Installation, Operation and Parts Manual

EE-6605S/A/B

3

IMPORTANTNOTES............................................................................................................................................................2

SAFETYNOTES....................................................................................................................................................................4

1.1Operationofliftingplatforms ...................................................................................................................................... 4

1.2Checkingoftheliftingplatforms.................................................................................................................................. 4

1.3Importantsafetynotices .............................................................................................................................................. 5

1.4Warninglabels ............................................................................................................................................................. 6

1.5Potentialsafetyrisks .................................................................................................................................................... 7

1.6Noiselevel .................................................................................................................................................................... 7

PACKING,STORAGEANDTRANSPORTATION.....................................................................................................................8

2.1Theliftwasdismantledinto3partsfortransportation............................................................................................... 8

2.2Storage......................................................................................................................................................................... 8

2.3Liftingandhandling ..................................................................................................................................................... 8

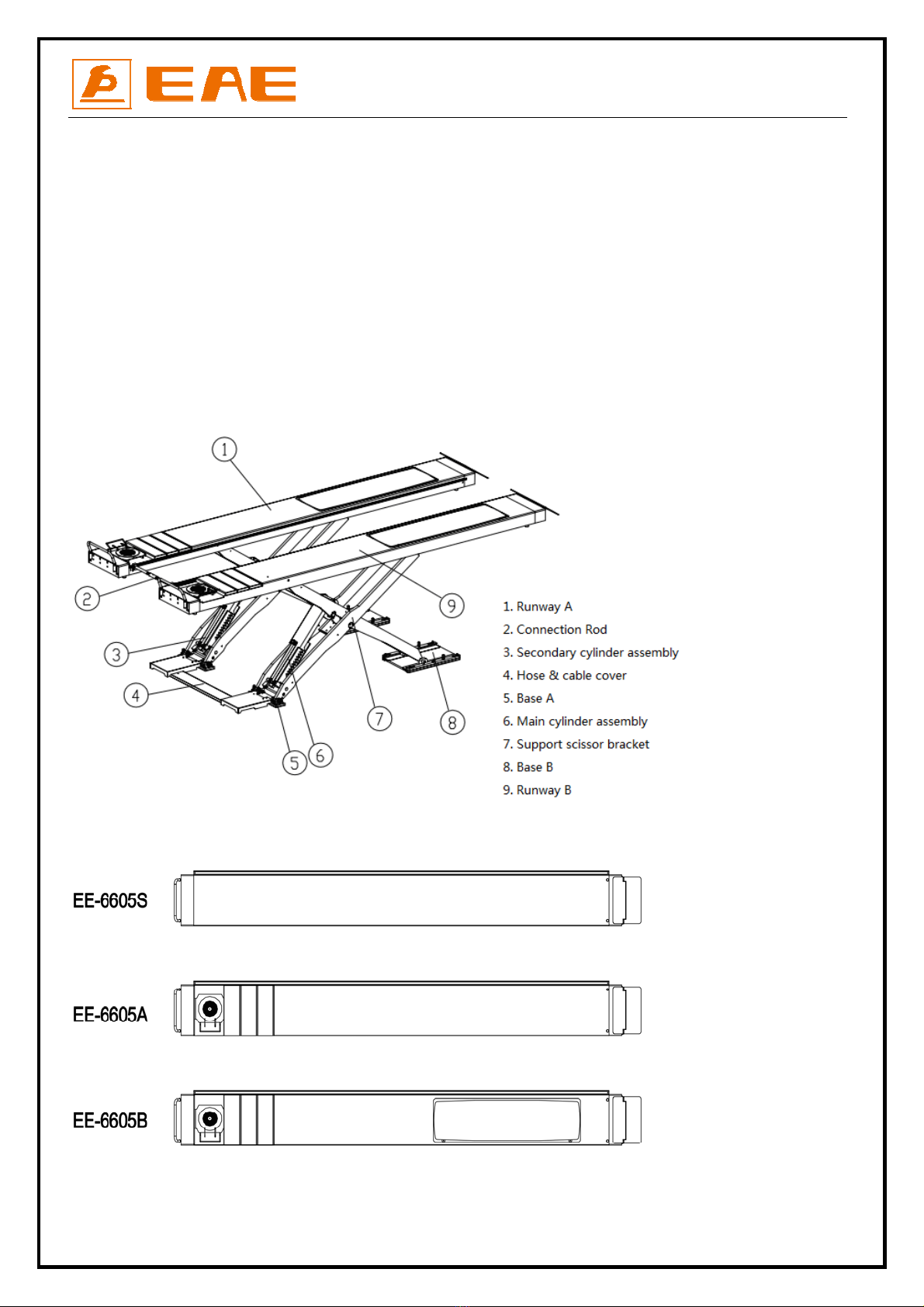

PRODUCTDESCRIPTIONS...................................................................................................................................................9

3.1Generaldescriptions .................................................................................................................................................... 9

3.2Generalconstructionofthelift .................................................................................................................................... 9

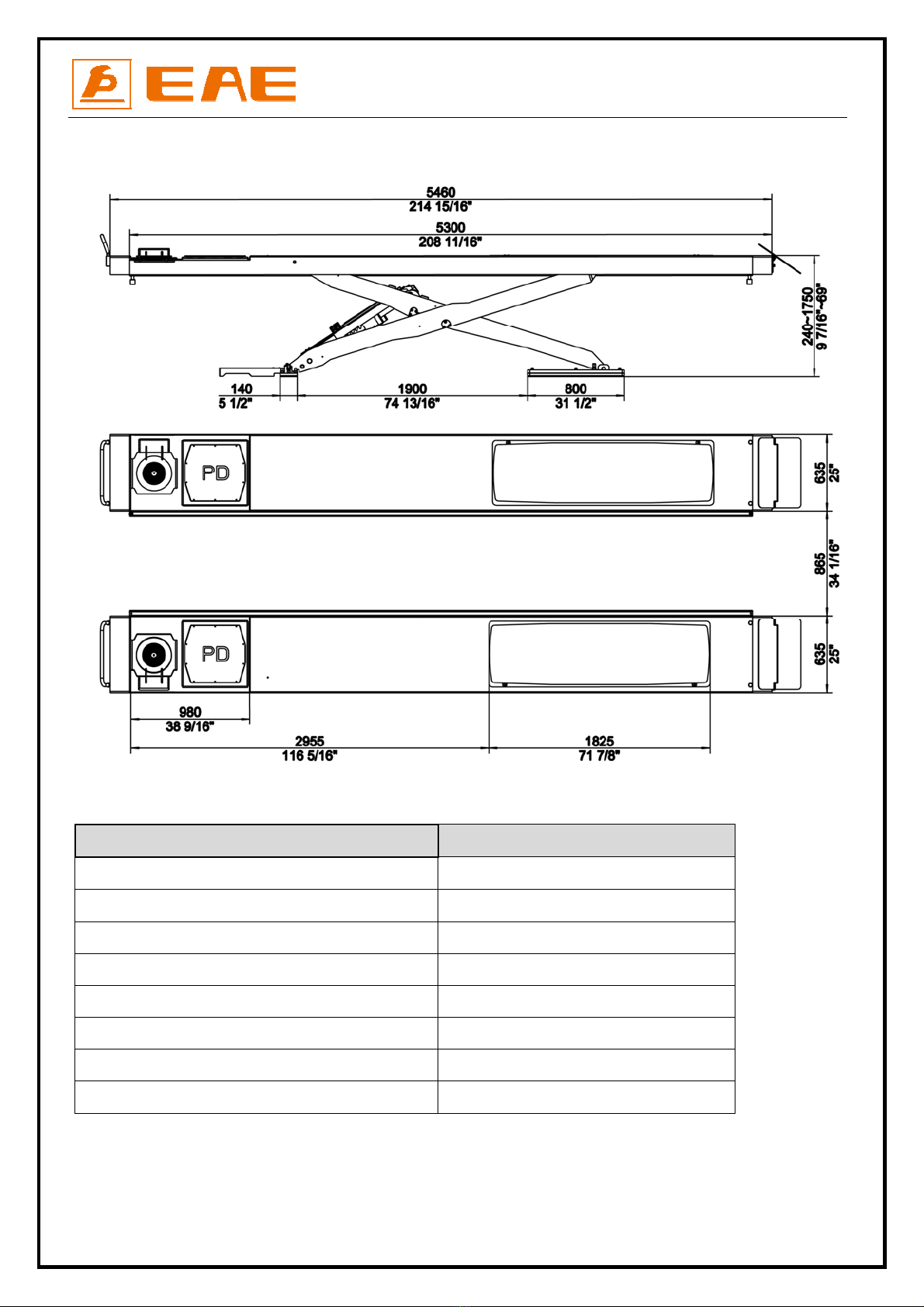

3.3Dimensions................................................................................................................................................................. 10

3.4Technicaldata............................................................................................................................................................ 10

INSTALLATIONINSTRUCTIONS.........................................................................................................................................11

4.1Preparationsbeforeinstallation .................................................................................................................................11

4.2Installationattentions................................................................................................................................................ 12

4.3GeneralInstallationSteps .......................................................................................................................................... 12

4.4Itemstobecheckedafterinstallation........................................................................................................................ 13

OPERATIONINSTRUCTIONS.............................................................................................................................................14

5.1Precautions ................................................................................................................................................................ 14

5.2Flowchartforoperation ............................................................................................................................................ 14

5.3Operationinstructions ............................................................................................................................................... 15

TROUBLESHOOTING........................................................................................................................................................16

MAINTENANCE.................................................................................................................................................................17

Annex1,FloorPlan .......................................................................................................................................................... 18

Annex2,Electricalschemesandpartslist ....................................................................................................................... 20

Annex3,Hydraulicschemesandpartslist....................................................................................................................... 25

Annex4,Pneumaticschemeandpartslist ...................................................................................................................... 28

Annex5,Explodeddrawingsandpartslist ...................................................................................................................... 29