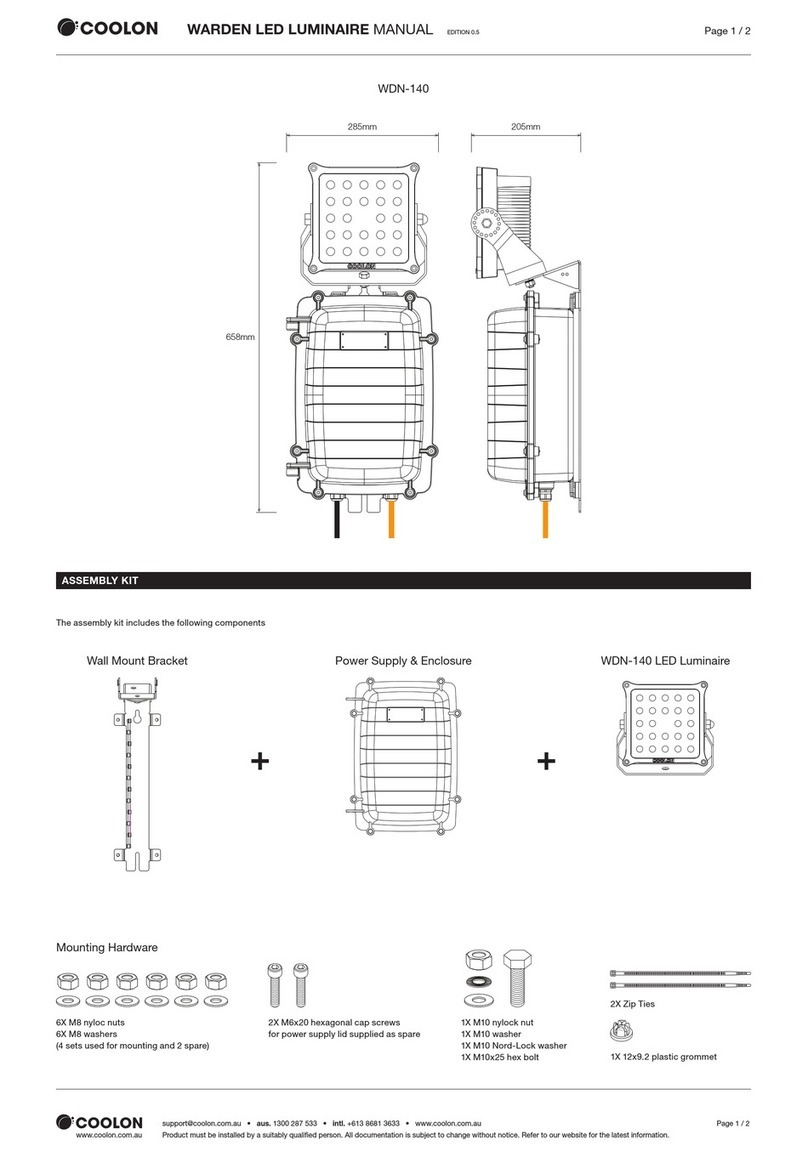

IM0217.Revision 5 05/17 Page 3 of 3

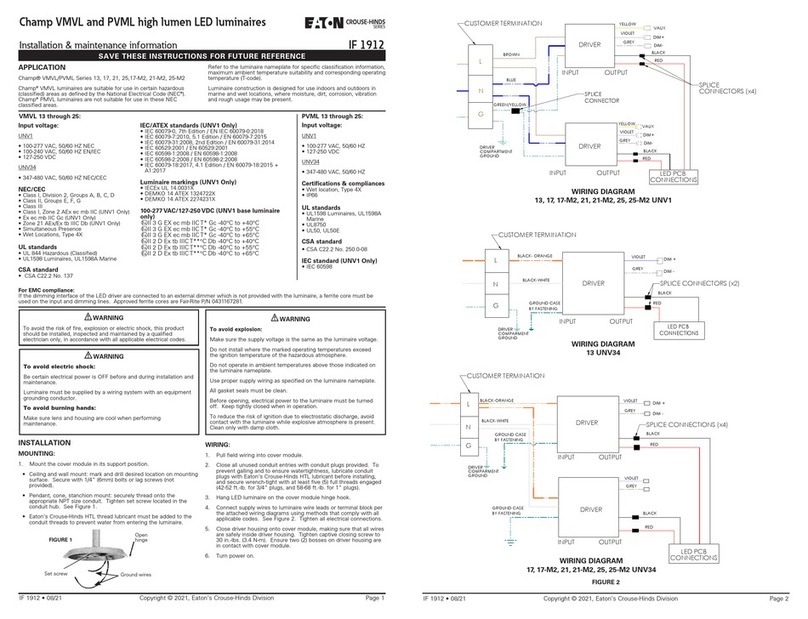

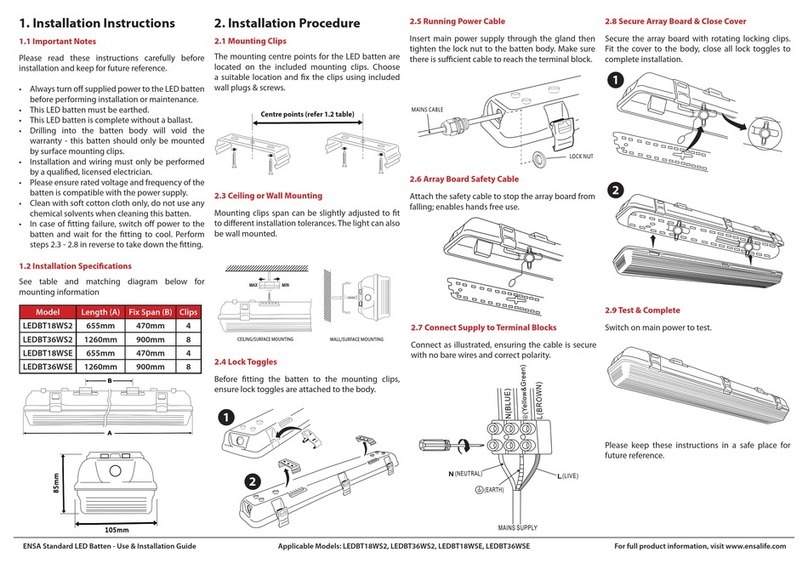

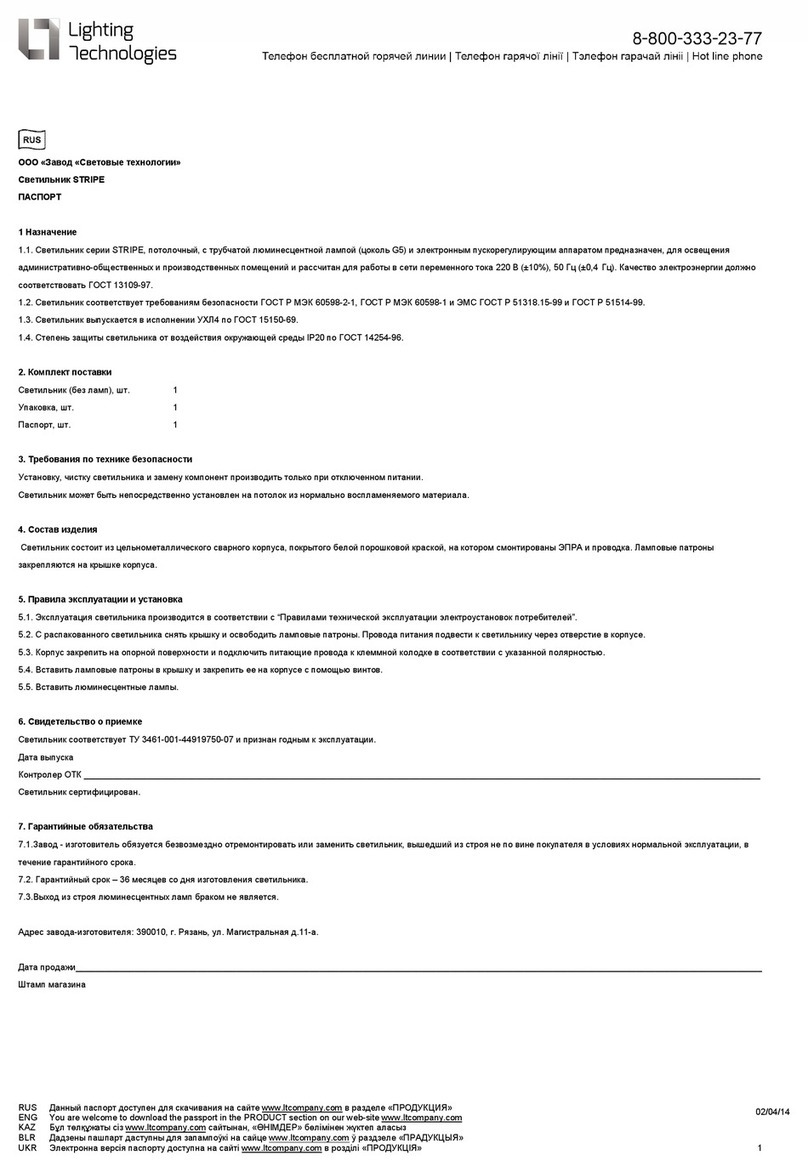

Fig.3 Wiring diagram(Normal version

)

))

)

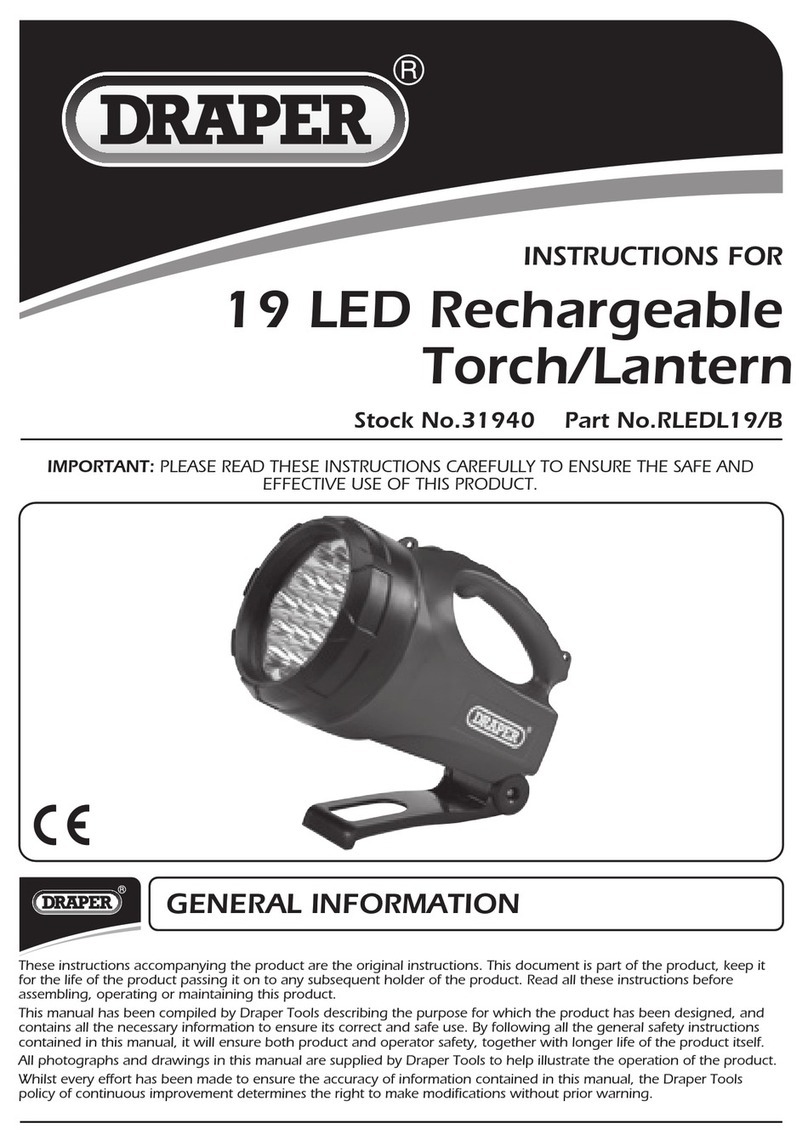

Fig.4 Wiring diagram(Emergency version)

10. Maintenance/Servicing

10.1 General

The relevant national regulations which apply to the

aintenance/servicing of electrical apparatus in

explosive at ospheres, shall be observed (IEC/EN

60079-17). The interval between aintenance

depends upon the a bient conditions and the hours

of operation. The reco endations given within IEC

60079-17 for recurring checks ust be observed.

10.2 Checks

The equipment must be de-energised before opening

Visual inspection should be carried out at a ini u

of 12 onthly intervals and ore frequently if

conditions are severe, refer to IEC/EN 60079-17. The

ti e between la p changes could be very infrequent

and this is too long a period without inspection.

10.3 Routine Examination

During aintenance, the parts affecting the level of

protection ust be checked in particular:

- Ensure the la p is lit when energised and exa ine

the enclosure and glass for any signs of cracks and

da age.

- When de-energised and left to cool, there should be

no significant sign of internal oisture. If there are

signs of water ingress, the lu inaire should be opened

up, dried out, and any likely ingress points eli inated

by re-gasketing, re-greasing or other replace ent.

- Check the gasket of ter inal cha ber gasket and LED

housing for any da age or per anent set and replace

as required.

- To aintain the light output, clean the protective

glass periodically with a da p cloth or a ild cleaning

fluid.

- If this product is used in the co bustible dust area,

outside of enclosure ust be cleaned on a regular

basis to prevent accu ulation of dust.

- Ter inal, screw glands and blanking plugs for secure

fitting.

- The ter inal cha ber should be opened periodically

and checked for oisture and dirt ingress. The cable

connections should be checked for tightness. The

gasket should be checked for cracks or lack of

elasticity, and if necessary, replaced. Cover bolt

torque: 1.5~2N .

- The fla eproof path can not be readily checked, it

will not go out of shape.

- The battery should be charged and discharged once

every 6 onths.

- Check that ountings are secure and the adjusting

bolts are tight.

- If it has been suspected that the lu inaire has

echanical da age, a stringent workshop overhaul

will be required. Where spares are needed, these ust

be replaced with factory specified parts.

No odifications should be ade without the

knowledge and approval of the anufacturer.

Cleaning the rests of grease and corrosion do not use

sharp metallic devices that can damage the threads of

the joint, and greasing them using appropriate grease

terminally and chemically stable with a drop

point≥200

℃

like e.g.: HTL lubricant from Cooper

Crouse-Hinds! When the housing need to be repainted,

pay attention that the flameproof joints test without

any part with coating!

11. Repair/Overhaul/Modifications

11.1 General

The national regulations E /IEC60079-19 have to be

observed! Repairs and overhaul may only be carried

out with genuine Cooper Crouse-Hinds spare parts.

Before replacing or disasse bling individual parts,

observe the following:

Disconnect the power supply to the equipment before

maintenance/repair.

Make sure that there is no explosive atmosphere

when opening the equipment. See section 8.4 for

notes on opening and closing the la p.

Battery pack replacement:

In the case of battery failure, the battery pack ust be

replaced as a co plete unit fro the anufacturer.

First, open the cover, then change the failure battery,

last, close the cover.

Only use original spare parts. If the luminaire was

previously in operation then wait to cool enough

before opening. Repairs that affect the explosion

protection, may only be carried out by Cooper

Crouse-Hinds or a qualified electrician in compliance

with the applicable national rules. Modifications to

the device or changes to its design are not permitted.

After carrying out repair or overhaul work, ensure

that the “Exde" properties have not been affected.

Assistance may also be obtained through Cooper

Electronic Technologies (Shanghai) Co., Ltd. Sales

Service department,

955 ShengLi Road, Pudong Shanghai 201201

Phone (86) 21-28993943

12. Disposal/Recycling

When the apparatus is disposed of, the respective

national regulations on waste disposal will have to be

observed.

The charging conductor L1 and the luminaire’s

mains connection must always be connected

to the same external conductor of the mains

supply!

See Fig.2, Fig.3 Fig.4 and Fig. for details.

9. Putting into operation

Prior to putting the apparatus into operation,

the tests specified in the relevant national

regulations shall be carried out. Insulation

easure ents ay only be carried out

between PE and the external conductor L1 (L2,

L3) as well as between PE and N.

- Measure ent voltage: Max. 1 KV AC/DC

- Measure ent current: Max.10 A

- The lu inaire ay only be operated when

closed.

- It is generally reco ended (see IEC/EN

60079-14) that you ensure the type of

protection of the construction is not i paired

during installation.

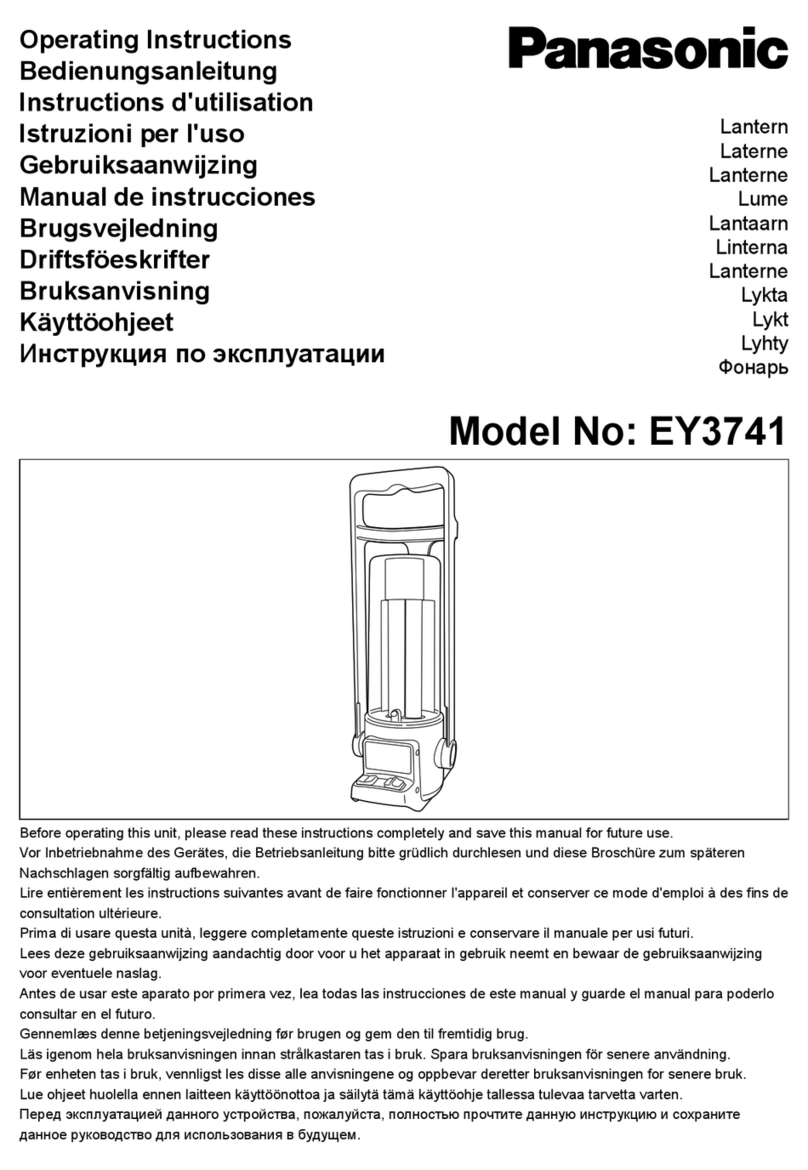

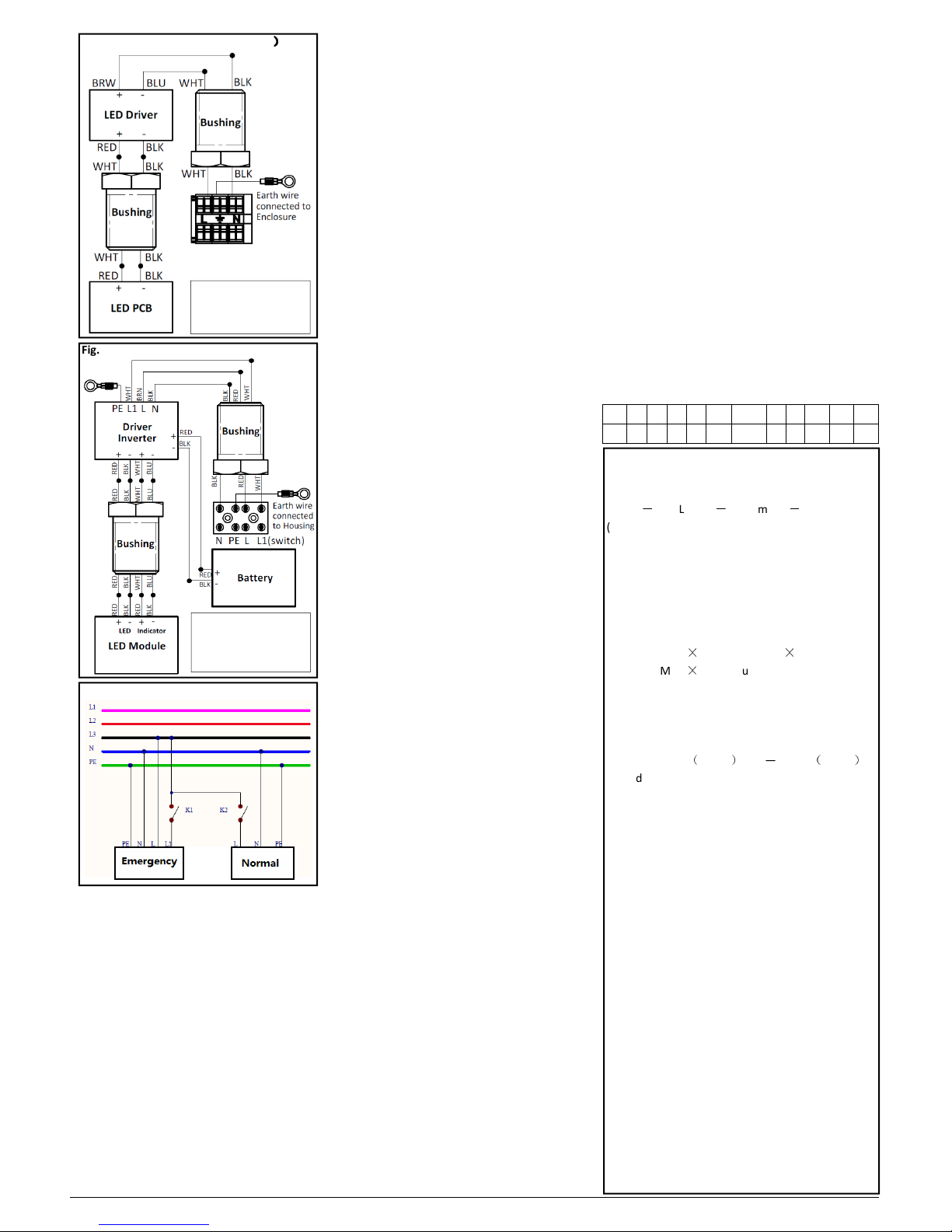

(1). HPL — Indicates basic catalog series designation.

(2). Indicates Total Lu inous Flux.

-3L—3000L , -4L—4000L , -5L—5000L

-6L

-

6000L , -7L

-

7000L , -8L

-

8000L

(3). Indicates LED colour te perature.

Default — 5700K, -W — 3000K

(4). Indicates Optics type.

Default — Type V optic standard

(5). Indicates ballast voltage.

Default — 100-240V AC 50/60Hz, 108-250V DC

(6). Indicates entry type and size.

-1M — M20

×

1.5, -2M — M25

×

1.5

-D1 — M25

×

1.5(only use for Direct entry)

(7). Indicates Entry quantity.

Default — One entry, -S886 — Dual entry

(8). Indicates Ter inal:

-T1—Pillar ter inal, -T2—MK 6/3, -T3— MK 6/6,

-T4—MUT 4

(

3 pole

)

, -T5—MUT 4

(

6 pole

)

(9). Indicates Glass

Default—Clear Glass, -F—Foggy Glass

(10). Indicates Entry Acc.

Default—No entry acc, -1P—two entries with 1 Plug

-2G—all entries, with plastic cable gland

-3G—two entries, with 1 plastic plug, 1 cable gland

(11). Indicates Mounting Type.

Default—G3/4 Pendant ount only

-B1—With Painted bracket ount only

-B2—with 304SST bracket ount only

-B3—with 316SST bracket ount only

-B4—with both Painted bracket ount,

also available for G3/4 Pendant ount

-B5—with both 304SST bracket ount,

also available for G3/4 Pendant ount

-B6—with both 316SST bracket ount,

also available for G3/4 Pendant ount

-B7—G3/4 Pendant ount, also with ounting

bracket hole cut, but bracket need to order separated.

-B8—only with ounting bracket hole cut,

ounting bracket need to be ordered separated.

(12). E ergency duration

Default—Nor al version

EM1—1.5H, 30% output; EM2—3H, 15% output;

13. Catalog No. definition

HPL -3L -W -1M -S886 * * * * *

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11) (12)

Fig. Wiring diagram

For version with cable

Brown: L

Blue:

Black: L1

Yellow/Green: Ground

For version with cable

Brown: L

Blue:

Yellow/Green: Ground