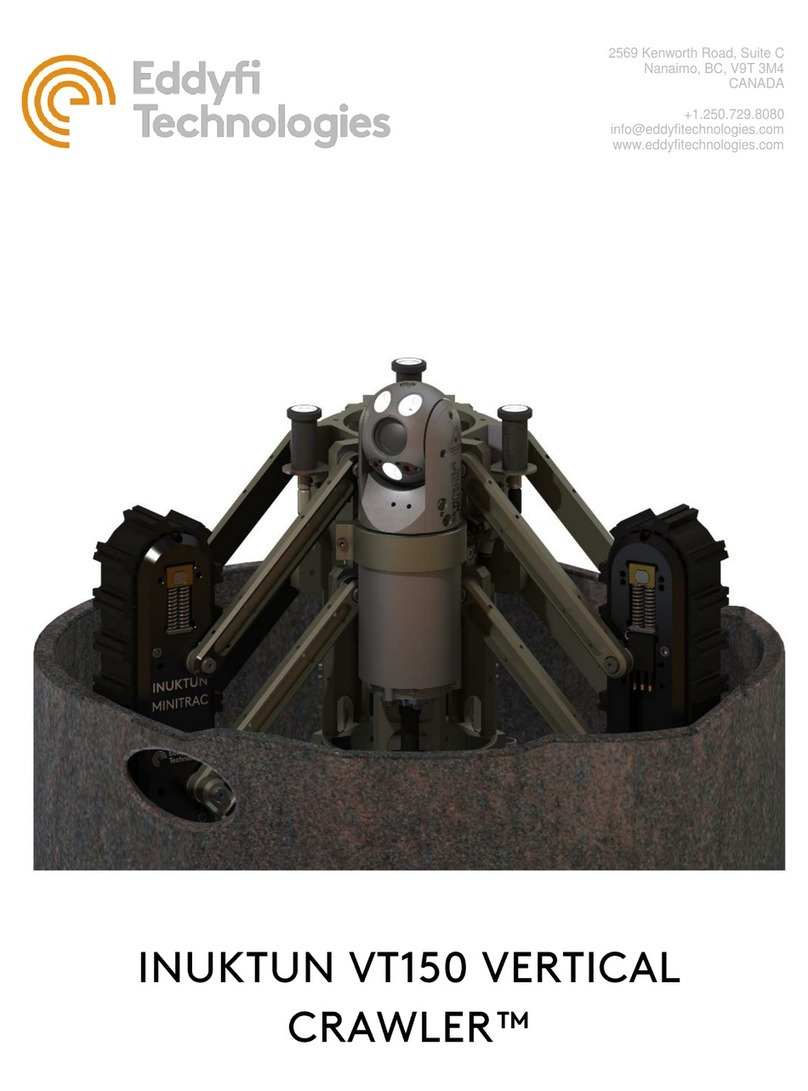

Microtrac Mounting.........................................................................................................................23

Traction Weight Kit.........................................................................................................................24

Magnet Kit ......................................................................................................................................25

Extended Parallel With Spectrum 90™ .................................................................................................28

Extended Parallel Chassis .............................................................................................................28

Camera & Light Installation............................................................................................................29

Extended Traction Weight Kit.........................................................................................................30

Extended Magnet Kit......................................................................................................................31

Inline Configuration................................................................................................................................32

Track Installation............................................................................................................................32

100 mm (4 in) Configuration...........................................................................................................33

125 mm (5 in) Configuration...........................................................................................................34

150 mm (6 in) Configuration...........................................................................................................35

Rear Camera..................................................................................................................................36

Front Sapphire™ Camera ..............................................................................................................37

Operation.....................................................................................................................................................38

Pre-Operations Check ...........................................................................................................................38

Post-Operations Check..........................................................................................................................39

ICON™ & ICON™ RPT .........................................................................................................................40

Dealing With Obstacles..........................................................................................................................40

Troubleshooting .....................................................................................................................................40

Camera Control Problems..............................................................................................................40

Video Problems..............................................................................................................................41

Vehicle Problems ...........................................................................................................................41

Reel Problems................................................................................................................................42

Maintenance................................................................................................................................................43

Rinsing and Cleaning.............................................................................................................................43

Fuse Replacement.................................................................................................................................43

Microtrac™ Maintenance .......................................................................................................................44

Camera Maintenance.............................................................................................................................44