Ebtron Advantage IV User guide

Startup_GTF116e-P_r1a Page 1 of 2

STARTUP INSTRUCTIONS:

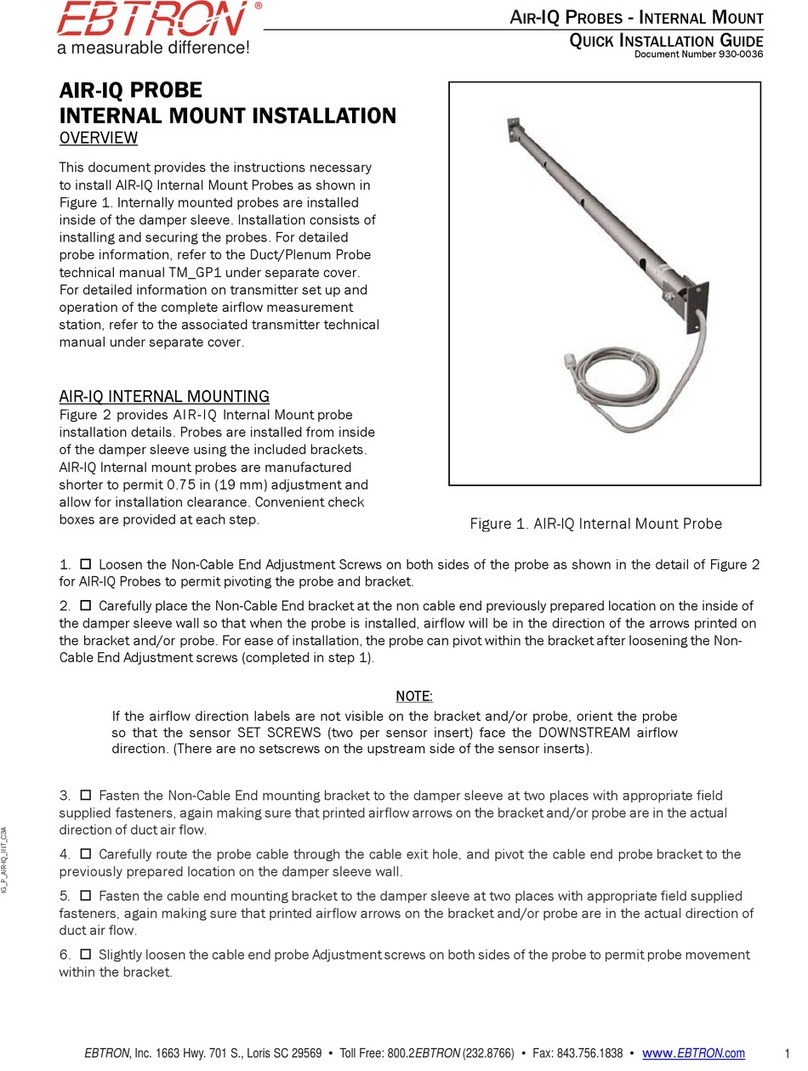

1. Verify that the sensor probes are located where they meet EBTRON published installation guides.

2. Verify that the probes are properly spaced with the airflow arrows pointing in the direction of airflow.

Improperly installed probes will compromise the installed accuracy of the device and degrade system

performance.

3. Verify that the transmitter is installed and wired in accordance with the GTF116e-P Wiring Guide

provided with the transmitter and power is provided to the transmitter.

4. Make sure the ductwork is clean and free of debris prior to fan startup.

5. Move the power switch to the “ON” position. Power-up faults, if detected, are displayed on the LCD.

If any power up faults are detected, resolve all conflicts or contact EBTRON customer service at

1-800-232-8766 before proceeding..

If extension cables have been added, the extension cable length must be entered into the transmitter.

Refer to the Operations and Maintenance Manual for more information.

Advantage IV (A4) GTF116e-P STARTUP GUIDE

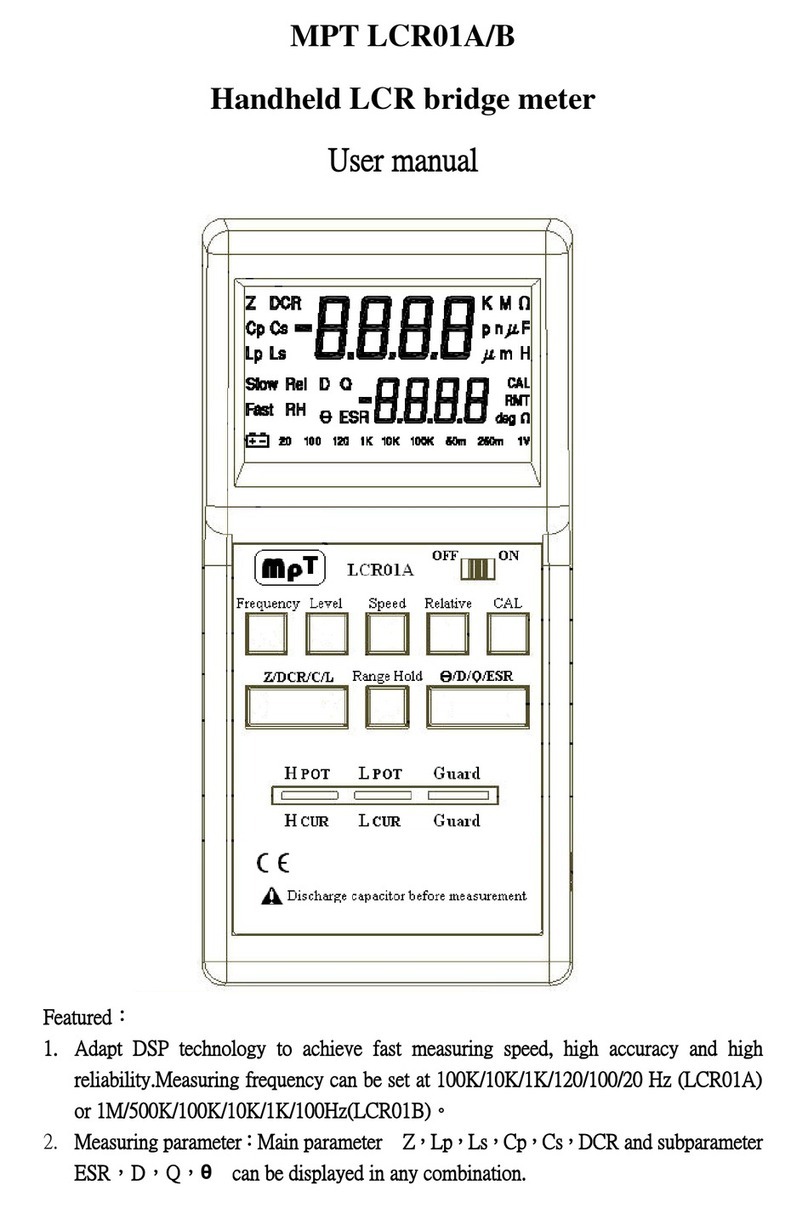

SW1

TX

RX

WINK

ACT

N1 N2

A1

A2

A3

C

L2

L1

TYPE B

TYPE A

Description Parameter Default Optional Settings/Ranges Units

System of Units SYS I-P (US customary) SI (metric)

Airflow Calculation Method AIRFLOW ACT (actual) STD (standard mass flow)

Altitude (for actual flow correction) ALT 0 AUTO, 0 to 20000 [0 to 6000] ft [m]

Low Limit Airflow Cutoff LLIMIT 0 FPM 0 to 500 FPM [0.0 to 2.5 m/s]

Area AREA {Order Area} 0.00 to 9999.99 [0.000 to 999.999] sq ft [sq m]

Humidity Sensor Config. (/H opt.) H CONFIG RH (relative humidity) ENTH (enthalpy ), DPT (dew point)

Auto Pb Correct Psych. Values Pb CORR ON (onboard sensor) OFF

AO1, AO2 and AO3 Type AOUT 4-20mA 0-10V, 0-5 V

AO1 Assignment AO1 ASGN AF (Airflow) None

AO1 Unit of Measure AO1 UM FPM [m/s] CFM [L/s]

AO1 Minimum Scale Reading AO1 MS 0None FPM [m/s]

AO1 Full Scale Reading AO1 FS 5000 [25.0] 100 to 15000 [0.5 to 75.0] FPM [m/s]

AO2 Assignment AO2 ASGN TEMP (Temperature) ALRM (Alarm) or TRBL (System Trouble)

AO2 Unit of Measure AO2 UM F [C] None °F [°C]

AO2 Minimum Scale Reading AO2 MS -20 [-30] -50 to 160 [-50 to 70] °F [°C]

AO2 Full Scale Reading AO2 FS 160 [70] -50 to 160 [-50 to 70] °F [°C]

AO3 Assignment AO3 ASGN RH None

AO3 Unit of Measure AO3 UM % RH None

AO3 Minimum Scale Reading AO3 MS 0 0 to 100 % RH

AO3 Full Scale Reading AO3 FS 100 0 to 100 % RH

AO3 Assignment AO3 ASGN ENTH None

AO3 Unit of Measure AO3 UM Btu/lb [kJ/kg] None

AO3 Minimum Scale Reading AO3 MS 0 -20 to 400 [-40 to 800] Btu/lb [kJ/kg]

AO3 Full Scale Reading AO3 FS 200 [400] -20 to 400 [-40 to 800] Btu/lb [kJ/kg]

AO3 Assignment AO3 ASGN DPT None

AO3 Unit of Measure AO3 UM F DPT [C DPT] None

AO3 Minimum Scale Reading AO3 MS 0 -50 to 160 [-50 to 70] °F [°C]

AO3 Full Scale Reading AO3 FS 100 [50] -50 to 160 [-50 to 70] °F [°C]

Lon Network xif File Link

Refer to the O&M Manual for more information and/or additional parameter defaults, settings and ranges.

GTF116e-P Parameters - Factory Defaults and Optional Settings/Ranges

H CONFIG=RH (default)

H CONFIG=ENTH

H CONFIG=DPT

https://ebtron.com/wp-content/uploads/software/EBTRON_116e.xif

Startup_GTF116e-P_r1a Page 2 of 2

6. The transmitter is fully functional as a factory calibrated airflow and temperature measurement device

in I-P units (ft, FPM, CFM °F). Airflow (CFM) and temperature (°F) are displayed on the LCD. If the

transmitter is provided with the /H humidity sensor option, relative humidity (%RH) is also displayed.

7. If the /H humidity sensor option is provided, relative humidity (%RH) is displayed on the LCD.

Enthalpy or dew point can also be displayed on the LCD by changing the H CONFIG parameter to

ENTH (enthalpy) or DPT (dew point). Press the ↑↓ arrow buttons simultaneously to enter the MAIN

MENU. The SETTINGS menu is displayed. Press the ENT button to select the top of the SETTINGS

submenu category. Press the ↓ button until the GENERAL submenu category is visible. Press the

ENT button to enter the GENERAL submenu. Press the ↓ button until the H CONFIG parameter is

visible. Press the ENT button and set the H CONFIG parameter to ENTH (enthalpy) or DPT (dew

point) using the ↑↓ buttons. Press the ENT button to save the selection. Press the ESC button twice

to return to normal operation.

The H CONFIG setting specifies the psychrometric property assigned to analog output AO3.

If SI units are required, refer to the Operations and Maintenance Manual.

The factory default airflow output is set to actual airflow (FPM, CFM). If standard (mass) airflow

(SFPM, SCFM) is required, refer to the Operations and Maintenance Manual.

8. Verify that the area on the hang-tag matches the actual area of the duct or opening where the probes

are located (less any internal insulation). If the area is different, modify the area parameter stored in

the transmitter and use the correct area for any external conversion calculations from FPM to CFM.

Failure to use the correct area will result in volumetric airflow (CFM) measurement error and degrade

system performance. If the area parameter must be changed, refer to the Operations and

Maintenance Manual.

9. If analog output signals are used continue to step 10, otherwise skip to step 15.

10. The output signal type and range (4-20 mA, 0-5 VDC or 0-10VDC) of AO1, AO2 and AO3 is

determined by the AOUT parameter. The transmitter is factory set to 4-20mA.

The 4-20mA is “4-wire type” and not loop powered. Do not apply any excitation voltage to the output

of the transmitter.

11. Verify that the transmitter is configured to match the analog input requirements of the host controller.

Press the ESC and ↑ buttons simultaneously to display the transmitter setting for the AOUT

parameter. If the AOUT parameter is not correct, press the ENT button and use the ↑ and ↓ buttons

to set AOUT. Press the ENT button to execute and display the change. Press the ESC button to

return to normal operation.

12. The analog output signal for airflow (AO1) is linear. The minimum scale reading (0% output) of the

airflow signal is fixed at 0 and the full scale reading (100% output) is factory set to 5,000 FPM.

Multiply the default full scale velocity (FPM )by the correct area of the measurement location to

determine the full-scale or span (CFM ) for the B.A.S. to avoid field configuration. EBTRON airflow

measurement device accuracy is percent-of-reading. Changing the full scale reading does not affect

measurement accuracy.

If custom airflow scaling or unit of measure are required, refer to the Operations and Maintenance

Manual.

13. The analog output signal for temperature (AO2) is linear. The minimum scale reading (0% output) is

set to -20 ºF and full scale reading (100% output) is set to 160 ºF.

If custom temperature scaling is required, refer to the Operations and Maintenance Manual.

AO2 can be configured for a high/low airflow alarm or system status alarm. Refer to the Operations

and Maintenance Manual for more information.

14. The analog output signal (AO3) for the psychrometric property specified is linear. The minimum scale

reading (0% output) and full scale reading (100% output) is based on the psychrometric specified by

H CONFIG. The factory default ranges for each psychrometric property output are as follows:

− Relative humidity (H CONFIG = RH): 0 to 100%

− Enthalpy (H CONFIG = ENTH): 0 to 200 Btu/lb

− Dew point (H CONFIG = DPT): 0 to 100 ºF

If custom psychrometric property scaling is required, refer to the Operations and Maintenance

Manual.

15. If the LON network connection is required continue to step 16, otherwise skip to step 18.

16. LON transmitters are provided with a full featured LonWorks compatible interface. No transmitter

configuration is required.

A “Service” push-button, SW1, is provided for device commissioning. Once the device is recognized

commissioning can be completed by uploading the parameters from the device.

17. Download the external interface file (.xif) if required by the installation software:

https://ebtron.com/wp-content/uploads/software/EBTRON_116e.xif

A “Wink” LED is provided for easy device identification.

An “Activity” LED and separate transmit and receive “TX” and “RX” indicators provide visual indication

of transmitter and communication status. The “Activity” LED flashes on for 1 second, off for 1 second

when the card is commissioned and online. The “Activity” LED remains illuminated constantly if there

is an error.

18. Startup is complete! If additional customization is desired, consult the Operation and Maintenance

Manual.

VERIFICATION

Many installations require third-party airflow verification. If the airflow measuring device is within the

measurement uncertainty of the verification technique, EBTRON strongly recommends that no field

adjustment correction is made. EBTRON airflow measurement devices are factory calibrated to NIST

traceable standards. Field adjustment is not recommended when installed in accordance to published

guidelines.

If field adjustment is required, refer to the Operation and Maintenance Manual.

If minimum placement guidelines cannot be achieved, installed accuracy may be compromised.

Transmitters can be field adjusted to match a third-party measurement. Adjusted field measurements

typically result in comparative readings within ±3% of the third-party measurement. Be advised that

the third-party measurement may have uncertainties greater than or equal to ±10% and should only

be used to adjust the airflow measurement device if the probes do not meet minimum placement

requirements or the discrepancy is greater than the uncertainty of the third-party source.

NEED MORE HELP?

EBTRON Customer Service

For toll-free factory support call 1-800-2EBTRON (1-800-232-8766), Monday through Thursday 8:00 AM

to 4:30 PM and Friday 8:00 AM to 2:00 PM eastern time.

Your Local EBTRON Representative

Visit EBTRON.com for the name and contact information of your local representative.

This manual suits for next models

1

Other Ebtron Measuring Instrument manuals