Operating instructions - SBU IO-Link

Page 8 of 50

A06 Note on copyright and property rights

No part of this documentation may be duplicated or made available to third parties without the special

permission of EBRO ARMATUREN Gebr. Bröer GmbH. It may only be made available to authorised

persons.

This documentation including all of its parts is protected by copyright. Duplication, translation and

microfilming as well as storage and processing in electronic systems require the written consent of EBRO

ARMATUREN Gebr. Bröer GmbH.

Infringements are punishable by law with obligatory compensation of damages.

All rights to the exercising of commercial property rights are reserved by EBRO ARMATUREN Gebr.

Bröer GmbH.

A07 Warranty and liability

Warranty and liability are based on the contractually defined conditions. For the warranty terms, please

refer to the Terms and Conditions of Sales and Delivery of EBRO ARMATUREN Gebr. Bröer GmbH.

Notify EBRO ARMATUREN GmbH of warranty and guarantee claims in writing immediately after discovery

of the defect or error. The guarantee or warranty lapses in all cases in which no liability claims can be

made.

Liability and warranty claims lapse in the case of software modifications without the knowledge and consent

of EBRO ARMATUREN Gebr. Bröer GmbH.

Illustrations and drawings serve the general exemplification and can differ from the SBU IO-Link delivered.

EBRO ARMATUREN GmbH will accept no warranty claims for damage caused by use other than for the

intended purpose, improper storage or improper transport.

A08 Legal conditions

The information, data and notes provided in the operating instructions were up to date at the time of going

to print.

No claims arising from the data, illustrations and descriptions can be asserted for SBU IO-Link units already

delivered.

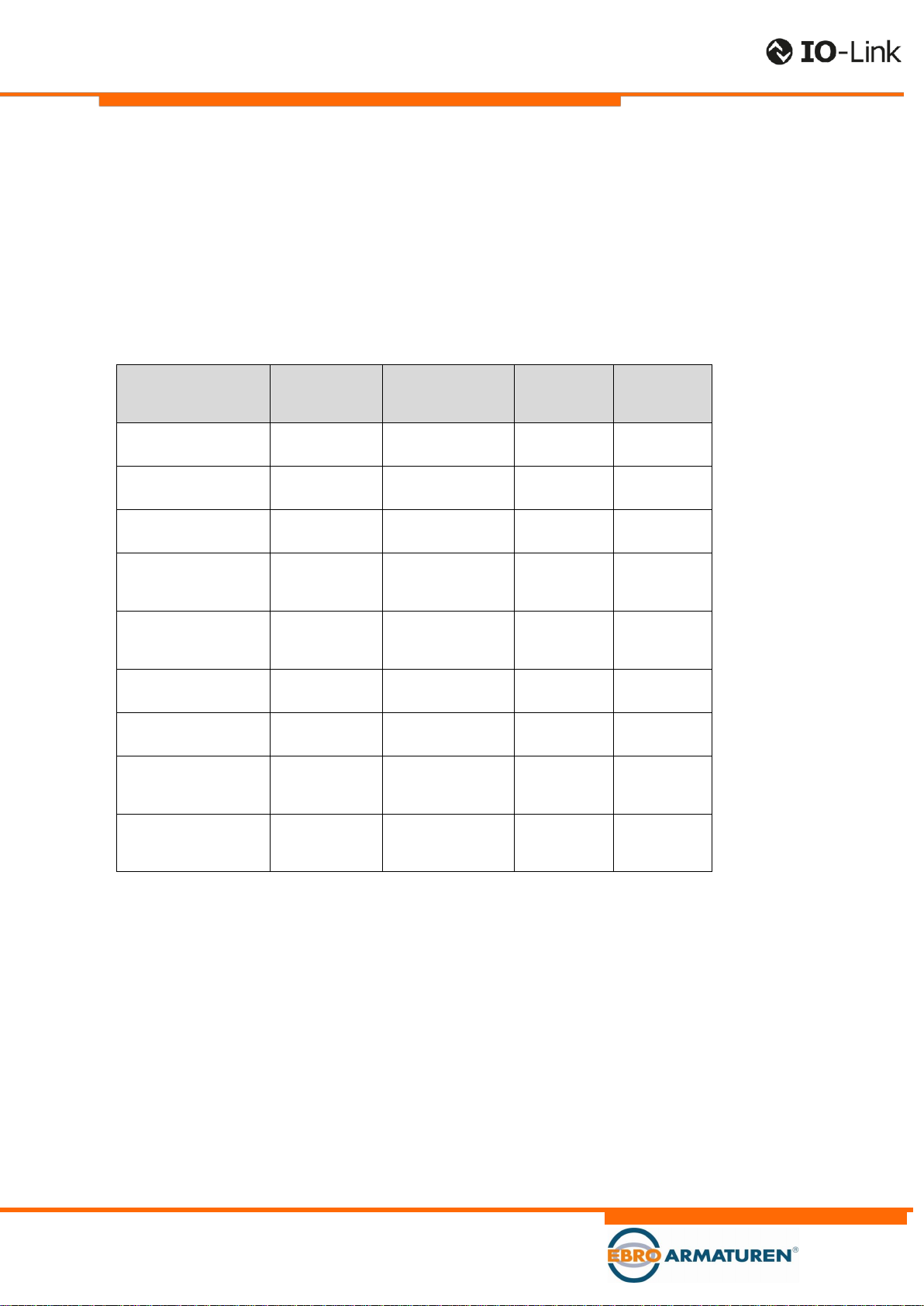

EBRO ARMATUREN Gebr. Bröer GmbH accepts no liability for damage and operational disruptions

caused by:

assembly.

improper operation and troubleshooting during operation.

maintenance (service, care, repair).

improper use.

unauthorised modifications to the SBU IO-Link .

improper working on and with the SBU IO-Link .

operating and setting errors.

errors in the programming of the controller.

disregard of existing standards, guidelines and accident prevention regulations.

disregard of these operating instructions.