Technical Manual TAR x810-2 Cold Storage Controllers Page 5

Functional Description

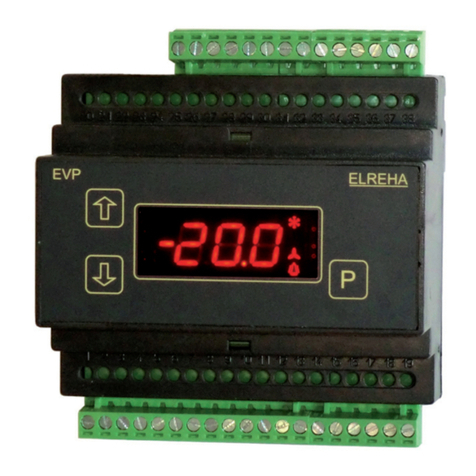

Display & Sensors

The controller is able to work with temperature

sensors of the TF 201 or TF 501 (Pt1000) series,

set by P21.

Ranges:

P21 = 1 (TF 201).................... -50...+100°C

P21 = 3 (TF 501/Pt1000)....... -100...+300°C

Please note the specic temperature restric-

tions of the used sensors (e.g. -40...+80°C of

the standard-TF-types) and ask for matching

types if necessary.

Sensor 2 (evaporator sensor) can be disabled.

Temperature Control

Theactualtemperaturefromthecontrolsensor(P01)

is compared with the control setpoint (P03). Depen-

ding on the result, the cooling relay switches power

relaysofcompressors orsolenoidvalves.Aswitching

hysteresis (P09) prevents from short cycling, an idle

time (P11) prevents a compressor from switching

ON again immediately. In order to be fail-safe in case

of any internal power failure, there is a possibility of

selecting the correct switching mode (P10). In refri-

geration mode the N/O relay contacts are used so

that the load is shut off in case of failure. In freezing

mode the load is connected to the N/C contact, with

the load running constantly in case of failure.

Setpoint range

With parameters P07/P08 you can limit the setpoint

range.

Switching mode of relay K1

The switching characteristic of relay K1 (= cooling

mode) is dened by parameter P10 (as explained

above).

1= refrigeration

Load is switched by the N/O contact,

If actual value = P03+P09 : Relay K1 activated

2= freezing

Load is switched by the N/C contact,

If actual value = P03+P09 : Rel. K1 de-activated

3= Heating

If actual value = P03-P09 : Rel. K1 is now a

heating relay and will be activated

2. Setpoint / day-night-shift

To economize energy, e.g. at night, the unit is able

to work with a 2nd setpoint (P04). This setpoint can

be activated by the internal time-switch (P05/P06) or

the digital input DI1. The decimal point of the display

ashes while the 2nd setpoint is present.

Temperature alarm

Analarmrelay(K4)andabuilt-in buzzer areavailable

for warning purposes. If the temperature measured

by the control sensor exceeds the range set by

P32/P33, then the display ashes and a time delay

(P31) starts. After this timer is run down, the alarm

relay and the buzzer will be activated. P32 is relative

to setpoint P03, so P32 will be shifted the same

amount as the setpoint.

-- Any keypress resets the buzzer. --

If the temperature has left the range, P18 shows the

remaining time until an alarm occurs.

If the temperature comes back to the working range,

relay and buzzer will be reset automatically.

Alarm relay operation modes

With parameter P30 you select the mode of alarm

relay and internal buzzer:

0= Alarm relay active ON

1= Alarm relay active OFF

2= Alarm relay active ON, buzzer de-activated

3= Alarm relay active OFF, buzzer de-activated

4= Alarm relay works like the built-in buzzer, to

connect an external horn

5= Continuous ON of relay K4 if control setpoint 2

is being activated. Alarm messages will be

forwarded by buzzer/alarm-LED only. With this

function, light can be switched by time control.

6= Alarm relay can be switched via data interface

only. This works as well as the controller is de-

activated by interface or digital input. The swit-

ching command keeps stored, so the relay

position will be restored after a breakdown of

supply voltage.

Additionally, the alarm function can be started by

interrupting the digital input DI1 (see P34).

Real time clock

TheTAR ColdStorageController containsa realtime

clock which allows you to initiate four (8 with AZV)

defrost cycles a day. The timer has a power backup

for about 10 days in case of power failure.

The time of the day and the date can be set with

parameters P41...P45.

The defrost times are set with P24...P27 in 10 minute

increments in a 24 hour (military) format. Example:

13.20 = 01:20 p.m.

The second setpoint switch is made with P05/P06.

Because the display has only three digits, the time

value comes in the following format:

Switch times can be de-activated by setting to

'oFF'.

While the data recording function is active, time and

date cannot be adjusted.

To adjust the clock, rst de-activate data logger

(P39=0).

Defrost

One relay output is used to control a defrost de-

vice.

Defrost Initiation

A. by internal timer, four times available

(P24...P27)

B. by digital input DI1 (see chapter 'digital input').

In this case P35 will take effect as a 'defrost

OFF' time.

C. manually (P49).

The defrost device is always driven from the n/o

contact of relay K2. There is no need for external

interlocking the defrost output with the cooling output

since the temperature controller is disabled while a

defrost cycle. With P23 you can select four different

defrost modes.

Parameter P15 shows the remaining time of the

momentary defrost cycle until termination by time.

Defrost Modes

With P23 a defrost mode can be set, which works in-

dependent from the behaviour of the control relay.

1 = Heater or Free Air Defrost

If a defrost cycle starts, the defrost relay is

energized (= heater ON) and K1 terminates

cooling. (relay de-activated if P10=1, activated

if P10=2 )

2 = Hot Gas Defrost

If a defrost cycle starts, the defrost relay is

energized (bypass-valve open) and also K1

(solenoid valve open/relay activated if P10=1,

de-activated if P10=2 ).

3 = like 1, but with additional

defrost time doubling (AZV)

4 = like 2, but with additional

defrost time doubling (AZV)

Defrost time doubling (AZV)

This is a simple function to double the quantity of the

potential defrost cycles (4 --> 8). The unit generates

new defrost times automatically by adding 12 hours

to existing times.

Example:

If a defrost cycle is xed at 14:30, the unit starts

an additional cycle at 2:30 (am) without entering

this time.

3rd Position=

minutes x 10

1st and 2nd

Position=hours

Manual Defrost Initiation

A. At parameter P49 with key ""

B. While the display shows the actual

temperature by holding the "" key (> 2,5 sec.)

Defrost Termination

A defrost cycle can be terminated as follows :

A: Thermal termination.

Whenever the evaporator sensor temperature

(P02) exceeds the temperature limit set with

parameter P22, defrosting will be terminated.

If not necessary, switch off the evaporator

sensor at P20.

B: Termination by (safety) time.

The time set by parameter P28 is the

maximum time a defrost cycle can last before

it is terminated automatically.

C: Manual termination.

With parameter P49 you can terminate a

defrost cycle by pressing the "" key.

While the actual temperature (P01) is on the

display, a defrost cycle can be terminated by

holding the "" key (> 2,5 sec.)

D. If the defrost limit sensor fails, the defrost cycle

will be stopped immediately.

After the defrost cycle is terminated, the beginning of

the cooling function is delayed (P29). This prevents

freezing water drops on the evaporators surface.

P16 shows the remaining time until cooling starts

again.

(DH) Display Hold Function

This function allows to hold the last measured actual

temperature value on the display during a defrost

cycle. After the defrost cycle has been terminated,

the displayshows the current measuredvalue again.

The DH-function can be initiated by P50.

Evaporator Fan Control

Fourdifferentmodes offanoperationcanbeselected

with parameter P13.

A temporal fan-ON delay is active after a defrost

cycle (P14).

A thermostatic delay is always active. That means

the fan starts only if the temperature measured with

the evaporator sensor is 3K below the fan stop/go

temperature (P12). If this function is not desired, P12

can be set to its upper border to make it inefcient.

While the drain time (P29) the fan remains stop-

ped.

Fan Modes (P13)

1 = Fan runs if compressor output (K1) is on.

After defrosting the fan output is OFF until the

programmed Fan Delay Time (P14) is

complete. .

2 = Fan runs continously, except during defrost

and Fan Delay Time (P14) after defrost.

Thermostatic fan delay: The fan stops if the

temperature measured with the evaporator

sensor exceeds (P12). If this function is

not desired, P12 can be set to its upper border

to make it inefcient.

3 = Fan runs if the compressor output (K1) is on,

and during defrost.

The temporal fan delay must be set to "0".

This mode can be used for free air defrost.

4 = Fan runs permanently, except if unit is

switched off via interface.

(P17) informs about the remaining time until the fan

starts again.

Special case

If digital input DI1 is used for door monitoring, the fan

will stop immediately if the door opens.

Practical conditions

The fan is always switched by the n/o contact of

relay K3.

If you want to realize a thermostatic delay, select fan

mode 2and adjust setpoint P12.

If you want to realize a thermostatic delay and free

air defrost, please realize a parallel connection of fan

relay and defrost relay.