3

INM9108 Rev 3

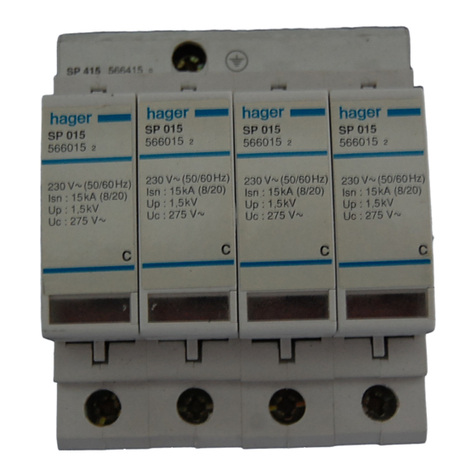

2.2 Module carrier

The module carrier provides fieldbus power for four fieldbus segments. It supports a pair of

redundant pluggable power supply and arbitration modules for each segment and all connection

facilities.

Each carrier has connections for redundant 24V input power supplies, ALF111 fieldbus

communication modules via AKB336 cables and intrinsically safe field trunks. A volt-free failure

alarm is also provided for connection to a digital input module in the host control system. There

are no active electronic circuits on the carrier, resulting in long calculated Mean Time to Failure

(MTTF) and overall high system availability.

The carrier dimensions (Figure 2.2) are designed to provide high packing density in typical

800mm wide equipment cabinets. Survival in high-vibration marine environments is achieved

by secure panel-mount fixings.

The FISCO power supply modules are pluggable versions of the MTL 9122-IS units applications,

and support the same level of features. These include a built-in repeater function for accurate

wave-shape transmission and communication error reduction, and three-way isolation between

bulk power, host and field trunks for elimination of cross-talk between segments. LED indicators

provide information on system health and assist with fault diagnosis.

3 INSTALLATION

WARNING !

This equipment must be installed, operated and maintained only by

trained competent personnel and in accordance with all appropriate

international, national and local standard codes of practice and site

regulation for intrinsically safe apparatus and in accordance with the

instructions contained here.

3.1 General

The 9108-22 power system may be mounted in a safe area or a Zone 2 IIB T4 hazardous area.

See also Section 6 - Appendix for further information. The mounting conditions must:

a. prevent any form of pollution that could compromise the operation of the unit. For example,

an unpolluted location or a suitable enclosure could be chosen.

b. provide an adequate level of mechanical protection. This can be achieved by selecting a

protected location, a suitable cabinet or enclosure, or a combination of both.

c. ensure that all cable entries and connections are secure by making provision for the careful

routing and securing of all cables.

d. provide adequate security against unauthorised interference.

e. ensure that the permitted ambient temperature range of the units (–20°C to +60°C) is not

exceeded. Be aware of the power dissipation in the equipment’s cabinet or enclosure and

consider the use of shading against direct sunlight, or even forced cooling.

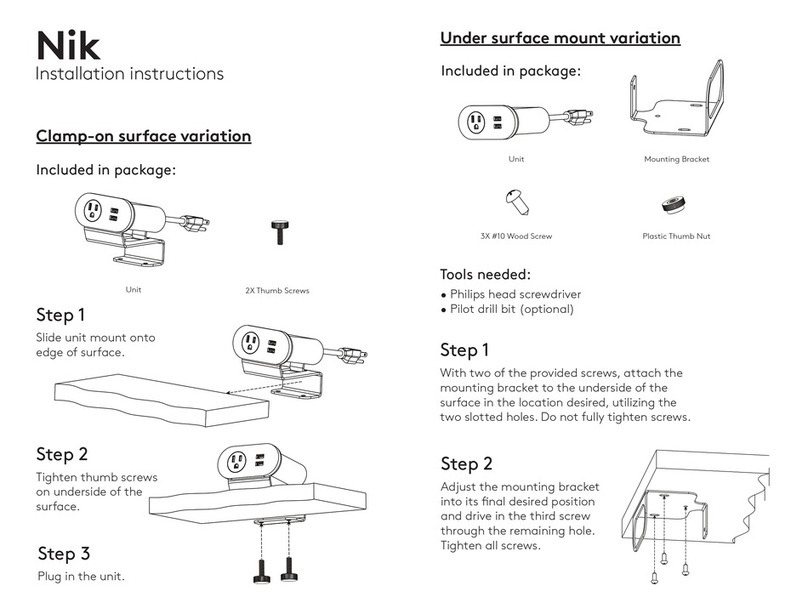

3.2 Required tools

To remove or replace a FISCO or a SAM module a straight-bladed screwdriver is required with a

minimum shaft length of 130mm (5¼”) and a maximum blade diameter of 5mm (3/16”).

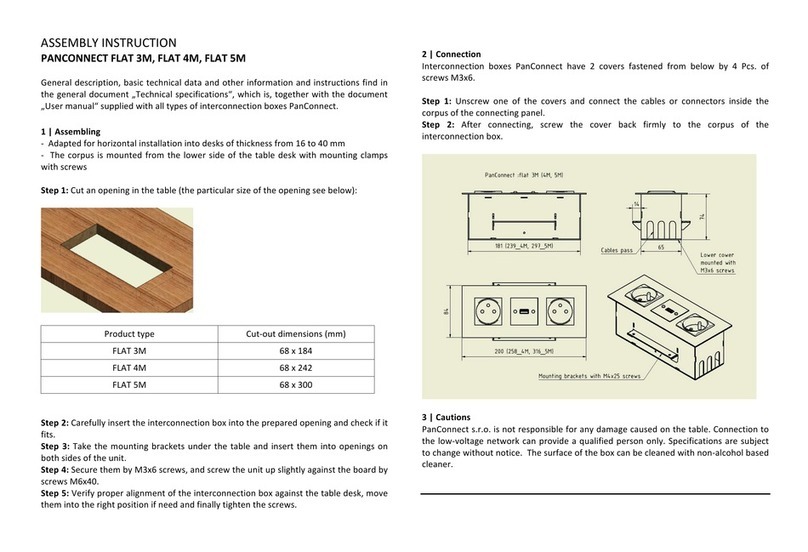

3.3 Mounting overview

Mount the 9108-22 assembly on a vertical surface with the orientation shown in Figure 2.2. Any

other orientation will reduce the permitted maximum operating temperature.

IMPORTANT: The mounting surface and any fixings must be capable of supporting the weight

of the complete assembly which is just under 5.5kg.

Four 7mm diameter slotted holes are provided in the backplate for mounting the assembly -

see Figure 3.1 - and access to the mounting screws is provided through the circuit board (after

removal of some modules). This feature allows the assembly to be fitted to, or removed from,

its mounting without removing the mounting screws.

Note: Because of the slotted mounting holes, 15mm of free space is required above the top

edge of the assembly to allow the backplate to be mounted and demounted.