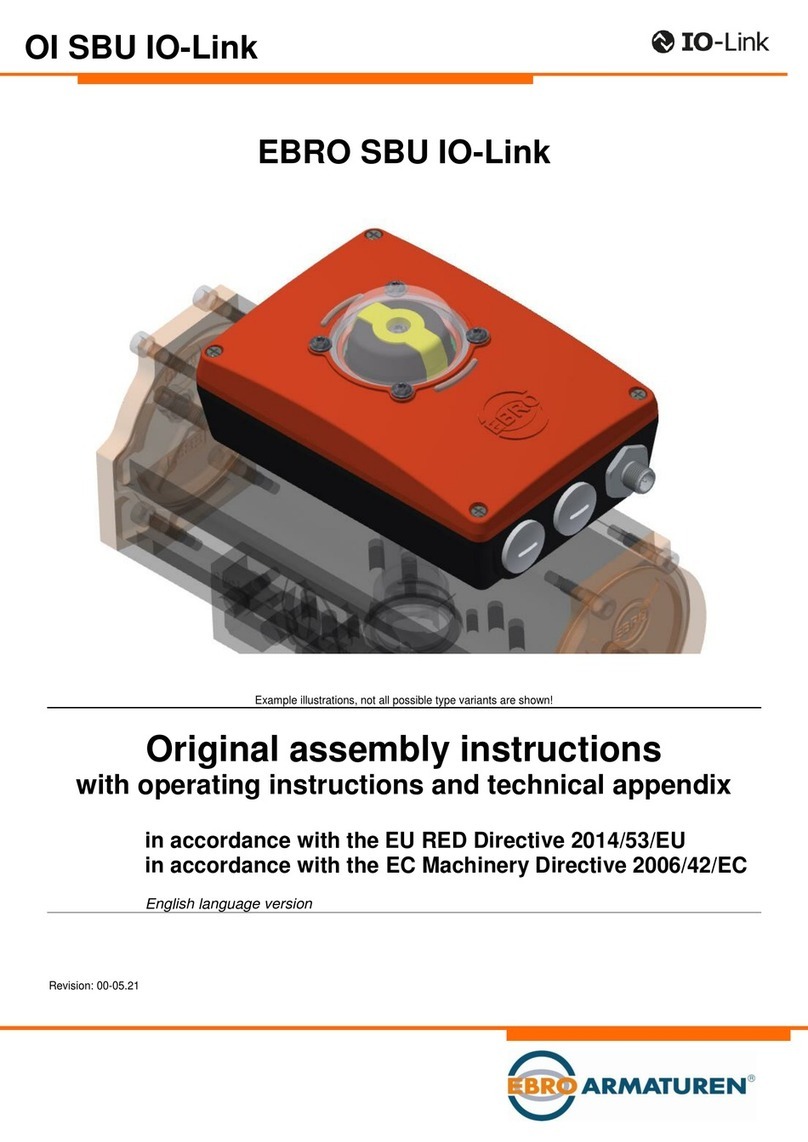

Quick Guide - SBU IO-Link

Page 5 of 10

B) Mounting and commissioning

Observe the safety information in the original assembly instructions regarding foreseeable risks in

the mounting / connection / dismounting of the SBU IO-Link in a control system.

It is the responsibility of the user to supplement this information to cover other, especially local risks.

Compliance with all requirements for this system is a prerequisite

B01 General safety information

Please read the safety information in the original assembly instructions carefully when handling the SBU IO-Link . It is

the responsibility of the operating company to supplement this information to cover other, specifically local or process-

related risks.

Please contact EBRO ARMATUREN Gebr. Bröer GmbH in case of questions or problems.

The SBU IO-Link conforms to the state of the art at the time of delivery and is deemed to be an incomplete machine

within the meaning of the Machinery Directive.

B02 Mounting the SBU IO-Link on the quarter turn actuator

The SBU IO-Link is suitable for direct mounting on quarter turn actuators with the mounting interface according to

VDI/VDE 3845 AA2 80 mm x 30 mm, shaft height 30 mm (max. dia. 30 mm).

Adapters are required for all other interfaces. The SBU IO-Link may only be operated with the accessories foreseen

and approved by EBRO ARMATUREN Gebr. Bröer GmbH.

The SBU IO-Link should be mounted as follows:

Unpack the SBU IO-Link from the factory packaging at the installation

location.

Check the SBU IO-Link for transport damage.

Check the SBU IO-Link for damage.

In case of outdoor installation of SBU IO-Link units, measures may need

to be taken to ensure operation as intended. These include the

"Diaphragm element" option for switch box ventilation or rain roofs and

possibly enclosures of an adequate protection class.

Determine the mounting position of the device (parallel to the actuator).

Open the switch box cover.

Align the drive shafts (groove) and switch box shaft (tongue).

Check the flush fitting of the insert seals on the underside of the switch

box housing.

Push the switch box onto the drive shaft.

Fasten the switch box to the actuator with 4 cheesehead screws and

spring washers.

Close the switch box cover again if the electrical connection is not to be

made immediately.

Risk of injury in case of improper mounting.

Mounting may only be carried out but authorised technical personnel using

suitable tools!

Risk of injury due to inadvertently switching on the plant and uncontrolled

restarting.

Secure the plant against inadvertent actuation.

Ensure controlled restarting after mounting.