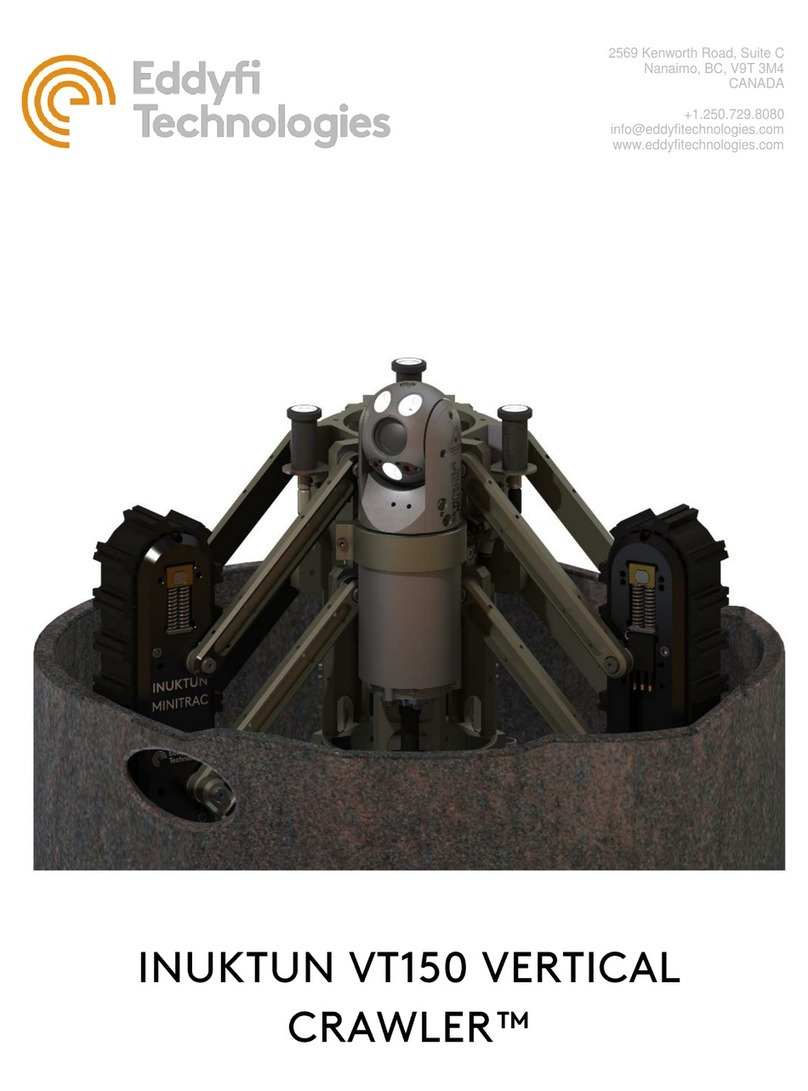

System Setup

Personnel Requirements

Basic deployment of the VT100™system may be performed by one person. Operations at more complex

worksites may require two people, especially when the console location is removed from the point of

deployment.

•Console Operator: This person is responsible for driving the vehicle, watching the pipe and

making comments about the location and pipe condition. It is also the operator’s responsibility to

assess whether a pipe is in the appropriate condition for safe passage of the vehicle or if there is

a risk of getting stuck. The operator may also assist in general site setup (cones, warning signs,

etc.), vehicle maintenance and configuration.

•Deployment / Tether Handler / Field Maintenance: This person has several tasks including:

oConfiguring the vehicle for the current pipe

oLowering the vehicle in and out of the manhole

oWatching the tether as the vehicle enters and exits the pipe

oOperating the reel and winding the tether during recovery

Establish a good channel of communication between the operator and deployment personnel. Good

communication can avoid accidents, damage to the equipment, and promotes efficiency and productivity.

In particular, the person deploying the vehicle and watching the tether must be able to quickly tell the

operator to stop the vehicle if something goes wrong. The operator should never turn on power or initiate

movement without first communicating with the vehicle handler.

Working And Storage Environment

The control rack, computer and interface box, are to be used in a dry, covered environment only.

These components are not waterproof. Keep all cords and cables away from water.

The tether and vehicle are depth rated to 60 meters (200 feet) of water. The tether connector is a wet-

mate type which may be wet when plugged in but cannot be plugged in underwater. Keep the tether

connector capped with a dummy plug when not connected to the vehicle to help keep out dirt. The tracks

are tolerant to sandy and muddy conditions, although this decreases seal life. The vehicle may also be

operated in dry or dusty environments.

The winch and portable reel are splash resistant only. Refer to the winch or reel manual.

To maximize component life and minimize deployment time it is recommended that the vehicle and tether

be cleaned after use and the entire system stored in a dry, dust free, location.

Refer to the Specifications section for operating and storage temperatures.