Edge Technologies SCOUT 320 User manual

SCOUT 320

HYDRODYNAMIC AUTOMATIC BAR FEEDER

SCOUT 320/37 EXT / SCOUT 320/37R EXT

MANUAL FOR USE AND MAINTENANCE

REV. 2 DATE:2016/05/10 COD:BS0104032

S/H

INDEX SCOUT 320

I

CONTENT(

((

(INDEX)

))

)

1 GENERAL INFORMATION

1.1 Contents of manual ----------------------------------------------------------------------

1-1

1.2 The label of manufacturer and bar feeder ------------------------------------------

1-2

1.3 Support of technique ---------------------------------------------------------------------

1-2

2 DATA OF TECHNIQUE

2.1 Instruction ----------------------------------------------------------------------------------

2-1

2.2 Machine size -------------------------------------------------------------------------------

2-2

2.3 General specification---------------------------------------------------------------------

2-2

2.4 Compressed air supply and power supply -----------------------------------------

2-3

2.5 Specification of the guide channel ----------------------------------------------------

2-4

3 TRANSPORTATION

3.1 Packing the bar feeder ------------------------------------------------------------------

3-1

3.2 Transportation and hoist ----------------------------------------------------------------

3-2

3.3 Installation area ---------------------------------------------------------------------------

3-3

4 INSTALLATION

4.1 Bar feeder - Installation -----------------------------------------------------------------

4-1

4.2 Adjustment of height ---------------------------------------------------------------------

4-1

4.3 Initial position ------------------------------------------------------------------------------

4-2

4.4 Adjustment of center ---------------------------------------------------------------------

4-2

4.5 Securing and fastening of the bar feeder -------------------------------------------

4-4

4.6 Accessory installation--------------------------------------------------------------------

4-5

4.7 Guide channel lubrication --------------------------------------------------------------

4-6

INDEX SCOUT 320

II

CONTENT(

((

(INDEX)

))

)

5 ADJUSTMENT AND SETTING

5.1 Structure of the bar feeder --------------------------------------------------------------

5-1

5.2 Adjust loading device --------------------------------------------------------------------

5-2

5.3 Adjust and fix the anti-vibration device ----------------------------------------------

5-3

5.4 Feeding Chain -----------------------------------------------------------------------------

5-3

6

OPERATIONS AND DESCRIPTION

6.1 Par storage distinction and preparation ---------------------------------------------

6-1

6.2 Operation description --------------------------------------------------------------------

6-2

6.3 Description of settings and parameter -----------------------------------------------

6-7

7 MAINTENANCE

7.1 General maintenance -------------------------------------------------------------------

7-1

7.2 Regular maintenance --------------------------------------------------------------------

7-2

8 CAUSE OF BREAKDOWN AND TROUBLESHOOTING

8.1 Frequent cause of breakdown ---------------------------------------------------------

8-1

8.2 Breakdown on frame device -----------------------------------------------------------

8-1

8.3 Breakdown on the collect ---------------------------------------------------------------

8-1

8.4 Breakdown on feeding material -------------------------------------------------------

8-1

8.5 Refer alarm message --------------------------------------------------------------------

8-2

1. GENERAL INFORMATION SCOUT 320

1-1

1. GENERAL INFORMATION

Please read the Manual carefully before operating bar feeder.

1.1 Contents of manual

The feeder manufacturer provides this manual, which is an essential part of the

integrated products. Please act according to the indication of the manual in order

to assure operators’ safety as well as the machines’, and greatly achieve

economic efficiency and to get the best output of the machine’s capability. The

important part is printed in boldface, and included the following marks:

Warning:

::

:

Hazard! It is possible to hurt you seriously, please be careful.

Watch out-Precautions:

::

:

For preventing the accident or the loss of property, you should take precautions.

Important information:

::

:

Special important know-how information

Please take use of the table of contents, you will quickly find the information you

need.

The mark shown in the manual means that the machine should be operated by a

qualified and expert operator. As to the other operation shall be handled by a

qualified personnel or professional operator of bar feeder.

1. GENERAL INFORMATION SCOUT 320

1-2

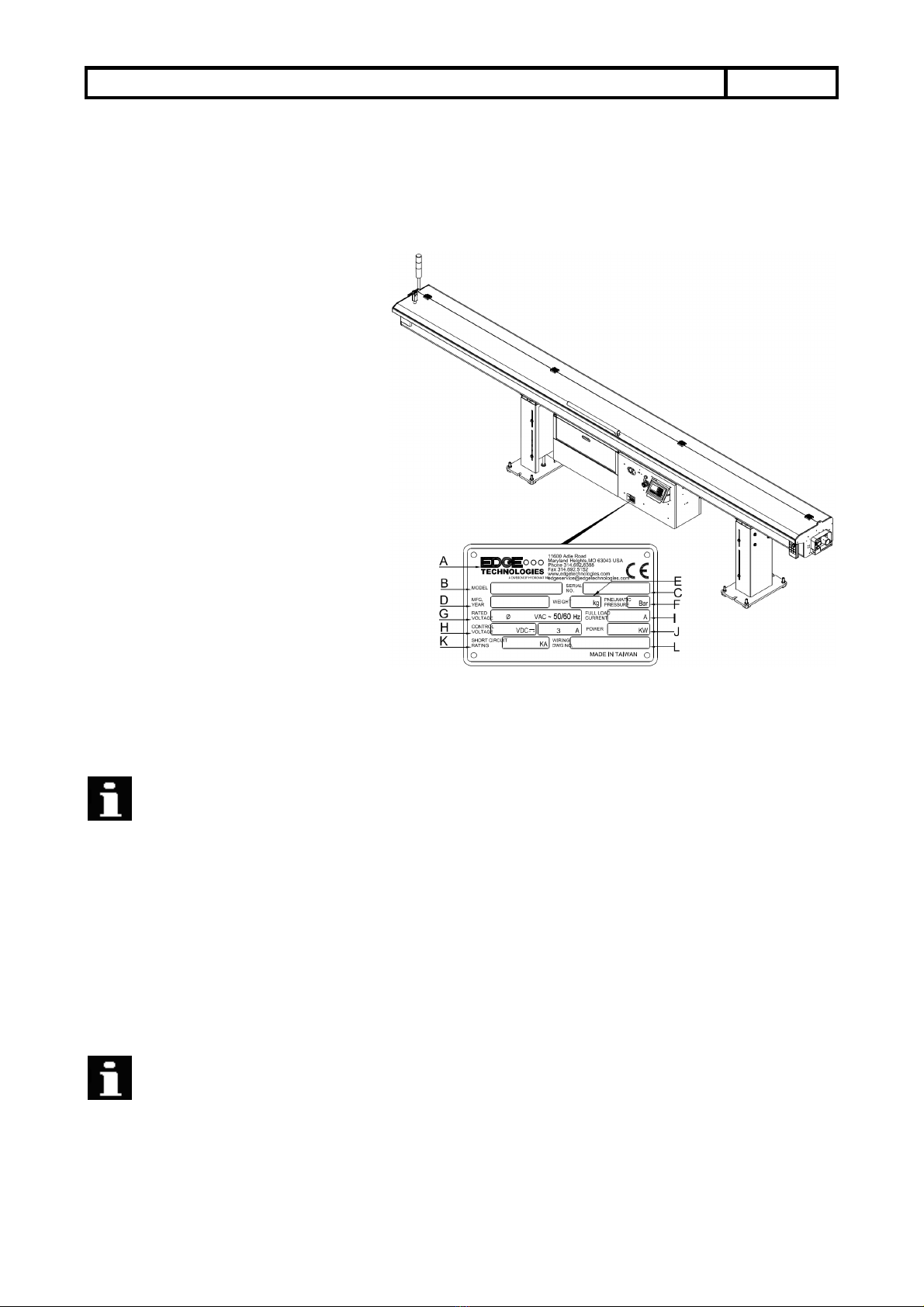

1.2 The label of manufacturer and bar feeder

A. Name of manufacturer

B. Model(Type)

C. Serial Number

D. Manufacture Date

E. Weight of Machine

F. Pneumatic Pressure

G. Rated Voltage

H. Control voltage

I. Full Load Current

J. Power

K. Short Circuit Rating

L. Wiring Drawing Number

INFORMATION:

::

:

When inquiring or ordering the parts, please notify the manufacturer the

above–mentioned in each standards.

1.3 Support of technique

If you need any support of technique, you can inquire the service center in the

appendix at anytime.

INFORMATION:

::

:

When you need the support of technique, please refer to the label on the bar

feeder. Tell us the data of the bar feeder.

2. DATA OF TECHNIQUE SCOUT 320

2-1

2. DATA OF TECHNIQUE

2.1 Instruction

The hydrodynamic automatic bar feeder is designed for full automatic lathe to auto

feed material, the bar feeder is suitable for digital control sliding headstock lathe

and fixed headstock lathe.

The program of the PLC system can control the bar feeder running with the lathe.

The remote control box is easily to be operated.

The bar feeder can feed circular material, cannular material and any other forms of

material. While the lathe is running, the guide channel is closed completely, at the

same time; lubricating oil into the guide channel so that the noise and vibration can

be reduced while the material is rotating in high speed.

Furthermore, lubricating oil also can reduce the temperature resulted from friction

so that the surface of the material can't be damaged.

The remnant material will be pushed out of the guide channel by the push bar or

the next material.

The descriptions and legends of the manual are according to the operator stands at

the left side of the lathe to be edited.

2. DATA OF TECHNIQUE SCOUT 320

2-2

2.2 Machine size

MOD 37

L 4599

A (Max.Bar Length) 3800

B 2150

C 584

Weight 420 kg

2.3 General Specification

Bar Diameter 3mm ( 1/8" ) ~26 mm ( 1" )

4 mm ( 3/16" ) ~21 mm ( 13/16" )

Channel Size 08 / 11 / 14 / 16 / 18 / 20 / 22 / 24 / 28

Bar Loading Capacity 220mm Ø10 x 22mm round bar

Lubricant Specification 40 (L) ISO CKB 100

Power Supply 220 / 380V 0.4A 50 / 60Hz

Pneumatic Supply 5 - 7 kg/cm²

2. DATA OF TECHNIQUE SCOUT 320

2-3

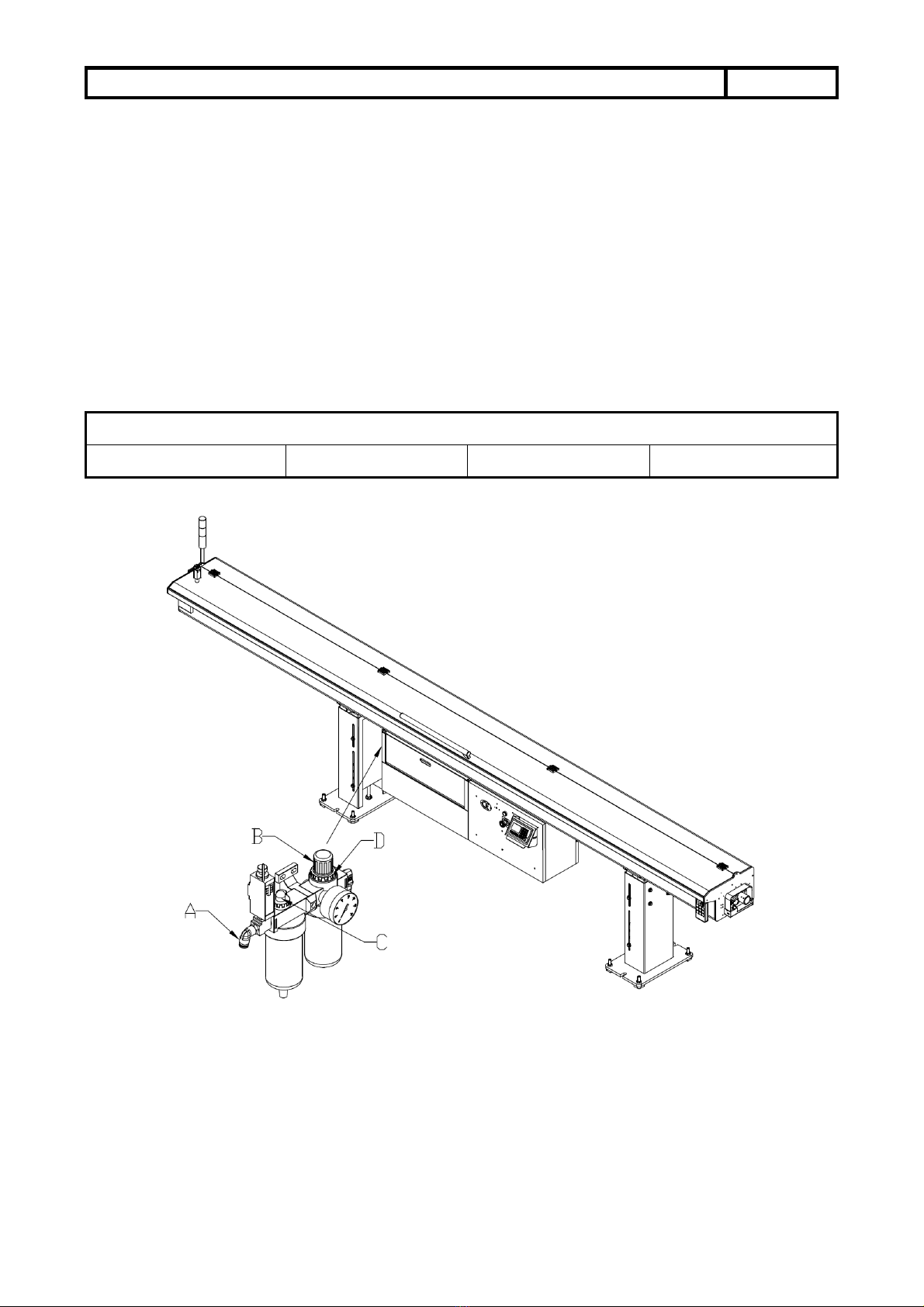

2.4 Compressed air supply and power supply

2.4.1

Tube for compressed air supply unit must be bigger than 8mm. Pressure must be

over 5~7kg / cm

2

,Consumption about 50L/H。

2.4.2

Put the air supply tube into(A). Then pull and turn around the knob(B)and set

the pressure at 6kg / cm

2

.

2.4.3

Control air lubrication from cylinder , adjust(C), 1-2 drops/1000 L air if

necessary.

2.4.4

Lubricate(D), viscosity 32 Cat , temperature 40℃, ISO VG type

Adaptive lubricant

BP ENERGOL HLP32

AGIP OSO 32 MOBIL DTE 24 ESSO NUTO H32

2. DATA OF TECHNIQUE SCOUT 320

2-4

2.5 Specification of the guide channel

TYPE

Diameter

of guide

channel

(mm)

Diameter

of bar

pusher

(mm)

Diameter of bar (mm)

Min. Max.

SCOUT 320

8 7 1.5 5.5 7

11 10 2 8 10

14 12 3 10 12

12.7

16 15 3 13 14

18 16 3 13 16

17

22 20 3 17 20

21

24 23 3 19 22

28 25 5 22 25

27 26

Note!

!!

!Outer diameter of the collet must be smaller 0.5 ㎜

㎜㎜

㎜than diameter of

bar pusher at leas

3. TRANSPORTATION SCOUT 320

3-1

3. TRANSPORTATION

Hazard-

--

-warning:

::

:

Transportation and hoist (please refer to the item 3.2.1 of following weight table)

You have to sure the crane; forklift or other related tools could take the weight.

Using the proper equipment to move and hoist the machine should be led by the

expert personnel.

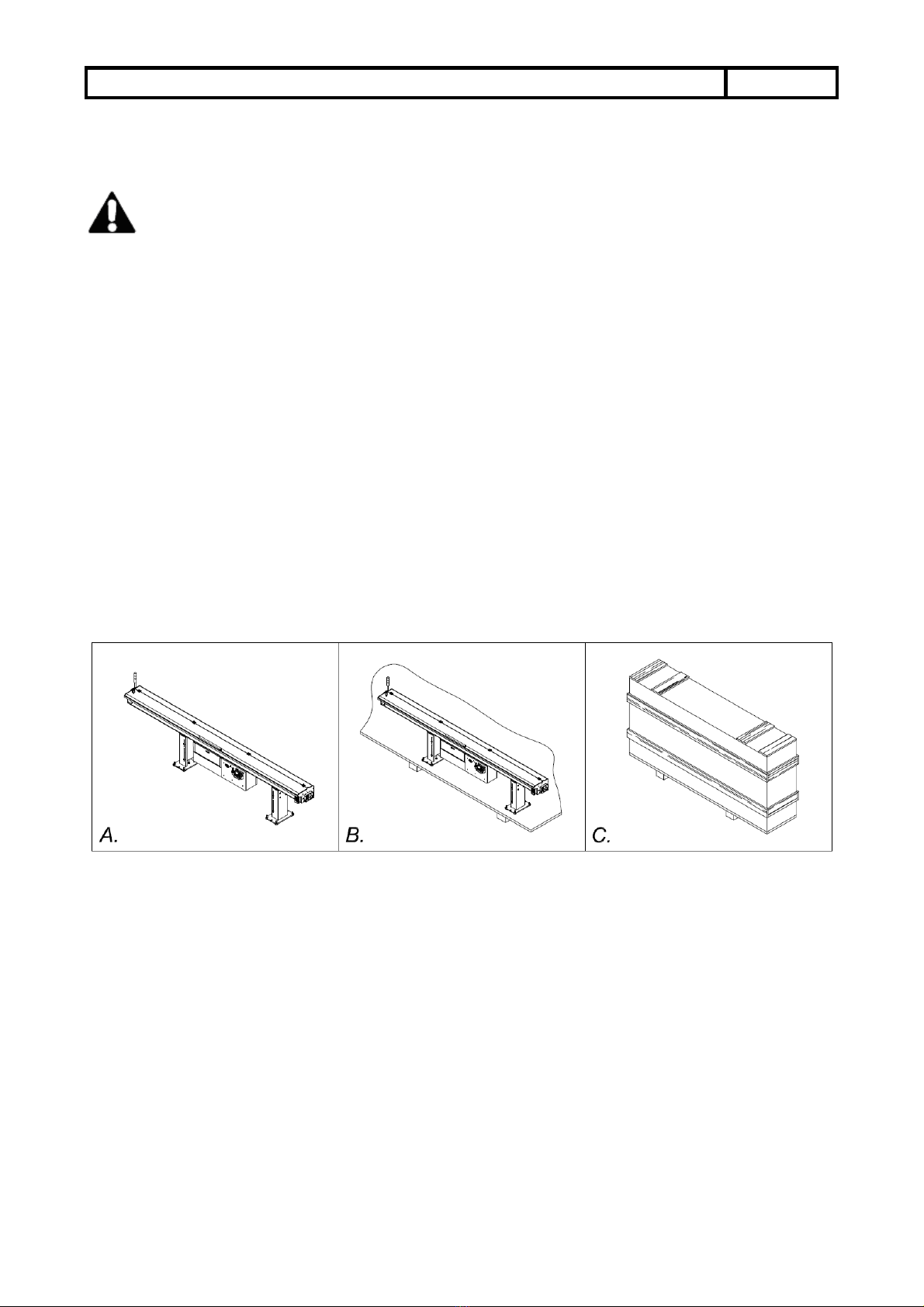

3.1 Packing the Feeder

There are three kinds of packing Feeder:

A. Unpacking.

B. On the pallet: Put the feeder on the pallet and wrap PE membrane around the

feeder.

C. Packing with wooden box: The Feeder was packed with wooden box and wrap

PE membrane around the box.

3. TRANSPORTATION SCOUT 320

3-2

3.2 Transportation and hoist

3.2.1 Unpacking

Putting two steel bars (Diameter:30mm,

length: 1M) under the bar feeder, using

suitable steel ropes which are able to

bear the weight to hoist.

SCOUT 320-37 420KG (NET)

3.2.2 On the pallet

Using suitable steel ropes which is able

to bear the weight to hoist the bar feeder.

3.2.3 Packing with wooden box

Using suitable steel ropes which is able

to bear the weight to hoist the bar feeder.

3. TRANSPORTATION SCOUT 320

3-3

3.3 Installation area

In order to fix the feeder securely, the floor must be flat and firm.

According to the operation of the feeder to reserve a suitable area in advance.

Area:(D-operator area),(E-supply area),(F-remnant material area)

The space must be enough to avoid the feeder caused crashed by the operator.

The area of installation needs to have suitable lighting, outlet and compressed air

joint.

The feeder can’t adapt to explosive surrounding.

List 1.-

--

-Size of appearance

Type Size A (mm)

SCOUT 320 37 4599

4. INSTALLATION SCOUT 320

4-1

4. INSTALLATION

4.1 Bar feeder -

--

-Installation

Before installing the bar feeder, the spindle of the lathe must be horizontal and the

lathe is fixed on the ground strongly.

4.2 Adjustment of height

4.2.1

Disengage the screw (1).

4.2.2

Adjust the screw(2)and shift from up to down. Adjust the height to a straight line

center of the bar feeder and the center of the lathe.

4. INSTALLATION SCOUT 320

4-2

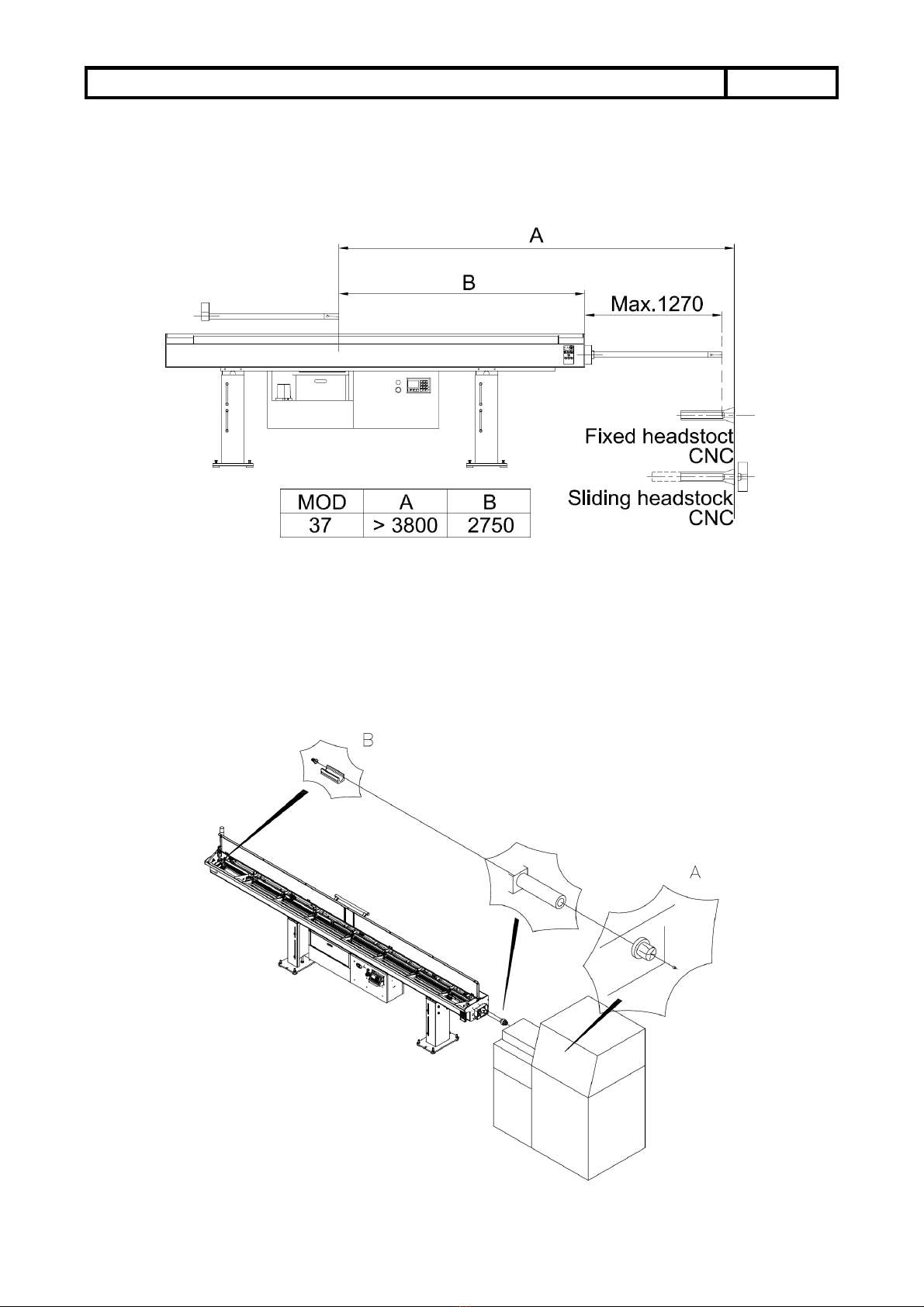

4.3 Initial position

The bar feeder is to place at the back of lathe. The distance is as below:

4.4 Adjustment of center

The bar feeder should be as near as possible to the lathe, When installing.

In order to have a perfect matching line, prepare a nylon thread (1mm).

Pull the nylon thread from the lathe (A) to the end of the bar feeder (B).

4. INSTALLATION SCOUT 320

4-3

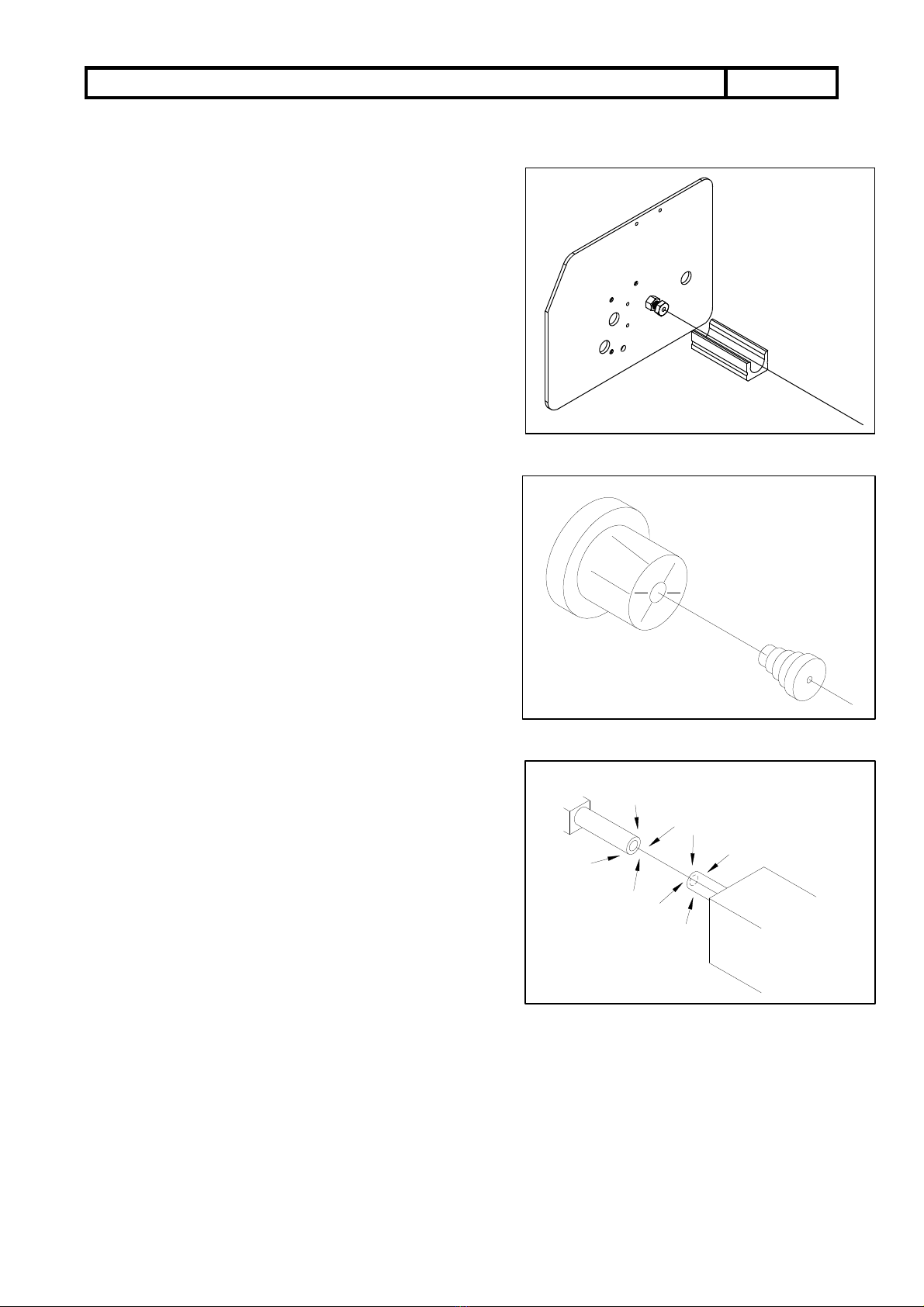

4.4.1

Secure nylon thread on to the axis screws

(B point) of bar feeder, then pull the thread

through spindle hole.

4.4.2

Choose proper ladder bar and insert the

chuck, pull the nylon thread and secured.

4.4.3 Directional adjusting

Use the ruler to check the center of the

nylon thread, guide(C), and spindle (D).

The distance of the four directions is to

be within 0.15 mm.

CD

A

4. INSTALLATION SCOUT 320

4-4

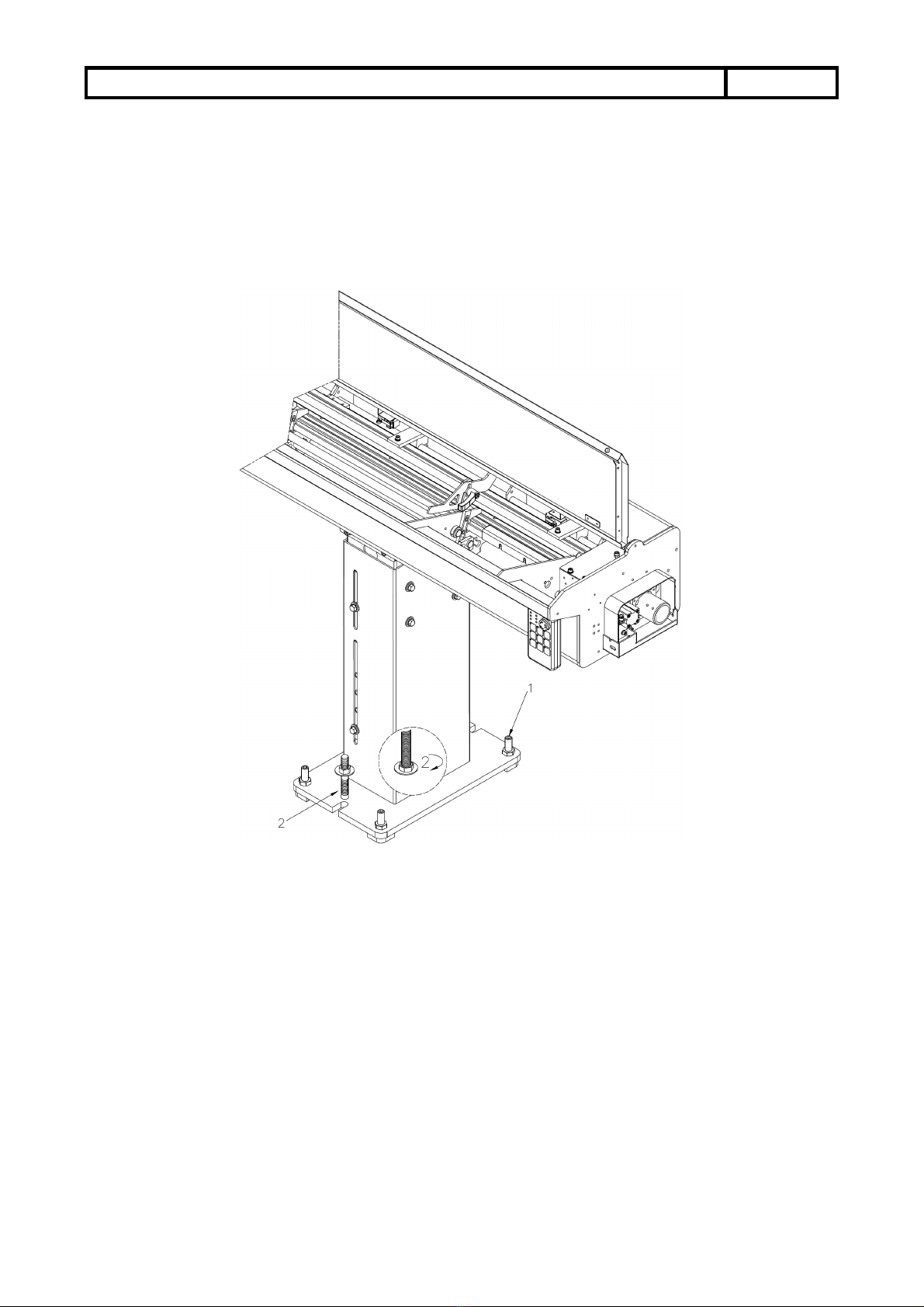

4.5 Securing and fastening of the bar feeder

4.5.1

Rotate the 4 ground-screws (1) to touch the ground, and fix the nuts.

4.5.2

Drill ground (2) with Ø19mm (¾”) of bit, and fix the spindle-screw.

4. INSTALLATION SCOUT 320

4-5

370715

370MM

456 225

225MM

4.6 Installation accessories

4.6.1

Movable anti-

--

-vibration:

::

:The anti-vibration device is fixed at the end of the

spindle of the lathe, using a bar to adjust the center of the anti-vibration.

4.6.2

Synchronization connecting rod:

::

:Fix the connecting rod at the movable

anti-vibration and makes it move smoothly.

4.6.3

Fixed front nose:

::

:Fix it at the support of nose which is in front of the bar feeder.

4.6.4

Telescopic front nose:

::

:End of the telescopic front nose fix at the front of the

telescopic front nose connects with the plate of the lathe.

4.6.5

Oil ring:

::

:Fix the oil ring in front of the fixed front nose or

telescopic front nose.

Type ØA

7 8

10 11

12 14

16 18

20 22

23 24

26 28

4. INSTALLATION SCOUT 320

4-6

4.7 To lubricate-

--

-Guide channel

ISO and UNI brand Brand Description

CKB 100

Agip Acer 100

Api Api Cis 100

BP Energol CS 100

Castrol Magna 100

Chevron Circulating Oil 100

Elf Movixa 100

Esso Nuto 100

Fina Solna 100

IP IP Hermea 100

Kluber Crucolan 100

Mobil Vectra Oil Heavy

Olio FIAT Daphne LPN 100

Roloil Arm V 100

Shell Vitrea 100

Tellus C 100

Tamoil Tellus C 100

Texaco Industrial Oil 100

Total Cortis 100

Q8 Azolla ZS 100

5. ADJUSTMENT AND SETTING SCOUT 320

5-1

5. ADJUSTMENTS AND SETTING

5.1 Structure of the bar feeder

Table of contents

Other Edge Technologies Industrial Equipment manuals