4. Configure settings.

-1. Select the “PV Mode Set ON” setting on the Measurement Settings screen.

Settings Settin

Descri

tio

Solar cell rated output

[kW] Enter the photovoltaic cell rated output or photovoltaic cell capacity for the solar panel being

measured. If measuring a branch circuit, for example in order to investigate a failed string, enter the

total rated out

ut for the tar

et

hotovoltaic cell onl

.

Cell temperature

coefficient

(maximum output)

Photovoltaic cells have negative temperature characteristics, meaning that their output decreases as

their surface temperature increases, and this coefficient expresses that relationship. This tendency is

particularly pronounced in crystalline silicon. Enter the appropriate value after checking the

specifications for the photovoltaic system. Following are reference values: Monocrystalline Si: -0.46;

ol

cr

stalline Si: -0.49; amor

hous Si: -0.26; CI

G

S: -0.46

Conditioner efficiency To display the AC estimated power (re

erence values) and AC estimated energy (reference values) on a

PV Waveform/Values screen, consult the power conditioner specifications and enter the device’s

conversion efficiency. The above value is subject to a larger error component in photovoltaic systems

that boost the voltage on the power conditioner side so that it is higher than the voltage at the

measurement

oint.

Other loss coefficient Coefficient for the effects of factors such as wiring resistance, dirt or snow buildup on the panel

surface, shadows, etc. A

eneral avera

e value of 0.07 is used b

default. Chan

e as necessar

.

Pyranomete

kind

Pyranometer output rate Choose the pyranometer kind. Output rate initial value of the ML-01 is 20.00. Output rate initial value

of the ML-020VM is 140.00. When Sensitivity indicated on the label of Pyranometer is A, the

calculated value of 1000/A is set to out

ut rate. Other

ranometer use Free Set.

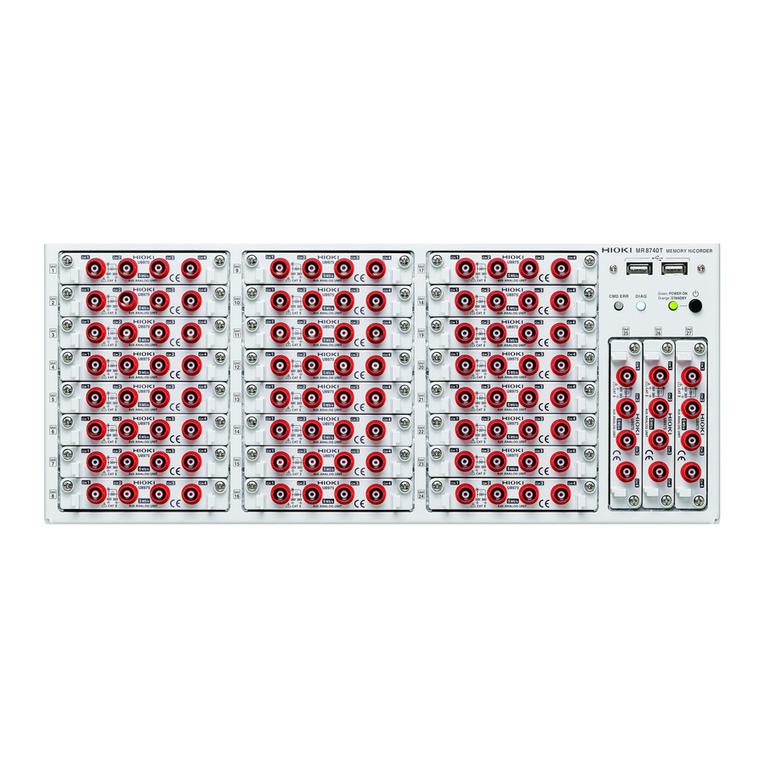

Clamp sensor range Select the same range as set for the CT6590 Sensor Unit. Next, press the “Monitor” key on the LR8400

while the clamp is not applied to anything and adjust the 0ADJ knob on the CT6590 so that the “ch1-2

current” is 0.

PV mode initialize Resets the following settings to their default values: Solar cell rated output, Cell temperature

coefficient, Conditioner efficiency, Other loss coefficient Pyranometer kind, Pyranometer output rate,

and Clam

sensor ran

e.

Please

erform, when

ou initialize PV mode setu

.

Extended channel set An input can be added to ch1-5 to ch1-11.Voltage, Thermo couple, and a clamp (2000A, 200A, 100A,

20A, 10A) can be chosen from the input item of the channel which select check mark. (Please use it,

when

ou increase the measurement channel in PV mode.

Interval Set the time interval at which to record data. The longe

the time interval, the lower the cutoff

frequency, increasing noise rejection effectiveness. It is recommended to increase the recording

interval in environments that are

rone to noise from inverters or other devices.

Cont Set whether to perform measurement for the set time or continuously.

OFF: Normal measurement (measurement for the specified recording time)

ON: Continuous measurement

Time/DIV Set the time

er division.

Filte

Set to either 60 Hz or 50 Hz depending on the power supply frequency in your region. The longer the

recordin

interval, the

reater the noise re

ection effectiveness.

Timer Set when you wish to perform measurement regularly. This setting allows the instrument to perform

measurement at a re

ular interval from the set start time to the set sto

time.

Auto save Set when you wish to save data automatically during measurement. For more information, see “Saving

Data Automaticall

” in Section 6.2, “Savin

Data,” of the LR8400 User Manual.

Note

・For photovoltaic systems that boost the voltage on the power conditioner side so that it is higher than the value at the junction box

where the measurement is being taken, select channel number 1-1 on the Setting screen’s “CH” sheet and enter a voltage value as

appropriate for the “Offset” setting under “Scaling” so that the voltage shown on the LR8400-23’s Monitor screen matches the

photovoltaic system monitor’s DC voltage value.

・The waveform data measured in "PV mode Set ON" LR8400-23 can be displayed by attached Logger Utility. However, "PV mode"

cannot be set up by Logger Utility.

5. Check measured values on the Monitor screen.

-1. If you encounter any of the following displays on the Monitor screen, refer to the indicated solution.

Dis

la

Solutio

Erroneous voltage value •Check whether the 9322 Differential Probe switch is set to “DC.”

• Check whether the voltage range has been set to take into account the fact that the differential

probe’s output ratio is 1/1,000.

• For photovoltaic systems that boost the voltage on the power conditioner side so that it is higher

than the value at the junction box where the measurement is being taken, select channel number

1-1 on the Setting screen’s “CH” sheet and enter a voltage value as appropriate for the “Offset”

setting under “Scaling” so that the voltage shown on the LR8400’s Monitor screen matches the

photovoltaic system monitor’s DC voltage value.

• Check whether the solar panels are susceptible to the effects of factors such as shadow, dirt, or

snow buildup.

• There ma

be a wirin

break on a strin

or a module failure.

Erroneous current value •Check the CT6590 Sensor Unit’s range setting.

• Check the LR8400’s clamp range setting.

• Check the adjustment of the 0ADJ knob on the CT6590 Sensor Unit.

• Check the CT6590 Sensor Unit’s remaining battery life.

• Check for noise sources such as inverters in the vicinity of the system.

• Check the site to see if the solar panels are susceptible to the effects of factors such as shadow,

dirt, or snow buildup.

• There ma

be a wirin

break on a strin

or a module failure.

Erroneous insolation value •Check the wiring connections.

• Check for noise sources such as inverters in the vicinity of the system.

• Check the kind of

ranometer and out

ut rate to be used.

Erroneous

anel temperature

value •Check the installation of the thermocouple.

•Check for a broken thermocouple connection.

* Turning on the broken connection check on the “CH”sheet will cause “Burn Out”to be

displayed for the measurement data. However, the broken connection check function cannot be

used if the recordin

interval is 10 ms.

Significant difference between

power and estimated power •Check the solutions for erroneous voltage, current, insolation, and panel temperature values

above.

• Check whether the PV specification setup have been set to appropriate value. In particular,

double-check the photovoltaic cell rated output and clamp range settings as these are easy to

overlook.

• This error is more likely to occur in climates and time zones characterized by low insolation.

Perform measurement during a time of high insolation.

• There may be a wiring break on a string or a module failure. Pinpoint the location of the failure,

for exam

le b

usin

an I/V tracer.

6. Start time-series recording.

If performing time-series recording, start recording. If the auto-save setting has been activated, data will be recorded simultaneously

to the instrument’s internal memory and the specified CF card or USB flash drive.

-1. Start measurement with the Start key.

-2. Stop measurement with the Stop key.

Note

The continuous operating time for the AAalkaline batteries

in the CT6590 Sensor Unit that ships with the CT9692-90

(or CT9693-90) Clamp Sensor is approximately 25 hours.

When performing time-series recording, use the optional

9445-02 AC Adapter.

7. Investigate the failed string. (See Figure 3.)

If the power value is significantly less than the estimated

power, a solar panel may have failed. The instrument can be

used to look for a string with a wiring break or a module

failure by means of the following method.

-1. Return to Step 3, “Place the sensors,” and connect the

9322 Differential Probe and CT9692-90 (or CT9693-90) Clamp Sensor

to the branch circuit as shown in Figure 3. Next, change the

photovoltaic cell rated output on the Measurement Settings

screen to the output value for the string being measured and

check the voltage, current, and output values on the Monitor screen.

Perform similar measurements for the other strings. Circuits with

relatively lower values may indicate wiring breaks or module failures.

-2. Without changing the settings made in (-1) above, cover the solar cell that you expect may be damaged with a piece of cloth, board,

or other material and compare the resulting voltage, current, and energy values with the corresponding values before the panel was

covered. Strings whose measured values do not change when they are covered may have a module failure or wiring break.

-3. The instrument can also be used as a normal data logger by using the “PV Mode Set OFF” setting. Up to 30 channels of current

data can be recorded by purchasing additional CT9692-90 (or CT9693-90) Clamp Sensors and BNC conversion cables. Current data

for multiple strings can be recorded simultaneously, allowing current variations to be investigated.

Note

•The instrument cannot be used to search for failures or wiring breaks within individual modules. For such applications, please use a

thermal camera or dedicated checker.

32

Figure 3

Note: The version of the

software until the V9.12, it was

ML-020 only rather than

selection of pyranometer kind.

From V9.13, please use it to

select "ML-01", "ML-020", and

"Free Set" pyranometer kind

used as shown in the figure on

the left. (In the system screen,

you can check the version.)