ECB BIG TUBE BT128SY User manual

BT128SY REPLACES: 00.00.00

REVISED: 04.10.11

FITTING INSTRUCTIONS

HILUX 09/11on 2WD / 4WD BIG TUBE™ PROTECTION BAR

WITH 9000LB WARN WINCH FITMENT

VEHICLE FRONTAL PROTECTION SYSTEM (VFPS)

FOR AIR BAG & ADR COMPLIANT VEHICLES

Check installation hardware before commencing.

1. Lift bonnet

2. Remove grille, two plastic clips and two PK self-tappers along top, pull grille forward at top enough to access

and release five fixed clips along bottom inside of grille.

3. Remove bumper cover, three plastic clips along top (grille area), one plastic clip (each side) at bumper cover top

side returns, four 10mm head self-tapper on inner guard (each side), three plastic clips along bottom of bumper

cover. Pull bumper cover outward at sides to release off clips.

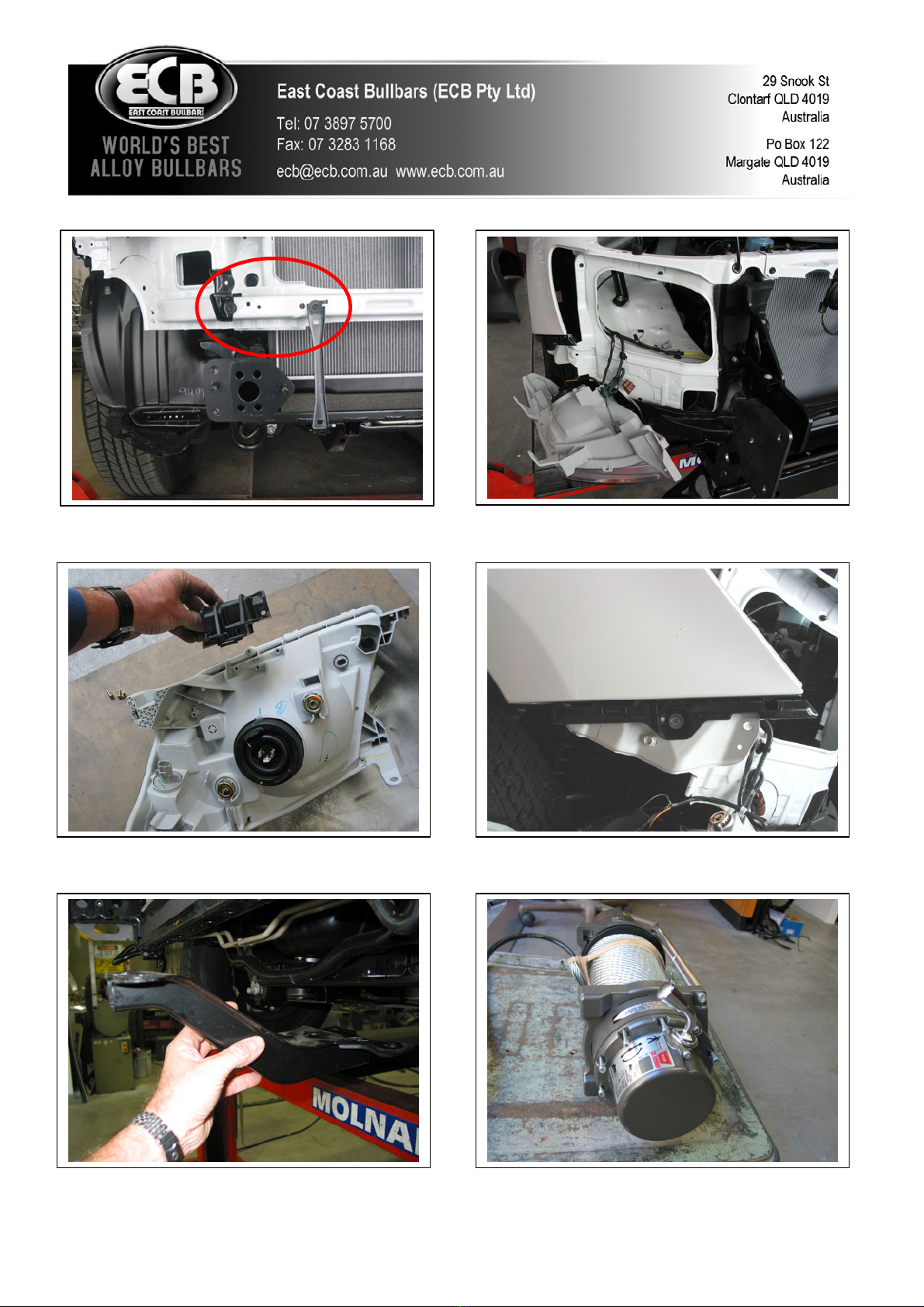

4. Remove steel chassis cross member from front of chassis, four 14mm nuts. See figure 1.

On 4WD models:Remove two plastic clips from plastic under body guard (each side).

5. On 4WD models trim plastic air deflectors at top of cross member. See figure 2.

6. Remove four bumper cover support brackets from vehicle. See figure 3.

7. Remove headlight / indicator assemblies from vehicle. Three 10mm head self-tappers and one 10mm head bolt.

Disconnect wiring as removing. See figure 4.

8. Remove plastic bumper cover support brackets from bottom of headlights. Two PK screws(per light) See figure5

9. Remove plastic bumper cover side supports from each guard. One 10mm head self-tapper. See figure 6.

10. Connect ECB Quick click indicator / park light wiring harness (supplied) to original wiring loom. Refit headlight

/ indicator assemblies connecting to the other side of the ECB wiring harness. Run ECB wiring harness out from

under headlight ensuring it is clear of all sharp edges and pinch points.

11. Remove steel under guard, four 12mm head bolts. Remove two cross member supports from chassis. See figure

7. Five 14mm head bolts (per support).

12. Rotate gearbox housing on winch if necessary. See figure 8. Remove ten allen head bolts – move housing out

just off spline to rotate.

13. Connect control box cables to winch and sit control box on top of winch.

14. Place winch mounting bracket (supplied) on trolley jack or similar, sit winch and control box in winch mount

with winch slightly toward passenger side. DO NOT BOLT winch to winch mount. See figure 9.

15. Jack up onto chassis just forward of chassis studs – once aligned push back onto chassis studs. Use original nuts

for chassis studs. FINGER TIGHTEN ONLY. See figures 10 and 11.

.© Copyright – ECB Pty Ltd – 2012 1

.© Copyright – ECB Pty Ltd – 2012 2

16. Refit two original cross member supports over winch mount. Use four M10 x 35 x 1.25 bolts, flat and spring

washers (supplied) for winch mount. See figure 12. Ensure 10mm holes on winch mount are aligned with middle

chassis hole. TIGHTEN FOUR ORIGINAL NUTS ON STUDS FIRST – THEN TIGHTEN ALL CROSS

MEMBER BOLTS.

17. Refit steel under guard.

18. Slide winch into position, insert top winch captive nuts, then bolt winch in place with top bolts only. Use 3/8 x

1¼ winch bolts with flat and spring washers (supplied). FINGER TIGHTEN ONLY. NOTE: Ensure any air

conditioning lines etc are clear of winch.

19. Fit control box bracket (supplied) to inside of winch mount. Use M8 x 30 bolts, nuts and washers (supplied)

FINGER TIGHTEN ONLY. NOTE: Attach motor earth lead to one of M8 x 30 bolts – Ensure good earth

contact.

20. Bolt control box to control box bracket. NOTE: Standard control box will require the 95x 50x6 spacer plate to

be positioned between control box and control box bracket. Use original nuts with four ¼ flat washers (supplied)

for each side of control box bracket and spacer. TIGHTEN ALL BOLTS AND NUTS Ensure all winch cables

are positioned to avoid any rubbing etc.

21. Centralise winch ensuring all clearances around winch are sufficient, insert lower captive nuts into winch. Align

lower captive nuts, then TIGHTEN top winch bolts.

22. Feed winch cable through winch mount. Fit roller fairlead over winch cable and bolt to winch. Use 3/8 x 1½

winch bolts with flat and spring washers (supplied). Align roller fairlead. TIGHTEN BOLTS.

23. Wire winch to battery as per winch instructions. Check winch for correct operation.

24. Place 3/8 x 4 bolt with flat washer (supplied) through 10mm hole in steel mounting bracket. Slide 52mm long

pipe chassis spacer (supplied) over bolt. See figure 13. Fit steel mounting bracket to chassis with pipe spacer

into middle chassis hole and insert through winch mount. See figure 14. Use 3/8 nut, flat and spring washers

(supplied) FINGER TIGHTEN ONLY.

25. Fit M12 x 35 x 1.25 bolt, flat and spring washers (supplied) and M8 x 30 bolt, flat and spring washers (supplied)

into captive nuts in chassis. FINGER TIGHTEN ONLY. See figure 15. Fit 3/8 x 1½ bolts, nuts and washers

(supplied) from winch mount to steel mounting brackets. See figure 16.

26. Tighten M12 x 35 x 1.25 bolts firm only. Level steel mounting brackets off front edge. See figure 17.

TIGHTEN ALL BOLTS / NUTS (as per the below sequence) ensuring steel mounting brackets remain

centralised with vehicle and are correct distance apart for alloy protection bar to mount on outside of steel

mounting brackets.

Mount bolt tighten sequence:

a) TIGHTEN M12 x 35 bolts first.

b) TIGHTEN 3/8 x 4 bolt/nut FIRM ONLY

c) Align steel mounting brackets level at sides and with enough distance apart for protection bar to mount on

outside of steel mounting brackets. See figure 18. TIP: Tighten 3/8x 1½ bolt/nut firm only then tap mounts into

position.

d) TIGHTEN 3/8 x 1 ½ bolts and nuts from winch mount to steel mounting bracket.

e) TIGHTEN 3/8 x 4 bolts/nuts.

f) TIGHTEN M8 x 30 bolts.

27. Use four 3/8 x 1¼ bolts, nuts and washers (supplied) for extra holes in front of chassis. See figure 19.

TIGHTEN.

.© Copyright – ECB Pty Ltd – 2012 3

28. Fit ECB LED indicator / park lights (supplied) into protection bar as per instructions supplied with the LED

indicator kit. NOTE: Ensure park light is to outside. See figure 20.

29. Attach ECB 6mm clip lock trim to centre section of protection bar and centre cut out of skirt. See figures 21 and

22.

30. Attach ECB infill trims (supplied) to protector bar. Use M6 nyloc nuts and flat washers (supplied) FINGER

TIGHTEN ONLY. See figure 23.

31. Fit ECB protection bar to outside of steel mounting brackets. Use ½ x 1 ¾ bolts, nuts, flat and spring washers

(supplied). FINGER TIGHTEN ONLY.

32. Align ECB protection bar with vehicle ensuring a gap of 10 to 12mm between protection bar and guard / flare at

sides. See figure 24 for side view and figure 25 for front view TIGHTEN ALL BOLTS. Impact wrench access

is from grille area. NOTE: A 10mm to 12mm gap each side is critical to allow for body/chassis twist in rough

terrain.

33. Connect indicator / park light wiring and CHECK OPERATION.

34. Carefully drill three 3/16 holes in lower lip on grille, one in centre and one each side, refit grille to vehicle. Zip

tie bottom of grille to head light / indicator assemblies and to steel bracket in centre. See figures 26 and 27.

35. Align ECB infill trims with vehicle and protection bar. TIGHTEN NUTS FIRM ONLY – DO NOT

OVERTIGHTEN.

36. Fit ECB inner guard bracket (supplied) to lower radiator support using one 10mm head bolt from lower bumper

mounts to radiator support and one M6x20 bolt, washer and nyloc nut (supplied)per side. See figure 28. Secure

outer hole in liner to inner guard bracket with bolt supplied M6 x 20 bolt, washers and nyloc nuts (supplied).

Then secure second hole in inner guard bracket to liner with M6 x 20 bolt , washer and nyloc nut (supplied),

ensure this is not pulled to tight as it may cause liner to tear. TIGHTEN bolts and trim any excess liner off. On

passenger side ensure washer bottle stays covered after trim. See figure 29.

ENSURE NUMBER PLATE IS CLEARLY VISABLE

Note: When fitting/refitting the licence plate to the vehicle, ensure there is no obstruction to licence plate vision in

accordance with local authorities. If required relocate licence plate to an alternate location.

Further VFPS Notes:

a) Do not attach VFPS to the vehicle using anchorages not intended for this purpose (e.g. engine mounting bolts).

b) Do not use this product for any vehicle make or model, other than those specified by the VFPS manufacturer.

c) Do not remove the plaque or label from the VFPS.

d) Do not modify the structure of the VFPS in any way.

e) No accessory or fitment should project forward of the VFPS forward profile.

f) ENSURE THESE INSTRUCTIONS ARE LEFT WITH VEHICLE OWNER AND/OR OPERATOR.

IMPORTANT INFORMATION

Periodically check bolts and nuts for correct tightness, especially if travelling on rough roads

FITTING KIT

1 – Pair steel mounting brackets 10 – 3/8 nuts

1 – steel winch mounting bracket 6 – ½ x 1 ¾ bolts

1 – Steel control box mount 14 – ½ flat washers

2 – Steel inner guard brackets 8 – ½ spring washers

1 – 95 x 50 x 6 steel spacer plate (two 10mm holes) 6 – ½ nuts

2 – 10nb tube spacer, 52mm long 4 – ¼ flat washers

2 – M12 x 35 x 1.25 bolts 6 – M6 x 20 bolts

4 – M10 x 35 x 1.25 bolts 18 – M6 flat washers

4 – M8 x 30 x 1.25 bolts 12 – M6 nyloc nuts

6 – M8 flat washers 1 – Pair ECB Hilux infills (IC11LUXINFL)

4 – M8 spring washers 1 – ECB indicator park light kit

2 – M8 nuts 1 – Quick Click Indi / Park kit (IC11HILLED100H)

2 – 3/8 x 4 bolts 1 – 1100mm length, 6mm clip lock trim

4 – 3/8 x 1 ½ bolts 1 – 700mm length , 6mm clip lock trim

6 – 3/8 x 1 ¼ bolts 6 – 300mm zip ties

24 – 3/8 flat washers 6 – 150mm zip ties

18 – 3/8 spring washers

Remove cross member

.© Copyright – ECB Pty Ltd – 2012 4

Figure 1 Figure 2: Trim lower section from air dam.

Passengers side shown.

.© Copyright – ECB Pty Ltd – 2012 5

Figure 4 – Remove headlight

Figure 3 – Drivers side shown

Figure 6 - Remove plastic bumper support from

under guard.

Figure 5 – Removing trim from lower headlights

Figure 7 Figure 8

.© Copyright – ECB Pty Ltd – 2012 6

Figure 13

Figure 11

Figure 9 Figure 10

Figure 12

Figure 14 - Finger tighten only at this time

.© Copyright – ECB Pty Ltd – 2012 7

Figure 15 Figure 16

Stainless steel self-tappers

Figure 18

Figure 17

Figure 20

Figure 19

Attach 6mm cli

p

lock trim

Attach 6mm clip lock trim

Note: Non winch bar shown

Figure 22

Figure 21

.

Figure 23 Figure 24

.© Copyright – ECB Pty Ltd – 2012 8

Figure 25 Figure 26 – Centre grille attach point

.© Copyright – ECB Pty Ltd – 2012 9

Figure 27 – Side grille attachment point. Drivers

side shown.

Figure 28 –Drivers side shown

Figure 29 –Passengers side shown

We value your comments

Dear Fitter,

ECB would like to know how you went with the installation of this product. We value your comment and may need to

contact you to clarify some details so please complete your contact details clearly.

We would appreciate if you could complete as many of the following details as possible.

Your Name:

Your contact No.

Product Part No.

Product Invoice No.

Product Description:

Make, model, and year of vehicle:

Product Work Order No.

Company your from/Company product purchased from:

Date of Fitment: ____/____/____

Yes No

Was the fitting hardware supplied complete?

If no what was not supplied

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

Yes No

Did the installation go well?

Please provide comments

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

Please draw diagrams if you need to.

Post to Fax to

Reply Paid 122 (07) 3283 1168

PO Box 122

Margate QLD 4019

.© Copyright – ECB Pty Ltd – 2012 10

DESPATCH CHECKLIST

BT128SY

Work Order #

Finish:

Transport:

Due Date:

See other side of

this page for

photos of all

mounts

O1 – Pair steel mounting brackets (pair)

O1 – Winch mounting bracket

O1 – Control box bracket

O2 – Steel inner guard brackets

O2 – 90 x 50 x 6 steel spacer plate

O1 – Bolt kit

O1 – 1100mm length, 6mm clip lock trim

O1 – 700mm length, 6mm clip lock trim

O1 – ECB LED Indicator / Park light kit.

O1 – Pair Hilux infill trims. (IC11LUXINFL)

O1 – Quick Click Indi / Park kit (IC11HILLED100H)

O2 – ECB overriders – Fitted to bar.

O5 – 6mm air scoops – Fitted to bar.

All parts checked and completed by:

Is this product “the best it can be” Yes ______/______

Wrapper’s initials / Checker initials

If NO fix before continuing

Nut and bolts: __________________________Date__/__/__

Order control: __________________________Date__/__/__

Final wrap check: __________________________Date__/__/__

.© Copyright – ECB Pty Ltd – 2012 11

.© Copyright – ECB Pty Ltd – 2012 12

3 BOLTS

Infill Trims - ICHILINFIL

Table of contents

Other ECB Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction