Ebtron Advantage IV HTA104-T User guide

Startup_HTA104‐T_r1aPage1of2

STARTUP INSTRUCTIONS:

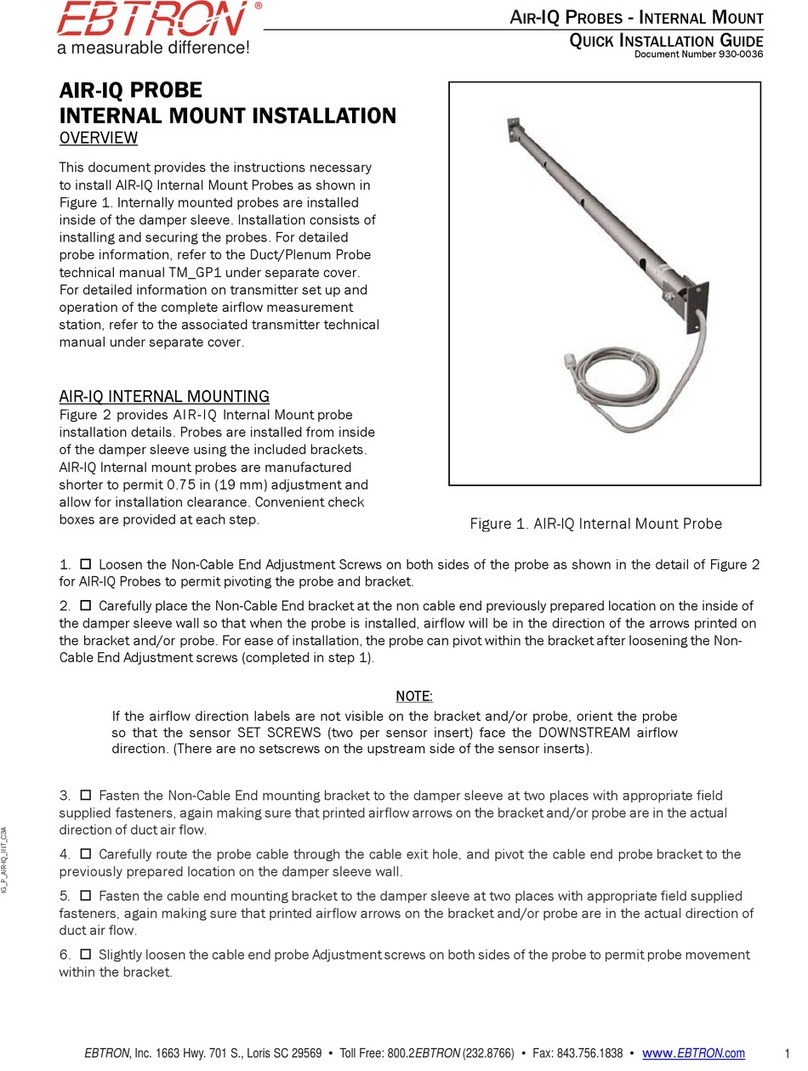

1. Verify that the sensor probe is located where they meet EBTRON published installation guides.

2. Verify that the probe is properly installed with the airflow arrow pointing in the direction of airflow.

Improperly installed probes will compromise the installed accuracy of the device and degrade system

performance.

3. Verify that the transmitter is installed and wired in accordance with the HTA104-T Wiring Guide

provided with the transmitter and power is provided to the transmitter.

4. Make sure the ductwork is clean and free of debris prior to fan startup.

5. Move the power switch to the “ON” position. Power-up faults, if detected, are displayed on the LCD.

If any power up faults are detected, resolve all conflicts or contact EBTRON customer service at

1-800-232-8766 before proceeding..

If extension cables have been added, the extension cable length must be entered into the transmitter.

Refer to the Operations and Maintenance Manual for more information.

6. The transmitter is fully functional as a factory calibrated airflow and temperature measurement device

in I-P units (ft, FPM, CFM °F). Airflow (CFM) and temperature (°F) are displayed on the LCD.

If SI units are required, refer to the Operations and Maintenance Manual.

The factory default airflow output is set to actual airflow (FPM, CFM). If standard (mass) airflow

(SFPM, SCFM) is required, refer to the Operations and Maintenance Manual.

7. Verify that the area on the hang-tag matches the actual area of the duct or opening where the probes

are located (less any internal insulation). If the area is different, modify the area parameter stored in

the transmitter and use the correct area for any external conversion calculations from FPM to CFM.

Failure to use the correct area will result in volumetric airflow (CFM) measurement error and degrade

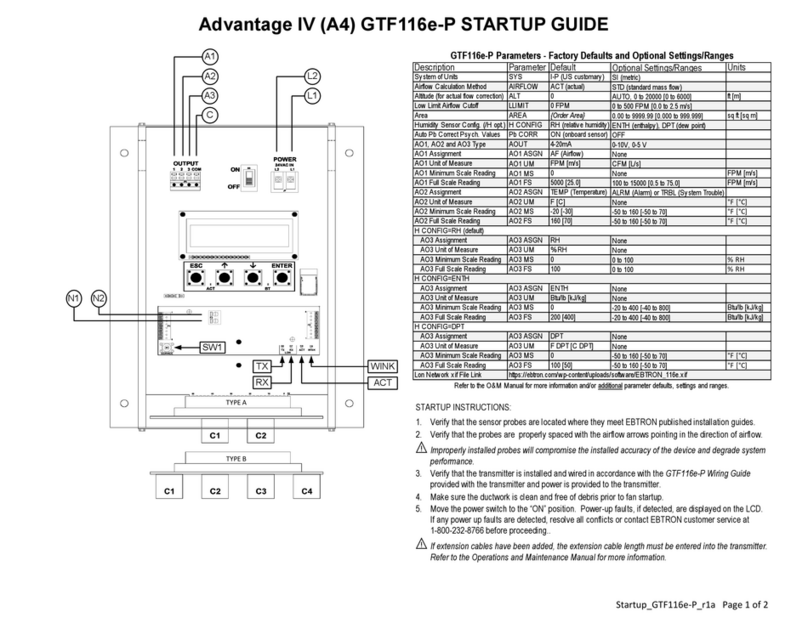

Advantage IV (A4) HTA104-T STARTUP GUIDE

Description Parameter Default Optional Settings/Ranges Units

System of Units SYS I-P (US customary) SI (metric)

Airflow Calculation Method AIRFLOW ACT (actual) STD (standard mass flow)

Altitude (for actual flow correction) ALT 0 0 to 20000 [0 to 6000] ft [m]

Low Limit Airflow C utoff LLIM I T 0 FP M 0 to 500 FPM [0.0 to 2.5 m/ s]

Area AREA {Order Area} 0.00 to 9999.99 [0.000 to 999.999] sq ft [sq m]

AO1 Type AOUT1 4-20mA 0-10V, 0-5 V

AO2 Type AOUT2 4-20mA 0-10V, 0-5 V

AO1 Assignment AO1 ASGN AF (Airflow) None

AO1 Unit of Measure AO1 UM FPM [m/s] CFM [L/s]

AO1 M inimum S cale Reading AO1 M S 0 N one FPM [m/s]

AO1 Full Scale Reading AO1 FS 3000 [15.0] 100 to 15000 [0.5 to 75.0] FPM [m/s]

AO2 Assignment AO2 ASGN TEM P (Temperature) ALRM (Alarm) or TRBL (Sy stem Trouble)

AO2 U nit of Measure AO2 U M F [C ] None °F[°C]

AO2 M inimum Scale Reading AO2 M S -20 [-30] -50 to 160 [-50 to 70] °F[°C]

AO2 Full Scale Reading AO2 FS 160 [70] -50 to 160 [-50 to 70] °F[°C]

HTA104-T Parameters - Factory Defaults and Optional Settings/Ranges

Refer to the O&M M anual for more information and/or additional parameter defaults, settings and ranges.

Startup_HTA104‐T_r1aPage2of2

system performance. If the area parameter must be changed, refer to the Operations and

Maintenance Manual.

8. If analog output signals are used continue to step 9, otherwise skip to step 14.

9. The output signal type and range (4-20 mA, 0-5 VDC or 0-10 VDC) of AO1 and AO2 is determined by

the AOUT parameter and the position of the output jumpers located on the left side of the PCB.

Position the jumpers (AOUT1 for AO1 and AOUT2 for AO2) to “mA” if a 4-20 mA signal is required or

“VDC” if a 0-5 or 0-10 VDC signal is required. The transmitter is factory set to 4-20mA (i.e. AOUT=4-

20mA and both jumpers are set to “mA”).

The 4-20mA is “4-wire type” and not loop powered. Do not apply any excitation voltage to the output

of the transmitter.

10. Verify that the transmitter is configured to match the analog input requirements of the host controller.

Press the ESC and ↑buttons simultaneously to display the transmitter setting for the AOUT

parameter. If the output signal type and range is not correct, use the ↑and ↓buttons to display the

proper output signal type and range and press the ENT button to execute the change.

11. Verify that jumpers AOUT1 and AOUT2 are set to “mA” if the AOUT parameter is set to “4-20mA” or

“VDC” if the AOUT parameter is set to “0-5V” or “0-10V”.

12. The analog output signal for airflow (AO1) is linear. The minimum scale reading (0% output) of the

airflow signal is fixed at 0 and the full scale reading (100% output) is factory set to 3,000 FPM.

Multiply the default full scale velocity (FPM )by the correct area of the measurement location to

determine the full-scale or span (CFM ) for the B.A.S. to avoid field configuration. EBTRON airflow

measurement device accuracy is percent-of-reading. Changing the full scale reading does not affect

measurement accuracy.

If custom airflow scaling or unit of measure are required, refer to the Operations and Maintenance

Manual.

13. The analog output signal for temperature (AO2) is linear. The minimum scale reading (0% output) is

set to –20 ºF and full scale reading (100% output) is set to 160 ºF.

If custom temperature scaling is required, refer to the Operations and Maintenance Manual.

AO2 can be configured for a high/low airflow alarm or system status alarm. Refer to the Operations

and Maintenance Manual for more information.

14. Startup is complete! If additional customization is desired, consult the Operation and Maintenance

Manual.

VERIFICATION

Many installations require third-party airflow verification. If the airflow measuring device is within the

measurement uncertainty of the verification technique, EBTRON strongly recommends that no field

adjustment correction is made. EBTRON airflow measurement devices are factory calibrated to NIST

traceable standards. Field adjustment is not recommended when installed in accordance to published

guidelines.

If field adjustment is required, refer to the Operation and Maintenance Manual.

If minimum placement guidelines cannot be achieved, installed accuracy may be compromised.

Transmitters can be field adjusted to match a third-party measurement. Adjusted field measurements

typically result in comparative readings within ±3% of the third-party measurement. Be advised that

the third-party measurement may have uncertainties greater than or equal to ±10% and should only

be used to adjust the airflow measurement device if the probes do not meet minimum placement

requirements or the discrepancy is greater than the uncertainty of the third-party source.

FOR MORE INFORMATION ….

Operations and Maintenance Manual.

The Operations and Maintenance Manual is a comprehensive reference document that contains

information on installation, startup, custom configuration, built-in tools, diagnostics, troubleshooting and

maintenance.

NEED MORE HELP?

EBTRON Customer Service

For toll-free factory support call 1-800-2EBTRON (1-800-232-8766), Monday through Thursday 8:00 AM

to 4:30 PM and Friday 8:00 AM to 2:00 PM eastern time.

Your Local EBTRON Representative

Visit EBTRON.com for the name and contact information of your local representative.

Other Ebtron Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Digi Sport Instruments

Digi Sport Instruments DW-2005 instruction manual

GREISINGER

GREISINGER GMH 3611 operating manual

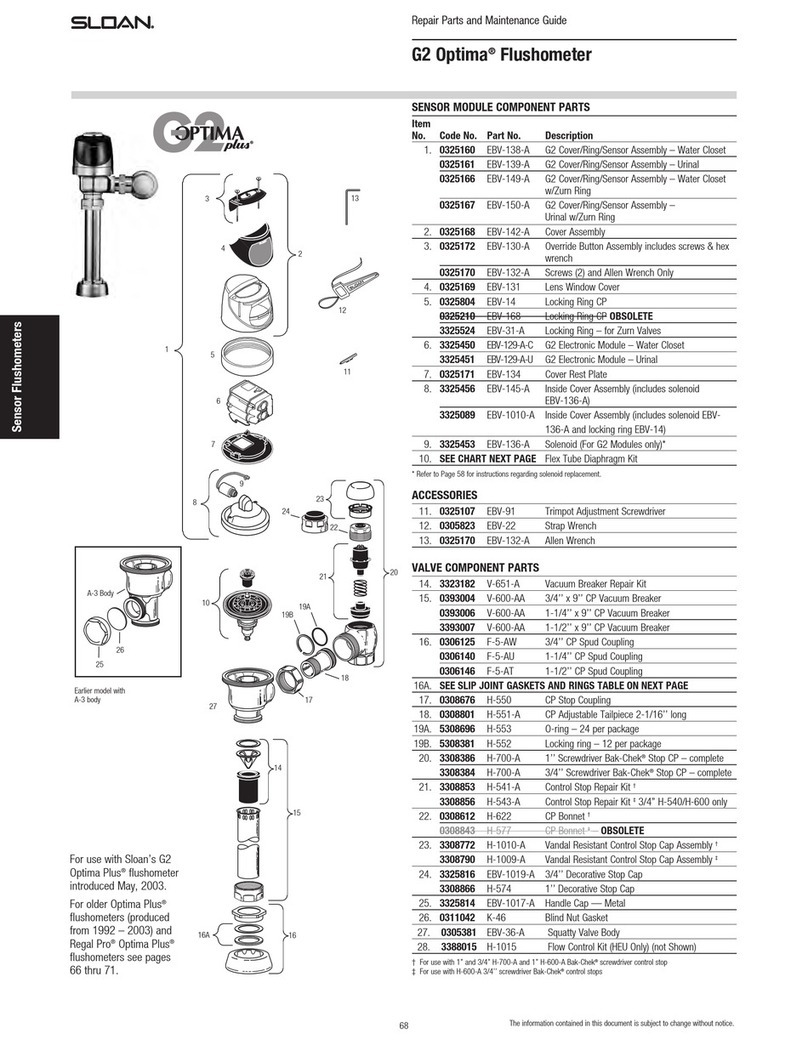

Sloan

Sloan G2 Optima Plus Repair Parts and Maintenance Guide

REED

REED R8050 instruction manual

LOVATO ELECTRIC

LOVATO ELECTRIC DMED301MID instruction manual

Vemer

Vemer ADR-D 230 D22 SPOT user manual