simple

setup

g

uide

DIPSWITCHES

After all connections have been made, you are now ready to program the gates. First lets start with

setting the correct dipswitches located at the top centre of the control board.

Whilst programming up the ‘Save’ switch should be set to ‘Off’ during this part of the setup.

If your system has a maglock wired in then dipswitch 2 should be set to ‘On’, if not then set this to

‘Off’.

If you have a double gate system, then switch the 3rd dipswitch to ‘Dual mode’. If just using a single

gate motor then switch it to ‘Single’.

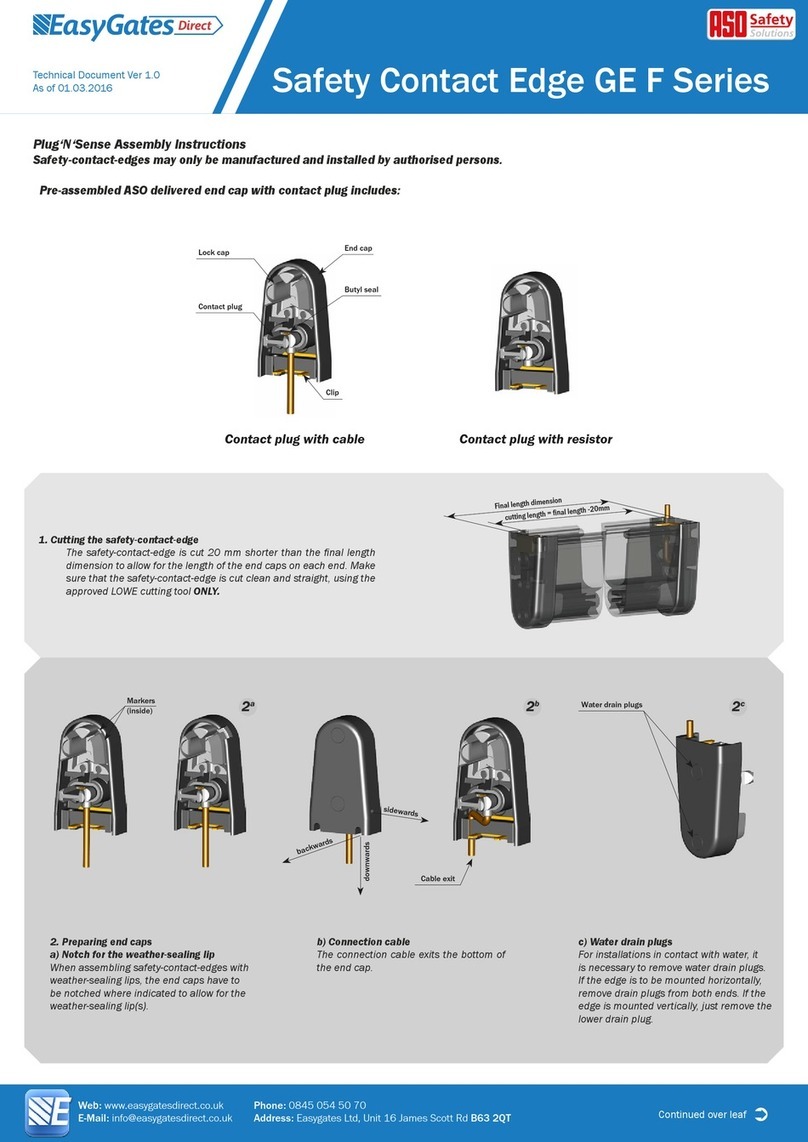

If you have any safety edges wired in, then the 4th dipswitch should be set to ‘NC’. If no safety

edges are connected, then switch this to ‘No’.

The nal dipswitch is for the photocells and this should be switched to ‘NC’.

cb

24

Now all the dipswitches have been set, we can set the dials for ‘Force’, ‘Bipart delay’ and

‘Timer to close’. These dials are located in the centre of the bottom half of the board and are

coloured, Red, White and Blue.

The rst dial is labeled ‘Force’

and should be set to around 40%

power (From min to max)

The second is the ‘Bipart delay’

(white), and should be set to the

same setting as ‘Force’.

The 3rd and nal is the ‘Timer

set to close’, and this should be set to off whilst setting up. Note: After setting up, these dials can be

set to suit the application.

CONFIGURE DIALSCHECK WIRING

Now the dipswitches and dials have

been set, we need to check that

there is a link in the control input

‘P10’, between ‘Stop’ and ‘Com’.

We also need to check the ‘Open

photo’ or ‘Close photo’ connections

are not being used and that they are

linked out.

Now check that the radio module is plugged

in correctly at the top of the board.

Next, connect the 2 battery connections at

the bottom right of the board, and the 24VAC

input (2 yellow wires) at the bottom left of

the board.

You should now have a ‘Power’ LED lit and

a ‘Stop’ LED lit, but you should have no con-

stant red LED’s.

(Before any

of the setup is

started, ensure

Power cables

are discon-

nected to begin

with.)