Sharpening

If the cutter blades need to be re-sharpened, they can be sharpened numerous times using standard

methods. Always make sure to leave a perfectly straight edge –irregularities or loss of perpendicularity

could result in compromised cutting ability. For replacement blades contact your Eddyfi Technologies

representative.

Compensation Oil

The Manipulator unit is pressure compensated with light, food safe oil to ensure reliable operation at

depth. If a new manipulator has been sitting on the shelf for an extended period of time, or has recently

been shipped via air, it is possible some of this oil may “weep” out of the o-ring grooves. This can be

alarming as it will appear as though the unit is leaking; in most cases, though, it is nothing to worry about.

To verify if there is a leak in the unit, perform the following procedure (this same process should be

repeated annually to ensure the integrity of the housing seals):

1. Wash the Manipulator body with hot soapy water (dish detergent work best) and heat the body up

to 40°C to 50°C (Approx. 104°F - 122°F). The soap will remove any oil, and the hot water should

help with moving the oil from the cracks.

2. Allow the unit to dry.

3. Place the dried unit on a facial tissue (or similar) in a warm area; if oil marks or slicks appear on

the tissue within a few minutes it could indicate a failure of one of the housing seals. Contact your

customer service representative to arrange for repairs.

At least once a year, check the quality of the oil by completing the following steps.

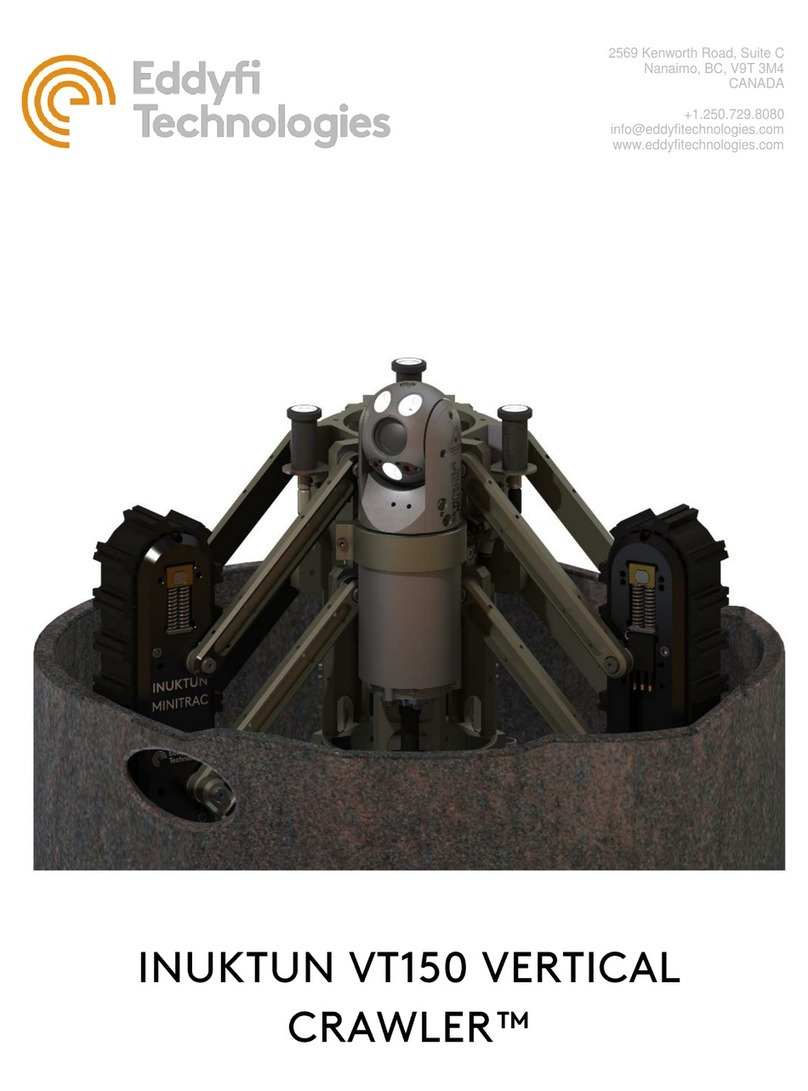

1. Insert an M3x25 socket cap screw into the bellows piston through the bellow port (see Figure 7

below) such that it gently seats on the front cap. Failure to do this will result in loss of oil.

2. With the drive unit held back up and jaws down, gently unscrew the oil plug on the back of the

unit; if the oil level is not near the top of the opening there could be a leaking seal and you should

contact your customer service representative.

3. Gently dip your finger in (do not splash out too much oil) and test the quality. The oil should have

a slick feel and should not be gritty or excessively dirty. If the oil is extremely degraded or dirty,

contact your customer service representative for an oil change or to receive a kit to change the

oil.

4. Before replacing the oil plug, top up the oil so that it is filled to the brim –use Schaeffer’s ISO 22

food safe hydraulic oil. Failure to top up the oil can result in air inside the housing, loss of

pressure compensation and failure at depth.