ECB BC53SY User manual

.© Copyright –ECB Pty Ltd –2012 1

BC53SY

FITTING INSTRUCTIONS

CHEVROLET SILVERADO MY08 (2/07on)

WINCH COMPATIBLE BIG TUBE™BAR (WITH FOG LAMPS)

VEHICLE FRONTAL PROTECTION SYSTEM (VFPS)

FOR AIR BAG & ADR COMPLIANT VEHICLES

Check installation hardware before commencing.

1. Lift bonnet

2. Remove grille to radiator support cover, eight push pull plastic clips.

3. From air opening on bumper, disconnect air damming from front bumper. (Five plastic Christmas tree plugs.)

4. From under bumper, remove bumper stays. One 15mm nut (per side) from bumper end and two 15mm bolts (per

side) from chassis end. See figure 1. Disconnect fog lights.

5. Remove two 21mm bolts from bumper brackets. Access from behind grille. See figure 2.

6. Remove bumper from vehicle.

7. Remove bumper brackets and tow hook from front of chassis rails (two 21mm nuts on factory “u” bolts) and two

19mm bolts and nut from tow hook. Note: One 19mm bolt from underside of chassis.

8. Fit ECB Steel inner mount brackets (supplied) to inside of chassis rails using three ½ x 5 ½ bolts and flat washers

and one 1 x 1 ½ bolt, flat washers, spring washers and nut (per side)(supplied). Fit ECB Steel outer mount

brackets to outside of chassis rail. Attach using flat washer, spring washer and nut (supplied). On lower bolt

place space tube on inside of chassis rail over bolt. See figure 3. Tighten bolt on underside of chassis only.

9. Fit fairlead rollers to side of winch frame with rectangular cut out using ½ x 1 bolt flat washers, spring washers

and nut (place bolt thru from inside to front of mount).

10. Remove lower tie bar from winch and refit to back of winch using 6mm Allen key. Place winch into winch frame

with motor end to passenger’s side of frame. Note: Winch rope will feed from underside of winch. Attach to

underside of winch frame using four 7/16 x 1 ½ bolts, flat washers and spring washers supplied with winch. Fit

two 7/16 x 1 ½ bolts, flat washers and spring washers (supplied) to winch from rear of winch frame. Ensure wire

winch rope is passed thru fairlead rollers upon installation of winch. Fit hook to wire rope. See figure 4.

11. For 12,000lb Warn Winch - Fit control box to winch motor. Clamp in position with large hose clamps (supplied

with winch) socket on control box mounted vertically on winch. Connect cables to motor as indicated. NOTE:

Motor ground terminal bolts to 8mm hole at front. Ensure good contact. Use M8 x 25 bolt, nut, flat and spring

washers (supplied).

12. For 15,000lb Warn Winch –Fit ECB control box bracket (supplied) to inside of winch mounting bracket on

passengers side. Use two 3/8 x 1 ¼ bolts, nuts, flat and spring washers (supplied). TIGHTEN parallel to roller

fairlead. Using original 15,000lb bracket bolted to 15,000lb control box, bolt to ECB bracket using two 3/8 x 1

¼ bolts, nuts, flat and spring washers (supplied). Align socket on control box to sit vertically on winch.

TIGHTEN IN POSITION. Connect cables to motor as indicated. See figure 5.

REPLACES: 14.03.08

REVISED: 11.07.10

.

.© Copyright –ECB Pty Ltd –2012 2

13. With the help of a second person, place winch frame onto inner steel mounting brackets, between outer steel

mounting brackets. Attach to mounts using four ½ x 1 ½ bolts, flat washers, spring washers and nuts on lower

points of mounts. Tighten all bolts on inner steel mount only. See figure 6. WARNING: Winch and frame are

very heavy, two person lift is required.

14. Feed winch wiring to battery. Ensure wiring is protected from sharp edges and other damage. Test winch for

correct operation.

15. Splice ECB indicator/park light and fog light wiring into original wiring loome. Use cable locks (supplied).

Wiring is accessible under headlamps. If original fog lamps not fitted, an accessory wiring kit will be required.

See figure 7 and 8.

16. Attach infill trim (supplied) to top sides of ECB Protection Bar as far as the cut out for the grille opening. Trim

infill to suit ear angle of bar. Attach 6mm clip lock trim neatly between infill panels. See figure 9.

17. Fit ECB LED indicator / park lights into protection bar as per instructions supplied with the LED indicator kit.

NOTE: Ensure park light is to outside. See figure 10.

18. Attach ECB fog lights to protection bar. Place M6 x 20 bolts, spring washers (supplied) through light mount

from inside and attach nut to top. Slide assembly into light mount in Protection bar and centralize light to hole.

See figure 11. Tighten Firm Only. NOTE: Do not fit ECB light trims to protection bar at this point.

19. Attach ECB Protection Bar to outside of steel mounting brackets. Use two ½ x 1 ½ bolts and one ½ x 2 ½ bolt to

lower hole, flat washers, spring washers and nuts (per side). Finger tighten only. Tighten all steel mounting

brackets to chassis.

20. Align ECB Protection Bar to vehicle. Tighten all bolts. See figures 12 and 13.

21. Connect ECB indicator/park lights and fog lamps. Ensure wiring is routed in such a manner to avoid any sharp

edges etc and fog lamps are pointed forward and at a slightly downward angle. Check for correct operation. Fit

Fog light trims (supplied), large side to inside of bar.

22. Trim lower wheel arch splash guard level with bottom of skirt on Protection bar. Cuts will be required to allow

splash guard to sit neatly behind Side of Protection Bar.

ENSURE NUMBER PLATE IS CLEARLY VISABLE

Note: When fitting/refitting the licence plate to the vehicle, ensure there is no obstruction to licence plate vision in

accordance with local authorities. If required relocate licence plate to an alternate location.

Further VFPS Notes:

a) Do not attach VFPS to the vehicle using anchorages not intended for this purpose (e.g. engine mounting bolts).

b) Do not use this product for any vehicle make or model, other than those specified by the VFPS manufacturer.

c) Do not remove the plaque or label from the VFPS.

d) Do not modify the structure of the VFPS in any way.

e) No accessory or fitment should project forward of the VFPS forward profile.

f) ENSURE THESE INSTRUCTIONS ARE LEFT WITH VEHICLE OWNER AND/OR OPERATOR.

IMPORTANT INFORMATION

Periodically check bolts and nuts for correct tightness, especially if travelling on rough roads

.© Copyright –ECB Pty Ltd –2012 3

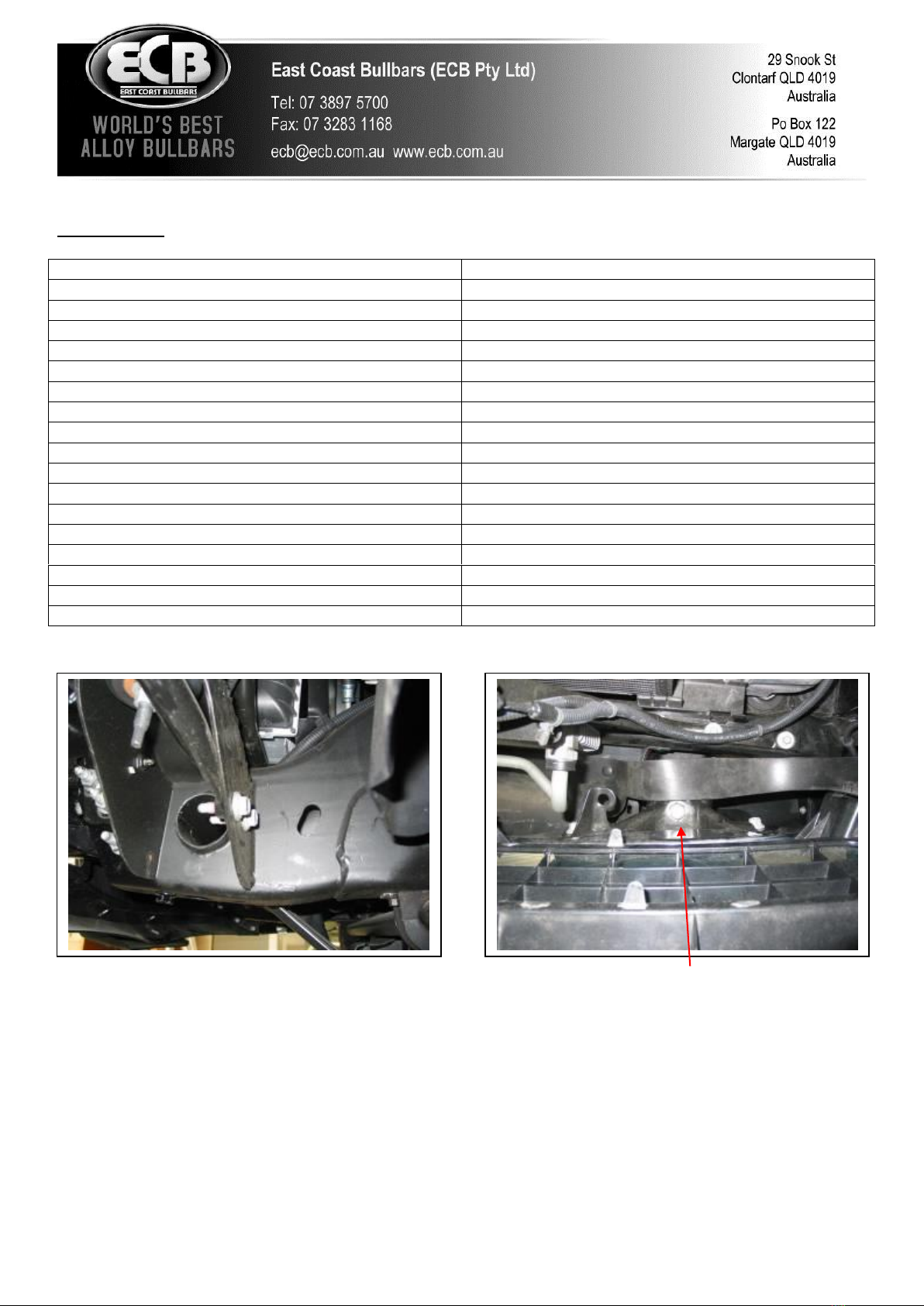

Figure 2: 21mm bolt looking down from behind

grille

Figure 1: Stay mount to chassis, two 15mm bolts

FITTING KIT

2 –ECB Outer Steel Mounting Brackets

2 –M8 flat washers

2 –ECB Inner Steel Mounting Brackets

1 –M8 spring washer

1 –ECB Steel Winch Frame

1 –M8 nut

1 –ECB Steel control box mount

4 –3/8 x 1 ¼ bolts

2 –ECB Steel chassis spacer tubes (15 nb x 78mm long)

8 –3/8 flat washers

6 –½ x 5 ½ bolts

4 –3/8 spring washers

10 –½ x 1 ½ bolts

4 –3/8 nuts

2 –½ x 1 bolts

1 –1600mm length, 6mm clip lock trim.

2 –½ x 2 ½ bolts

2 –600mm length, infill trim

40 –½ flat washers

1 –ECB LED Indicator / Park light kit

20 –½ spring washers

1 –Pair ECB Fog Lamps.

20 –½ nuts

2 –Fog lamp surrounds.

2 –7/16 x 1 ½ bolts

2 –M6 x 20 bolts.

4 –7/16 flat washers

2 –M6 flat washers.

2 –7/16 spring washers

2 –M6 spring washers.

2 –7/12 nuts

2 –M6 nuts

1 –M8 x 25 bolt

10 –Cable locks

6 –300mm cable ties

.© Copyright –ECB Pty Ltd –2012 4

Figure 7: Wiring harness under driver’s headlamp

Figure 8: Infill trim finishing point

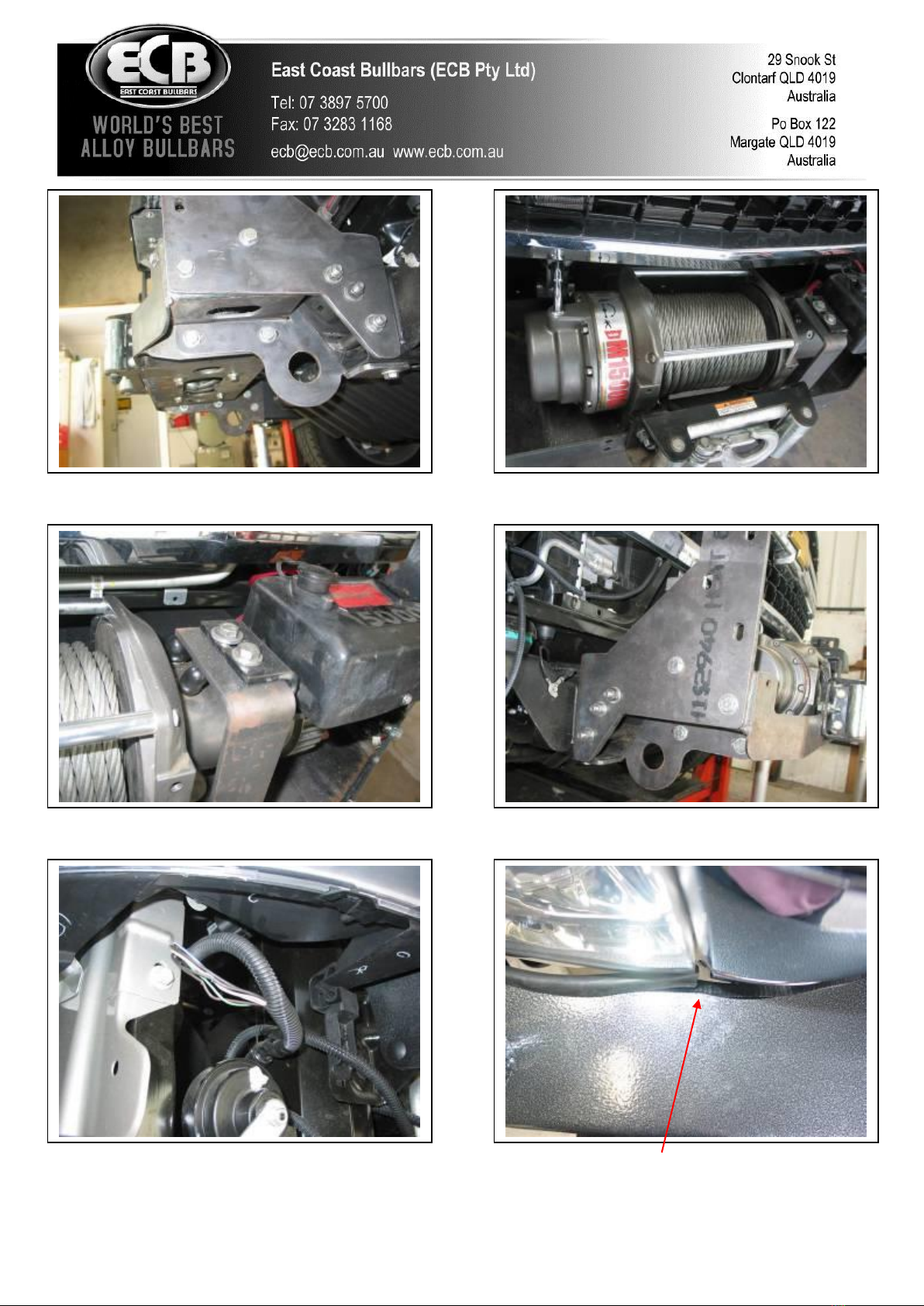

Figure 3: View of mounts no chassis with winch

attached

Figure 4: Placement of winch in mount

Figure 5: Direction and mounting of winch control box

Figure 6: Mounting of winch frame to chassis mount

.© Copyright –ECB Pty Ltd –2012 5

Figure 10

Figure 11

Figure 9: Overall view, rear of alloy bar

Figure 12: Winch Bar, front view

Figure 13: Winch bar, side view

We value your comments

Stainless steel self-tappers

M6 bolt

.© Copyright –ECB Pty Ltd –2012 6

Dear Fitter,

ECB would like to know how you went with the installation of this product. We value your comment and may need to

contact you to clarify some details so please complete your contact details clearly.

We would appreciate if you could complete as many of the following details as possible.

Your Name:

Your contact No.

Product Part No.

Product Invoice No.

Product Description:

Make, model, and year of vehicle:

Product Work Order No.

Company your from/Company product purchased from:

Date of Fitment: ____/____/____

Yes No

Was the fitting hardware supplied complete?

If no what was not supplied

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

Yes No

Did the installation go well?

Please provide comments

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

Please draw diagrams if you need to.

Post to Fax to

Reply Paid 122 (07) 3283 1168

PO Box 122

Margate QLD 4019 DESPATCH CHECKLIST

.© Copyright –ECB Pty Ltd –2012 7

BC53SY

ICZBKCC53 *ICZBKCC53*

Work Order #

Finish:

Transport:

Due Date:

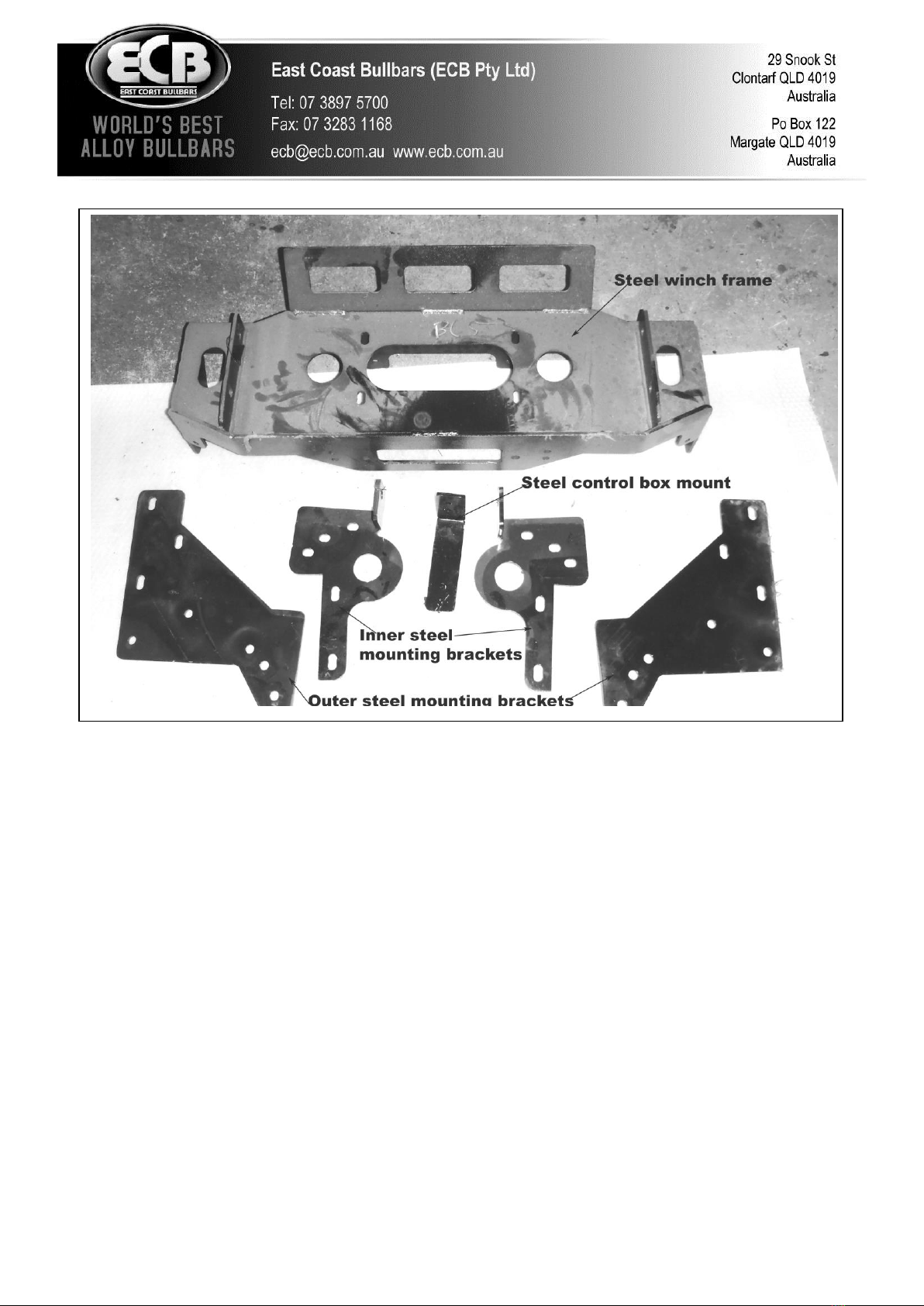

O2 –ECB outer steel mounting brackets.

O2 –ECB inner steel mounting brackets.

O1 –ECB steel winch frame.

O1 –ECB steel control box mount.

O2 –ECB steel chassis spacer tubes (15nb x 78mm long).

O1 –Bolt Kit.

O1 –ECB Indicator / park light kit.

O1 –Pair ECB fog lamps.

O2 –Fog lamp surrounds.

O1 –1600mm length 6mm clip lock trim.

O2 –600mm lengths infill trim.

O2 –ECB overriders –Fitted to Bar.

O6 –6mm air scoops –Fitted to Bar.

All parts checked and completed by:

Nut and bolts: __________________________Date__/__/__

Order control: __________________________Date__/__/__

Final wrap check: __________________________Date__/__/__

Is this product “the best it can be”Yes ______/______

Wrapper’s initials / Checker initials

If NO fix before continuing

See other side of

this page for

photos of all

mounts

.© Copyright –ECB Pty Ltd –2012 8

Table of contents

Other ECB Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction