8. Installation

8.1 General

The respective national regulations, IEC/EN 60079-14 as well

as the general rules of engineering which apply to the

installation and operation of explosion protected apparatus

must be observed!

Improper installation and operation may result in the

explosion protection method being compromised and

invalidate the guarantee.

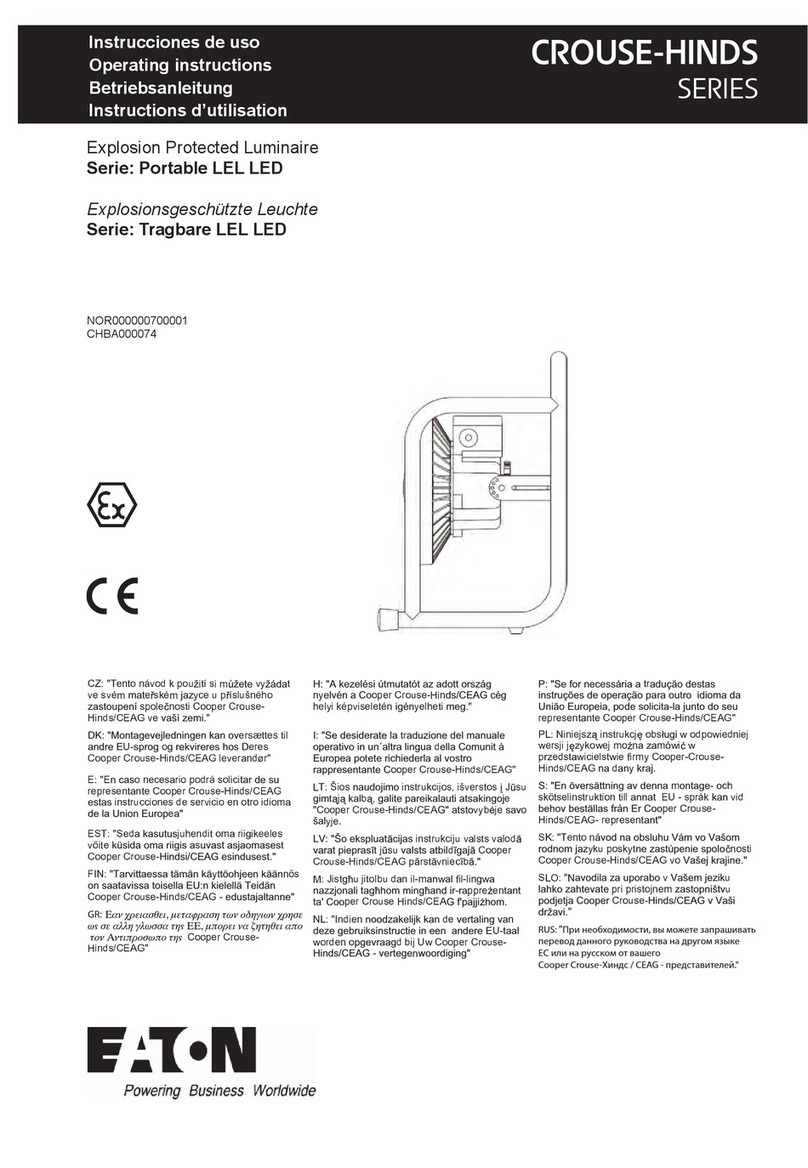

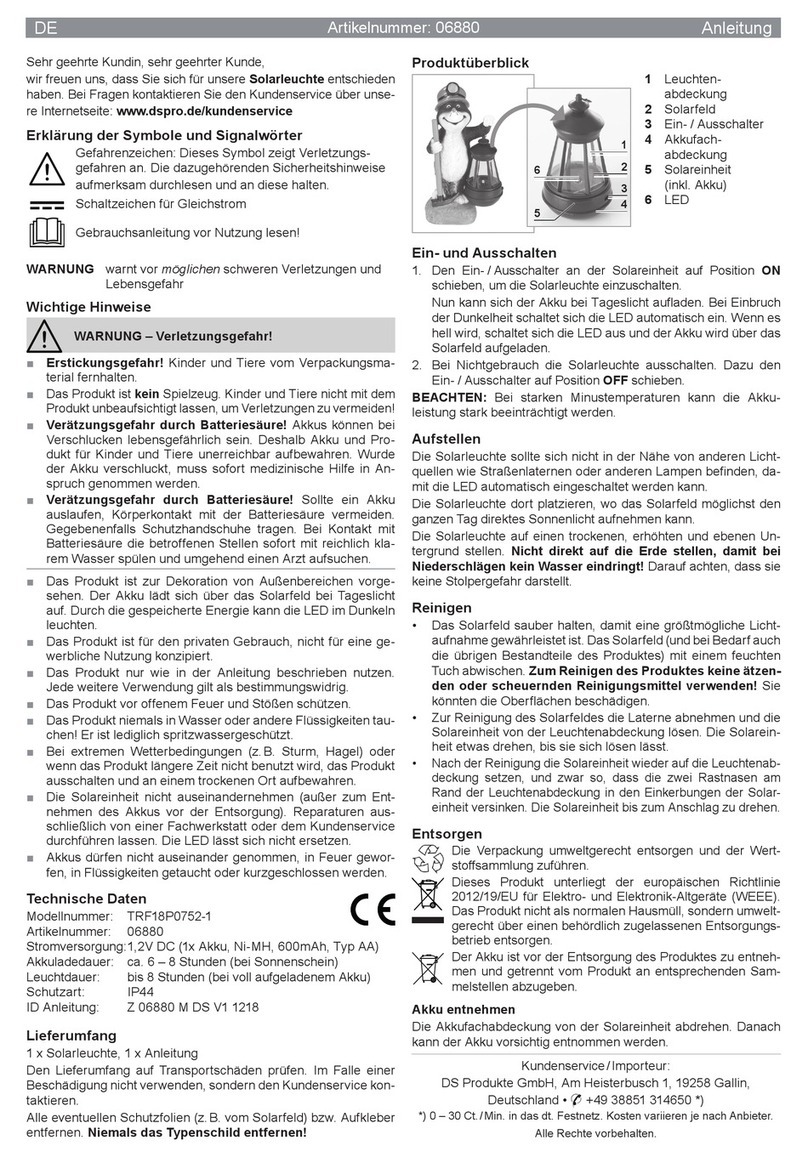

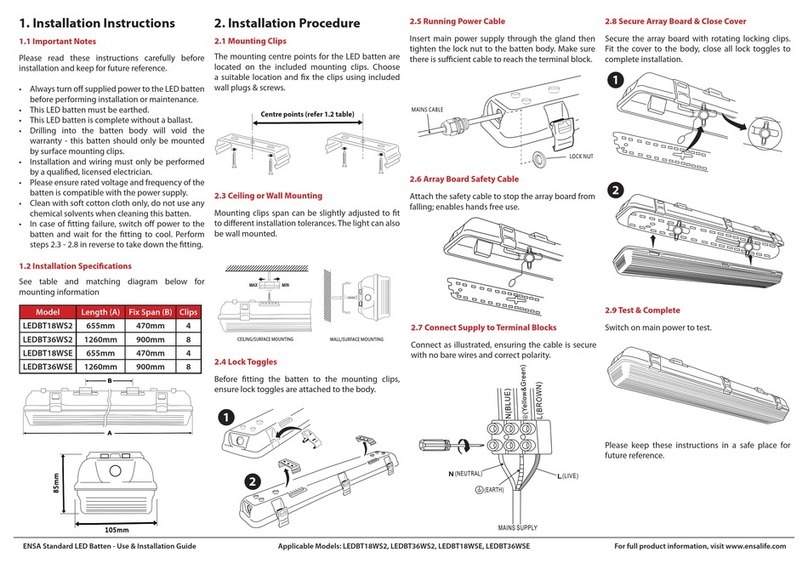

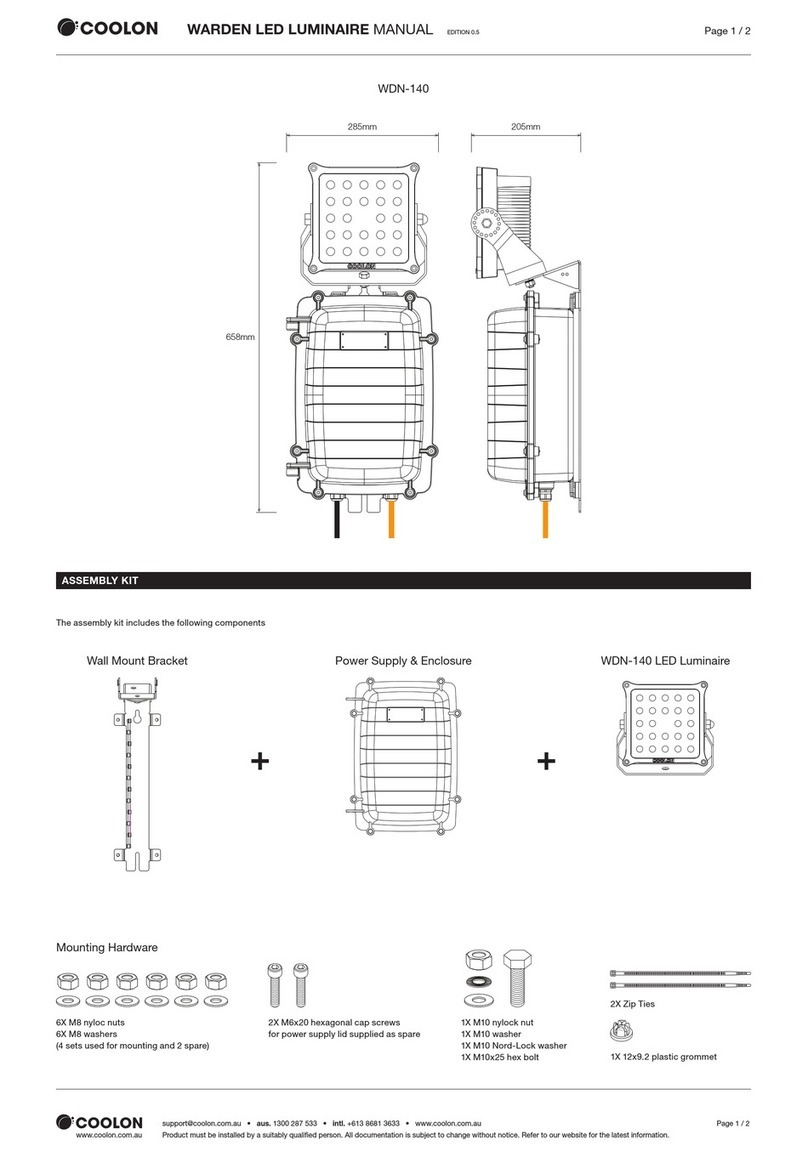

8.2 Mounting luminaire

8.2.1 Mounting bracket

Only use the accompanying mounting bracket! Securely

fasten the mounting bracket to a suitable base with

sufficient load-bearing capacity. The mounting should be

secured with M8 bolts, lock washers and nuts.

8.2.2 Pole mounting

The pole mounted light fitting is mounted and installed in

the following order:

–Unscrew the three recessed head screws in the cover of

the pole connecting compartment, see fig. 5.1, item 1.

–Open the connecting compartment by folding down the

cover, see fig. 5.5, item 2.

–Pull the stay shackle of the cable entry socket up to its

stop and take off the cover plate, see fig. 5.5, item 3.

–Remove the cable entry sockets from the guiding

grooves in the connecting compartment.

–Push the 42mm diameter pole (fig. 5.5, item 4) into the

opening of the light fitting, see fig. 5.4.

–Adjust the light fitting and screw down the preassembled

M 6 special screws, applying a torque of 3.0 Nm, see fig.

5.5, item 5.

–Introduce the cable through the tube and strip the

insulation to the required length.

–Introduce the cable through the Ex cable entry (KLE) and

tighten it down with the pressure screw of the cable entry

(see Technical data).

–The complete support (with the cable being introduced)

is put into the guiding grooves of the pole mounted light

fitting, see fig. 5.5, item 6.

–Lock the support with the stay shackle, see fig. 5.5, item

3.

–Insert the cable into the pull-relief and tighten it down,

see fig. 5.5, item 7.

–Then connect the cable in accordance with the terminal

marking.

The minimum distance between the luminaire and

illuminated surface, directly in front of the luminaire, is 0.5

meter. The lighting must not be illuminated when at a

distance of less than 0.5m from inflammable material

8.3 Cable entries/Plugs and Breathing valve

The “Increased safety (Exe)" properties must be preserved

when mounting cable entry/plug and breathing valve.

Unused holes must be closed with certified plug to establish

the Exe protection category. The cable glands/plugs and

breathing valve should be Ex tb certified if the whole

product is Ex tb certified also. Cable entries sealing

washer(if required by manual of cable gland/plug) must be

used to obtain IP66.

IM0535 Ver.4 2023/10 Cooper Electric (Changzhou) Co., Ltd. Page 3/6

The authoritative mounting guidelines for the

cable glands and breathing valve used must be

observed. Mounting the selected cable entries acc.

type and dimensions of the main connection cable

following their manufacturer instructions. The

cable temperatures are given as the rise over the

max. rated ambient (Tamb). This allows the user

to adjust the cable specification for actual

maximum site ambient. Only heat resistant cable

according to the data on the type label may be

used! The max. conductor size is 6mm². The

standard looping cable size is 4mm².

8.4 System modes

8.4.1 Independent system mode:

8.4.1.1 In the event of a mains failure, an

automatic changeover to emergency operation

occurs.

8.4.1.2 Battery Indicator Matrix:

8.4.1.3 Battery charging:After first mains

connection, an uninterrupted charging time for 24

hours is strongly recommended. A charge-

discharge activation cycle should be applied if

stored for more than 6 months.

8.4.2 Inhibit switch system mode:

8.4.2.1 The emergency light function can be

separately switched on and off via a inhibit switch

installed outside in the event of a mains failure.

8.4.2.2 If using the inhibit switch, remove the wire

on the small terminal (refer wiring diagram).

8.5 Opening/closing the luminaire

8.5.1 General

The equipment must be de-energised before

opening! All gasket seals must be clean and

undamaged before closing the luminaire! Make

sure the luminaires is fully closed before

operation!

8.5.2 Exe chamber cover

Open the buckles and remove the PC cover. And carry

out the steps in reverse order to close the luminaire.

Check all buckles to ensure a secure fit during

operation.(Illustration 4 )

8.6 Electrical connection

The electrical connection of the luminaire must only be

carried out by qualified electricians.

Make sure the supply voltage is the same as the

luminaire voltage! Use proper supply wiring as

specified on the nameplate of the luminaire and in this

instructions! Excessive tightening may affect or damage

the connection.

8.6.1 Wire connection

The conductors shall be connected with special care in

order to maintain the explosion category.

The conductor itself shall not be damaged.

The min. and max. conductor cross-sections

shall be observed (see technical data). All

terminals, used and unused, shall be tightened

between 1.2Nm for Exe T6P and 0.6~0.8Nm for

MK3/2/E. Main connection: See wiring diagram.

Remove the single core cable which shorts the

terminals of MK3/2/E when installing the inhibit

switch.

Type of connected conductors: Rigid with cable

lug, flexible with ferrule, pin cable lug or cable

lug.

9. Putting into operation

Prior to putting the apparatus into operation, the tests

specified in the relevant national regulations shall be

carried out. Insulation measurements may only be

carried out between PE and the external conductor L1

(L2, L3) as well as between PE and N.

- Measurement voltage: Max. 1.5 KV AC

- Measurement current: Max.5 mA

- The luminaire may only be operated when closed.

- It is generally recommended (see IEC/EN 60079-14)

that you ensure the type of protection of the

construction is not impaired during installation.

10. Maintenance/Servicing

10.1 General

The relevant national regulations which apply to the

maintenance/servicing of electrical apparatus in

explosive atmospheres, shall be observed (EN/IEC

60079-17). The interval between maintenance depends

upon the ambient conditions and the hours of

operation. The recommendations given within EN/IEC

60079-17 for recurring checks must be observed.

10.2 Checks

The equipment must be de-energised before opening

Visual inspection should be carried out at a minimum

of 12 monthly intervals and more frequently if

conditions are severe, refer to EN/IEC 60079-17. The

time between luminaire changes could be very

infrequent and this is too long a period without

inspection.

10.3 Routine Examination

During maintenance, the parts affecting the level

of protection must be checked in particular:

- Ensure the luminaire is lit when energised and

examine the enclosure and cover for any signs of

cracks and damage.

- When de-energised and left to cool, there should be

no significant sign of internal moisture. If there are

signs of water ingress, the luminaire should be opened

up, dried out, and any likely ingress points eliminated

by re-gasketing, re-greasing or other replacement.

- Check the gasket of pc cover and LED housing for any

damage or permanent set and replace as required.

- Check wiring into terminals, glands and blanking plugs

are securely fitted.

- To maintain the light output, clean the protective pc

cover periodically with a damp cloth or a mild cleaning

fluid.

If this product is used in the combustible dust area, the

outside of the enclosure must be cleaned on a regular

basis to prevent accumulation of dust.

7. Type configuration and Max. Ambient and Temperature Ratings

Charging Fully Charged Emergency Damaged

Green light

"blinking"

Green light

"steady on"

Red light

“blinking “

Red light

“steady on"

Std. Cat No.