2X7502026702

© 4/2013 ECHO Inc.

TABLE OF CONTENTS SHC-266

TABLE OF CONTENTS

Table of contents ............................................................................................................................... 2

Introduction ........................................................................................................................................ 3

The Operator’s Manual ................................................................................................................ 3

The Safety Manual....................................................................................................................... 3

Servicing information ......................................................................................................................... 3

Parts/Serial Number..................................................................................................................... 3

Service......................................................................................................................................... 3

Echo Consumer Product Support ................................................................................................ 3

Warranty Registration .................................................................................................................. 3

Additional or Replacement Manuals ............................................................................................ 4

Safety................................................................................................................................................. 4

Manual Safety Symbols and Important Information..................................................................... 4

International Symbols .................................................................................................................. 5

Personal Condition and Safety Equipment .................................................................................. 5

Equipment.................................................................................................................................... 8

Emission Control (Exhaust & Evaporative)........................................................................................ 9

EPA 2010 and Later and/or C.A.R.B. TIER III ............................................................................. 9

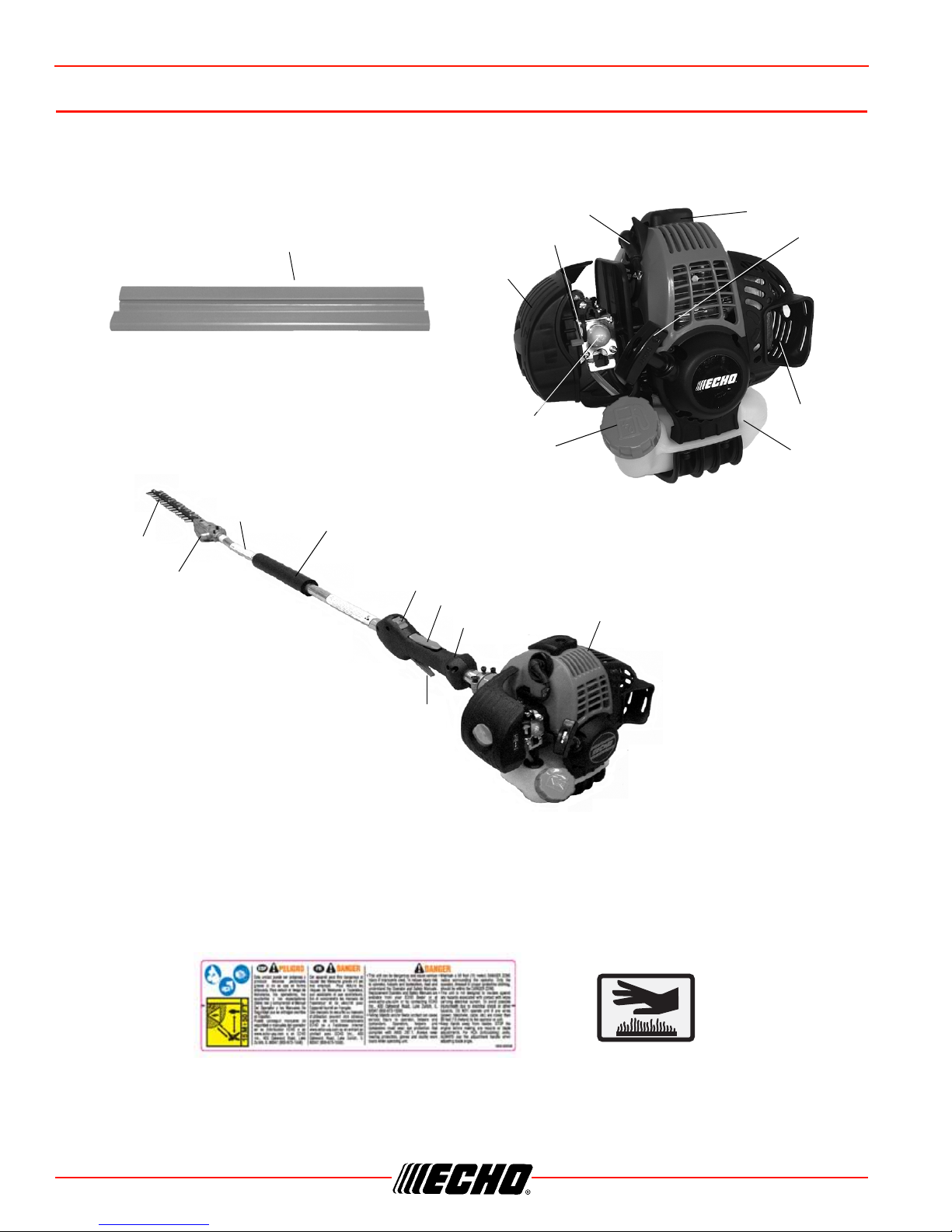

Description....................................................................................................................................... 10

Contents .......................................................................................................................................... 12

Assembly ......................................................................................................................................... 13

Drive Shaft/Power Head ............................................................................................................ 13

Throttle Linkage and Ignition Leads........................................................................................... 13

Gear Housing Assembly / Drive Shaft ...................................................................................... 14

Operation ......................................................................................................................................... 15

Fuel............................................................................................................................................ 15

Starting Cold Engine.................................................................................................................. 17

Starting Warm Engine................................................................................................................ 18

Stopping Engine......................................................................................................................... 19

Hedge Trimming ........................................................................................................................ 19

Maintenance .................................................................................................................................... 20

Skill Levels................................................................................................................................. 20

Maintenance Intervals................................................................................................................ 20

Air Filter...................................................................................................................................... 21

Fuel Filter................................................................................................................................... 21

Cooling System.......................................................................................................................... 22

Exhaust System......................................................................................................................... 23

Carburetor Adjustment............................................................................................................... 24

Lubrication ................................................................................................................................. 25

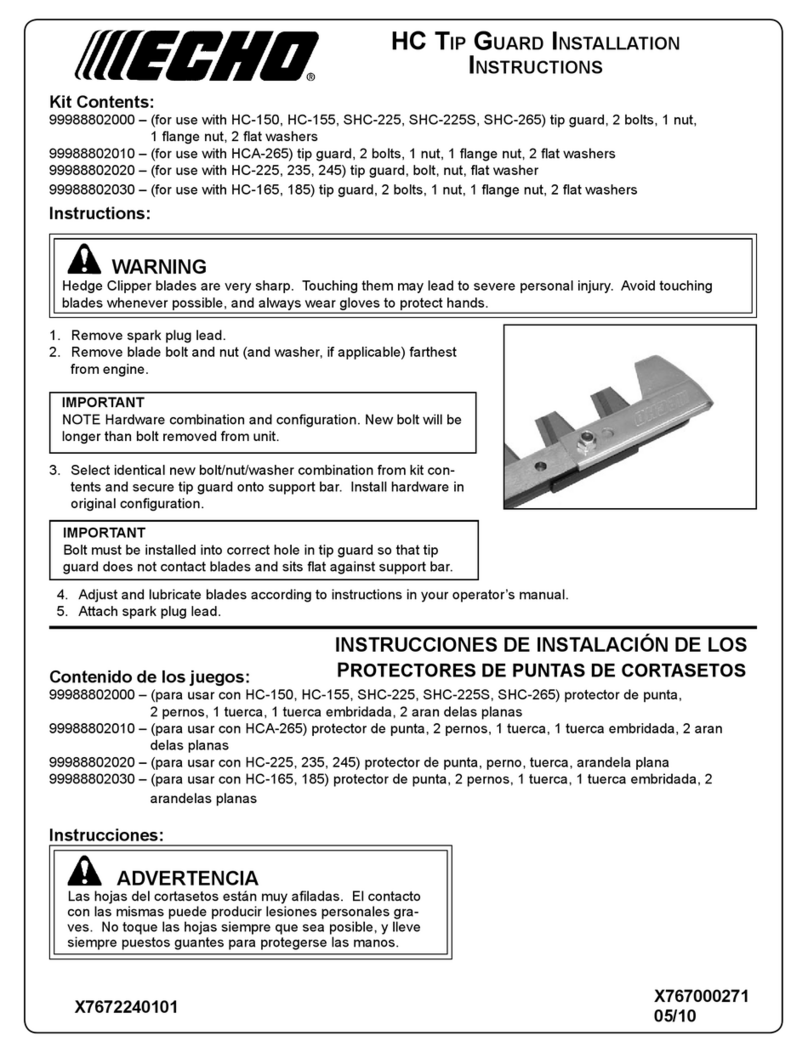

Blades........................................................................................................................................ 27

Troubleshooting ............................................................................................................................... 29

Storage ............................................................................................................................................ 30

Long Term Storage (Over 30 Days)........................................................................................... 30

Specifications................................................................................................................................... 31

Warranty Statements ....................................................................................................................... 32

Notes ............................................................................................................................................... 34