NOTES

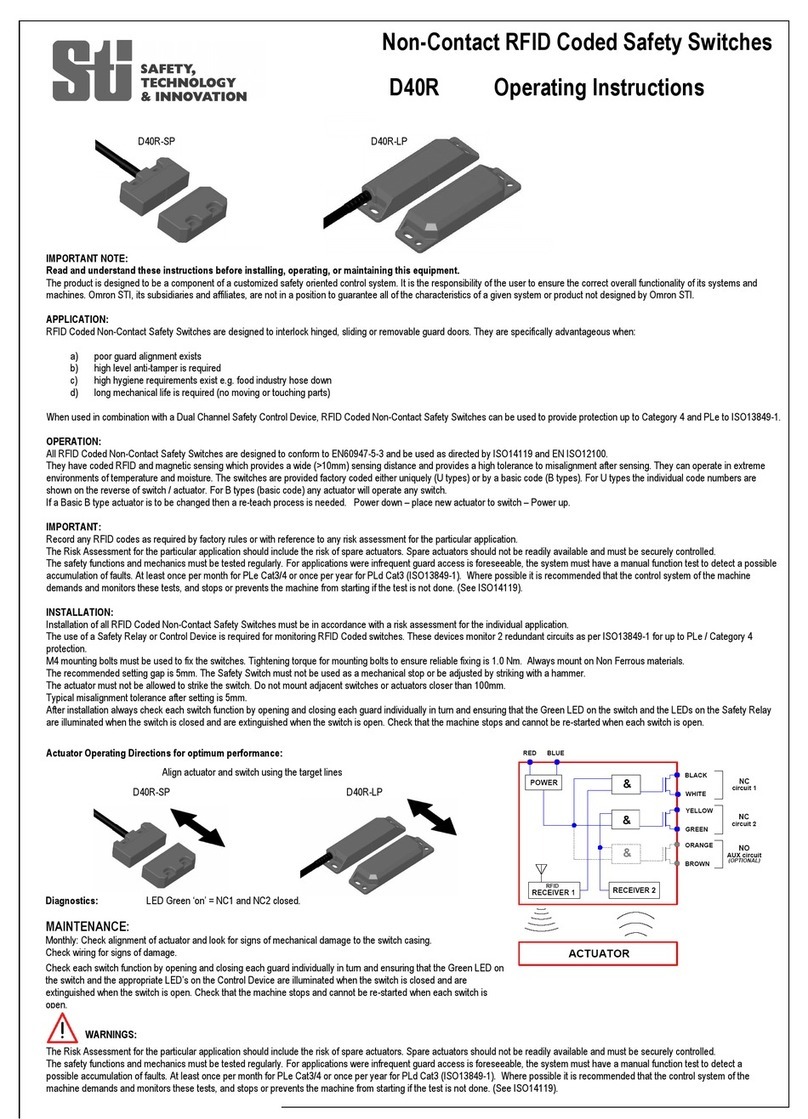

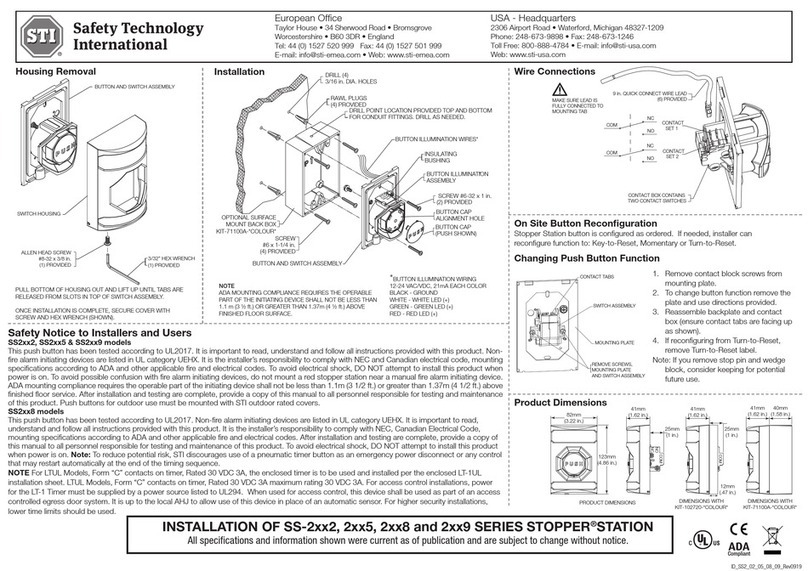

It is important to read, understand and follow all instructions provided with this product. It

is the installer’s responsibility to comply with NFPA 70 & 101, NEC, mounting specifications

according to ADA and other applicable electrical codes.This switch is rated Type NM (Non-

Monitored) for non-emergency signaling. Not to be used in place of panic hardware. To

avoid electrical shock, DO NOT attempt to install this product when power is on. ADA

mounting compliance requires the operable part of the initiating device shall not be less

than 3 1/2 ft. (1.1m ) or greater than 4 1/2 ft. (1.37m) above finished floor surface. After

installation and testing are complete, provide a copy of this manual to all personnel

responsible for testing and maintenance of this product.

REMARQUES

Il est important de lire, de comprendre et de suivre toutes les instructions fournies avec

ce produit. Il incombe à l’installateur de se conformer aux normes NFPA 70 et 101, NEC,

aux spécifications de montage selon l’ADA et aux autres codes de l’électricité en vigueur.

Pour les cotes de type SM (auto surveillée), le message d’Urgence peut être apposé sur le

modèle UB-1 lorsqu’il est utilisé dans un système intégrant un dispositif de déclenchement

compatible et homologué. Toutes les autres applications sont cotées de Type NM (non

surveillée) pour la signalisation non urgente. Pour éviter un choc électrique, NE tentez

PAS d’installer ce produit lorsqu’il est sous tension. La conformité aux règles d’installation

de l’ADA exige que la partie utilisable du dispositif de déclenchement soit installée à une

hauteur située entre 3 1/2 pi (1,1 m) et 4 1/2 pi (1,37 m) au-dessus du plancher fini.

Une fois l’installation et les essais terminés, vous devez fournir une copie de ce manuel à

l’ensemble du personnel chargé de l’essai et de l’entretien de ce produit.

SWITCH RATING

2 Independent Form “C” contacts Model UB -2/LTUL

UB-2 rated at: 10A, 1/2 HP, 125/250 VAC Form “C” contacts on timer rated:

6A, 30 VDC 30 VDC 3A, 1.0 pf

100,000 Operations

Temperature: -40° to 185°F (-40° to 85°C)

- 2 -

UL294 Performance Levels:

Line Security: I

Attack: I

Endurance: IV

Standby Power: I