ECD DO82 Operating and maintenance manual

HYDRA-DS NO3 –Rev A

INSTRUCTIONAL MANUAL

HYDRA-DS NITRATE ANALYZER

HYDRA-DS NO3-N Page 1

PREFACE

Purchasing products from Electro-Chemical Devices, Inc. provides you with the finest liquid analytical instrumentation

available. If this is your first purchase from ECD, please read the entire manual before installing and commissioning your

new equipment.

Manuals are accessible on the ECD website at https://ecdi.com/product-literature/manuals/.

If there are any questions concerning this equipment, please contact your local ECD representative, or the factory

directly at:

Electro-Chemical Devices, Inc.

1500 Kellogg Dr.

Anaheim, CA 92807 USA

Telephone: +1-714-695-0051

FAX: +1-714-695-0057

Website: www.ecdi.com

HYDRA-DS NO3-N Page 2

SYMBOLS USED IN MANUAL

This symbol is used to designate important information, warnings and cautions. Failure

to follow this information could lead to harm to the instrument or user.

No operator serviceable parts, service by authorized service personnel only.

This symbol is used to designate a WARNING “Risk of Electrical Shock”

Disconnect supply before servicing

Equipment protected throughout by double insulation.

Contents of this manual are believed to be correct at the time of printing and are subject to change without notice. ECD

is not responsible for damage to the instrument, poor performance of the instrument or losses resulting from such, if

the problems are caused by:

•Incorrect operation by the user.

•Use of the instrument in incorrect applications.

•Use of the instrument in an inappropriate environment or incorrect utility program (power supply).

•Repair or modification of the related instrument by anyone not authorized by ECD.

•There are no operator accessible parts. Service and maintenance to be done by authorized personnelonly.

•If the equipment is used in a manner not specified by the manufacturer, the protection provided by the

equipment may be impaired.

Read the complete manual before installing or using the equipment.

© 2019 Electro-Chemical Devices, Inc. All rights reserved. No part of this manual may be used or reproduced in any

form or by any means, or stored in a database or retrieval system without prior written permission from Electro-

Chemical Devices, Inc. Making copies of any part of this manual for any purpose other than personal use

HYDRA-DS NO3-N Page 3

TABLE OF CONTENTS

Preface........................................................................................................................................................1

Symbols Used in Manual ............................................................................................................................2

Terms and Conditions of Sale.....................................................................................................................6

Return Goods Policy ...................................................................................................................................8

Unpacking the Instrument .........................................................................................................................9

1.0 General Description............................................................................................................................10

1.0.0 Description................................................................................................................................10

1.0.1 Chloride Ion Compensation ......................................................................................................10

1.0.2 Optional pH or Ammonium Measurement...............................................................................10

1.0.3 Temperature Compensation.....................................................................................................10

1.0.4 Cleaning and Maintenance .......................................................................................................10

1.1 Features ..........................................................................................................................................11

1.2 HYDRA-DS Sensor Specifications.....................................................................................................11

1.2.1 Measurement Range ................................................................................................................11

1.2.2 Operating Temperature............................................................................................................11

1.2.3 Min/Max Flow Rate by the sensor............................................................................................11

1.2.4 Wetted Materials......................................................................................................................11

1.2.5 Accuracy....................................................................................................................................11

1.2.6 Response Time..........................................................................................................................11

1.2.7 Electrode Life ............................................................................................................................11

1.3 Hydra Dimensional Drawing ...........................................................................................................12

1.3.1 Parts List:...................................................................................................................................12

1.4 T80 Transmitter Specifications........................................................................................................13

1.6 LQ800 Controller Specifications......................................................................................................14

2.0 Installation..........................................................................................................................................15

2.1 Unpacking........................................................................................................................................15

2.2 Assembly .........................................................................................................................................15

2.2.1 Spray Cleaner............................................................................................................................15

HYDRA-DS NO3-N Page 4

2.2.2 Immersion/Support Tube .........................................................................................................15

2.3 Mounting.........................................................................................................................................16

2.3.1 HYDRA Sensor Mounting ..........................................................................................................16

2.3.2 T80 Analyzer Mounting.............................................................................................................16

2.3.3 LQ800 Controller Mounting......................................................................................................18

2.4 Wiring..............................................................................................................................................19

2.4.1 HYDRA-DS to T80 Transmitter ..................................................................................................19

2.4.2 HYDRA-DS to LQ800 Controller.................................................................................................20

2.4.3 T80 Transmitter Wiring.............................................................................................................20

2.4.4 LQ800 Wiring ............................................................................................................................24

3.0 Operation ...........................................................................................................................................27

3.1 T80 Transmitter...............................................................................................................................27

3.2 LQ800 Controller.............................................................................................................................27

3.2.1 Screens......................................................................................................................................27

3.2.2 Menu Structure.........................................................................................................................27

3.2.3 Start Up Guide ..........................................................................................................................28

4.0 Calibration ..........................................................................................................................................29

4.0.1 Recommended Materials..........................................................................................................29

4.0.2 Temperature Calibration ..........................................................................................................30

4.0.3 Single Point Calibration.............................................................................................................30

4.0.4 Two Point Calibration ...............................................................................................................31

4.0.5 Chloride Ion Compensation ......................................................................................................31

4.1 Calibration –T80 Transmitter .........................................................................................................31

4.1.1 AUTO Calibration Description...................................................................................................31

4.1.2 STANDardize Calibration Description .......................................................................................32

4.1.3 MANUAL Calibration Description .............................................................................................32

4.2 Calibration –LQ800 Transmitter.....................................................................................................32

4.2.1 AUTO Calibration Description...................................................................................................32

4.2.2 STANDardize Calibration Description .......................................................................................33

HYDRA-DS NO3-N Page 5

4.2.3 MANUAL Calibration Description .............................................................................................33

4.2.4 CAL (Calibration Menu).............................................................................................................33

5.0 Maintenance ......................................................................................................................................34

5.1 Maintenance Schedule....................................................................................................................34

5.2 Cleaning the Sensor ........................................................................................................................34

5.3 Replacing the Electrodes.................................................................................................................34

6.0 Troubleshooting .................................................................................................................................35

7.0 Engineering Documentation ..............................................................................................................36

7.1 Specifications ..................................................................................................................................36

7.1.1 Sensor .......................................................................................................................................36

7.1.2 T80 Transmitter ........................................................................................................................36

7.1.3 Model Codes .............................................................................................................................38

7.2 Installation ......................................................................................................................................39

7.2.1 Mounting ..................................................................................................................................39

7.2 HYDRA-DS Sensor Dimensional Drawing ........................................................................................40

8.0 Ordering Information .........................................................................................................................41

8.1 Part Numbers/Model Numbers ......................................................................................................41

8.2 Accessories......................................................................................................................................41

8.3 Calibration Solutions .......................................................................................................................41

8.4 Spare Parts ......................................................................................................................................41

Appendix ..................................................................................................................................................42

A. Auto Cal Buffer Tables ......................................................................................................................42

B. T80 HART Menu ................................................................................................................................42

C. MODBUS RTU Register Listing ..........................................................................................................43

HYDRA-DS NO3-N Page 6

TERMS AND CONDITIONS OF SALE

1. ACCEPTANCE. If this writing differs in any way from the terms and conditions of Buyer's order or if this writing is construed as

an acceptance or as a confirmation acting as an acceptance, then Seller’s acceptance is EXPRESSLY MADE CONDITIONAL ON

BUYER’S ASSENT TO ANY TERMS AND CONDITIONS CONTAINED HEREIN THAT ARE DIFFERENT FROM OR ADDITIONAL TO

THOSE CONTAINED IN BUYER'S WRITING. Further, this writing shall be deemed notice of objection to such terms and

conditions of Buyer. If this writing is construed as the offer, acceptance hereof is EXPRESSLY LIMITED TO THE TERMS AND

CONDITIONS CONTAINED HEREIN. In any event, Buyer's acceptance of the goods shall manifest Buyer's assent to Seller's

terms and conditions. No addition to or modification of these terms will be effective, unless set forth in writing and agreed to

by Seller.

2. WARRANTIES AND REMEDIES

a. Warranty. Seller warrants to Buyer that it holds and will pass marketable title to the goods sold hereunder. Seller

warrants to Buyer that the items and components manufactured by Seller will be free from defects in material and

workmanship (subject, however, to tolerances and variances permitted by the trade hereunder) for a period one (1) year

for non-consumable products. Consumable electrodes and sensors have a conditional warranty based shelf life and

process conditions and is determined by Seller.

b. Exclusion and Conditions. Seller’s obligations with respect to the express warranties and remedies contained herein are

conditioned on the following: (i) Buyer's return of the non-conforming goods, if authorized by Seller: (ii) Buyer shall not

assign its rights under these express warranties and any attempted assignment shall render such warranties, but not any

disclaimers or limitations, void and the goods sold shall be sold AS IS; and (iii) all products shall be carefully inspected for

damage by Buyer upon receipt, be properly calibrated for Buyer's particular use, and be used, repaired, and maintained by

Buyer in accordance with the instructions set forth in Seller’s product literature. Repair and maintenance by non-qualified

personnel, product subjected to misuse or negligence, and/or damaged during shipment will invalidate the warranty, as

will the use of non-approved consumables or spare parts. As with any other sophisticated product, it is essential, and a

condition of Seller’s warranty, that all personnel using the product be fully acquainted with its use, capabilities and

limitations as set forth in the applicable product literature.

3. DISCLAIMER OF IMPLIED WARRANTIES. Seller gives no warranties except those expressly contained herein. Seller disclaims

all other warranties implied by law usage of the trade, course of dealing or course of performance including, but not limited

to, the implied warranties of MERCHANTABILITY and fitness for a particular purpose.

4. LIMITATIONS OF LIABILITY. The following limitations of Seller's liability are acknowledged by the parties to be fair and

reasonable and shall apply to any act or omission hereunder, and to any breach of this contract of which these terms and

conditions form a part:

a. Disclaimer of Damage. In no event shall Seller be liable for special, indirect, consequential or incidental damages whether

arising under contract, warranty, tort, strict liability or any other theory of liability. Such damages include but are not

limited to loss of profits, loss of use of goods, damage to property, and claims of third parties.

b. Suitability. Buyer acknowledges that it alone has determined the intended purpose and suitability of the goods sold

hereunder. It is expressly agreed by the parties that any technical or other advice given by the Seller with respect to the

use of the goods or services is given without charge and at Buyer's risk; therefore Seller assumes no obligation or liability

for the advice given or results obtained.

c. Notice and Time of Claims.

i. Buyer agrees to check and inspect all products against shipping papers and for damage or shortage upon receipt of

goods at destination.

ii. Every claim for shortage, damage in transit, or other cause visible upon inspection shall be deemed waived by the

Buyer, or the Buyer’s customer in the case of resale, unless delivered in writing to Seller by Buyer thirty (30) days from

the tender of delivery of the goods to Buyer, provided, however, that claims for shortage must be made within seven

(7) days of receipt.

iii. The parties expressly waive the statute of limitations and agree that any legal proceeding for any breach of this

contract shall be waived unless filed within one (1) year after the accrual of the cause of action thereof.

HYDRA-DS NO3-N Page 7

5. FORCE MAJEURE. Seller shall not be liable for any delay in delivery, or failure to deliver, due to any cause beyond the Seller’s

control including but not limited to fires, floods, or other forces of the elements; strikes, or other labor disputes; accidents to

machinery; acts of sabotage; riots; precedence or priorities granted at the request or for the benefit, directly or indirectly of

the federal or any state government or any subdivision or agency thereof; delay in transportation or lack of transportation

facilities; restrictions imposed by federal, state or other governmental legislation or rules or regulations thereof. If Seller, in

its sole discretion, determines that Seller’s performance hereunder would result in a loss to Seller’s on this sale as computed

under Seller’s normal accounting procedures because of causes beyond Seller's control, then the Seller may terminate this

agreement in whole or in part without liability for any delay in the delivery of, or failure to deliver, the goods sold hereunder

6. TAXES AND OTHER CHARGES. The Buyer will pay, or reimburse Seller if it pays, any and all taxes or tariffs or any other similar

charges imposed upon this contract, the goods covered hereby or the delivery or use or resale thereof.

7. FREIGHT CHARGES. If the sale hereunder is other than F.O.B. Seller's facility, this acknowledgement is based upon the freight

charges now in effect. In the event of an increase or decrease in applicable freight charges before the goods are shipped,

such charge in freight will be for the Buyer's account.

8. PRICES AND DELIVERY. Prices quoted herein are F.O.B. shipping point. Deliveries specified are only our best estimate and are

subject to change. This quotation is based upon freight charges now in effect. Buyer will be invoiced at the freight charge

prevailing at the date of shipment. Prices are firm for orders meeting Seller's normal shipping schedules. If shipments are

held or postponed for any reason other than Seller's fault, and a price increase becomes effective during the period of such

hold or postponement, the increase will apply to all shipments that are held or postponed thirty (30) days or more from the

effective date of the increase.

9. PAYMENTS. If in the judgment of Seller the financial condition of Buyer at any time prior to shipment does not justify the

terms of payment specified, Seller may cancel the order, withhold shipment, and/or require full or partial payment in

advance. If payment is not made when due, Seller may suspend all future delivery or other performance with respect to

Buyer without liability or penalty and, in addition to all other sums payable hereunder, Buyer shall pay to Seller (i) the

reasonable costs and expenses incurred by Seller in connection with all actions taken to enforce collection or to preserve and

protect Seller’s rights hereunder, whether by legal proceedings or otherwise, including without limitation reasonable

attorneys’ fees, court costs and other expenses and (ii) interest on all amounts unpaid after 30 days charged at the monthly

rate of 1-1/2% or the highest rate permitted by law, whichever is lower.

10. CANCELLATION OR ALTERATION. Buyer may not alter or cancel any order without Seller’s written consent. For any order

altered or cancelled with Seller's consent, Buyer must pay for all expenses and labor incurred up to the time of Seller’s

consent, plus a reasonable percentage for profit. Any order delayed or deferred by Buyer will be subject to price escalation

for increased costs of production, and any other expenses caused by the delay. Material on such orders will be stored at

Buyer's risk. Seller reserves the right to invoice Buyer and require payment before shipment of any delayed or deferred order.

11. TITLE AND RISK OF LOSS. Title and risk of loss shall pass to buyer at Anaheim, California, unless otherwise specified in the

contract. If delivery is made by common carrier, risk of loss shall pass upon delivery to the carrier. Claims for loss or damage

in transit must be made by Buyer to the carrier. Seller accepts no responsibility for loss or damage to product in transit.

12. PATENT OR TRADEMARK INFRINGEMENT. If the goods sold hereunder are to be prepared for manufacture according to

Buyers specification, Buyer shall indemnify Seller against any claim or liability for patent, trademark, service mark or trade

name infringement on account of preparation, manufacture and/or sale.

13. NON-WAIVER. If Government Contract Regulations require the addition, deletion, or modification of these terms and

conditions upon prior notification to Seller and Seller's written acceptance thereof, such changes shall become a part of these

terms and conditions. Seller shall not be bound by any Government Contract Regulations applicable to Buyer’s contracts with

the U.S. Government unless Buyer has expressly acknowledged, on the face of this document, the applicability of such

Regulations to the transaction between Buyer and Seller contemplated herein. Absent such acknowledgement, Seller is

making the assumption in issuing this document that no such Regulations apply.

14. JURISDICTION. All such disputes shall be resolved in a court of competent jurisdiction in Orange County, California. Buyer

hereby consents to the jurisdiction of the State and Federal Courts sitting in Orange County. Notwithstanding the above,

should either party contest the jurisdiction of such courts, the other party may institute its suit in any court of competent

jurisdiction.

15. APPLICABLE LAW. All questions arising hereunder or in connection with the quotations or any order submitted in connection

therewith and/or the performance of the parties hereunder shall be interpreted and resolved in accordance with the laws of

the state of California without regard to its conflict of law provisions and excluding the United Nations Convention on the

International Sale of Goods.

HYDRA-DS NO3-N Page 8

RETURN GOODS POLICY

All requests for returned goods must be initiated through our Customer Service Department. Please call our phone

number (714) 695-0051 with the specifics of your request. The following conditions must be satisfied for consideration

of applicable credit for the return of products purchased from Electro-Chemical Devices:

1) The item is unused and in the original package.

2) The item was shipped directly from Electro-Chemical Devices.

3) The item has not been damaged in shipment to Electro-Chemical Devices.

4) Items containing date-sensitive parts such as electrodes, must be returned within 1 month of the invoiced date.

5) Items without date-sensitive parts must be returned within 3 months of the invoiced date.

A Return Merchandize Authorization Number must be obtained from Customer Service and be provided on all

paperwork and packaging. To obtain a Return Merchandize Authorization Number, please provide the reason for return,

the date of purchase, your original purchase order number, and either our order number or our invoice number. The

issuance of a Return Merchandize Authorization Number is a verbal approval for return only and does not guarantee

credit or allowance. Returned goods must be received within 30 days of the issuance date of the Return Merchandize

Authorization Number or it will become null and void.

Necessary physical and mechanical inspection is completed upon receipt of the item. Applicable credit or equivalent

allowance is determined after inspection of the returned item. If all of the above conditions are met, and the item has

been approved to return to our stock, a restocking charge of 25% of the purchase price is deducted from the applicable

credit.

HYDRA-DS NO3-N Page 9

UNPACKING THE INSTRUMENT

Your Electro-Chemical Devices instrument has been carefully packaged to protect it from damage during shipment and

dry storage. Upon receipt please follow the procedure outlined below.

1. Before unpacking, inspect the condition of the shipping container to verify proper handling by the carrier.

If damage is noted, save the shipping container as proof of mishandling for the carrier.

2. Check the contents of the shipping container with the items and quantities shown on the packing list.

Immediately report any discrepancies to ECD.

3. Save the original packing material until you are satisfied with the contents. In the event the product(s)

must be returned to ECD, the packing material will allow you to properly ship it to ECD.

4. Familiarize yourself with the instrument before installation, and follow proper installation and wiring

procedures.

WARNING Electrical installation must be in accordance with the National

Electrical Code (ANSI/NFPA-70), Canadian Electrical Code and/or any other

applicable national or local codes.

Installation and Wiring

Failure to follow the proper instructions may cause damage to this instrument and warranty invalidation. Use only

qualified personnel to install, operate and maintain the product.

The Model DO82 Sensor should only be used with equipment that meets the relevant IEC, American or Canadian

standards. ECD accepts no responsibility for the misuse of this unit.

HYDRA-DS NO3-N Page 10

1.0 GENERAL DESCRIPTION

1.0.0 DESCRIPTION

The HYDRA-DS Nitrate Analyzer measures the concentration of dissolved nitrate ion as nitrogen (NO3-N) in water. The

sensor uses two electrodes to determine the NO3-N concentration, a Nitrate Ion Electrode, and a Chloride Ion Electrode.

An optional pH or Ammonium electrode is available for additional process information. It is designed for use in all kinds

of water. Typical applications include monitoring environmental waters, lakes, streams, and wells as well as wastewater

treatment in aeration basins, sludge digesters, and effluent.

1.0.1 CHLORIDE ION COMPENSATION

The Nitrate Ion Electrode provides the primary measurement. Any Chloride ion in the sample, due to its similar size,

and charge to the Nitrate ion, causes a positive interference in the measurement. The Chloride Ion Electrode measures

the amount of chloride ion present in the sample and HYDRA-DS Analyzer subtracts the appropriate amount of signal

from the Nitrate Measurement.

1.0.2 OPTIONAL PHOR AMMONIUM MEASUREMENT

An optional pH or ammonium electrode is available in the HYDRA-DS NO3 sensor providing additional information about

the process solution. The HYDRA-DS Analyzer provides an additional 4-20 mA output to transmit this information.

1.0.3 TEMPERATURE COMPENSATION

Temperature is also measured and used to compensate each of the three electrode measurements. While the pH

electrode response is well defined with respect to temperature, the ion electrode tends to be less well behaved. For

the best results calibrate the sensors near the process temperature.

1.0.4 CLEANING AND MAINTENANCE

The HYDRA-DS Nitrate Analyzer is configured to periodically actuate a cleaning cycle using the integral spray cleaner in

the sensor. The period and duration of the cleaning cycle is user configurable. The 4-20 mA output is held at either the

last value or a preset value during the cleaning. This minimizes the formation biofilms or other coatings on the

electrodes keeping maintenance to a minimum.

The rugged HYDRA-DS sensor has a 1 ¼” NPT rear facing thread for attaching an extension/immersion tube for easy

installation from catwalks or handrails. The HYDRA-DS sensor is submersible with an IP68 degree of ingress protection.

A removable electrode guard facilitates easy electrode replacement when necessary. The HYDRA-DS sensor features

internal signal conditioning that allows the sensor to be mounted up to 200 meters from the analyzer.

HYDRA-DS NO3-N Page 11

1.1 FEATURES

Separate, economical, easily replaceable Nitrate, Chloride, and optional pH electrodes

Fast and Accurate Nitrate Measurement NO3 or NO3-N

Automatic compensation for Cl interference

Temperature compensated NO3-N measurement

Rugged PVC design with removable electrode guard for easy maintenance

Integral Spray Head Cleaner

oCleans sensor in situ with turbulence caused by pressurized air

Internal Signal Conditioning allows up to 200 meters between Sensor and Analyzer

1.2 HYDRA-DS SENSOR SPECIFICATIONS

Three Electrode System with spray cleaner

Nitrate ISE (NO3-N) is the primary measurement

Chloride ISE is used for compensation of the NO3signal

Optional pH or NH4+electrode

The Sensor is waterproof with an ingress rating of IP68

1.2.1 MEASUREMENT RANGE

NO3-N

0.1 to 1000 ppm

Cl

0.1 to 10,000 ppm

pH

2-12 ph

NH4+

0.1 to 1000 ppm

1.2.2 OPERATING TEMPERATURE

0 °C to 40 °C (32 °F to 104 °F)

1.2.3 MIN/MAX FLOW RATE BY THE SENSOR

Minimum 0.1 m/s

Maximum 3.0 m/s

1.2.4 WETTED MATERIALS

PVC, PEC, PVDF, PTFE, Viton, Glass, 316 SS

1.2.5 ACCURACY

± 3% of reading, dependent on Calibration

1.2.6 RESPONSE TIME

T90 approximately 1 minute

1.2.7 ELECTRODE LIFE

ISEs: 4-6 months, typical

pH electrode: 6-12 months, typical

HYDRA-DS NO3-N Page 12

1.3HYDRA DIMENSIONAL DRAWING

1.3.1 PARTS LIST:

HYDRA-DS Sensor with Electrodes, Calibration Cap

30’ of ¼” air tubing, Electrode Removal Tool

HYDRA-DS NO3-N Page 13

1.4 T80 TRANSMITTER SPECIFICATIONS

The ECD Model T80 transmitter is an intelligent single or dual channel multi-parameter transmitter designed for the

online continuous measurement of pH, ORP, pION, conductivity, resistivity, or Dissolved Oxygen in a general purpose

industrial environment. The Model T80 transmitter digitally communicates with any ECD S80 digital sensor. The

measurement identity is contained in the sensor’s memory. Then an S80 sensor is connected to the transmitter it

automatically configures the transmitter’s menus and display screens to the measured parameter.

The Model T80 transmitter can be loop powered, 24 VDC powered, or 100-240 VAC line powered. The standard

configuration has a 4-20 mA output and an RS485 serial communication port with MODBUS®RTU output. A HART®

communication version (single channel version only) is also available. Alarm relays are optionally available on either

line powered transmitter.

Features:

Multi-Parameter, pH, ORP, Specific Ion, Dissolved Oxygen, Conductivity, Resistivity

Simple, user friendly menu structure

Noise free digital communication with sensor

Reads and writes calibration data to sensor

Dual Channel option has interactive channels, pH compensated reading, and interfering ion corrections

Non-isolated 4-20 mA output and MODBUS® RTU standard, optional HART®

HYDRA-DS NO3-N Page 14

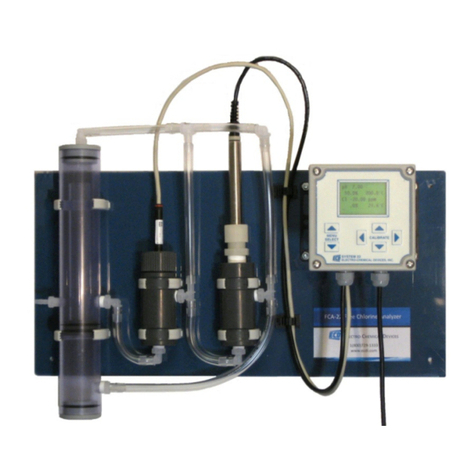

1.6 LQ800 CONTROLLER SPECIFICATIONS

The ECD LQ800 transmitter is a one to eight channel, intelligent, multi-parameter transmitter designed for the online

continuous measurement of pH, ORP, pION, dissolved oxygen, conductivity, resistivity, turbidity, flow, level, and many

others in carrying configurations for a given application. The Model LQ800 Controller digitally communicates with any

ECD DS80 digital sensor, automatically configuring the transmitter’s menus and display screens to the measured

parameter.

The Model LQ800 Controller can be 24 VDC powered or 100-240 VAC line powered. Available options include, (8) 4 to

20 mA outputs, (8) configurable Relays (for Alarm, activated timers, control, and Fault), and Ethernet communication.

Features:

Multi-Parameter, pH, ORP, Specific Ion, Dissolved Oxygen, Conductivity, Resistivity, Turbidity, Flow, and Level

Simple, user friendly menu structure

Noise free digital communication with sensors

Reads and writes calibration data to sensor

Multi-channel option has interactive channels, pH compensated readings, interfering ion corrections

Non-Isolated 4-20 mA output and Ethernet

HYDRA-DS NO3-N Page 15

2.0 INSTALLATION

2.1 UNPACKING

Carefully remove the HYDRA-DS sensor from its shipping container. Inspect the sensor for damage. Verify the

electrodes, Ammonium, Potassium, and pH and the Spray Cleaner Nozzle are installed in the sensor housing. The

electrodes should be hand tightened into place so that the sealing o-rings are not visible. The electrodes are supplied

with protective caps that must be removed before start up. Do not remove the caps until ready to use.

***Never support the HYDRA-DS Sensor by the cable, irreparable damage will occur***

2.2 ASSEMBLY

The Hydra-DS Sensor is shipped completely assembled. Before use, it must be connected to the analyzer and an air

supply. Connect the spray cleaner feed tube to a compressed air supply controlled by a solenoid valve (not supplied).

Attach an immersion/support tube (not supplied). Finally connect the sensor wires and 110 VAC power to the analyzer

as shown on the wiring diagram. Connect the Cleaner Relay to the solenoid, and connect the 4-20 mA Output(s) and

Alarm Relays to the Control System (PLC or DCS). The HYDRA-DS is then ready to use.

2.2.1 SPRAY CLEANER

The Spray Cleaner uses compressed air to create turbulence around the electrodes which removes dirt and films from

the measurement surfaces. Depending on the process being measured the cleaner should be actuated for 15-30

seconds every 0.25-2 hour period. The spray cleaner connection is a ¼” compression fitting and requires between 35-

75 psi air pressure. The air supply is controlled with a user supplied solenoid valve through Relay 1 in the T80 analyzer.

The solenoid valve should be a 110 AC powered, < 10 watt devices. Wire the solenoid to Relay 1 as described in Section

2.4.4 below.

If no air supply is available use the ECD Model AC10 Air Blast Spray Cleaner compressor. The AC10 uses redundant intake

air filters and redundant fuses on both the relays and the compressor. A highly reliable high current contactor assures

years of trouble free service. The 115 VAC 3.0 Amp or 220 VAC 1.3 Amp Air Compressor is housed in a rugged, corrosion

resistant, hot compression molded, fiberglass reinforced polyester enclosure with a stainless steel piano hinge to secure

the cover to the base. The AC10 can be wall mounted or use the optional 2” handrail mounting system that uses stainless

steel support rails with two 2” galvanized pipe clamps.

***Never support the HYDRA-DS Sensor by the cable, irreparable damage will occur***

2.2.2 IMMERSION/SUPPORT TUBE

Feed the cable and compressed air line through the immersion/support tube (not supplied). Connect a support tube to

the 1 ¼” MNPT thread at the rear of the sensor. The HYDRA-DS Sensor weighs approximately 5.3 lbs. The support tube

must be able to support the weight of the HYDRA-DS Sensor in the user’s installation, whether vertical or angled. The

recommended material for the immersion tube is 1.5” Schedule 80 PVC pipe with a reducer fitting to 1 ¼” FNPT.

HYDRA-DS NO3-N Page 16

2.3 MOUNTING

2.3.1 HYDRA SENSOR MOUNTING

Install the sensor where the measured sample is representative of the entire process. Although the sensor will function

in a quiescent sample, flow improves the measurement. The recommended minimum flow is 0.1 m/sec.

Securely mount the HYDRA-DS sensor with the measuring end at least 6” away from the tank wall and bottom. Ensure

that the sensor is immersed at least 6” at all times.

Use care when servicing the sensor to ensure that the sensor does not hit the tank wall or bottom, which could break

the sensing electrodes.

2.3.2 T80 ANALYZER MOUNTING

Mount the T80 in a location where there is easy access to the analyzer and sensor. Install the system in an area where

vibrations, electromagnetic, and radio frequency interference are minimized or absent. So not mount in direct sunlight

or areas of extreme heat (temperature > 120°F). The IP65 T80 is suitable for outdoor use but it is best to mount it with

a protective cover or sunshield to prevent discoloring over the years.

Universal Mounting Brackets

Rail Mounting

HYDRA-DS NO3-N Page 17

Panel Mounting

Cut Out: 5.35” x (13.6cm x 13.6cm)

HYDRA-DS NO3-N Page 18

2.3.3 LQ800 CONTROLLER MOUNTING

Mount the LQ800 in a location where there is easy access to the analyzer and sensors. Install the system in an area

where vibrations, electromagnetic, and radio frequency interference are minimized or absent. Do not mount in direct

sunlight or areas of extreme heat (temperature > 120°F). The IP65 LQ800 is suitable for outdoor use but it is best to

mount it with a protective cover or sunshield to prevent discoloring over the years.

Universal Mounting Brackets

HYDRA-DS NO3-N Page 19

2.4 WIRING

2.4.1 HYDRA-DS TO T80 TRANSMITTER

This manual suits for next models

3

Table of contents

Other ECD Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

HP

HP Q METER 4342A Operating and service manual

Fineco Electric

Fineco Electric PM835 user manual

WAGNER

WAGNER FORCE DIAL FDL Series Operation manual

Rohde & Schwarz

Rohde & Schwarz RT-ZC30 user manual

AEMC instruments

AEMC instruments Simple Logger AmpFlex AL24-2500 user manual

AR

AR DC7164 Operating and service manual