Copyright © Parallax Inc. Product Name (#28106) v2.1 5/5/2009 Page 4 of 4

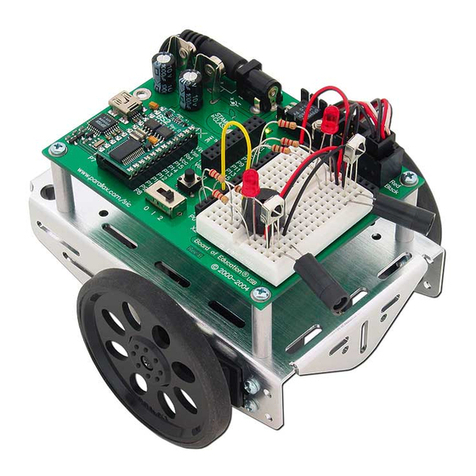

Step 10: The Boe-Bot robot’s breadboard circuit

can be protected by installing the (2) 1.5”

screws and (2) 1.25” spacers on the front of the

Board of Education®. The assembly is now done.

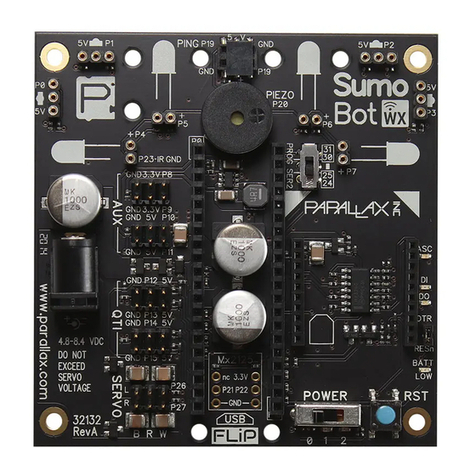

P15

P14

P13

P12

P11

P10

P9

P8

P7

P6

P5

P4

P3

P2

P1

P0

X2

X3 Vdd VssVin

Board of Education

© 2000-2003

Rev C

Vdd

Black

Red

X4 X5

15 14 13 12

To Servos

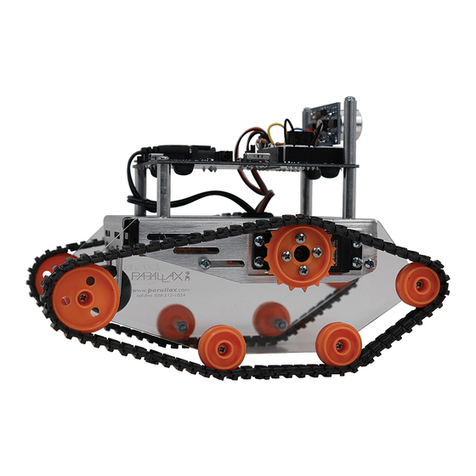

Troubleshooting the Tread

If the tread is loose and comes off, check to see

that all the wheels have very little movement when

pulled. They should roll easily but should not be

floppy. If the wheels are floppy, loosen the two

nuts and re-tighten. If the treads are still loose, the

servo mounting screws can be loosened, the servo

moved up, and the screws re-tightened.

Should the tread come off while turning and the

wheels have been adjusted and tightened, try

swapping the two bottom wheels (front to rear and

rear to front). The plastic might be too rounded.

Also check the tread connection joints. If the

interlocking rubber tabs are not pressed together

firmly, they could snag on carpet. If there is still a

problem, the two unused wheels with sprockets can

replace the two front bottom wheels. You will need

to drill or cut the end of the wheel so the screw will

go through.

If you experience any problems with the assembly

or use of your Tank Treads, you may contact us at

(1-888-997-8267) M-F 7:00 am to 5:00 pm PT.

Example Code for Basic Maneuvers

The program below is a modified version of the

program ForwardLeftRightBackward.bs2. from

Robotics with the Boe-Bot.

The FOR...NEXT loop

EndValue

arguments have been increased, because

the Tank Treads cause a slower ground speed than

the regular Boe-Bot wheels. Any program from

Robotics with the Boe-Bot can be used with the

Tank Treads kit, but programs that rely on

maneuvers of a certain distance or rotation will

need to have these

EndValue

arguments adjusted.

' Boe-Bot Tank Tread Kit –

' BasicTankMoves.BS2

' Drives forward, turns left, turns right,

' reverse

'{$STAMP BS2}

'{$PBASIC 2.5}

DEBUG "Program Running!"

counter VAR Word

FOR counter = 1 TO 100 ' Forward

PULSOUT 13, 850

PULSOUT 12, 650

PAUSE 20

NEXT

FOR counter = 1 TO 50 ' Turn left

PULSOUT 13, 650

PULSOUT 12, 650

PAUSE 20

NEXT

FOR counter = 1 TO 50 ' Turn right

PULSOUT 13, 850

PULSOUT 12, 850

PAUSE 20

NEXT

FOR counter = 1 TO 100 ' Reverse

PULSOUT 13, 650

PULSOUT 12, 850

PAUSE 20

NEXT

END

Download additional application examples and code

from www.parallax.com.