Catalog

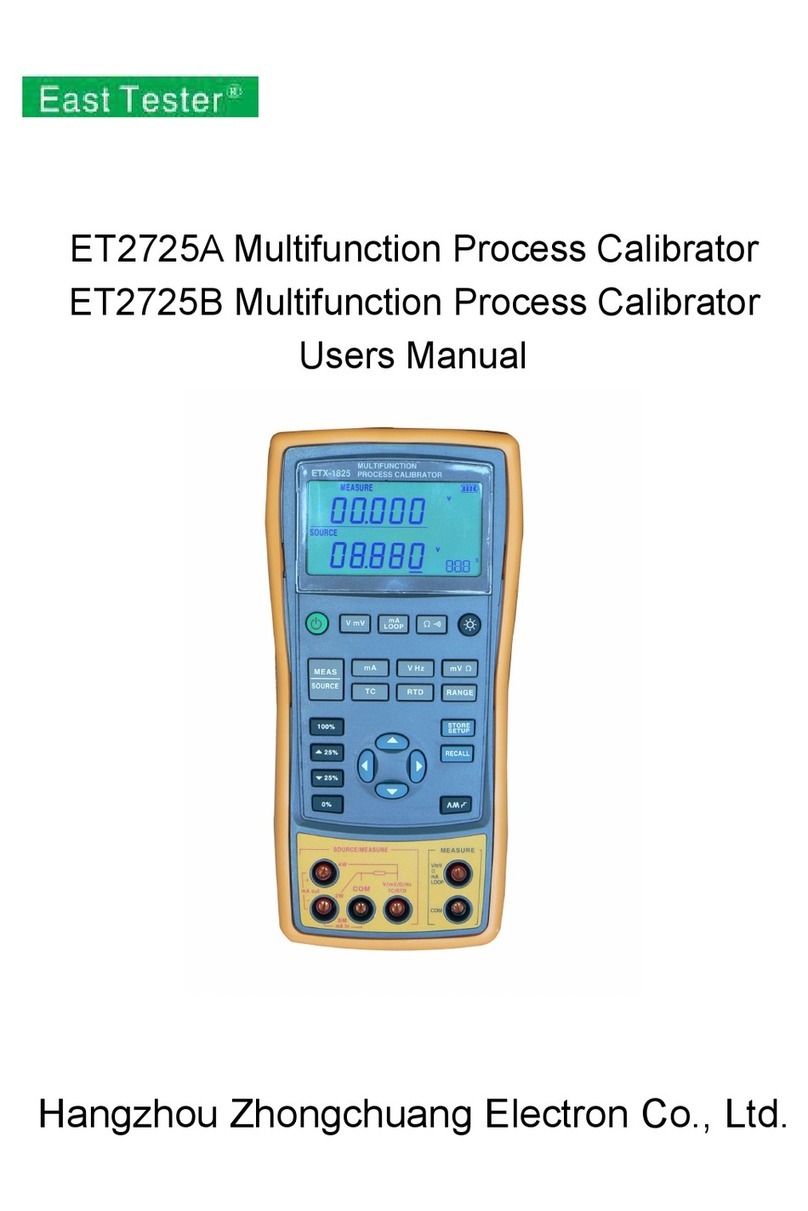

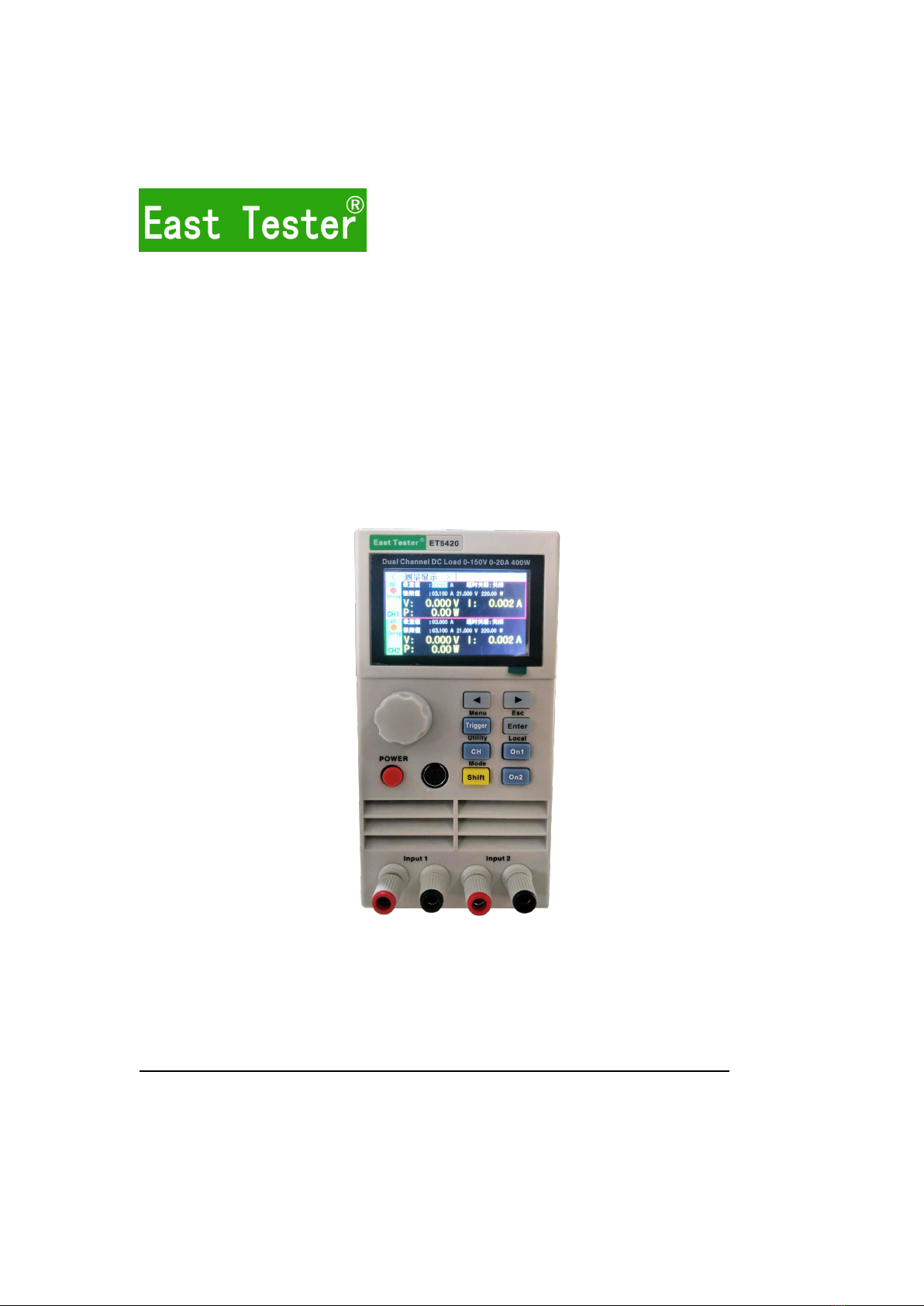

一、Quick Reference.......................................................................................................................... 1

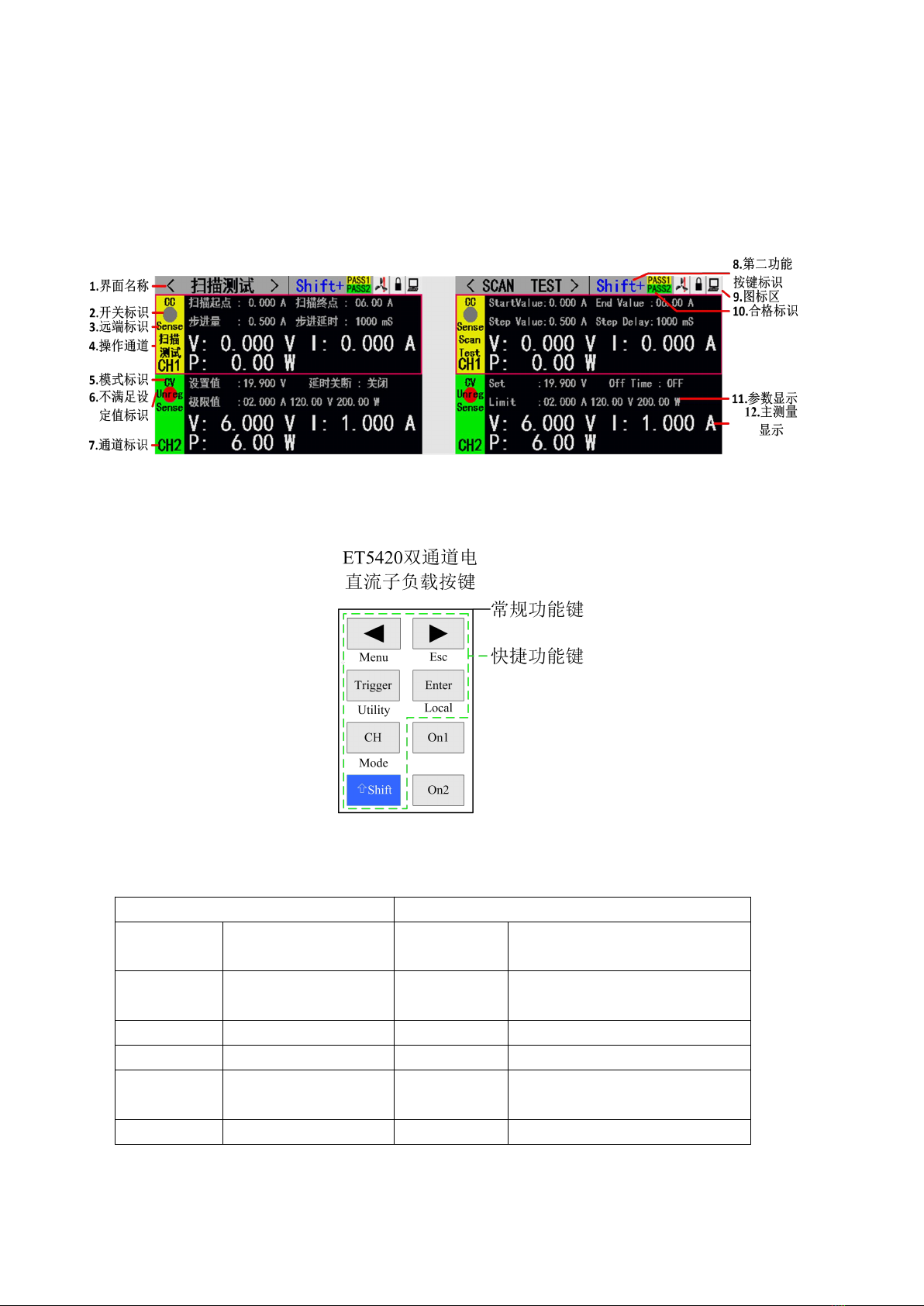

1.1 Front Panel Display ...............................................................................................................1

1.2Front Panel Press........................................................................................................................ 1

1.3Press Introduction .....................................................................................................................1

二、Function Operation ..................................................................................................................2

2.1 Remote/ Local Switch Opertion ............................................................................................2

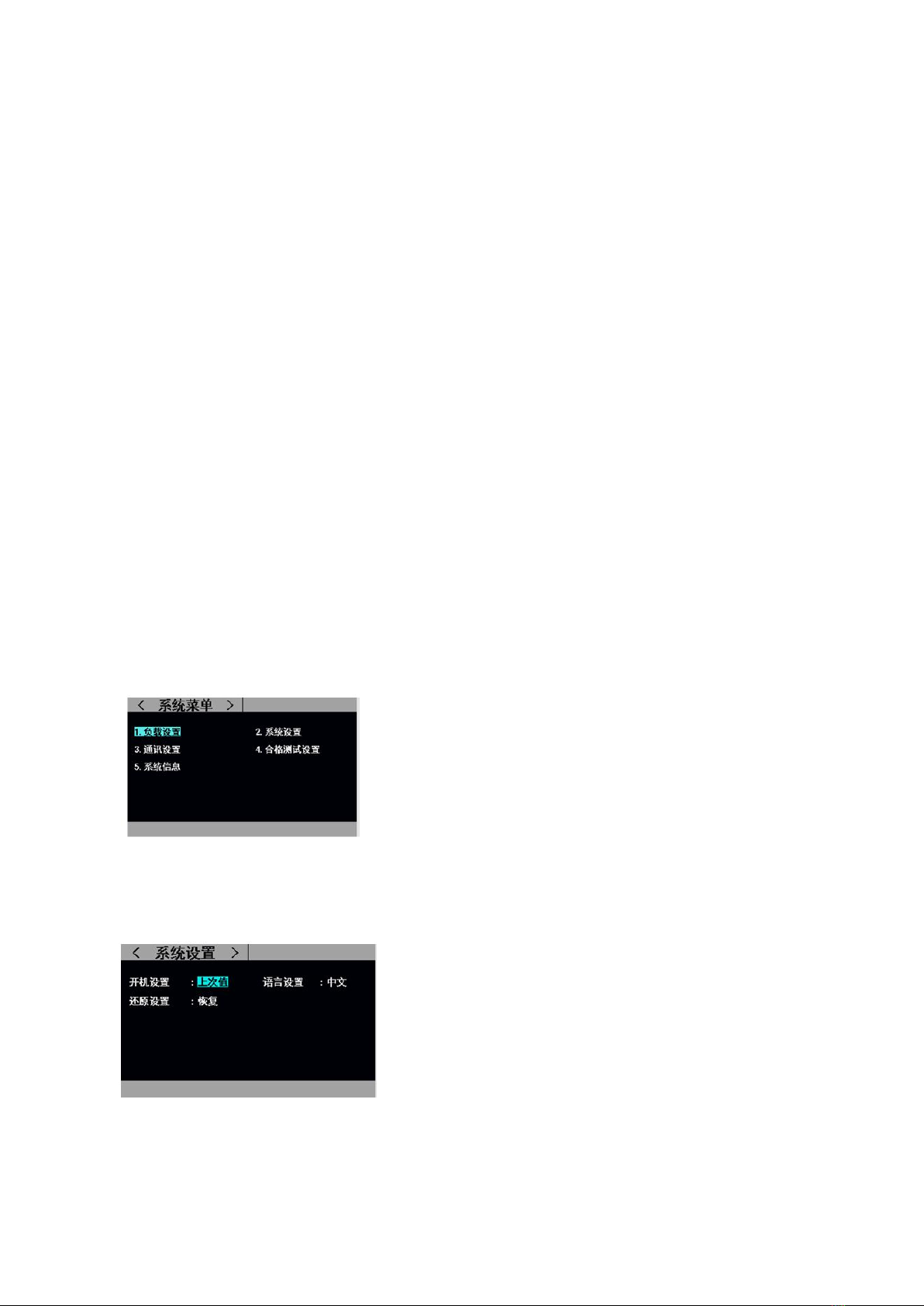

2.2 System Setting Operation..........................................................................................................2

2.3 Load Setting operation ............................................................................................................ 3

2.4 Basic Mode operation ..............................................................................................................3

2.4.1Constant Current Test Mode ............................................................................................. 3

2.4.2Constant Voltage Test Mode...............................................................................................4

2.4.3 Constant Resistance Test Mode......................................................................................... 5

2.4.4 Constant Power Test Mode .............................................................................................. 5

2.4.5 Constant Current Switch To Voltage Test Mode .............................................................6

2.4.6 Constant Resisitance Switch To Voltage Test Mode ...................................................... 6

2.5 Dynamic Mode Test Operation..............................................................................................7

2.6 Listing Mode Test Operation ............................................................................................... 9

2.7 Scanning Mode Test Operation ........................................................................................11

2.8 Battery Test Operation ....................................................................................................... 12

2.9 LED Test Operation ........................................................................................................... 13

2.10 Short Circuit Test Operation .......................................................................................... 15

2.11 Protection Function............................................................................................................... 15

2.12Triggle Function ...................................................................................................................15

2.13Qualified test operation.......................................................................................................... 16

2.14 Other system settings .......................................................................................................... 16

2.14.1 Key Lock Funtion .........................................................................................................16

2.14.2 Outer Interface Function................................................................................................ 17

四、 Technic Specification........................................................................ 错误!未定义书签。