• DISASSEMBLY RIGHT SIDE

1. Disconnect A.I.R. injection hose from exhaust manifold and catalytic

converter tube.

2. Disconnect electrical connector and vacuum hoses from A.I.R.

diverter valve assembly (note position of hose and electrical

connections).

3. Remove A.I.R. pump feed hose from diverter valve assembly.

4. Remove nut from diverter valve support bracket at exhaust manifold

and loosen lower alternator pivot bolt, then remove diverter valve

assembly.

5. Disconnect spark plug wires and remove spark plugs.

6. Remove dip stick/tube from engine. CAUTION: Do not damage tube.

7. Remove bolts and exhaust manifold from top side.

8. At this time clean exhaust flange surfaces on cylinder heads.

9. Unbolt oil coolant tube from frame rail (where applicable) and bend

rear brace around tube. Bolt new flat brace (supplied) to frame rail.

This will move coolant tube above and on top of frame which will

allow more clearance for exhaust system.

• ASSEMBLY LEFT SIDE

1. Install T.E.S. flange gasket and one 3/8” 16 x 1” bolt and lock washer

at rearmost bolt hole (leave bolt loose enough to accept T.E.S.).

2. Install left side T.E.S. manifold from top side.

3. Install all but the front three bolts and washers on left side (do not

tighten at this time).

4. install rear power steering support bracket. Do not tighten.

5. Reinstall rear A/C support bracket with bolts, lock washers and

spacers supplied (see Figure 2 for spacer locations).

6. Align all parts and tighten left side bolts and nuts at this time.

7. Re-connect steering column coupler. WARNING: Make sure coupler

bolt is tight and check to see that steering wheel is in same

orientation as prior to disassembly.

8. Form brake lines to clear T.E.S. pipes where necessary; do not

disconnect.

9. Reinstall spark plugs and re-connect wires left side.

10. Change spark plug wire ends and boots as needed.

11. Reinstall temperature sensor wire support bracket and re-connect

wire to temperature sensor.

•ASSEMBLY RIGHT SIDE

1. Install T.E.S. flange gasket and one 3/8” - 16 x 1” bolt and lock

washer at rearmost bolt hole (leave bolt loose enough to accept TES.).

2. Install right side T.E.S. manifold from top side with dip stick tube at

same time.

3. Install remaining bolts, lock washers and dip stick tube clamp. (see

Figure 3) Do not tighten bolts at this time.

4. Re-install O.E.M. front stud bolt with spacer (supplied). Align all parts

and tighten all right side bolts at this time.

5. Re-install spark plugs and re-connect wires.

6. Change spark plug wire ends and boots as needed.

7. Reinstall diverter valve assembly in front O.E.M. stud bolt and tighten.

8. Re-connect electrical connections and vacuum lines to diverter valve

assembly.

9. Remove A.I.R. check valves from O.E. manifolds and reinstall them on

T.E.S. For 1986 & 1987 models, use plastic connector and 5” hose

supplied. Re-connect air hoses. For 1988 models remove 1/2” from

formed 900 rubber O.E.M. elbow and install plastic connector. Use 2”

of hose supplied and re-connect air hose. Re-connect all injection

hoses at this time.

10. Raise vehicle and support with jackstands.

•EXTENSION PIPE PREPARATION

1. The exhaust pipe/catalytic converter assembly must be cut off with a

hack saw as shown in Figures 4, 4a, and 4b. Note that the tab which

is welded to both pipes must be cut off of the right side pipe only and

will be re-welded to the new pipe after it is in place.

2. With gasket in place, bolt right side T.E.S. exhaust pipe to manifold

leaving bolts loose enough to align pipe.

3. Put catalytic converter/exhaust pipe assembly back into original

position, slipping right pipe into T.E.S. extension pipe.

4. With gasket in place, bolt left T.E.S. pipe onto manifold and slip over

OEM pipe.

5. Position T.E.S. extension pipes against T.E.S. manifolds so that an

equal amount of donut gasket is showing all around the flare on both

pipes (see Figure 5). This assures correct alignment of the two parts

before welding the rest of the system.

6. Tighten bolts so pipes won't move and make sure the catalytic

converter assembly is up in the original position, then tack weld to

both extension pipes. MIG welding is recommended, but gas can be

used if MIG is not available. Each pipe should be tack welded in at

least three places.

7. Remove complete assembly and finish welding. Be sure to re-weld

the tab between both pipes.

8. Install new extension pipe/catalytic converter assembly.

9. Before re-attaching the A.I.R. pipe, clean the mating surfaces

thoroughly with sandpaper, wire brushes, etc. If the joint was difficult

to loosen, it may help to apply some grease before assembly.

• LOWER VEHICLE TO THE GROUND

1. Connect negative cable to battery. At this point, it would be a good

idea to look everything over and make sure nothing was missed in

assembly.

2. Start vehicle and bring up to normal operating temperature and check

for possible leaks.

3. Turn engine off and let cool. Tighten all bolts again.

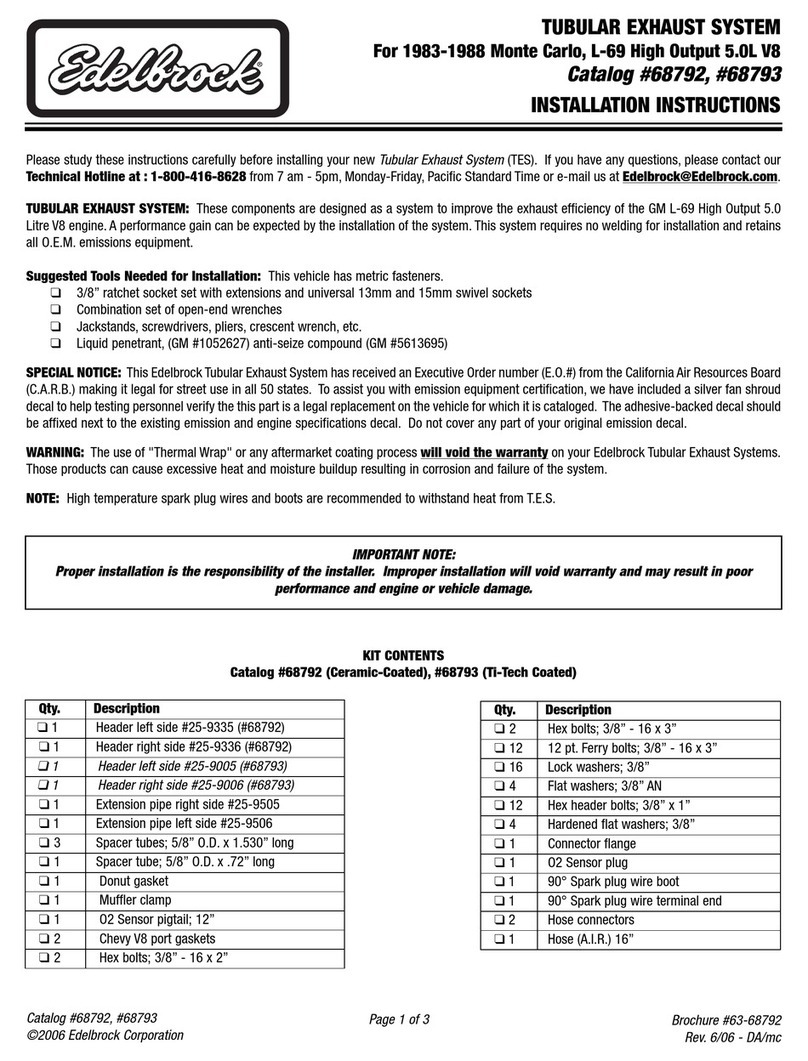

• HARDWARE SUPPLIED

1— Manifold left side #25-9007

1— Manifold right side #25-9008

1— Extension pipe left side #25-9560

1— Extension pipe right #25-9561

1— 12” 02 sensor pig tail wire

1— Flange connector

1— Air hose Connector

2— Chevrolet V8 port gaskets

2— 2-1/2” donut gaskets

1— Air hose 5/8” I.D. x 5” long

3— Spark plug boots and ends (if needed)

1— Coolant tube bracket

1— Umpco clamp; 3/8" I.D.

1— Umpco clamp; 1-5/8" I.D.

4— 3/8” flat washers

12— 3/8” - 16 x 1” Header bolts

2— 3/8”- 16 x 2-3/4” Ferry bolts

1— Hex nut; 10-32

4— 3/8” - 16 x 2” Hex cap screws

1— 5/8” x .72 Spacer tube

2— 5/8” x 1.53 Spacer tube

1— 5/8” x 1.12 Spacer tube

1— Hex cap screw; 10-32 x 1"

1— Star washer; 3/16" internal

12— 3/8” Split lock washers

page 2