Eaton AMPGARD RVSS Operating and maintenance manual

Other Eaton Controllers manuals

Eaton

Eaton CDAU-01/04 Manual

Eaton

Eaton ATC-900 User manual

Eaton

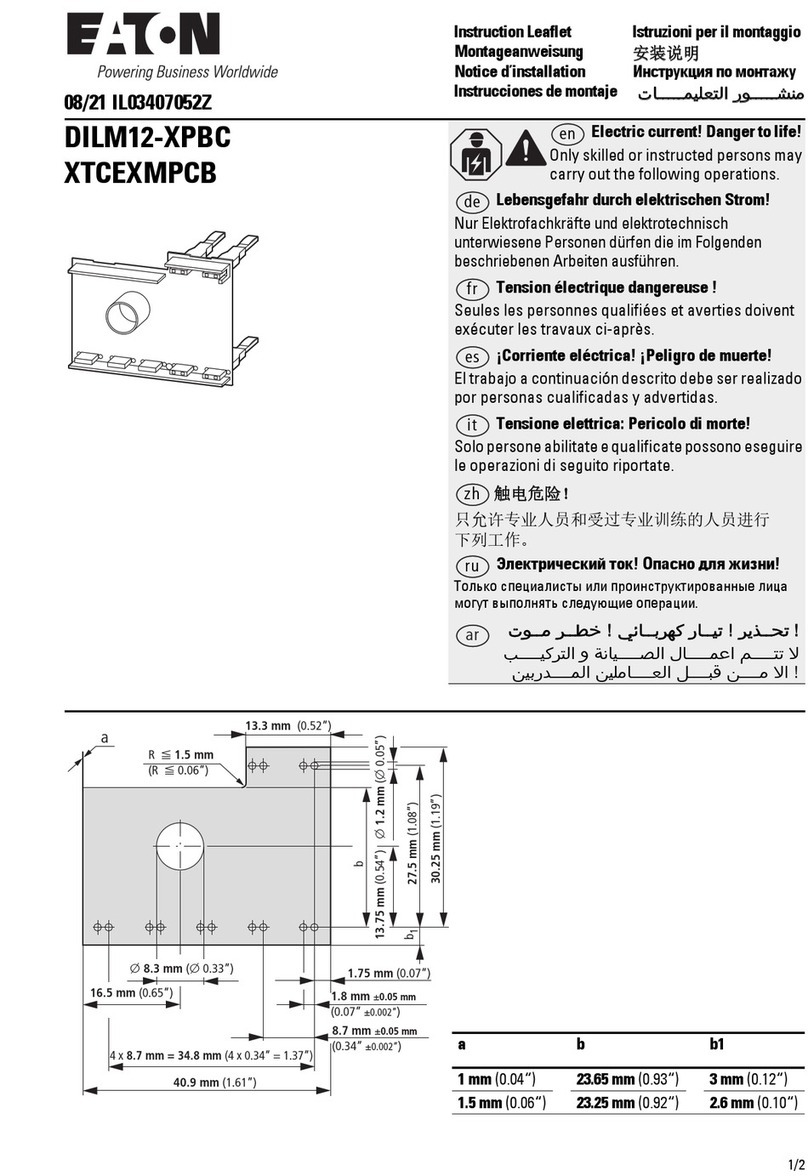

Eaton DILM12-XPBC Manual

Eaton

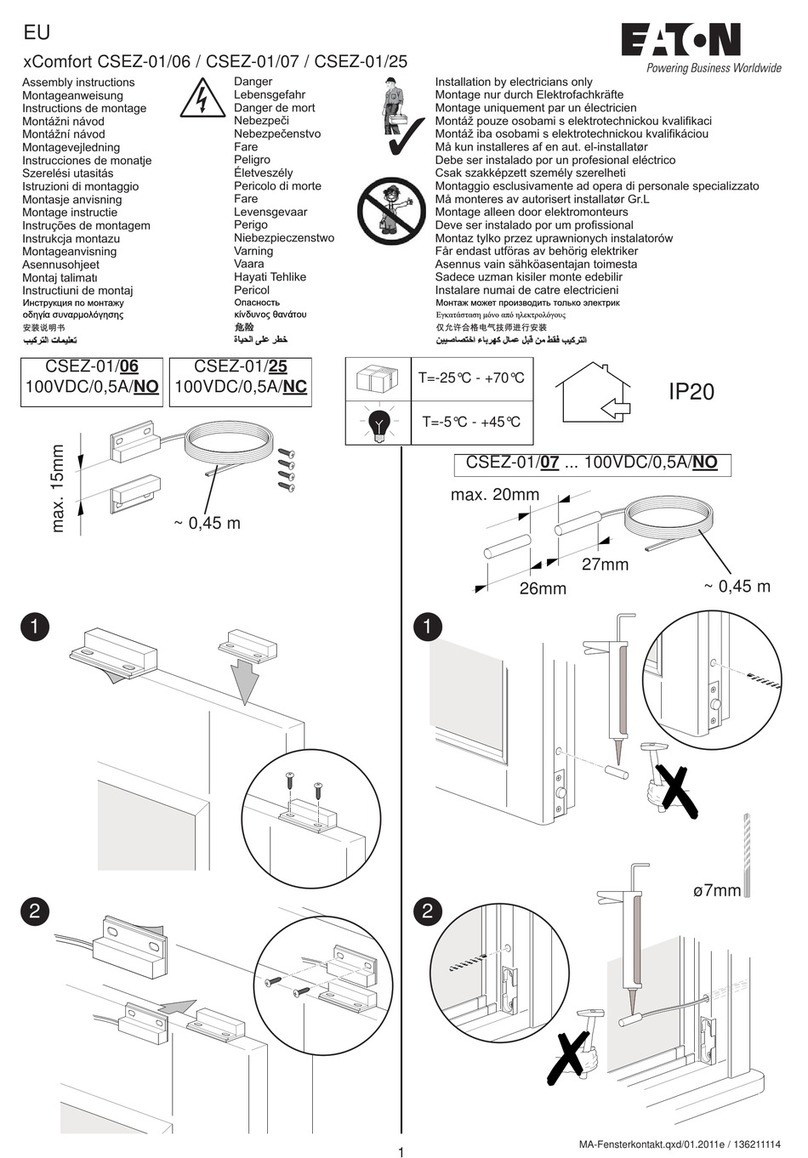

Eaton xComfort CSEZ-01/07 User manual

Eaton

Eaton Cutler-Hammer ATC-300 User manual

Eaton

Eaton CGLine+ Web-Controller User manual

Eaton

Eaton SC100 User manual

Eaton

Eaton NFX9000 User manual

Eaton

Eaton SFX Series User manual

Eaton

Eaton DE1-121D4 Series Manual

Eaton

Eaton Cutler-Hammer FD100 User manual

Eaton

Eaton ELCM TC Series User manual

Eaton

Eaton SVCH0203 SPX Advanced Instructions for use

Eaton

Eaton ATC-800 Programming manual

Eaton

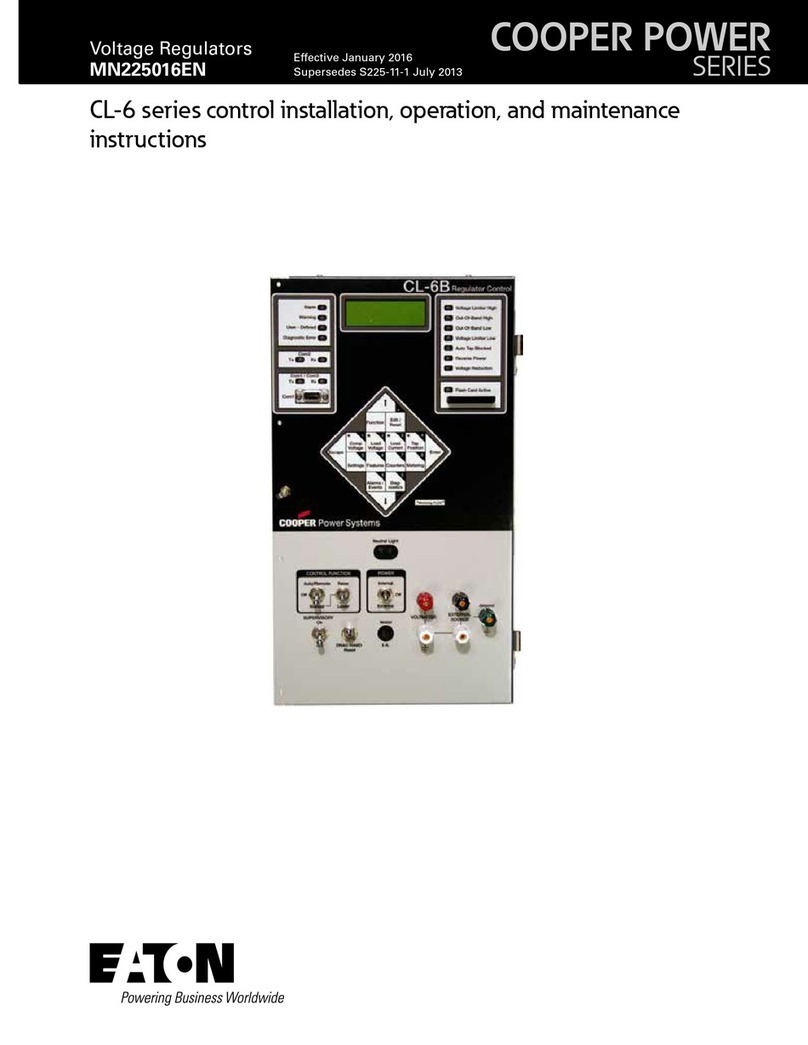

Eaton COOPER POWER SERIES Manual

Eaton

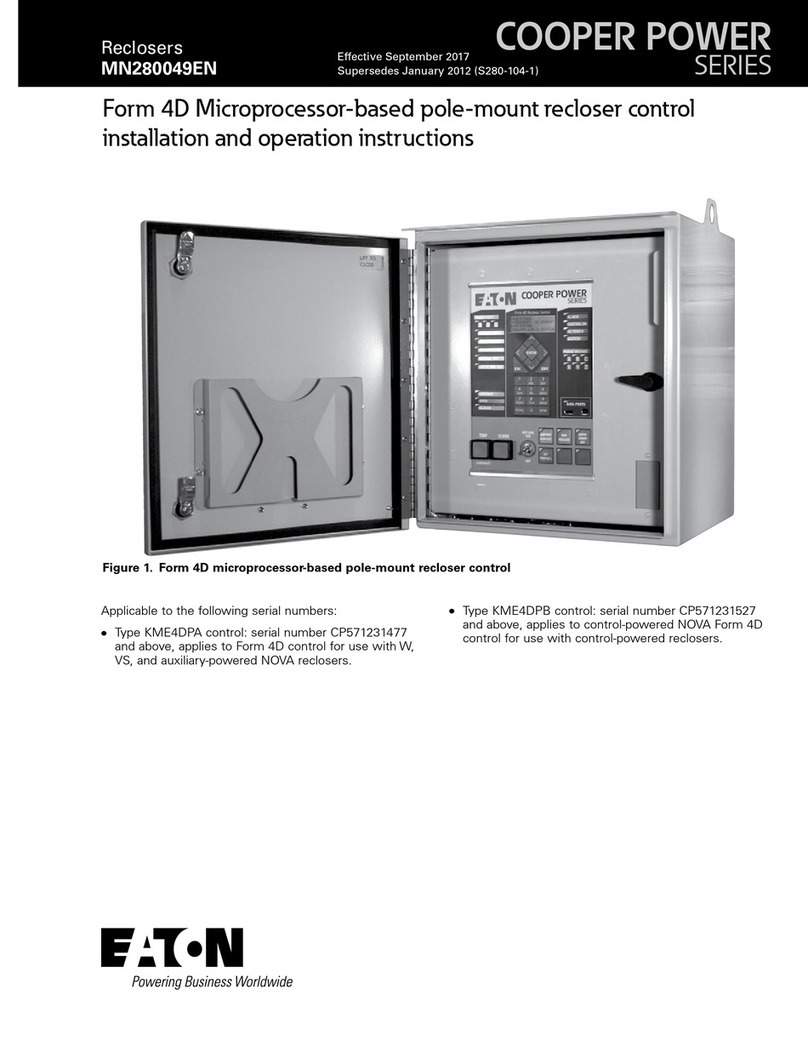

Eaton COOPER POWER SERIES Service manual

Eaton

Eaton xComfort CAAE Series Manual

Eaton

Eaton Cuttler-Hammer Pow-R-Command 100 Instruction manual

Eaton

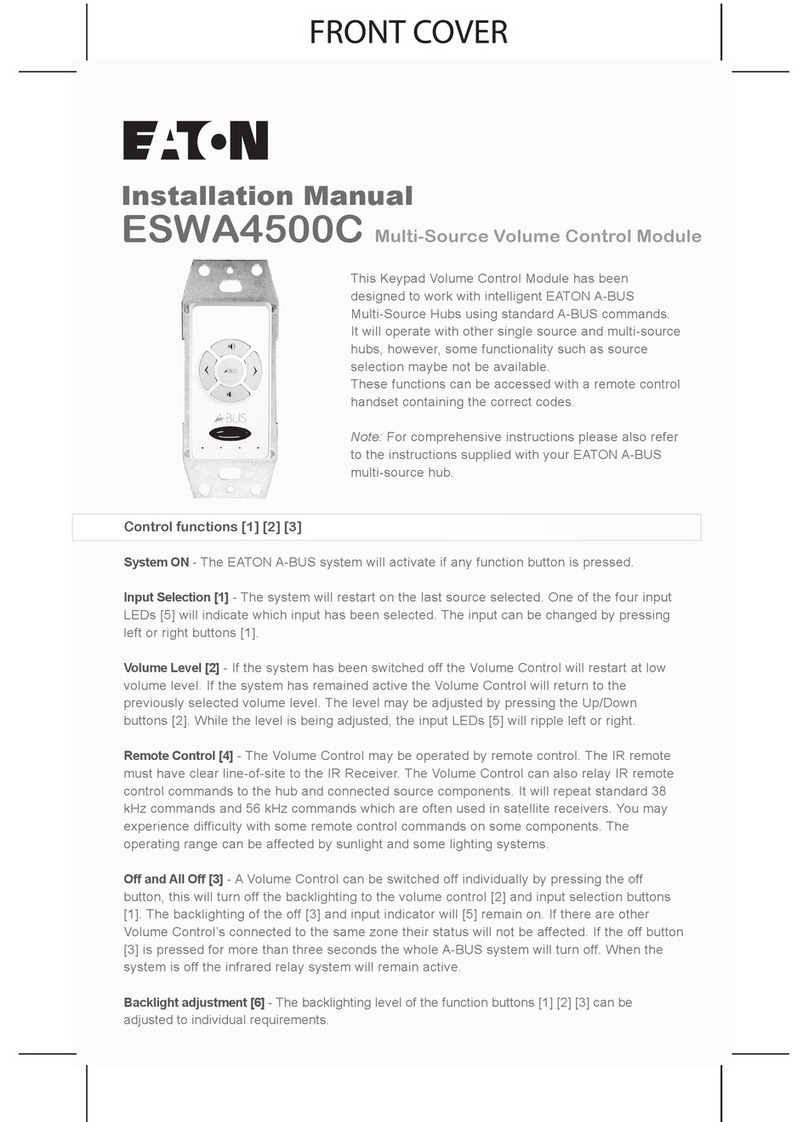

Eaton ESWA4500C User manual

Eaton

Eaton DS7 Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions