Catalog #s 68572, 68573, 68582, 68583

©2006 Edelbrock Corporation Page 2 of 3

Brochure #63-68572

Rev. 6/06 - DA/mc

DISASSEMBLY

1. Disconnect battery negative cable from battery.

2. Raise vehicle and support with jackstands.

3. Use penetrating oil on all nuts and bolts to be

removed. This will prevent the possibility of broken

or stripped nuts and bolts.

4. Making sure the converter is cool, remove the

exhaust crossover pipe.

5. Lower vehicle to the ground.

• DISASSEMBLY - LEFT SIDE

6. Remove air cleaner system (note position of line and

hose connections).

7. Disconnect A.I.R. (air injection reactor) tube from

exhaust manifold (#68582/68583 only).

8. Remove air conditioner compressor rear support

bracket (if air conditioning equipped).

9. Remove power steering pump support bracket (if

power steering is applicable).

10. Disconnect spark plug wires and remove spark

plugs.

11. Remove O2 sensor, being careful not to rupture or

destroy the unit.

WARNING: Do not clean this unit in any cleaning

solvent and do not rupture wire.

12. Disconnect temperature sensor wire.

13. Remove bolts and exhaust manifold from top side.

• DISASSEMBLY - RIGHT SIDE

14. Disconnect A.I.R. injection tube from exhaust

manifold (#68582/68583 only).

15. Disconnect spark plug wires and remove spark

plugs.

16. Remove bolts and exhaust manifold from top side.

17. Clean exhaust flange surfaces on cylinder heads at

this time.

• ASSEMBLY - LEFT SIDE

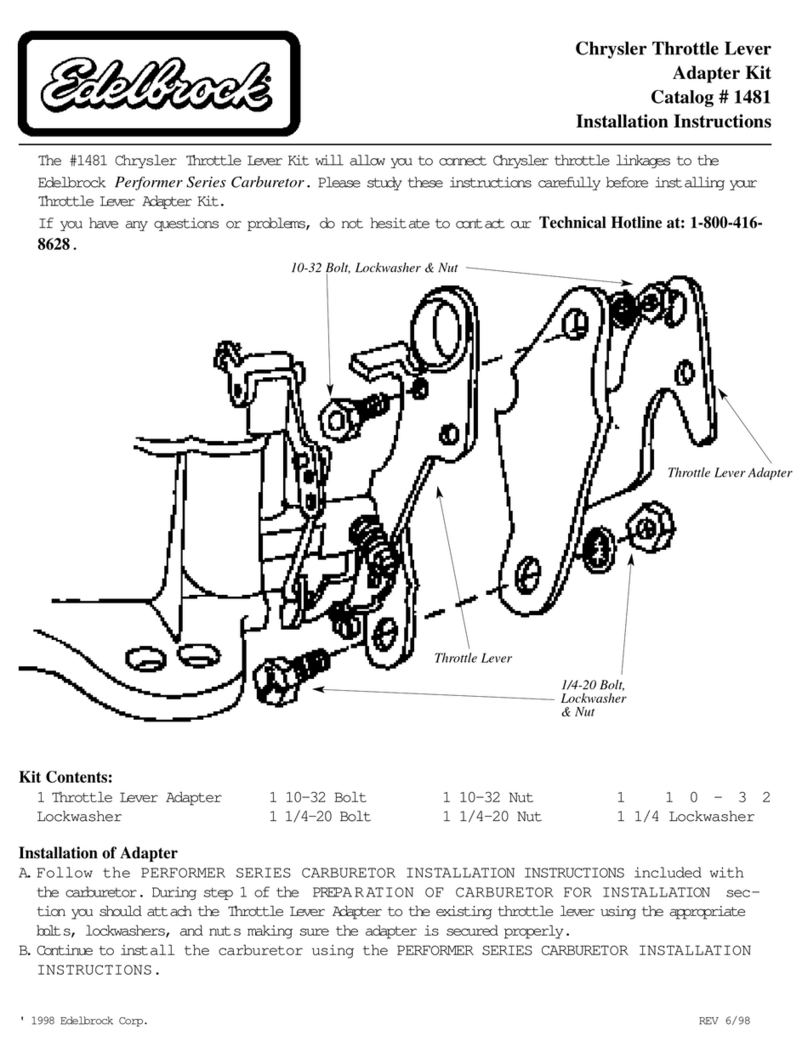

1. Install T.E.S. flange gasket and one 3/8"-16 x 1" bolt,

lock washer, and flat washer at rearmost bolt hole

(leave bolt loose enough to accept T.E.S.).

2. Install left side T.E.S. manifold from top side.

3. Install all but the front two bolts and washers on left

side (do not tighten at this time).

INSTALLATION INSTRUCTIONS

4. Re-install rear power steering support bracket. Do

not tighten at this time.

5. Re-install rear A/C support bracket with bolts, lock

washers, and spacers supplied.

6. Align all parts and tighten left side bolts and nuts at

this time.

7. Re-install spark plugs and re-connect wires on left

side.

8. Re-install temperature sensor wire to temperature

sensor.

9. Re-install O2 sensor. Use anti-seize on threads of

sensor and torque to 30 ft./lbs. Re-route O2 sensor

wire from wire loom to O2 sensor making sure all

wires are clear of exhaust system (O2 sensor

extension wire is included in kit).

• ASSEMBLY - RIGHT SIDE

1. Install T.E.S. flange gasket and one 3/8"-16 x 1" bolt,

lock washer and flat washer at rearmost bolt hole

(leave bolt loose enough to accept T.E.S.).

2. Install right side T.E.S. manifold from top side.

3. Install remaining bolts, lock washers, and spacer

tube for dipstick to clear exhaust flange.

4. Align all parts and tighten all right side bolts at this

time.

5. Re-install spark plugs and re-connect wires.

6. Remove A.I.R. check valves from original manifolds

and re-install them on T.E.S. With hose supplied in

kit, re-connect all A.I.R. injection hoses at this time

(#68582/68583 only).

7. Raise vehicle and support with jackstands.

• CROSSOVER PIPE ASSEMBLY

1. Carefully align and tap adapter tube into converter

using a piece of wood or a mallet to protect the end

of the adapter.

NOTE: Be sure adapter goes all the way in,

approximately 2-1/2".

2. Install crossover pipe assembly on vehicle using four

3/8" x 2" bolts with lock washers and donut gaskets

supplied.