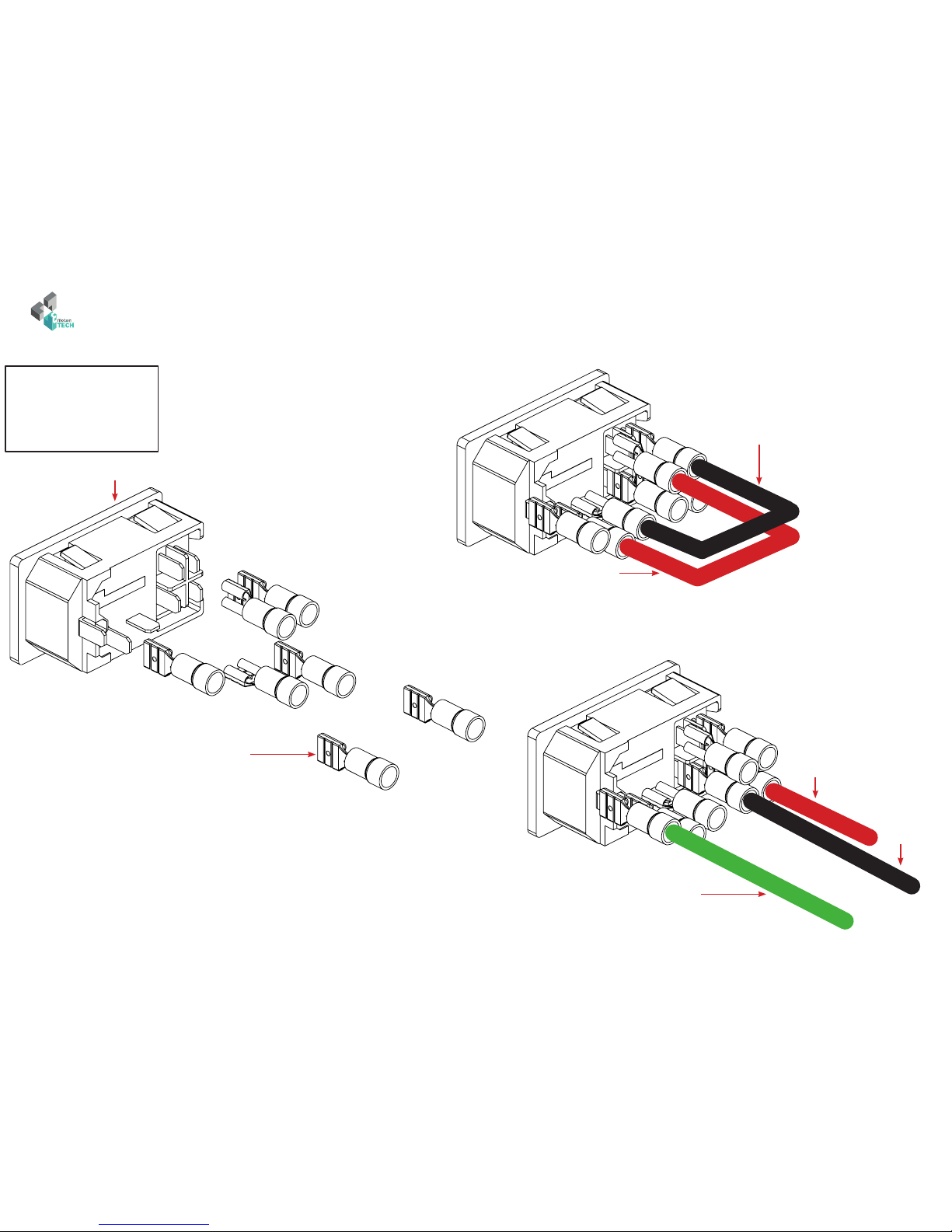

ASSEMBLY OF THE IEC CONNECTOR

Target : preparation of the two cables of the IEC connector

Needed parts :

• Lower part

• IEC connector

• 2 x Short strap cable

Short strap cable

IEC connector

Insulated pod

Green cable = GND

Red cable

=

phase

Black cable

=

neutral

Short strap cable

in black on the illustration for the

visibility but red in IRL

MECHANICAL ASSEMBLY / 15

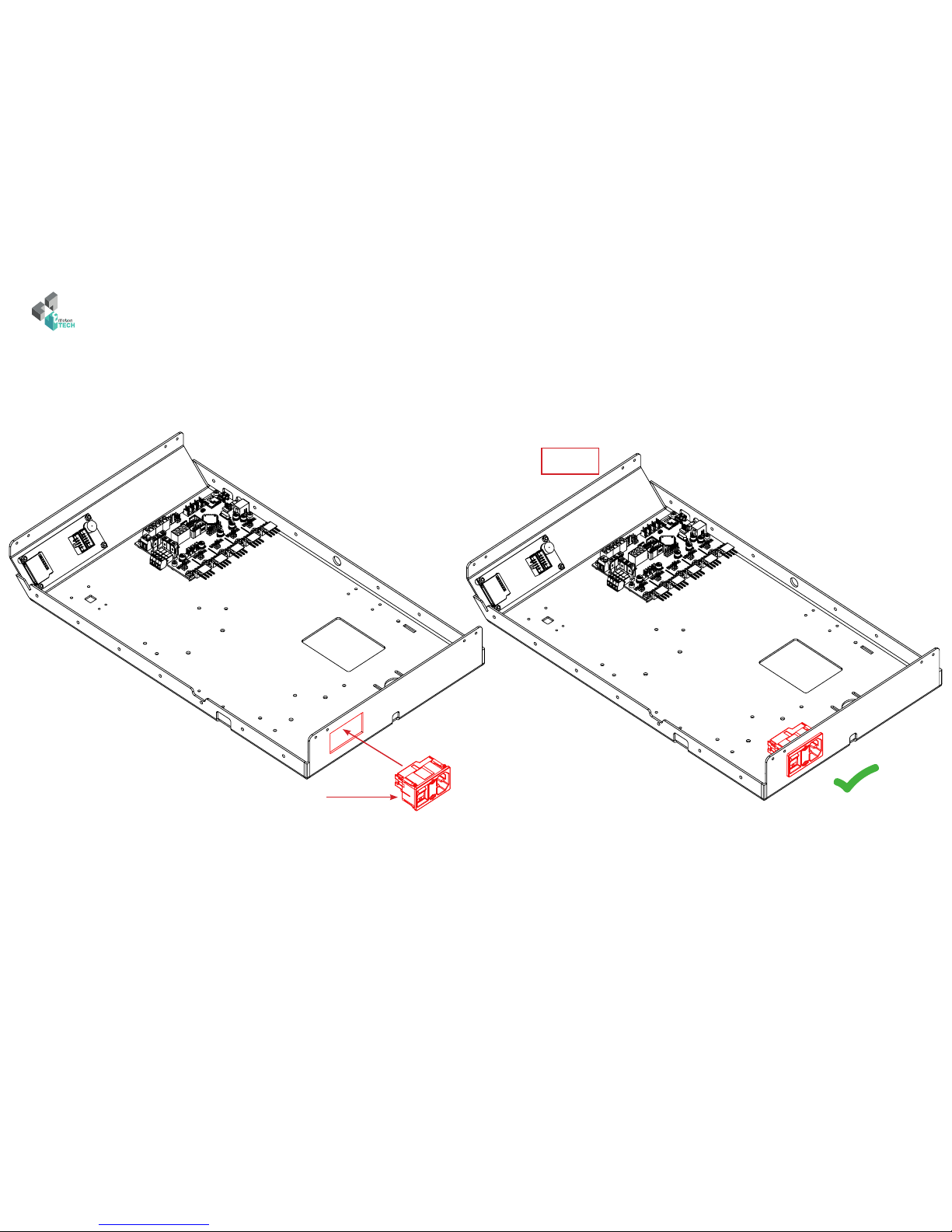

Version 1.1.0 Version 1.1.0

IEC connector

«Clips»

Result

Target : mount the IEC connector on the lower part

Black cable

=

neutral

MECHANICAL ASSEMBLY / 16

Version 1.1.0

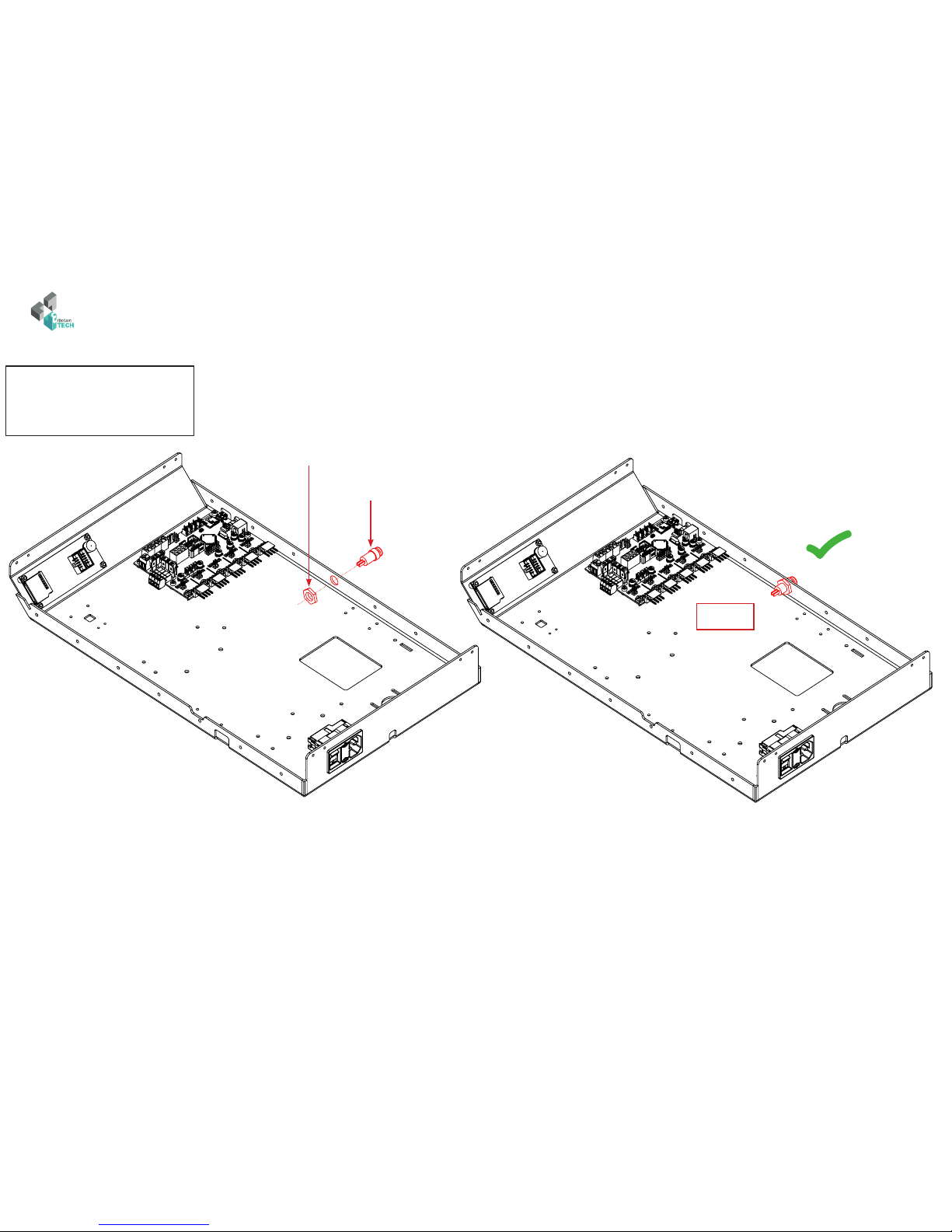

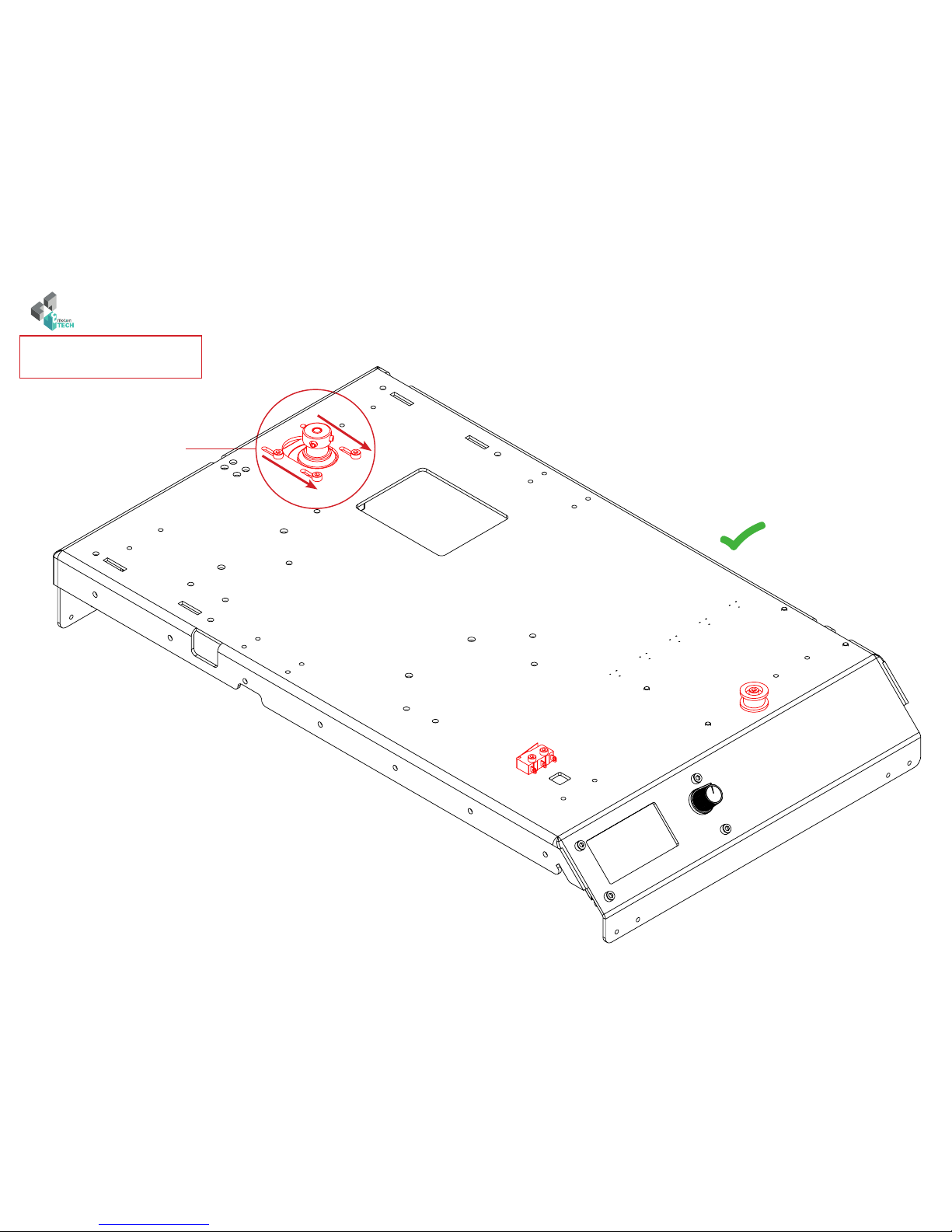

ASSEMBLY OF THE RESET BUTTON

Target : mount the reset button on the lower part

Needed parts :

• Lower part

• Reset button

Result

Reset button

Button nut

MECHANICAL ASSEMBLY / 17

Version 1.1.0 Version 1.1.0

ASSEMBLY OF THE Y AXIS (part 1)

Target : mount the motor, pulleys and the Y axis endstop on the lower part

Needed parts :

• Lower part

• Nema 17 motor

• Blue endstop

• GT2 pulley

• Idler pulley

• Pulley bearing

• 4 x M3 x 8 mm screw

• 1 x M3 x 12 mm screw

• 2 x M2.5 x 8 mm screw

• 2 x Ø3 x H3 spacer

• 4 x Ø 3 mm washer

The grub screw must be in

contact with the at part of the

axis.

M3 x 8 mm screw (do not tighten the motor screws for the moment)

GT2 pulley

NEMA 17 motor

M2.5 x 8 mm screw

M3 x 12 mm screw

Idler pulley

Pulley’s bearing

Ø3 x H3 spacer

!

Connector’s

orientation

!

Lamella’s

orientation

Flat side

Screw

3 mm

Ø 3 mm washer

Blue endstop

MECHANICAL ASSEMBLY / 18

Version 1.1.0

RESULT

The motor must be

positioned towards the

front of the machine

MECHANICAL ASSEMBLY / 19

Version 1.1.0 Version 1.1.0

ASSEMBLY OF THE POWER SUPPLY

Target : mount the power supply on the lower part

Needed parts :

• Lower part

• Power supply

• 4 x M4 x 6 mm screw Result

M4 x 6 mm screw

!

Power supply

orientation

MECHANICAL ASSEMBLY / 20

Version 1.1.0

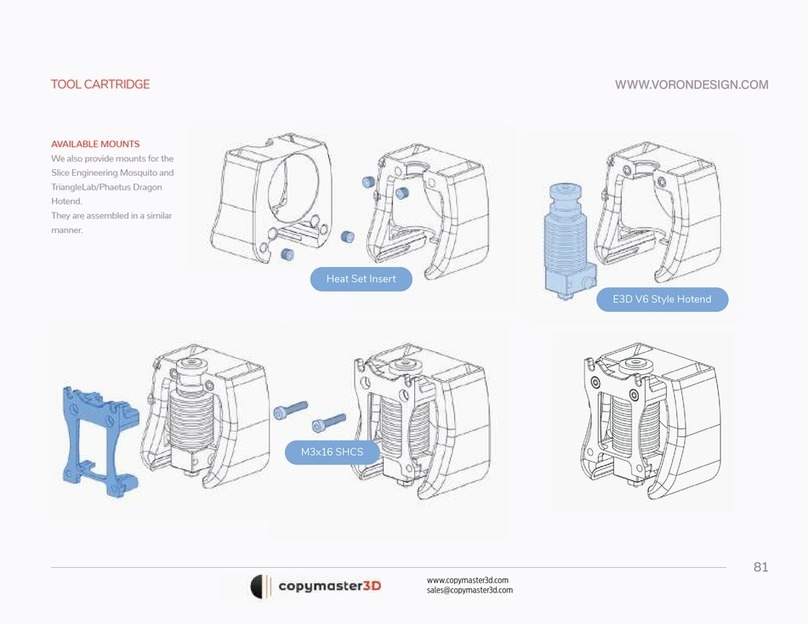

ASSEMBLY OF THE Y AXIS (part 2)

Target : mount rods, bearing blocks and holders on the lower part.

Needed parts :

• Lower part

• 4 x Y axis rod holder

• 2 x 8 x 360 mm rod

• 3 x Linear bearing block

• 8 x M3 X 20 mm screw

8 x 360 mm rod

1 linear bearing block

Y axis rod holder

2 linear bearing rod

Table of contents