Table of Contents

About This Manual........................................................................................................................................4

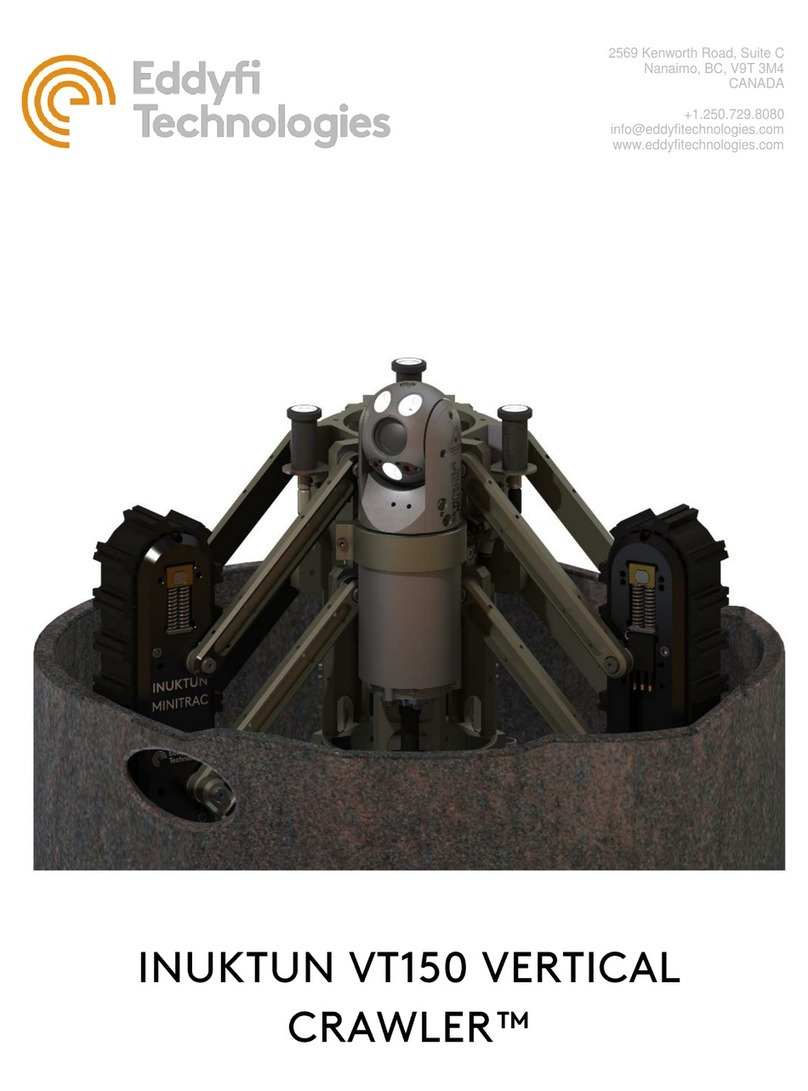

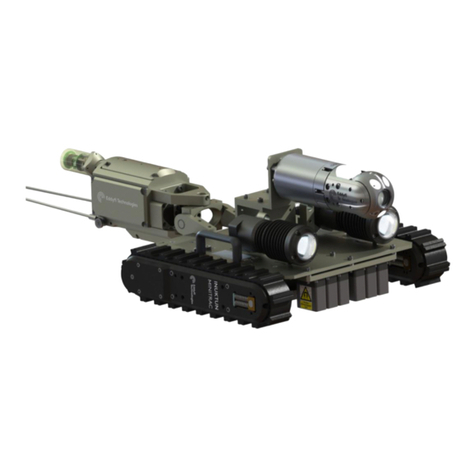

System Description.......................................................................................................................................4

Specifications............................................................................................................................................5

Precautions...............................................................................................................................................6

Certification...............................................................................................................................................6

Vehicle Overview......................................................................................................................................6

Dimensions...............................................................................................................................................7

Safety........................................................................................................................................................8

Intended Use...........................................................................................................................................10

Laser Lines .............................................................................................................................................11

System Setup..............................................................................................................................................12

Personnel Requirements........................................................................................................................12

Working and Storage Environment.........................................................................................................12

System Power.........................................................................................................................................13

Galvanic Corrosion Control.....................................................................................................................13

ICON™ Portable Controller Connection .................................................................................................13

Vehicle and Tether Connection ..............................................................................................................13

Portable Reel Setup................................................................................................................................14

Mini-Reel Setup ......................................................................................................................................15

Tether Handling ......................................................................................................................................16

Connector Handling................................................................................................................................16

SubConn Connector: Lubrication and Cleaning ..................................................................................17

Impulse Connector: Lubrication and Cleaning.....................................................................................17

Vehicle Configuration..................................................................................................................................18

Camera Mounting ...................................................................................................................................18

Standard Mounting...............................................................................................................................18

Pole Mounting......................................................................................................................................19

Alternate Mounting...............................................................................................................................19

Magnet Spacing......................................................................................................................................20

Fall Arrest................................................................................................................................................22

Operation.....................................................................................................................................................22