Donaldson Company, Inc.

4

CAUTION!

• Misuse or modification of this

equipment may result in personal

injury.

• Do not misuse or modify.

Description

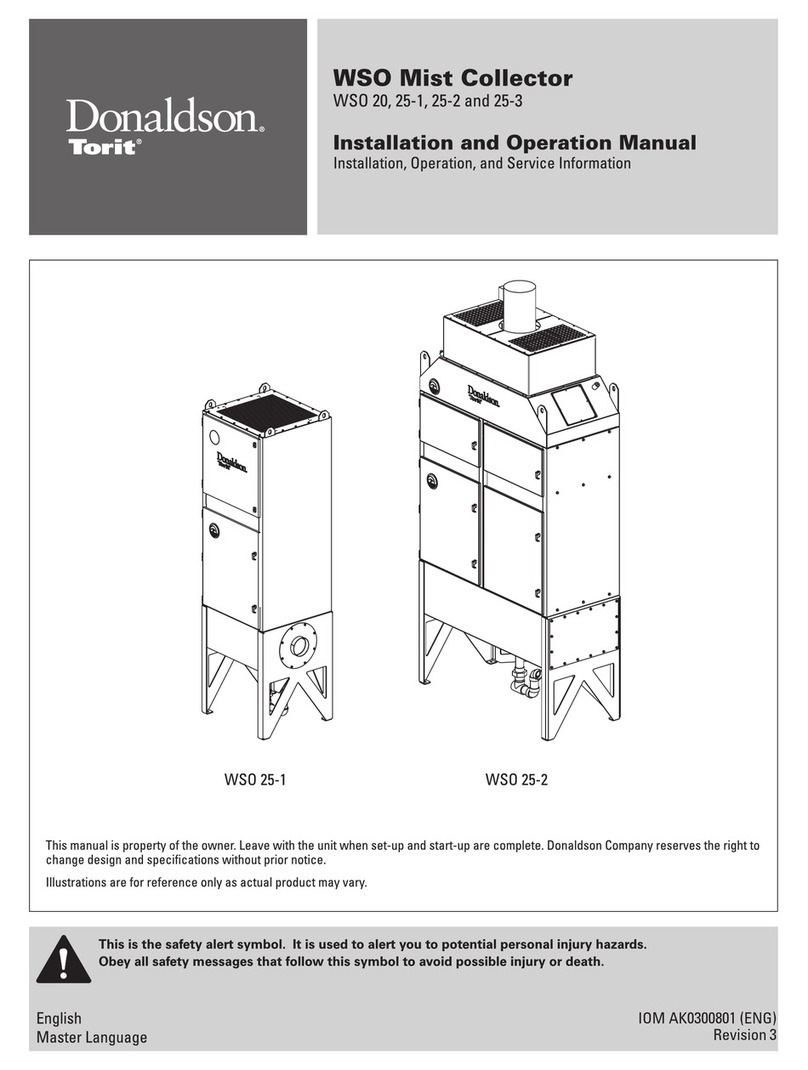

Designed for versatility, the WSO (Water, Smoke,

and Oil) mist collector is specifically engineered for

water-soluble, smoke, and oil-based mist

applications. WSO mist collector, Machine-

Mountable Models WSO 10, 15, and 20 collect

airborne mist such as oil, water-soluble, semi-

synthetic and synthetic coolant from machining

operations. Two stages of filtration, plus an

optional HEPA or 95% DOP filter, provide a

cleaner, healthier work environment as well as a

more cost effective means of mist collection. With

airflow capacities up to 1200 cfm for the WSO 10,

15, and 20, the WSO is a strategic component to

meeting industrial and government air-quality

standards. The high efficiency filter cartridges allow

air and coolants to be recycled.

Designed to increase the versatility of the unit, a

variety of filter media specifically designed for mist

collection is a standard offering on the product line.

The WSO model number (10, 15, or 20) indicates

the height of the primary filter in inches for that

particular model. For examples, the WSO 15

contains a 15 inch tall primary filter. The primary

filter is uniquely designed for either water-based

coolants, straight oils, or thermally-generated

smoky applications. Standard options include drain

collection containers, P-traps, adjustable floor

mounting stands, and afterfilters.

The WSO machine-mountable unit is powered by a

blower and motor mounted in the filter cabinet.

Purpose and Intended Use

Airborne mist is small droplets of metalworking

fluids suspended in the air. Metalworking fluids

include straight oils, water-soluble coolants, semi-

synthetic and synthetic coolants. These fluids

perform a variety of functions such as lubricating or

cooling the part or the tool, flushing chips away

from the part, and suppressing dust and smoke.

Mist is created in two ways: mechanical action or

thermal effects. Mechanical action involves coolant

used for light lubrication and generally creates mist

greater than one micron in size. Thermal effects

occur when heat vaporizes the coolant, the vapor

cools and recondenses into a mist. Thermal effects

create mist from 0.01 to 1 micron in size. Other

contaminants, such as dust from the part or the

tool or smoke from the vaporization of the oil or

coolant are also generated when using

metalworking fluids.

The WSO mist collector is not designed to handle

water mist alone. There should be some type of oil

content to allow coalescing since water vapor will

simply pass through the filters. The extremes of

very heavy oil and light, thin oil should be avoided.

Very heavy oil, similar to tar consistency, will not

drain while very light, thin oil, similar to paint

thinner consistency, may evaporate.