General Instructions

Compressors require protection from elements. DO NOT

place your compressor in low spots or any place water

may puddle. Flooded compressors are not covered under

warranty.

1. Select preferred installation style (see

previous page) and determine position

of compressor.

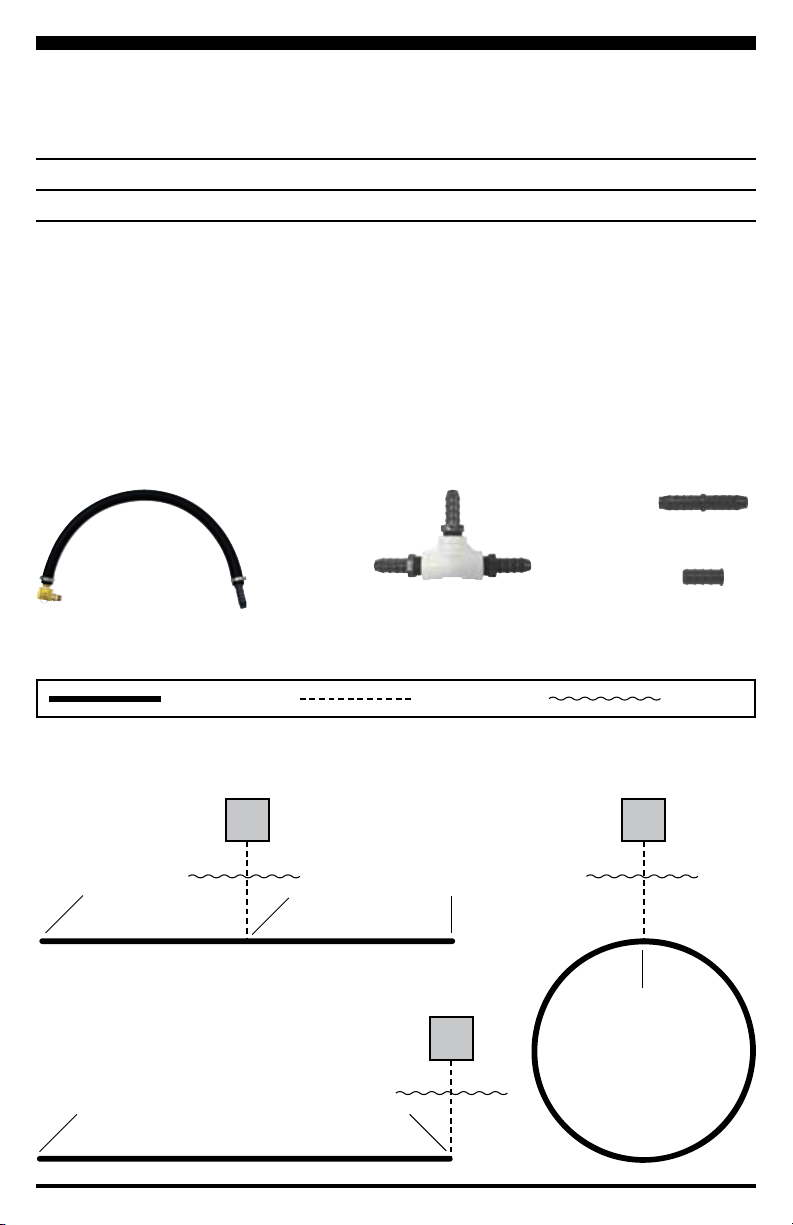

2. Install threaded outlet assembly and air lter to correct

port on the compressor, Figure 1. NOTE: Be careful to

not over tighten. Use Teon tape on threads.

3. Unroll the bubble tubing and feeder tubing.

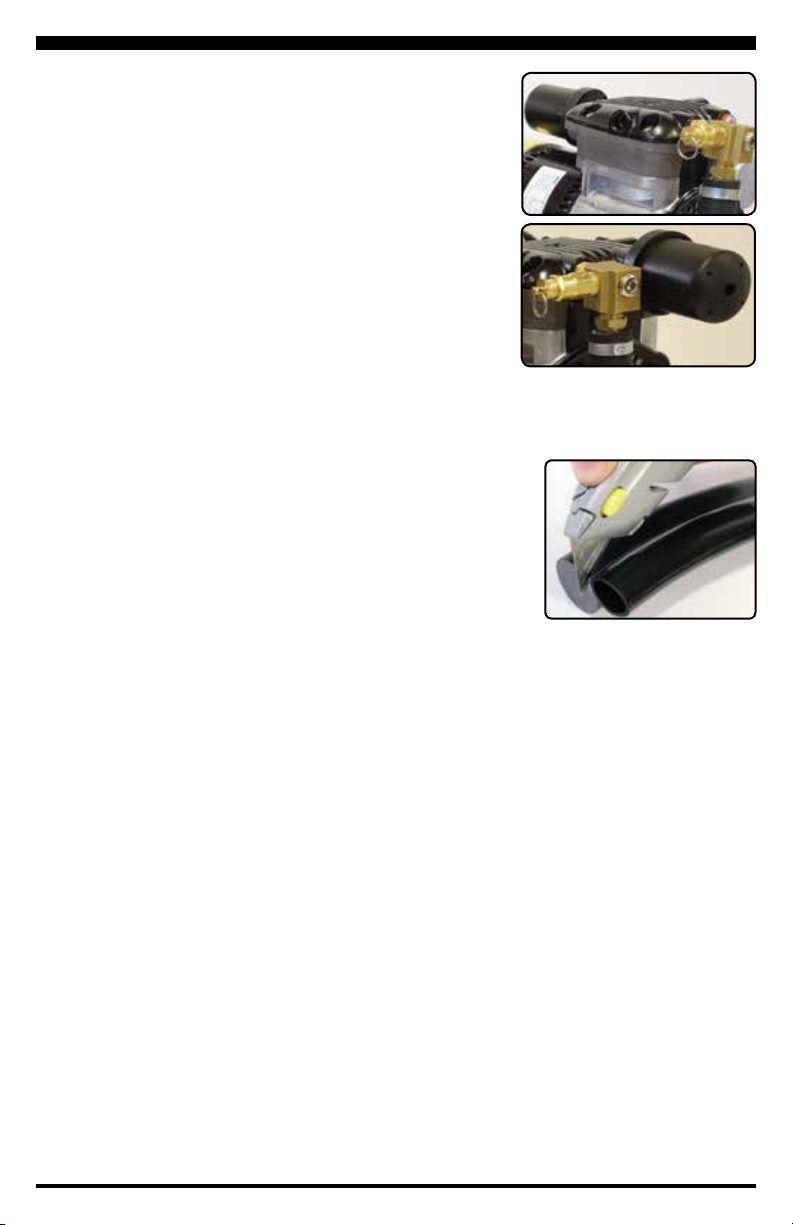

4. Install plugs as needed in the bubble tubing and secure

with small clamps. NOTE: To clamp the bubble tubing

to all barbed ttings, carefully separate the tubing

portion from the ballast by cutting it, Figure 2. This

will allow a clamp to go only around the smaller tubing to

secure the tting. Do not attempt to clamp around ballast

and tubing.

5. Install weighted bubble tubing in the water in desired

location. Lower tubing into place and let it sink to the

bottom. In some applications it is easiest to start at the

farthest end and work toward the compressor/feeder

tubing.

6. Secure weighted feeder tubing to the outlet assembly at

the compressor with large clamp. This connection can be

submerged if necessary.

7. Connect the bubble tubing to the feeder tubing with appropriate clamps. Excess

tubing can be trimmed to length at this point.

8. When all connections are made and tubing is in place the system is ready for

operation by plugging compressor into 120v GFCI protected outlet.

Winter Operation

• You must clearly mark with warnings that there is open water or thin ice. Many states

will require this by law.

• It becomes critical to protect the compressor from the elements. A cabinet or shelter

is required. Be sure that adequate air ventilation is provided or compressor will fail

prematurely.

• If lines become frozen, rubbing alcohol can be run down the line to thaw it out.

Maintenance

1. Always unplug unit before service, cleaning or any maintenance.

2. Keep intake lter clean.

3. Over time the compressors may need to have wearable components replaced. See

chart on previous page for compressor repair kits.

Figure 1. Note the compressor

intake and outlet when installing

air lter and outlet assembly.

Figure 2. Be careful not to

damage the bubble tubing

when splitting the ends away

from the ballast.

DDK50

DDK100E