IL05003003E.pdf

ELC-AN06AANN EXPLANATION

#25 H 40E1 O R/W

To adj. GAIN

value of CH2 Voltage input: setting range is K-800 ~K4,000

Current input: setting range is K-800 ~K2,600

#26 H 40E2 O R/W

To adj. GAIN

value of CH3

#27 H 40E3 O R/W

To adj. GAIN

value of CH4

#28 H 40E4 O R/W

To adj. GAIN

value of CH5 GAIN setting of CH5~CH6. Factory setting is K2,000 and unit is LSB.

The setting range is K-1,600~K8,000

#29 H 40E5 O R/W

To adj. GAIN

value of CH6

#30 H 40E6 X R Error status Data register stores the error status, refer to fault code chart for details.

#31 H 40E7 O R/W

Communication

address setting

RS-485 communication address.

Setting range is K1~K255 and factory setting is K1

#32 H 40E8 O R/W

Communication

baud rate setting

Communication baud rate (4,800, 9,600, 19,200, 38,400, 57,600 and 115,200 bps).

For ASCII mode, date format is 7Bits, even, 1 stop bit (7,E,1). For RTU mode, date

format is 8Bits, even, 1 stop bit (8, E,1).

b0: 4,800 bps (bit/sec), b1: 9,600 bps (bit/sec). (factory setting)

b2: 19,200 bps (bit/sec), b3: 38,400 bps (bit/sec).

b4: 57,600 bps (bit/sec), b5: 115,200 bps (bit/sec).

b6~b13: Reserved, b14: switch between low bit and high bit of CRC code (only for

RTU mode), b15: RTU mode.

#33 H 40E9 O R/W

Reset to factory

setting and set

characteristics

adjustable

priority

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

CH6 CH5 CH4 CH3 CH2 CH1

Example: Setting of CH1

1. When b0=0, user can set OFFSET and GAIN value of CH1 (CR#18, CR#24).

When b0=1, inhibit user to adjust OFFSET and GAIN value of CH1.

2. b1 means if characteristic register is latched. b1=0 (factory setting, latched),

b1=1 (not latched).

3. b2: Set to 1 and ELC-AN06AANN will be reset to factory settings.

The setting of CH5~CH6, give CH5 setting for example: b13, b12:

00: can be adjusted, latched, 01: can be adjusted, non-latched.

10: inhibit adjust, 11: reset to factory settings and clear b12, b13 to 0.

#34 H 40EA O R System Version Display software version in hexadecimal. Example: H 010A = version 1.0A.

#35~#48 System used

O means latched. X means non-latched.

R means can read data by using FROM command or RS-485. W means can write data by using TO command or RS-485.

LSB (Least Significant Bit): 1. Voltage input: 1LSB=10V/2,000=5mV. 2. Current input: 1LSB=20mA/1,000=20μA.

3. Voltage output: 1LSB=10V/4,000=2.5mV. 4. Current output: 1LSB=20mA/4,000=5μA.

Explanation:

1. CR#0: The ELC model type.

2. CR#1: b11~b0 is used to set 4 inner channels working mode of analog input module (AD).

b12~b15 is used to set 2 channels working mode of analog output module (DA). Every channel

has four modes to set and can be set individually. For example: if setting CH1 to mode 0

(b2~b0=000), CH2 to mode 1(b5~b3=001), CH3: mode2 (b8~b6=010), CH4: mode

3(b11~b9=011). It needs to set b0~b11 to H688. If setting CH5: mode 2 (b13~b12=10), CH6:

mode 1 (b15~b14=01), it needs to set b12~b15 to H5. The factory setting is H0000.

3. CR#2 ~ CR#5: Used to set the number of input readings used for the average temperature

calculation. The available range is K1~K100 and factory setting is K10.

4. CR#6 to CR#9: they are used to save the average value of input signal of CH1~CH4.

5. CR#10 ~ CR#11 are used to set the output value of CH5 and CH6. The setting range is

K0~K4,000. The factory setting is K0 and unit is LSB.

6. CR#12 ~ CR#15: they are used to save the present value of input signal of CH1~CH4.

7. CR#16, CR#17, CR#28, CR#29 are reserved.

8. CR #18~ CR #21: the content is the value of adjusting OFFSET value of CH1~CH4 if analog

input voltage or current is 0 after it transfers from analog to digital. Voltage setting range:

-5V~+5V(-1,000LSB~+1,000LSB). Current setting range: -20mA~+20mA (-1,000LSB~+1,000LSB).

9. CR #22~ CR #23: the content is the value of adjusting OFFSET value of CH5~CH6 if analog

input voltage or current is 0 after it transfers from analog to digital. The factory setting is K0 and

the unit is LSB. The setting range is -2,000~+2,000. Voltage setting range:

-5V~+5V(-2,000LSB~+2,000LSB). Current setting range: -10mA~+10mA (-2,000LSB~+2,000LSB).

10.CR #24~ CR #27: That is the value of adjust GAIN value of CH1~CH4. That is the value of

analog input voltage or current when conversion value from analog signal to digital is 4,000.

Voltage setting range: -4V~+20V(-800LSB~+4,000LSB). Current setting range: -16mA~+52mA

(-800LSB ~+2,600LSB). But it needs to notice that GAIN VALUE – OFFSET VALUE =

+200LSB~+3,000LSB (voltage) or +200LSB~+1,600LSB (current). When this value under this range,

the resolution of the input signal will be thin and the variation of value will be larger. When this

value exceeds this range, the resolution of input signal will be thick and the variation of value

will be smaller.

11.CR #28~ CR #29: That is the value of adjust GAIN value of CH5~CH6. That is the value of

analog input voltage or current when conversion value from analog signal to digital is 2,000.

Voltage setting range: -4V~+20V(-1,600LSB~+8,000LSB). Current setting range: -8 mA ~+40 mA

(-1,600LSB~+8,000LSB). But it needs to notice that GAIN VALUE – OFFSET VALUE = +400LSB

~+6,000LSB (voltage/current). When this value under this range, the resolution of the input signal

will be thin and the variation of value will be larger. When this value exceeds this range, the

resolution of input signal will be thick and the variation of value will be smaller.

12.CR#30 is fault code. Please refer to the following chart.

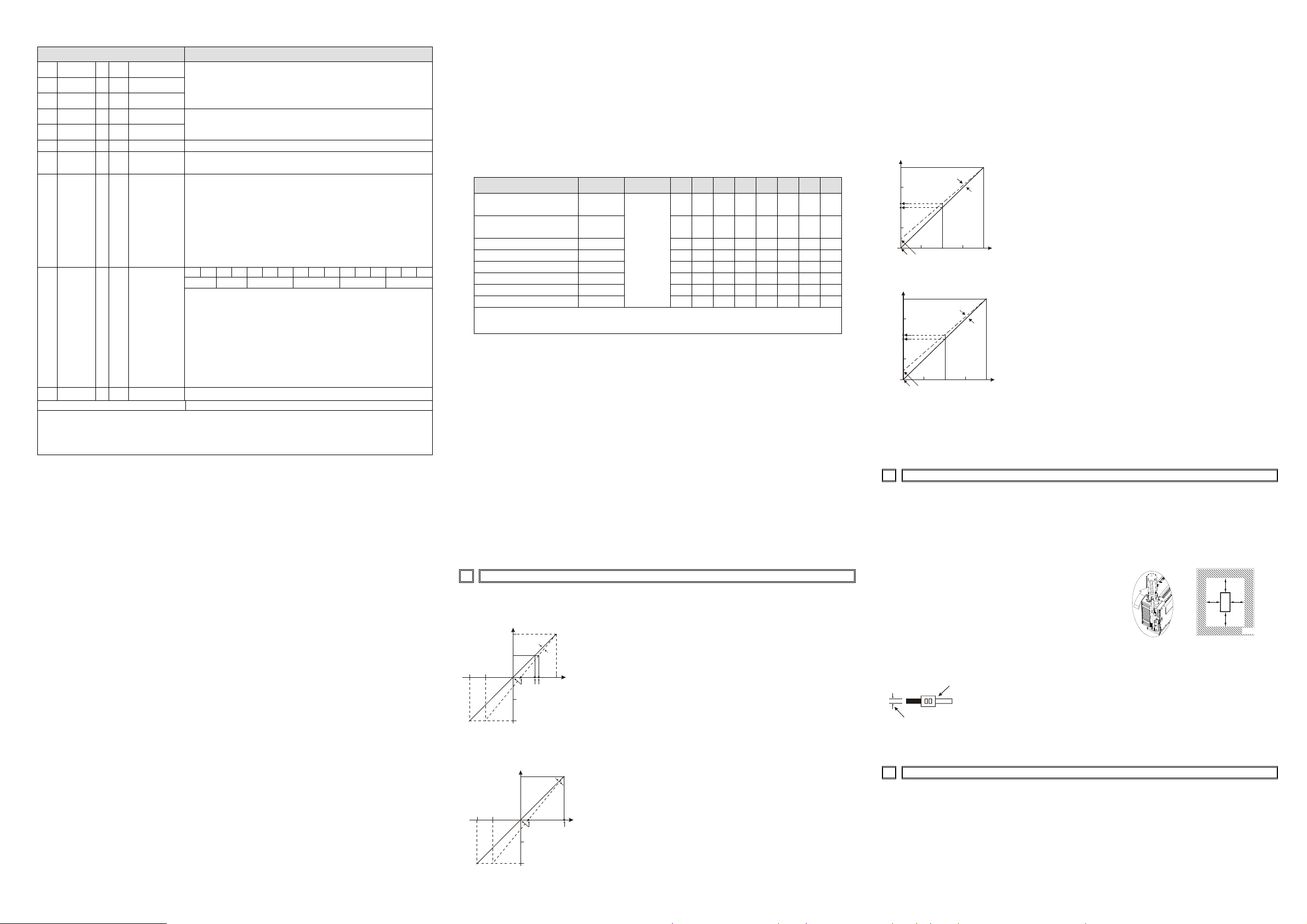

Fault description Content b15~b8 b7 b6 b5 b4 b3 b2 b1 b0

Power source abnormal

(Low voltage alarm) K1(H1)

Reserved

0 0 0 0 0 0 0 1

User setting D/A output

exceeds range K2(H2) 0 0 0 0 0 0 1 0

Setting mode error K4(H4) 0 0 0 0 0 1 0 0

Offset/Gain error K8(H8) 0 0 0 0 1 0 0 0

Hardware malfunction K16(H10) 0 0 0 1 0 0 0 0

Digital range error K32(H20) 0 0 1 0 0 0 0 0

Average times setting error K64(H40) 0 1 0 0 0 0 0 0

Command error K128(H80) 1 0 0 0 0 0 0 0

Note: Each fault code will have corresponding bit (b0~b7). Two or more faults may happen at the same

time. 0 means normal and 1 means having fault.

13.CR#31: RS-485 communication address. Setting range is 01~255 and factory setting is K1.

14.CR#32: RS-485 communication baud rate: 4,800, 9,600, 19,200, 38,400, 57,600 and 115,200.

b0:4,800bps, b1:9,600bps (factory setting), b2:19,200bps, b3:38,400 bps, b4:57,600 bps,

b5:115,200 bps, b6~b13: Reserved, b14: switch between low bit and high bit of CRC code (only

for RTU mode) b15: ASCII / RTU mode. For ASCII mode, date format is 7Bits, even, 1 stop bit

(7,E,1). For RTU mode, date format is 8Bits, even, 1 stop bit (8,E,1).

15.CR#33 is used to set the inner function priority. For example: characteristic register. Output

latched function will save output setting in the inner memory before loss power.

16.The corresponding parameters address H 40C8~H 40EA of CR#0~CR#34 can provide user to

read/write data by RS-485.

a) Communication baud rate: 4,800, 9,600, 19,200, 38,400, 57,600, 115,200 bps.

b) Communication format: ASCII mode is 7Bit, even bit, 1 stop bit (7,E,1). Communication

format of RTU mode is 8Bit, even bit, 1 stop bit (8,E,1).

c) Function code: 03H—read data from register. 06H—write a WORD into register.

10H—write many WORDs into register.

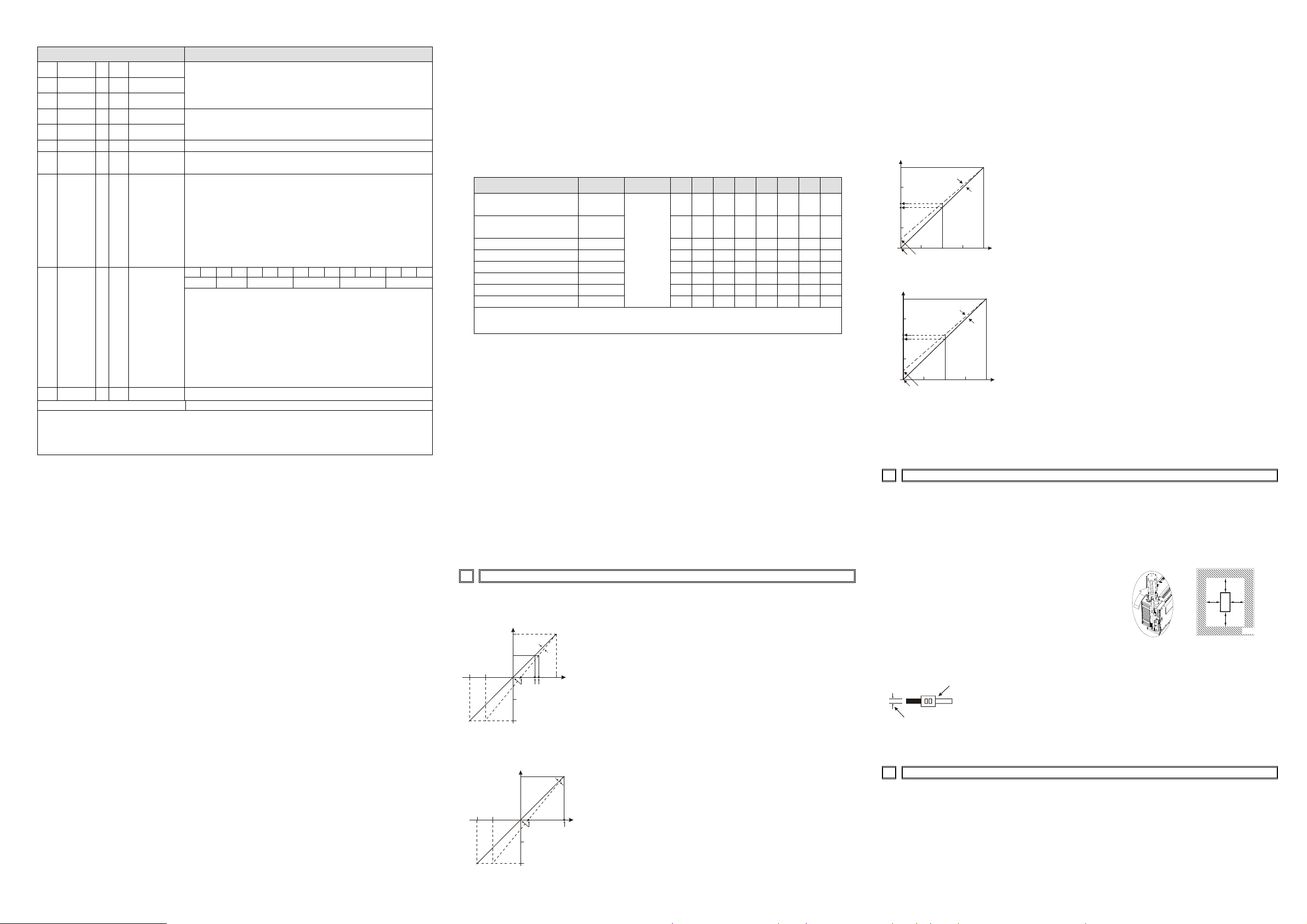

4 ADJUST A/D CONVERSION CHARACTERISTIC CURVE

4.1 Adjust A/D Conversion Characteristic Curve of CH1~CH4

Voltage input mode

+2000

+1000

-1000

10V

digital output

Voltag e

input

-2000

-6V-10V

6V5V2V

0

Mode 1

Mod e 0

GAIN

OFFSET

Mode 0 of CR#1: GAIN=5V(1,000LSB), OFFSET=0V (0LSB).

Mode 1 of CR#1: GAIN=6V(1,200LSB), OFFSET=2V (400LSB).

GAIN: Voltage input value when digital output is 1,000.

Setting range is -4V~+20V(-800LSB~ +4,000LSB)

OFFSET: Voltage input value when digital output is 0.

Setting range: -5V~+5V(-1,000LSB ~ +1,000LSB)

GAIN-OFFSET: Setting range is +1V~+15V (+200LSB~ +3,000LSB)

Current input mode:

+1000

Digital output

Current

Input

-1000

-12mA-20mA

4mA

0

Mod e 2

Mode 3

OFFSET

20mA

GAIN

Mode 2 of CR#1: GAIN = 20mA(1,000LSB), OFFSET=4mA (200LSB).

Mode 3 of CR#1: GAIN = 20mA(1,000LSB), OFFSET=0mA (0LSB).

GAIN: Current input value when digital output is +1,000.

Setting range is -16 mA ~+52 mA (-800LSB ~

+2,600LSB)

OFFSET: Current input value when digital output value is 0.

Setting range is -20 mA~+20 mA (-1,000LSB ~

+1,000LSB )

GAIN-OFFSET: Setting range is +4mA ~ +32mA (200LSB~ +1,600LSB)

The chart above is to adjust A/D conversion characteristic curve of voltage input mode and current

input mode. Users can adjust conversion characteristic curve by changing OFFSET values

(CR#18~CR#21) and GAIN values (CR#24~CR#27) depend on application.

Voltage input: 1LSB=10V/2,000=5mV. Current input 1LSB=20mA/1,000= 20μA.

4.2 Adjust D/A Conversion Characteristic Curve of CH5~CH6

Voltage output mode

0+2000 +4000

2V

5V

6V

10V

OFFSET

GAIN

Voltage output

mode 1

mode 0

Digital

input

Mode 0 of CR#1: GAIN = 5V(2,000LSB), OFFSET=0V (0LSB)

Mode 1 of CR#1: GAIN = 6V(2,400LSB), OFFSET=2V (800LSB).

GAIN: Voltage output value when digital input is K2,000.

Setting range is -4V~+20V(-1,600LSB ~+8,000 LSB).

OFFSET: Voltage output value when digital input is K0.

Setting range: -5V~+5V(-2,000LSB ~ +2,000 LSB).

GAIN-OFFSET: Setting range is +1V~+15V(+400LSB ~ +6,000 LSB)

Current output mode:

0+2000 +4000

20mA

OFFSET

GAIN

12mA

10mA

4mA

Current output

Mode 2

Mode 3

Digital

input

Mode 2 of CR#1: GAIN = 12mA(2,400LSB ),OFFSET=4mA (800LSB).

Mode 3 of CR#1: GAIN = 10mA(2,000LSB), OFFSET=0mA (0LSB).

GAIN: Current output value when digital input value is

K2,000. Setting range is -8 mA ~ +40 mA (-1,600LSB

~+8,000LSB).

OFFSET: Current output value when digital input is K0. Setting

range is -10 mA ~ +10 mA (-2,000LSB ~+2,000LSB).

GAIN-OFFSET: Setting range is +2mA~+30mA(+400LSB ~+6,000LSB)

The chart above is to adjust D/A conversion characteristic curve of voltage output mode and current

output mode. Users can adjust conversion characteristic curve by changing OFFSET values

(CR#14~CR#15) and GAIN values (CR#18~CR#19) depend on application.

Voltage output: 1LSB=10V/4,000=2.5mV., Current output: 1LSB=20mA/4,000=5μA.

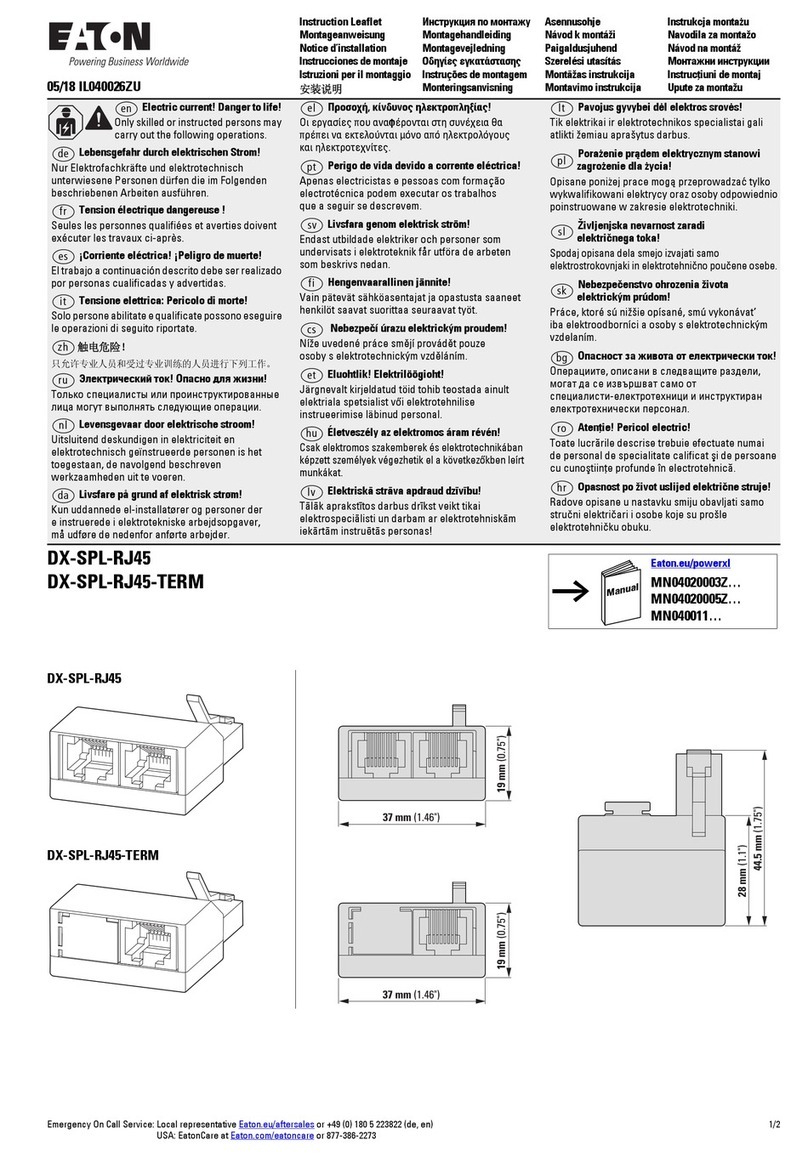

5INSTALLATION & WIRING

1. Installation of the DIN rail

The ELC can be secured to a cabinet by using the DIN rail that is 35mm high with a depth of 7.5mm.

When mounting the ELC on the DIN rail, be sure to use the end bracket to stop any side-to-side

motion of the ELC, thus to reduce the chance of the wires being pulled loose. At the bottom of the

ELC is a small retaining clip. To secure the ELC to the DIN rail, place it onto the rail and gently push

up the clip.

To remove it, pull down the retaining clip and gently pull the

ELC away from the DIN rail. As shown on the right:

When installing the ELC, make sure that it is installed in an

enclosure with sufficient space (as shown on the right) to its

surroundings so as to allow heat dissipation.

D

D

DD

E

L

C

D>50mm

2. Wiring

22-16AWG

<1.5mm

Notes:

1. Please use 22-16AWG (1.5mm) wiring (either single or multiple

core) for I/O wiring terminals. The specification for the terminals is

as shown on the left. ELC terminal screws should be tightened to

1.95 kg-cm (1.7 lb-in). Use Copper Conductor Only, 60/75 °C.

2. I/O signal wires or power supply should not run through the same

multi-wire cable or conduit.

6INITIAL ELC START-UP

Lamp display:

1. Upon power-up, the ERROR LED will light for 0.5 seconds the POWER LED will light

continuously.

2. No errors= POWER LED on and ERROR LED off.

Low Voltage error (lower than 19.5V), ERROR LED will blink continuously till the power

supply rises above 19.5V.

3. ELC-AN06AANN connected to ELC in series = RUN LED on MPU will be lit and A/D