Rev. 04

IL125001EN

Installation Instructions for PSG480B24RM BUFFER MODULE

READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING THIS DEVICE.

KEEP FOR FUTURE REFERENCE.

1. Safety instructions

• Switch main power off before connecting or disconnecting the device. Risk of explosion!

• To guarantee sufficient convection cooling, please keep a distance of 50 mm above and below the

device as well as a lateral distance of 20 mm to other units.

• Note that the enclosure of the device can become very hot depending on the ambient temperature

and load of the power supply. Risk of burns!

• The main power must be turned off before connecting or disconnecting wires to the terminals!

• Do not introduce any objects into the unit!

• Dangerous voltage present for at least 5 minutes after disconnecting all sources of power.

• The unit is a built-in unit and must be installed in a cabinet or room (condensation free

environment and indoor location) that is relatively free of conductive contaminants.

• The unit must be installed in an IP54 enclosure or cabinet in the final installation.

• Warning: Explosion Hazard – Substitution of components may impair suitability for Class I, Division 2.

• Warning: Explosion Hazard – Do not disconnect equipment or adjust switch unless the power has

been switched off or the area is known to be non-hazardous.

• CAUTION: “FOR USE IN A CONTROLLED ENVIRONMENT”.

2. Device description (Fig. 1)

(1) Input / Output terminal block connector

(2) Signal terminal block connector

(3) Select switch (operation mode)

(4) LED display status

(5) Universal mounting rail system

3. Mounting (Fig. 2)

The unit can be mounting on 35 mm DIN rails in accordance with EN 60715. The device should be

installed with input / output terminal block on the top.

Each device is delivered ready to install.

Snap on the DIN rail as shown in Fig. 2:

1. Tilt the unit slightly upwards and put it onto the DIN rail.

2. Push downwards until stopped.

3. Press against the bottom front side for locking.

4. Shake the unit slightly to ensure that it is secured.

4. Dismounting (Fig. 3)

To uninstall, pull or slide down the latch as shown in Fig. 3. Then, slide the unit in the opposite direction,

release the latch and pull out the unit from the rail.

5. Connection

The terminal block connectors allow easy and fast wiring. The terminal block is IP20 compliant thus

provides the user safety and protection from electrical shock hazards.

You can use flexible (stranded wire) or solid cables with cross sections:

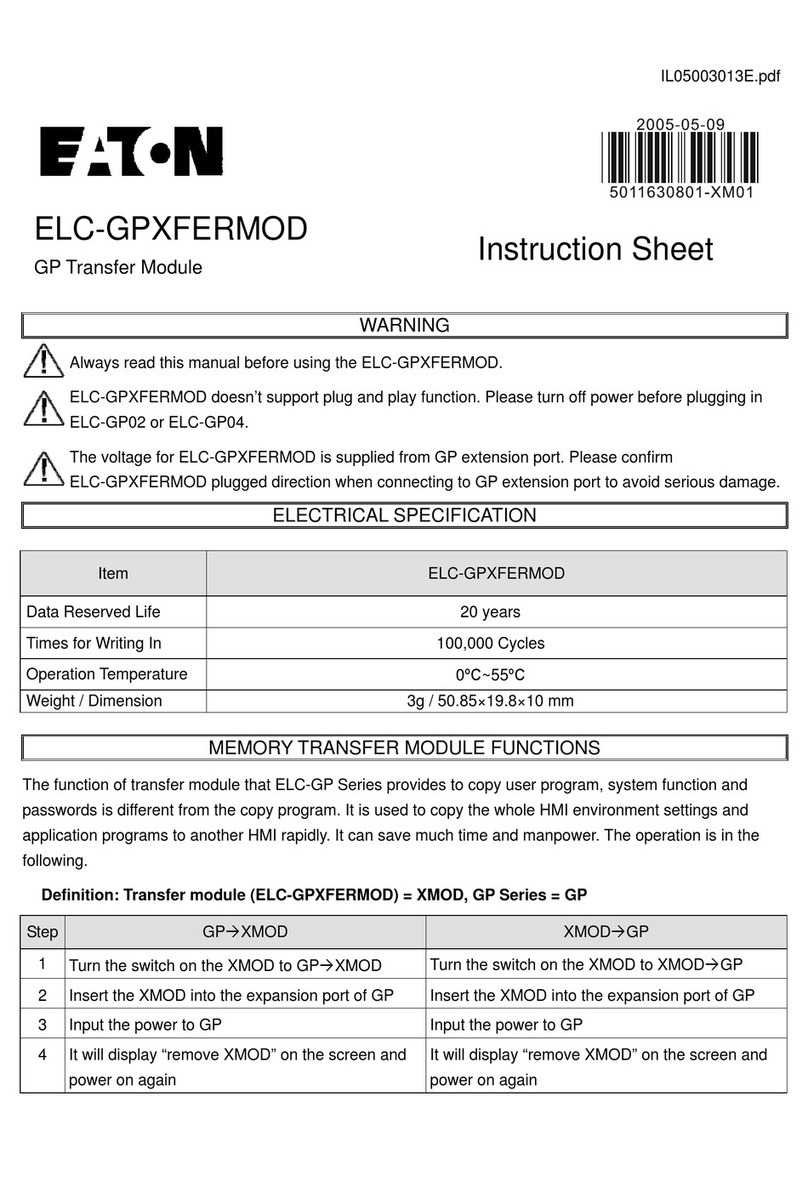

Table

To secure reliable and shock proof connections, the stripping length should be 7 mm (see Fig. 4 (1)).

Please ensure that wires are fully inserted into the connecting terminals as shown in Fig. 4 (2).

In accordance to EN 60950 / UL 60950, flexible cables require ferrules.

Use appropriate copper cables that are designed to sustain operating temperature of:

1. 60°C, 60°C / 75°C for USA

2. At least 90°C for Canada.

6. Typical application notes (Fig. 5)

1. General connection / wiring diagram

2. Paralleling of buffer units

3. Decoupling of buffered branches

4. General signals wiring

5. Signals supplied from external voltage

6. Wiring schematics

Risk of electrical shock, fire, personal injury or death.

(1) Turn power off before working on the device.

(2) Make sure of the wiring is correct by following all local and

national codes.

(3) Do not modify or repair the unit.

(4) Use caution to prevent any foreign objects from entering into the

housing.

(5) Do not use in wet locations.

(6) Do not use the unit in area where moisture or condensation can be

expected.

7. Connectable power supplies

The buffer module is recommended to be connected with the following power supplies:

• PSG60E24SP

• PSG60E

• PSG120E

• PSG240E

• PSG480E

FOR TECHNICAL ASSISTANCE CALL 1 - 877 - ETN - CARE

Buffering Relay,

lampor signal

Buffering Relay,

lampor signal

0

10

20

30

40

50

60

70

80

90

100

110

-25 -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75

Load (%)

Ambient Temperature (°C)

• PSG120E24RM

• PSG240E24RM

• PSG480E24RM

Power Derating Curve for PSG Buffer Module in Vertical Position

5.1 General connection / wiring diagram

5.2 Paralleling of buffer units

5.5 Signals supplied from external voltage

5.3 Decoupling of buffered branches

5.4 General signals wiring

W126N7250 Flint Drive

Menomonee Falls, WI 53051

www.eaton.com

EU: Eaton Industries GmbH

Hein-Moeller-Str. 7-11

53115 Bonn, Germany