Installation, Operation and Parts Manual

EE-6604 V2.BWF

- 3

IMPORTANTNOTES.................................................................................................................................................2

SAFETYNOTES.........................................................................................................................................................4

1.1Operationofliftingplatforms.......................................................................................................................................4

1.2Checkingoftheliftingplatforms...................................................................................................................................4

1.3Importantsafetynotices...............................................................................................................................................5

1.4Warninglabels..............................................................................................................................................................6

1.5Potentialsafetyrisks.....................................................................................................................................................7

1.6Noiselevel.....................................................................................................................................................................7

PACKING,STORAGEANDTRANSPORTATION...........................................................................................................8

2.1Theliftwasdismantledinto3partsfortransportation................................................................................................8

2.2Storage..........................................................................................................................................................................8

2.3Liftingandhandling......................................................................................................................................................8

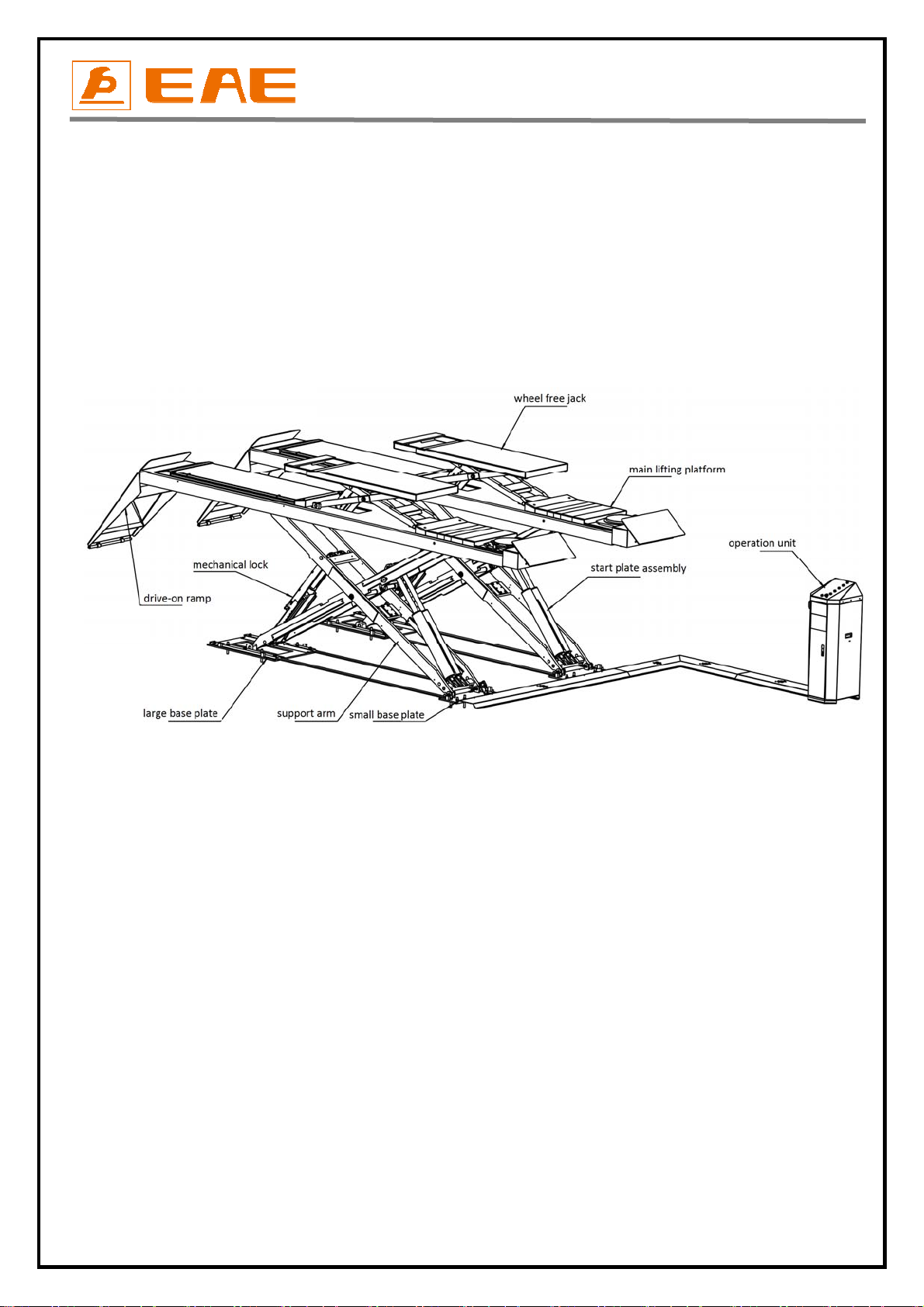

PRODUCTDESCRIPTIONS.........................................................................................................................................9

3.1Generaldescriptions.....................................................................................................................................................9

3.2Constructionofthelift..................................................................................................................................................9

3.3Dimensions..................................................................................................................................................................10

3.4Safetydevicedescriptions...........................................................................................................................................11

3.5Technicaldata.............................................................................................................................................................12

INSTALLATIONINSTRUCTIONS...............................................................................................................................12

4.1Preparationsbeforeinstallation.................................................................................................................................12

4.2Installationattentions.................................................................................................................................................13

4.3GeneralInstallationSteps...........................................................................................................................................14

4.4Itemstobecheckedafterinstallation........................................................................................................................16

OPERATIONINSTRUCTIONS...................................................................................................................................17

5.1Precautions.................................................................................................................................................................17

5.2Descriptionsofcontrolpanel......................................................................................................................................17

5.3Flowchartforoperation.............................................................................................................................................18

5.4Operationinstructions................................................................................................................................................18

TROUBLESHOOTING.............................................................................................................................................20

MAINTENANCE......................................................................................................................................................21

Annex1,FloorPlan...........................................................................................................................................................22

Annex2,Electricalschemesandpartslist........................................................................................................................24

Annex3,Hydraulicschemesandpartslist.......................................................................................................................28

Annex4,Pneumaticschemeandpartslist.......................................................................................................................32

Annex5,Mechanicallyexplodeddrawingsandpartslist.................................................................................................33