ElectricalSpecications

Model HP Watts* Volts Amps Cable Length

TH150 1/4 270-350 115 2.6-3.1 6m/20'

TH1502 1/4 270-350 230 1.3-1.5 6m/20'

TH250 1/3 345-500 115 3.0-4.2 6m/20'

TH2502 1/3 345-500 230 1.5-2.1 6m/20'

TH400 1/2 440-670 115 3.7-6.0 6m/20'

TH4002 1/2 440-670 230 1.8-3.0 6m/20'

TH750 1 600-910 115 6.0-9.9 6m/20'

TH7502 1 600-910 230 3.0-4.9 6m/20'

*Actualrunningconditionsaectwatts

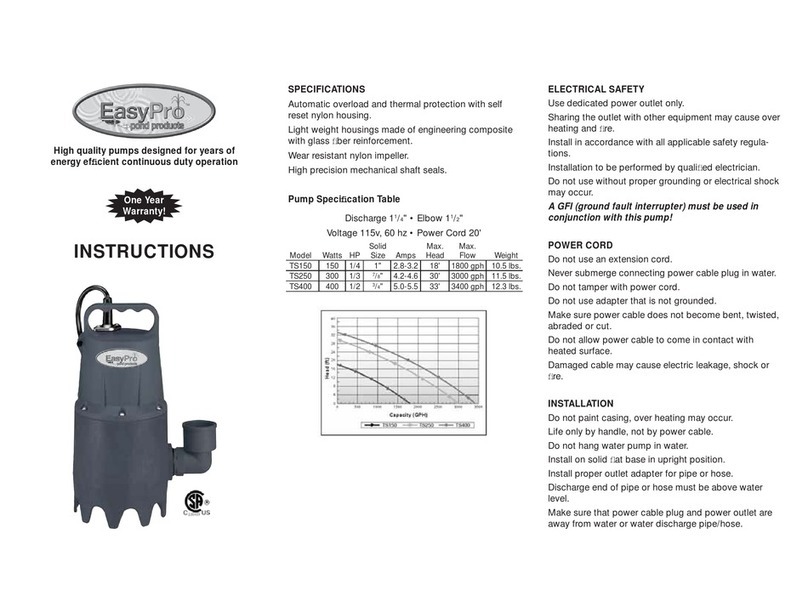

PumpSpecications

Model Max. Flow Max. Head Outlet Weight

TH150 3100GPH 7m/23' 2" 6.75kgs/15lbs.

TH1502 3100GPH 7m/23' 2" 6.75kgs/15lbs.

TH250 4100GPH 9m/30' 2" 7.85kgs/18lbs.

TH2502 4100GPH 9m/30' 2" 7.85kgs/18lbs.

TH400 5100GPH 11m/36' 2" 9.07kgs/20lbs.

TH4002 5100GPH 11m/36' 2" 9.07kgs/20lbs.

TH750 6000GPH 14m/46' 2" 10.88kgs/24lbs.

TH7502 6000GPH 14m/46' 2" 10.88kgs/24lbs.

Safety & Electrical Connections

1. Alwaysdisconnecttheelectricitysupplybeforehandling,

maintaining,repairingorinstallinganypondequipment.

2. Alwaysmakesureyouknowthecorrectampsandvoltagerequired

beforeinstalling.

3. Usededicatedpoweroutletonly.Sharingtheoutletwithotherequip-

mentmaycauseoverheatingandre.

4. AlwaysconnecttoaGroundFaultCircuit(GFCI)topreventelectrical

shock.Neversubmergeconnectingpowercablepluginwater.

5. Neverletthepumprunwithoutwaterasthiswilldamagethe

impeller,overheatandpossiblyburnoutthepump.Thispump

muststaysubmergedentirelywhenopeating.Ifusedinaskimmer,

thedebrisnetmustbekeptcleantoensureadequatewaterowto

pump.Runningpumplowonwaterwillcauseoverheating,premature

failureandwillvoidwarranty.

6. Donotusethisproductinbathroomsorswimmingpools.

7. Donotletthewaterlevelinyourwaterfeaturefallbelowthetopofthe

pumpbody.

8. Allelectricalworkmustbeperformedbyaqualiedtechnician.

AlwaysfollowtheNationalElectricalCode(NEC)ortheCanadian

ElectricalCodeaswellasalllocal,stateandprovincialcodes.Code

questionsshouldbedirectedtoyourlocalelectricalinspector.Failure

tofollowelectricalcodesandOSHAsafetystandardsmayresultin

personalinjuryorequipmentdamage.Failuretofollowmanufactur-

er’sinstallationinstructionsmayresultinelectricalshock,rehazard,

personalinjuryordeath,damagedequipment,provideunsatisfactory

performanceandmayvoidmanufacturer’swarranty.

9. Donotattempttodisassemblepumpduringthewarrantyperiod.If

thereareanyquestionspleasecontactyoulocaldealer.

10. Neveruseanextensioncordortamperwithpowercord.Powercord

cannotbecomebent,twisted,abradedorcut.Adamgedcablemay

causeelectricleakage,shockorre.

11. Themotorhasabuilt-inprotectionsystemwhichstopsthepump

whenoverheatingoccursduetoexcessiveloadorlowwater,thiscan

becausedbycloggingatinlet/outletorwhenucuationsoccurin

power supply.

Installation

• Donotpaintcasing,overheatingmayoccur

• Liftonlybyhandle,notbypowercable

• Donothangpumpinwater,installonsolidatbaseinupright

position

• Installproperoutletadapterforpipeorhose

• Makesurethatpowercableplugandpoweroutletareawayfrom

waterandwaterdischargepipe/hose.

Operation

1. Donotstartoperationwithpeoplestandingnearintakeoroutlet.

2. Donotoperateoutofwater.

3. Neveroperatebelowminimumwaterlevel,whichis6"above

baselevel.Forcontinuousoperationpumpmustbefully

submersed.Operateforamaximumof30minutesifwaterlevelis

betweenthesetwolevels.

4. Onlyusepumpforcirculation,transferorremovalofwaterorwaste

water.

5. Donotpumpoil,saltwater,chlorinatedwaterorchemicalliquids.

6. Donotallowdryoperation

7. Donotallowforeignobjectstoenterintake

8. Incaseofpoweroutage,turnopowerswitchtoavoiddamagewhen

power is restarted.

9. Ifexcessivevibrationoccursturnopowerimmediately.

Service & Maintenance

1. Disconnectallpowersuppliesbeforeinspectionorserviceto

avoidpossibleelectricalshock.

2. Thepumpshouldberemovedfromthepondonaregularbasis,

cleanedandcheckedoverfordamagetoprolongthelifeofthepump.

3. Cleantheimpellerandintakescreenwhentheowisvisiblyreduced.

4. Cleanthepumpandimpellerwithcleanfreshwater.

5. Checkinsidetheimpellerhousingforlargedebrisoralgae,which

couldreducetheow.

6. Checkandtightennutsandboltsifrequired,refertodealerforadvice

on other repairs.

7. Winterization/Storage:Whenthepumpisoutofuseforextendedtime

-washanddryitthenstoreindoorsinanon-freezinglocation.Itis

besttostoreinabucketwithaboutan8"waterdepth.

8. Ifthepumpisleftinwaterbutnotoperatingregularly,testrunitat

least once a week.

TH Series Pump Trouble Shooting

Humming • Linecircuitbreakeriso,fuseisburnedorloose

• Pumpcordisnotmakingcontactinreceptacle

• Mayhaveairlock

Running,nowater• Checkvalve(optional)isinstalledbackwards

• Dischargeshut-ovalveclosed

• Inletorimpellerclogged

• Pumpisair-locked,startandstopseveraltimesby

plugging and unplugging cord,

may need to

disconnect and reinstall pump.

• Impellernotturningafterextendedtimeoutof

service.Unpluganddisconnectpump.Manuallyturn

theimpellerbyspinninguntilfree.Reconnectpump

andplugbackin.

• Verticalpumpingdistanceistoohighorthepipe

sizeistoosmall

Running,very • Pumpisair-locked,startandstopseveraltimesby

little water plugging and unplugging cord

• Verticalpumpingdistanceistoohighorthepipe

sizeistoosmall

• Inletorimpellerclogged/damaged

• Lowwaterconditionswithpumpsuckingair

GFCIbreaker • Mechanicalsealsmayneedtobereplaced

tripping • Powercordmaybedamagedorcut

• Nuisancetripduetoimpropergrounding

• Motorstatormaybedefective

• Overloadedcircuit

Motorbriey • Lowwaterconditions,pumpoverheating

startsandstops • Inletorimpellerclogged

• Improperpowersupply

• Motorstatormaybedefective