Catalog PN 6606

©2002 Edelbrock Corporation Page 2 of 3 Rev. 9/02

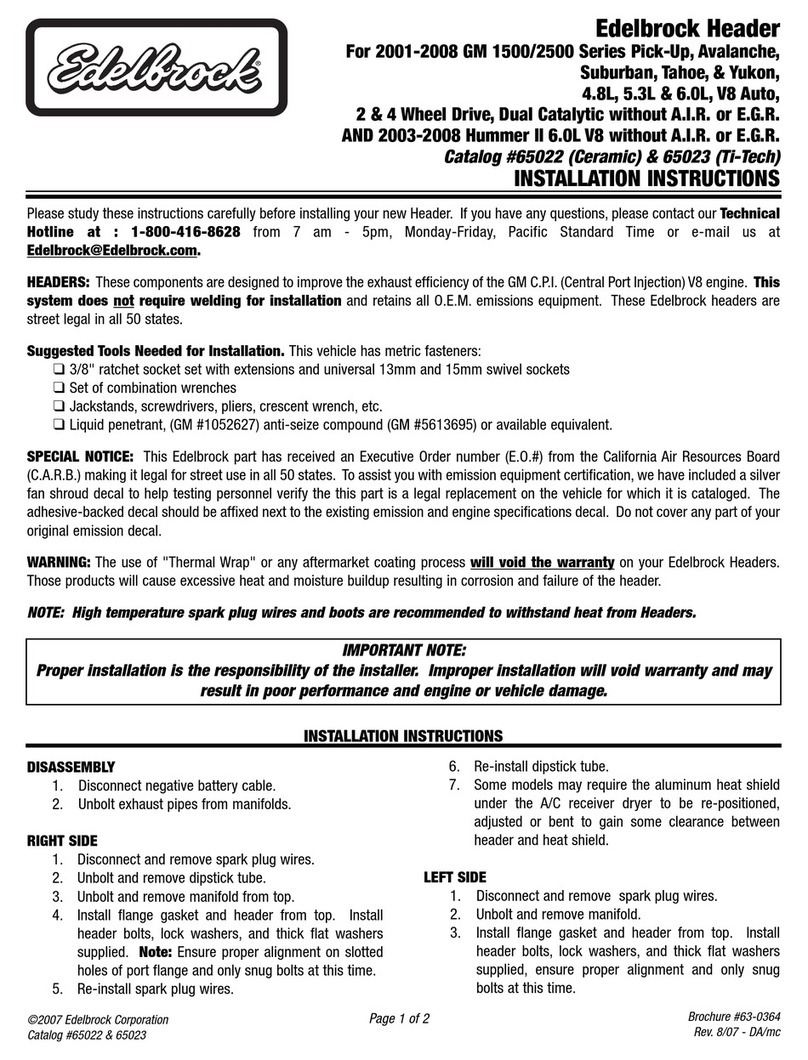

Disassembly

1. Disconnect negative battery cable.

2. Remove side exhaust covers. NOTE: Have someone

assist you to prevent damage to side covers or body.

3. Remove two O2 sensors from stock exhaust.

4. Remove rubber mounts and bracket holding stock

exhaust system at front of side pipes. They will not

be re-installed.

5. Remove bolts holding the exhaust pipe to exhaust

manifold.

6. Remove starter.

7. Number spark plug wires and remove from spark

plugs. Lay the wires over the rear of the engine to

prevent damage to wires.

8. Remove plastic spark plug wire separators from

valve cover area.

9. Remove top of heater air box (right side).

10. Unplug wire from temperature sending unit on left

cylinder head.

11. Remove the retaining nuts securing the heat shields

to exhaust manifolds. NOTE: The right side will

come off easily. The left side will only come off after

all manifold retaining bolts have been removed and

the manifold is completely loose. You may need to

remove the front bolt that holds the water pipe to

allow you to remove the heat shield and manifold.

12. Remove stock exhaust manifolds.

13. Clean gasket surfaces on cylinder heads.

NOTE: Be careful not to damage soft aluminum.

14. Cut stock exhaust at inlet of catalytic converter.

Assembly - Left Side

1. Install upper half of header from top along with new

gasket, bolts and washers supplied.

2. The thick hardened flat washers will be used on the

three slotted holes on each header flange.

3. Start all ten bolts but leave bolts loose at this time.

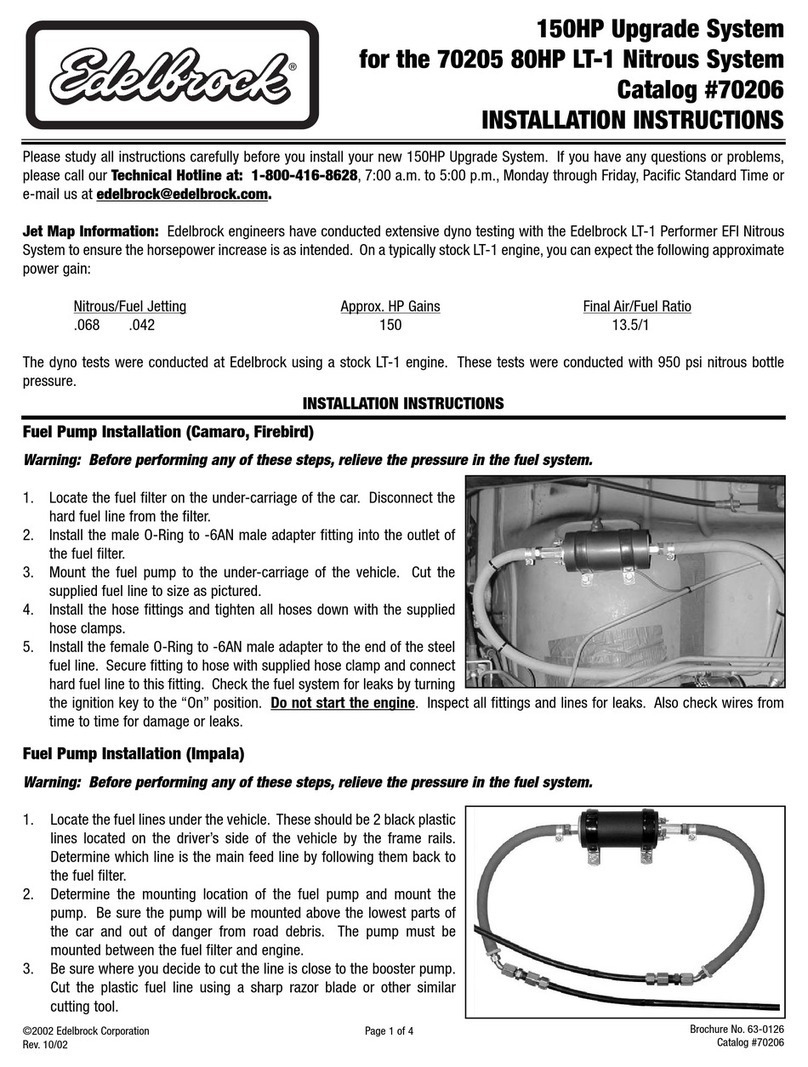

4. Install lower half of header from under car. Place

outlet end over frame rail and rotate into place.

Install gasket and 3/8" Allen head bolts and self-

locking nuts supplied.

5. Tighten cylinder head flange bolts evenly.

6. Tighten connector flange bolts evenly. NOTE: It is

very important that these bolts be tightened evenly.

Assembly - Right Side

1. The right side installs basically the same as the left

side.

NOTE: Remember all flange bolts must be tightened

evenly!

Flex Coupler Installation

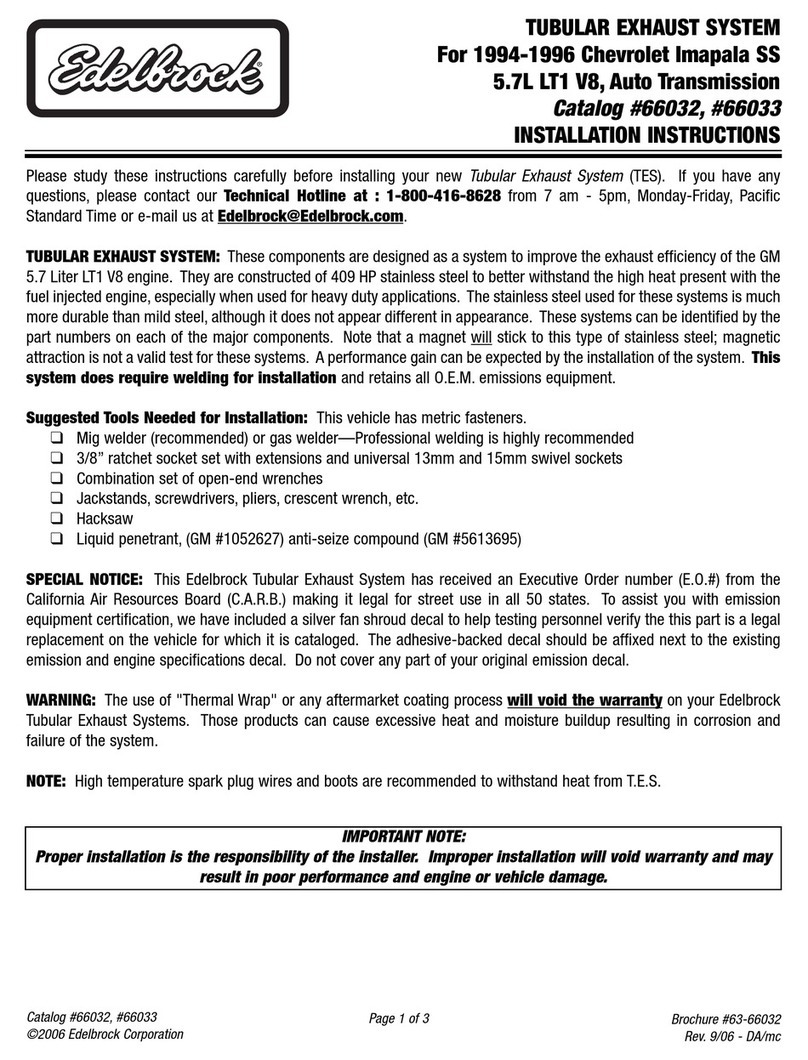

1. Install flex coupler and elbow assembly using band

clamp onto outlet end of header. NOTE: The catalytic

converter must remain in stock location. Therefore,

the new turnout elbows will need to be shortened to

fit onto the inlet of your catalytic converters.

2. Once you have trimmed the outlet end of the turnout

elbows tack weld the catalytic converter inlet to

elbow.

3. Recheck all alignment and critical points, such as

outlet positioning, side pipe clearance to outer

covers catalytic converter location, etc.

4. If everything is correct, remove side pipe and flex

coupler/elbow assembly and weld together.

5. Reinstall onto car.

6. Repeat for other side.

7. Reinstall two O2 sensors and tie wrap sensor wires

away from hot parts with the tie wraps supplied.

NOTE: It may be necessary to re-route or re-position

the wires for the O2 sensors to make it easier to plug

in the O2 sensors.

Final Check

1. After all bolts have been properly installed and

torqued, reconnect battery cable, sparkplug wires,

separators,etc.

2. Start car and check for exhaust leaks. DO NOT

DRIVE AT THIS TIME.

3. After letting engine fully warm up, shut off and let

engine fully cool down.

4. Re-tighten all bolts and nuts on TES (Tubular Exhaust

System) headers.

INSTALLATION INSTRUCTIONS