I.L. 32-693 A

Page3

Effective September 1998

SECTION1: INTRODUCTION

1.1 GENERAL INFORMATION

TheTrip Unit Test Kit is used to test and verify the pickup

levels and time delay settings of a breaker’s Trip Unit. The

original Test Kits were developed to test the Amptector

Trip Units of the DS Breaker. With the introduction of

microprocessorbasedTrip Units(Digitrip,Optim, etc),

modificationstotheoriginalTestKits(-G01and–G02)

were required to accommodate lower power requirements

ofthemicroprocessor. These modifications,in combina-

tionwith variousTest Kit Adapters, allow maintenance

personnel to utilize theTest Kit they already own when

testing the newer generations ofTrip Units.

TheTest Kit Adapter (Style#8779C02G04) forthe Mag-

numDS DigitripTrip Units,convertsthe11-pin banana plug

on theTest Kit, to a 14-pin plug. This 14-pin plug, plugs

into the Trip Unit Test Port, located on the face of theTrip

Unit.(seeFigure4)

SECTION2: TESTKIT/ BREAKERINFORMATION

2.1 TEST KIT / ADAPTER INFORMATION

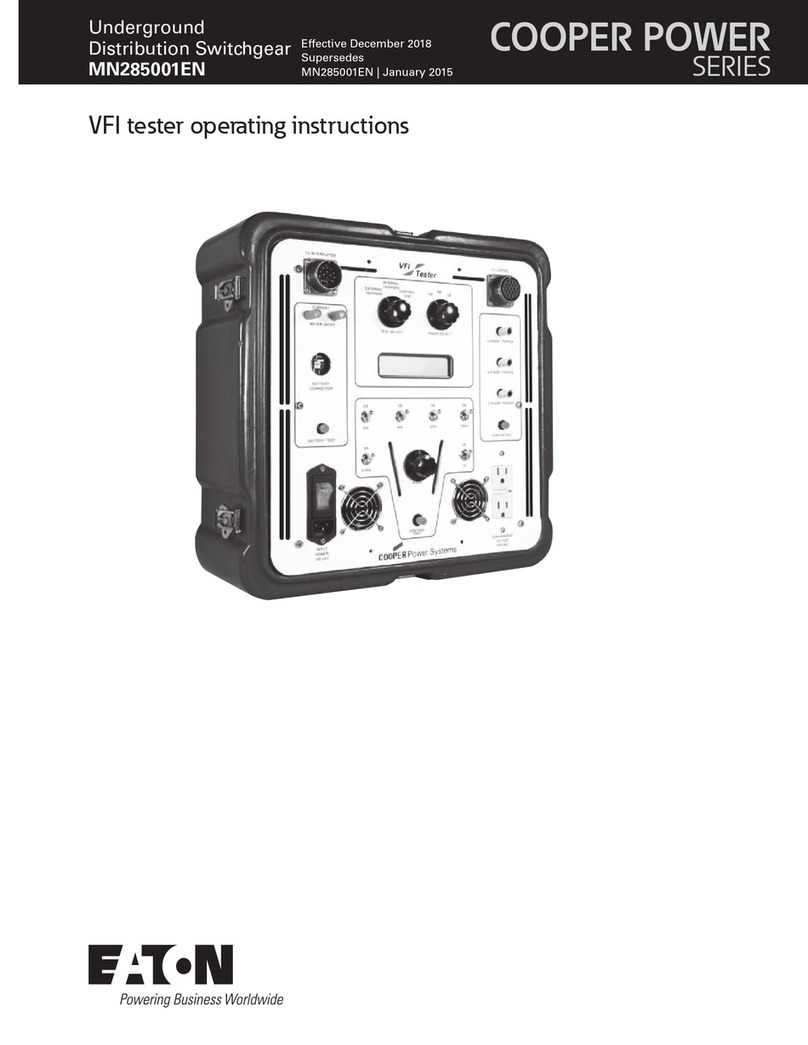

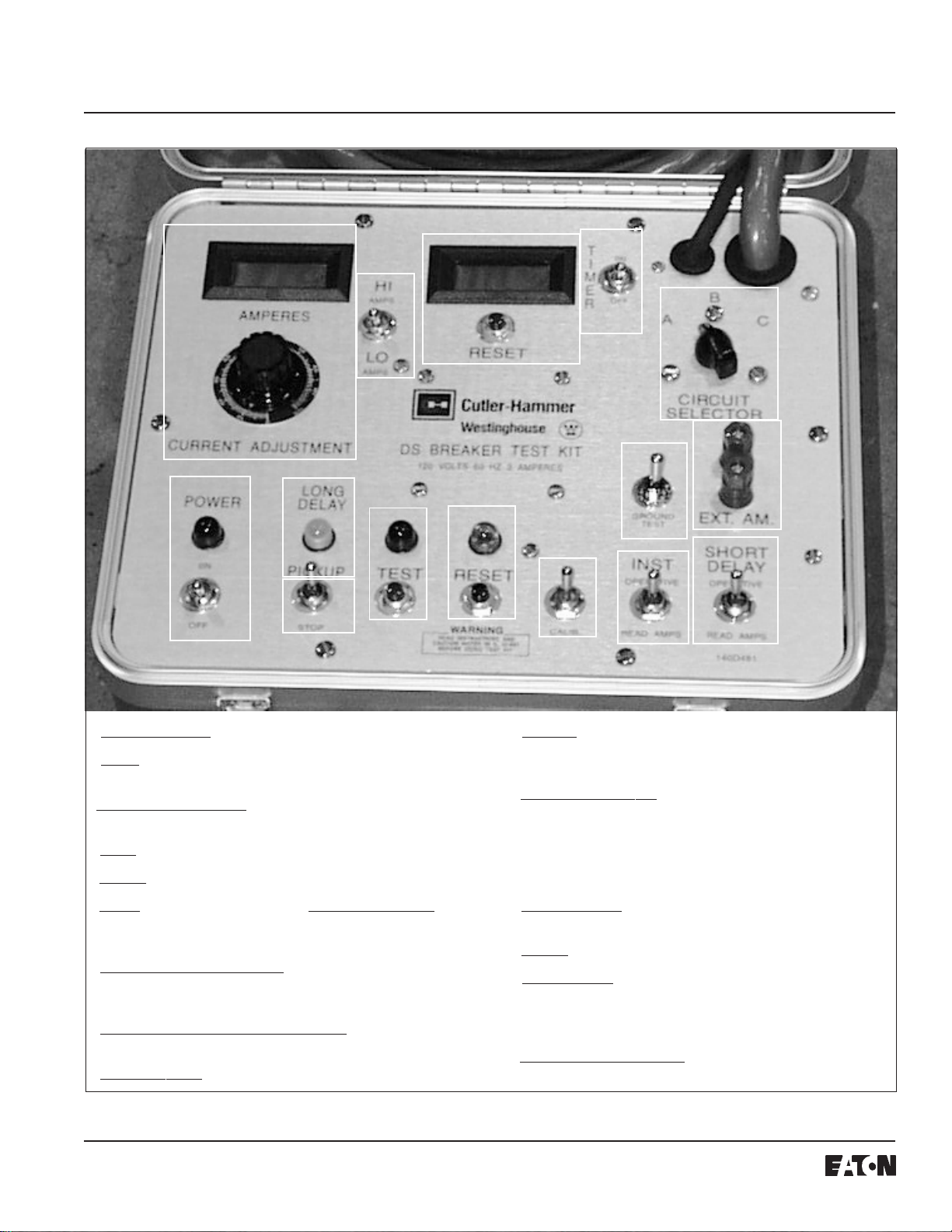

2.1.1 TESTKITCONTROLS(SEE FIGURE1)

The following are the identifications and fuctions of the

Test Kit controls. Any time these are referred to in the

following portions of this publicaiton they will be in italics

and underlined as shown in the following definitions of the

functions.

POWERON/OFF

–Turns on powerto theTestKit.

STOP

– This switch manually cuts offthe test current to

the Trip Unit.

LONGDELAYPICKUP

-Thislightisnotfunctionalfor

MagnumDStrip units.

TEST

– Starts the test.

RESET

–ResetstheTest Kit afteratest.

CALIB

–Usedinconjunctionwith

CURRENTADJUST

allowing for setting a pre-determined current level prior to

a test.

INSTOperative / Read Amps

–Fortesting the Instanta-

neousfunctionon AmptectorTripUnits.(Not functional

withMagnumDS trip units.)

SHORTDELAYOperative/Read Amps

–Fortestingthe

ShortDelay function.

GROUNDTEST

– For testing the Ground Fault function.

EXT.AM

– Allows for connection of an external ammeter

to read current levels. Jumper must be installed when not

usingexternalammeter.

CIRCUITSELECTOR

-PermitscheckingofallTripUnit

phaseinputcircuits.Sinceallfeed into a common pickup

andtiming circuit, it isonly necessary to use one phase to

test all the solid state circuitry functions. It is only neces-

sary to use one circuit function (e.g., long delay pickup) to

verify that each phase (A, B, and C) performs similarly.

TIMERON/OFF

–The timer isusedtocalculateand display

the time-delay functions of theTrip Unit.

RESET

(Timer) - Resets the timer after a test.

HI / LO AMPS

– Selects the “level” of current to be in-

jected. (LOAMPS is typicallyforchecking Long Delay

PickuporGroundFaultPickup,and HIAMPSis forchecking

ShortDelay PickuporInstantaneous Level)

CURRENTADJUSTMENT

–Adjuststhesecondarycurrent

injected into theTrip Unit.

2.1.2 TESTKIT ADAPTER

TheMagnum DSTestKitAdapter (8779C02G04) isusedto

connecttheTest Kit’s11-pinplugtotheMagnumDS

Digitrip Trip Unit 14-pin test port. In additon, the Auxiliary

PowerModule (PRTAAPM),whichispermanently con-

nected to the Adapter, must be connected to a 120V, 50/

60 HZ source to supply control power to theTrip Unit.(see

Figure2)

2.1.3 ZONE INTERLOCK SHORTING PLUG

TheZoneInterlockShorting Plug (8779C02G06) is

requiredwhenthebreakeris removed from the switchgear

cell for testing.The Shorting Plug must be installed on the

breakersecondarycontacts to defeat zone-interlock

wiring.(seeFigure3)

2.1.4 TEST KIT OPERATION GUIDELINES

To minimize thermal stress on theTest Kit andTrip Unit,

hold

CALIB

(momentary)toggle switch for no more than15

to 20 seconds at a time.

Ifcurrent persists after the testis complete, use

STOP

switch to turn off the current.

When checking settings on theTrip Unit, the general

procedure is to start with the high current settings and

work down to the lowest current setting. This avoids

unnecessarydialchanges after calibration.