Product documentation, IRC5

Categories for user documentation from ABB Robotics

The user documentation from ABB Robotics is divided into a number of categories.

This listing is based on the type of information in the documents, regardless of

whether the products are standard or optional.

All documents listed can be ordered from ABB on a DVD. The documents listed

are valid for IRC5 robot systems.

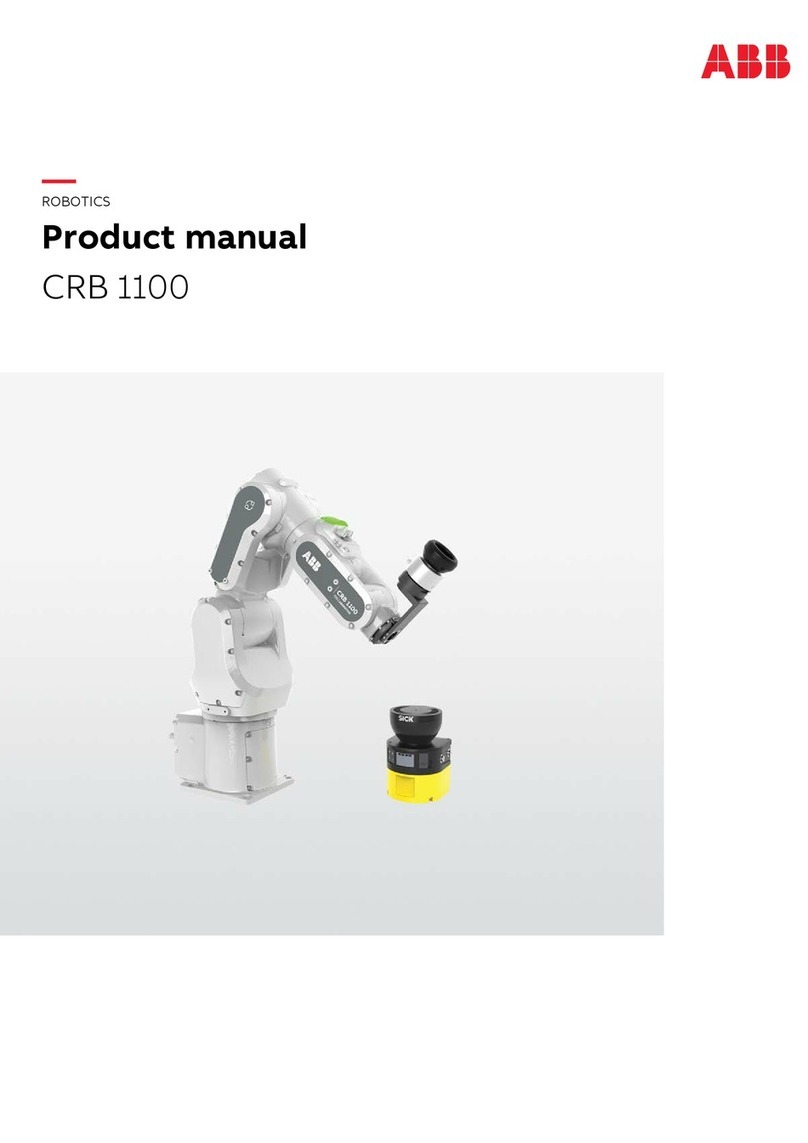

Product manuals

Manipulators, controllers, DressPack/SpotPack, and most other hardware is

delivered with a Product manual that generally contains:

• Safety information.

• Installation and commissioning (descriptions of mechanical installation or

electrical connections).

•Maintenance (descriptions of all required preventive maintenance procedures

including intervals and expected life time of parts).

• Repair (descriptions of all recommended repair procedures including spare

parts).

• Calibration.

• Decommissioning.

•Reference information (safety standards, unit conversions, screw joints, lists

of tools).

• Spare parts list with exploded views (or references to separate spare parts

lists).

• Circuit diagrams (or references to circuit diagrams).

Technical reference manuals

The technical reference manuals describe reference information for robotics

products.

•Technical reference manual - Lubrication in gearboxes: Description of types

and volumes of lubrication for the manipulator gearboxes.

•Technical reference manual - RAPID overview: An overview of the RAPID

programming language.

•Technical reference manual - RAPID Instructions, Functions and Data types:

Description and syntax for all RAPID instructions, functions, and data types.

•Technical reference manual - RAPID kernel: A formal description of the

RAPID programming language.

•Technical reference manual - System parameters: Description of system

parameters and configuration workflows.

Continues on next page

8 Application manual - Signal description for arc welding products

3HAC050975-001 Revision: -

© Copyright 2004-2016 ABB. All rights reserved.

Product documentation, IRC5