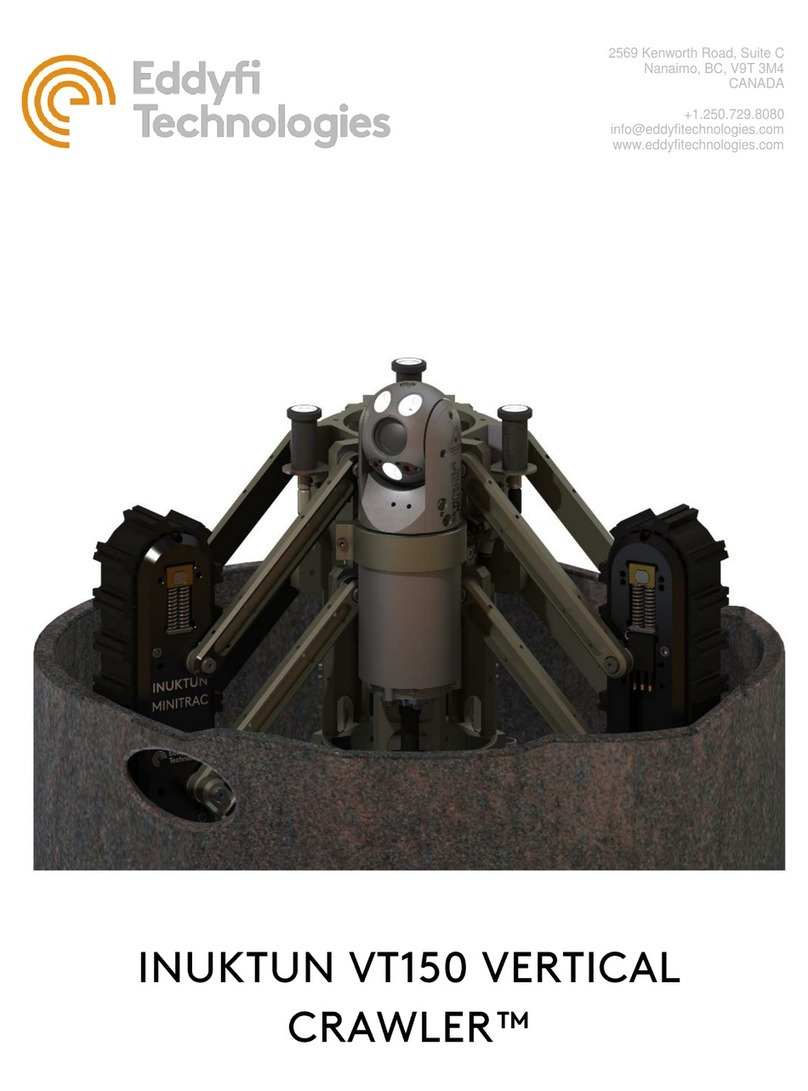

Typical Installation

The following describes a typical installation scenario recommended by us.

A typical set up for a pipe inspection system is based on a covered two-ton or larger box truck. The truck

carries the power source (generator) and houses the power supply and control system in a dry, covered

environment. The computer/ control console and recording equipment are placed in an office-like room

built into the truck. The rear wall of the truck should open completely. The winch, crane and other

equipment can be mounted at the back of the truck box near the door for easy deployment. The truck

should also contain the maintenance shop, ample bench space for maintaining and configuring the

vehicle and system wash down equipment.

The vehicle should be operated by a crew of at least two. Most importantly, a person should be available

to tend the tether at all times. This person may also play a role in vehicle inspection and deployment. A

second person drives the vehicle and operates the recording equipment.

The operations crew should be able to communicate quickly with each other to allow fast response in

case of an emergency such as a tether hang up. It is recommended that a signal system be set up so

that the operators may work efficiently and safely as a team. It is always advantageous for both

operators to be aware of full system status.

Vehicle Handling Equipment

Because the vehicle is heavy, some handling equipment is recommended with the system installation.

•The first of these is a swinging overhead boom for vehicle deployment which must hold the

payout sheave axle at least 9 feet above ground level. The capacity of the arm needs to be at

least ½-tonne at full extension –enough for full vehicle weight plus full winch power.

•The payout sheave diameter should be at least 10-inch diameter to help prevent tether fatigue.

•An electric cable hoisting winch with at least ½-tonne load capacity is necessary to raise and

lower the vehicle. The cable on this hoist needs to be long enough for the deepest expected

deployment.

We recommend a dedicated work bench for vehicle configuration and maintenance. Ideally this is at least

30 inches by 60 inches and is accessible from both sides. The lower portions of the bench may be

equipped with racks or drawers where tools, spare parts and fasteners are kept.

Personnel Requirements

A typical pipe inspection van operation usually requires two people for operations.

Console Operator –This person is responsible for driving the vehicle, watching the pipe and making

notes and comments about location and pipe situation. It is also the operator’s responsibility to assess

whether a pipe is in condition for safe passage of the vehicle or risk getting stuck. The operator may also

assist in general site setup (cones/ warning signs), vehicle maintenance and configuration.

Deployment / Tether Handler / Field Maintenance –This person has several tasks: