IL05003015E.pdf

5011632305-PH05

2007-05-08

ELC-PH12NNDT

Logic Controller with Special Pulse

Input/Output Function

Instruction Sheet

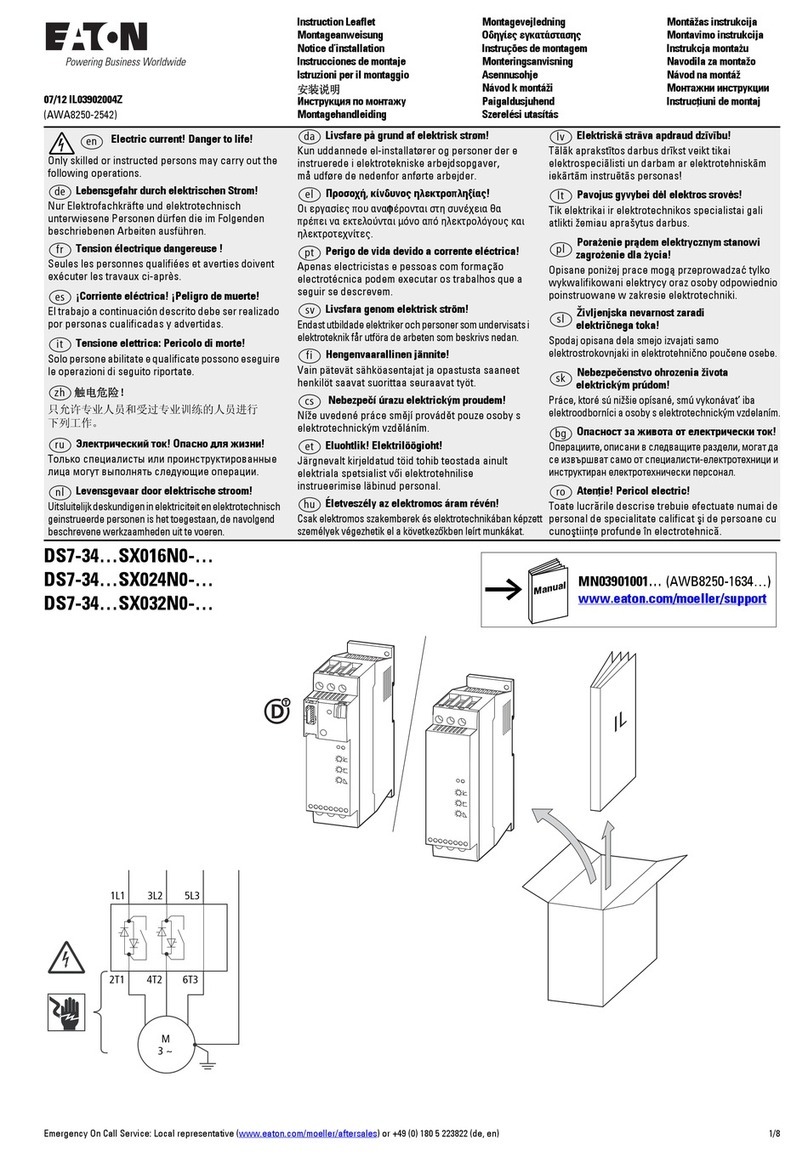

WARNING

•This Instruction Sheet only provides descriptions for electrical specifications, general specifications,

installation & wiring, troubleshooting and peripherals. Other detail infromation about programming and

commands is compatible with ELC-PC/PA/PH series; please see ELC Application Manual. For more

information about the optional peripherals , please see individual product manual.

•This is an OPEN TYPE Controller. The ELC should be kept in an enclosure away from airborne dust, humidity,

electric shock risk and vibration. Also, it is equipped with protective methods such as some special tools or

keys to open the enclosure, so as to avoid the hazard to users and the damage to the ELC.

•Never connect the AC main circuit power supply to any of the input/output terminals, as it will damage the

ELC. Check all the wiring prior to power up. To avoid any electromagnetic noise, make sure the ELC is

properly grounded . Do NOT touch terminals when power on.

•Battery replacement: use UL component type: TDRTL-2150/S lithium battery. Refer to following table for

battery life. (NOTE: RTC should be reset after changing battery).

Temperature (°C) 0 25 50 70

Life (Years) 9 8 6 5

Precision of calendar timer:

At 0°C/32°F, less than –117 seconds error per month.

At 25°C/77°F, less than 52 seconds error per month.

At 55°C/131°F, less than –132 seconds error per month.

•Warning – Do not disconnect while circuit is live unless area is known to be non-hazardous.

•Power, input and output (I/O) wiring must be in accordance with Class 1, Div. 2 wiring methods -–Article

501-10(B)(1) of the National Electrical Code.

•Suitable for use in Class 1, Division 2, Groups A, B, C, D or Non-Hazardous locations only.

•Warning – Explosion hazard – Substitution of components may impair suitability for Class 1, Division 2.

•Warning – Explosion hazard – Do not disconnect equipment unless power has been switched off or the area

is known to be Non-Hazardous.

1 INTRODUCTION

5.1 Model Name Explanation and Peripherals

Thank you for choosing Eaton Logic Controller (ELC) series products. The ELC-PH series has a 12-points (8 input

points + 4 outputs) MPU with powerful instructions (the same instruction sets as PC/PA series) for use. It also has

an 8K Steps program memory and high-speed pulse inputs(X10 and X11)/outputs (Y10 and Y11). For high-speed

pulse, total bandwidth can up to 130KHz and 100KHz maximum for single input/output. Besides, it also provides

instructions of position control and zero point return to use with high-speed pulse output.

5.2 Product Profile and Outline

RUN

RUN

ERROR

POWER

ELC-PH12NNDT

Y3

RS-232

RS-485

Y1

Y2

C2

Y0

C1

Unit: mm

1 Status indicators of POWER, RUN,

ERROR and BAT.LOW

2 RUN/STOP switch

3 VR0: Start-up by M1178/D1178

Corresponding value

4 VR1: Start-up by M1179/D1179

Corresponding value

5 DIN rail clip

6 I/O terminals

7 I/O point indicators

8 COM1 (RS-232) (Rx) indicator

9 COM2 (RS-485) (Tx) indicator

10 COM1 (RS-232) port

11 Nameplate

Warning: Battery replacement: Please change the battery within 3

minutes, or the internal data of the ELC (including the program area,

perpetual calendar and latched registers) could be lost or destroyed.

12 Extension port for wire to connect

extension module/unit

13 Mounting hole

14 DIN rail track (35mm)

15 Extension unit clip

16 RS-485 communication port

(Master/Slave)

17 DC Power input

18 2 pin removable terminal (standard

accessory)

19 Power input cable (standard

accessory)

20 Battery cover

21 Battery socket connection

22 Battery holder

2 FUNCTION SPECIFICATIONS

Items Specifications Remarks

Control Method Stored program, cyclic scan system

I/O Processing Method Batch processing method (when END instruction is

executed)

I/O refresh instruction is

available

Execution Speed Basic instructions (several us) Application Instructions

(10~hundreds us)

Program Language Instructions + Ladder Logic + SFC Including the Step

instructions

Program Capacity 7,920 STEPS SRAM+ Battery

Instructions 32 Basic sequential instructions (including step

instructions)

168 Application

instructions

Relay (bit mode)

X External Input Relay X0~X177 in octal, 128 points in decimal Total

256

points

Correspond to external

input point

Y External Output

Relay Y0~Y177 in octal, 128 points in decimal Correspond to external

output point

M Aux.

Relay

General M0~M511, 512 points (*1) Total

4,096

points

Contacts can switch to

On/Off in program

Latched M512~M999, 488 points (*3)

M2000~M4095, 2,096 points (*3)

Special M1000~M1999, 1,000 points (some are latched)

T Timer

100ms

T0~T199, 200 points (*1)

Total

256

points

When the timer that set

by TMR instruction

reaches the preset value,

the T contact with the

same number will be On.

T192~T199 for Subroutine

T250~T255, 6 points Accumulative (*4)

10ms T200~T239, 40 points (*1)

T240~T245, 6 points Accumulative (*4)

1ms T246~T249, 4 points Accumulative (*4)

C Counter

16-bit C0~C95, 96 points (*1)

Total

253

points

When the counter that set

by CNT (DCNT)

instruction reaches the

preset value, the C

contact with the same

number will be On.

1-phase high-speed

counter: 20KHz max.

AB-phase high-speed

counter: 4KHz max.

C96~C199, 104 points (*3)

32-bit C200~C215, 16 points (*1)

C216~C234, 19 points (*3)

32bit

High-speed

C235~C240, 1-phase 1 input, 6 inputs (*3)

C243, C245, 1-phase 1 input, 2 points (*3)

C246~C249, 1-phase 2 inputs, 3 points (*3)

C250, 1-phase 2 inputs, 1 point (*3)

C251~C254, 2-phase 2 inputs, 3 points (*3)

S Step

point

Initial S0~S9, 10 points (*1)

Total

1,024

points

Usage device of step

ladder diagram (SFC)

Latched Range:

Start: D1214 (K512)

End: D1215 (K895)

Zero

Return

S10~S19, 10 points, (use with IST instruction)

(*1)

General S20~S511, 492 points (*1)

Latched S512~S895, 384 points (*3)

Alarm S896~S1023, 124 points (*3)

Register (WORD data)

T Current Value of the

Timer T0~T255, 256 points

When the timer reaches

the preset value, the

contact of timer will be

On.

C Current Value of the

Counter

C0~C199, 16-bit counter, 200 points

C200~C254, 32-bit counter, 50 points

When the counter

reaches the preset value,

the contact of counter will

be On.

D Data

Register

General D0~D199, 200 points (*1)

Total

5,000

points

Can be memory area for

storing data. E and F can

be used as the special

purpose of index

indication.

Latched D200~D999, 800 points (*3)

D2000~D4999, 3,000 points (*3)

Special D1000~D1999, 1,000 points

Index E0~E3, F0~F3, 8 points (*1)

None

File Register 0~1,599(1,600 points) (*4) Extension register to

store data.

Pointer

N For Master Control

Nested Loop N0~N7, 8 points Control point of master

control nested loop

P For CJ, CALL

Instructions P0~P255, 256 points The location point of CJ,

CALL.

I

Interrupt Service

Input Interrupt I001 (X0), I101 (X1), I201 (X2), I301 (X3), I401 (X4),

I501 (X5); 6 points (all are rising-edge trigger)

The location pointer of

interrupt subroutine

Timer Interrupt I6□□(1ms), 7□□(1ms), (□□=01~99ms)

High-speed

Counter I010, I020, I030, I040, I050, I060, 6 points

Communication I150, 1 point

Communication Port in

Series (program read/write)

COM1: only for slave, ASCII/RTU are available, 115,200 bps max.

COM2: can be Maser/Slave, ASCII/RTU are available, 115,200 bps max.

COM1and COM2 can be used simultaneously

Potentiometer / RTC MPU built-in 2 points VR / MPU built-in RTC

Items Specifications

High-speed Counter

1-phase 1 input: inputs X10 (C243) and X11 (C245). Input frequency can up to

100KHz. 1-phase 2 inputs: inputs (X10, X11) C250. Input frequency can up to

100KHz.

Position Control

High-speed pulse outputs Y10 and Y11. Output frequency can up to 100KHz. It can

be used as position control of servo drive or step drive when using with position

instructions (DDRVI and DDRVA) and DZRN (zero point return).

*1: The non-latched area is fixed, and can’t be changed.

*2: The non-latched area can be changed to a latched area with parameter setting.

*3: The latched area can be changed to a non-latched area with parameter setting.

*4: The latched area is fixed, and can’t be changed.

M

Auxiliary

Relay

General Latched Special auxiliary relay Latched

M0~M511 M512~M999 M1000~M1999 M2000~M4095

Non-latched (fixed)

Latched (default) Some are latched and

can’t be changed

Latched (default)

Start: D1200 (K512)

End: D1201 (K999)

Start: D1202 (K2,000)

End: D1203 (K4,095)

T

Timer

100 ms 10 ms 10ms 1 ms 100 ms

T0 ~T199 T200~T239 T240~T245 T246~T249 T250~T255

Non-latched (fixed) Non-latched (fixed) Accumulative Latched (fixed)

C

Counter

16-bit count up 32-bit count up/down 32-bit high-speed count

up/down

C0~C95 C96~C199 C200~C215 C216~C234 C235~C245 C246~C255

Non-latched

(fixed)

Latched (default) Non-latched

(fixed)

Latched (default) Latched (default)

Start: D1208 (K96)

End: D1209 (K199)

Start: D1210 (K216)

End: D1211 (K234)

Start: D1212 (K235)

End: D1213 (K255)

S

Step relay

For general Latched Special register Latched For general

S0~S9 S10~S19 S20~S511 S512~S895 S896~S1023

It is fixed to be non-latched

Factory setting is latched

It is fixed to be latched

Start: D1214 K512( )

End: D1215 K895( )

D

Register

General Latched Special registers Latched

D0~D199 D200~D999 D1000~D1999 D2000~D4999

Non-latched (fixed)

Factory setting is latched. Some are latched and

can’t be changed.

Factory setting is

latched.

Start: D1216 (K200)

End: D1217 (K999)

Start: D1218 (K2,000)

End: D1219 (K4,999)

File Register K0~K1,599, Latched (fixed)

ELECTRICAL SPECIFICATIONS

3

Model

Item ELC-PH12NNDT

Power Supply Voltage MPU: 24VDC (-15%~20%) (With DC input reverse polarity protection),

Extension Unit: supplied by the MPU

Fuse 2A

Power Consumption 4W MAX

Insulation Resistance 5 MΩand above at 500 VDC (Between all inputs / outputs and earth)

Noise Immunity

ESD: 8KV Air Discharge

EFT: Power Line: 2KV, Digital I/O: 1KV, Analog & Communication I/O: 250V

RS: 26MHz~1GHz, 10V/m

Grounding

The diameter of grounding wire cannot be smaller than the wire diameter of

terminals 24V and 0V (All ELC units should be grounded directly to the ground

pole).

Environment Operation: 0℃~55℃(Temperature), 50~95% (Humidity), Pollution degree 2;

Storage: -25℃~70℃(Temperature), 5~95% (Humidity)

Agency Approvals

UL508

UL1604, Class1,Div2 Operating temperature code: T5

European community EMC Directive 89/336/EEC and Low Voltage Directive

73/23/EEC

Vibration / Shock Resistance Standard: IEC61131-2, IEC 68-2-6 (TEST Fc) / IEC61131-2 & IEC 68-2-27 (TEST

Ea)

Weight (approx.) (g) 158

Input Specifications

Output Specifications

Input Type Photo coupler Isolation Output Type Transistor

Input Current 24VDC 5mA Rated Current 0.3A/1 point @ 40℃(Room

Te m p . )

Active Level

X0,X1,X10,X11:

Off→On, 18.5VDC and above

X2~X5:

Off→On, 16.5VDC and above

Voltage Specification 5~30VDC

Max. Inductive Load 7.2W/24V

Output

Protection

Internal None

Outside Rated value according to the load

X0~X11: On→Off, below 8VDC Maximum Loading

Y0, Y1 9W / 1 point

Response Time X0~X5 10ms or 0~20ms

(Setting by D1020)

Y10, Y11 0.9W / 1 point

Response Time Off→On <20us

<1us (Y10, Y11 only)

X10, X11 The constant of filter