2

CONTENTS

SAFETY PRECAUTIONS ..…………………………………………………………………………….…………………………………….…2

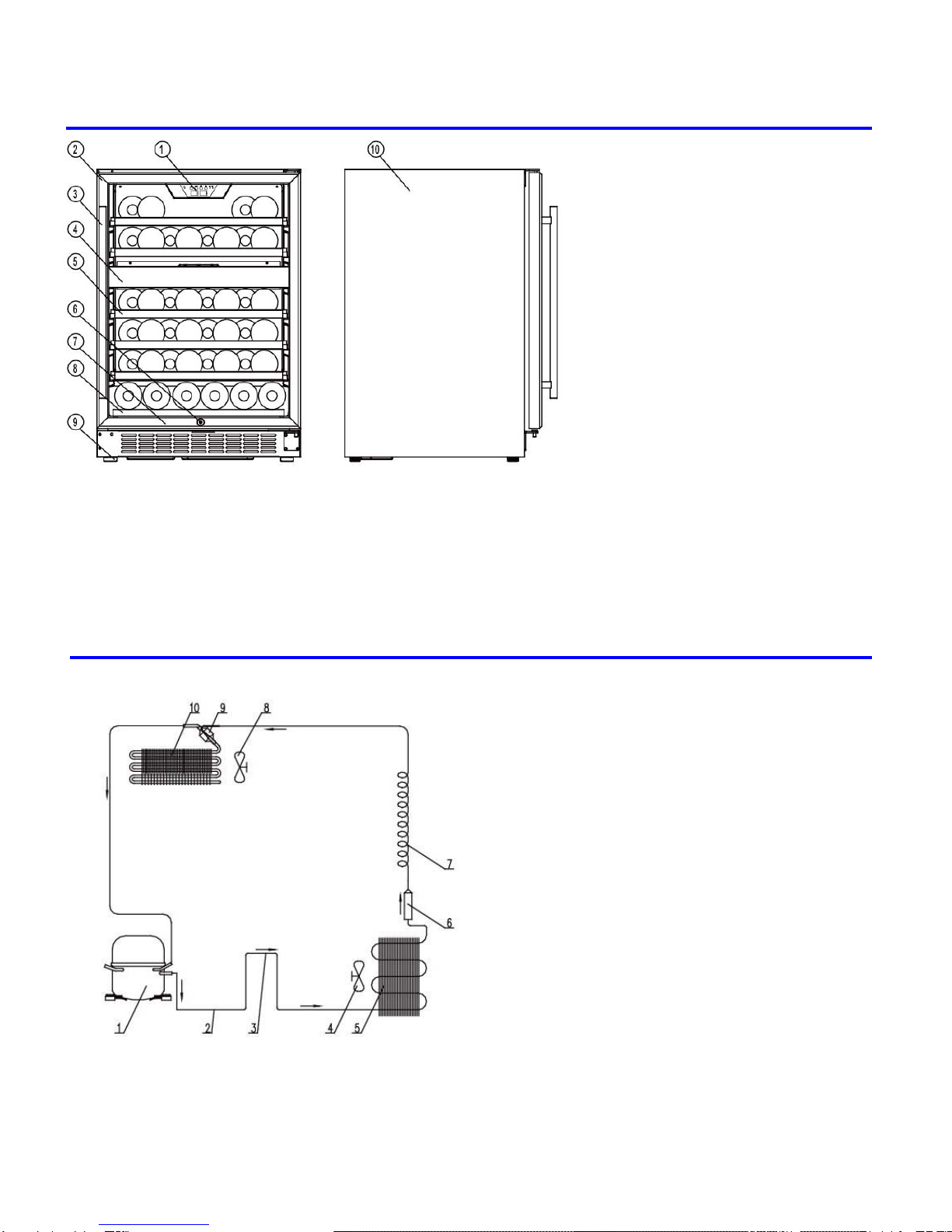

NAME OF PARTS…………………………………………………………………………………………………..……..…….………………3

REFRIGERANT CYCLE DIAGRAM…………………………………………………………………………………………...………..…….3

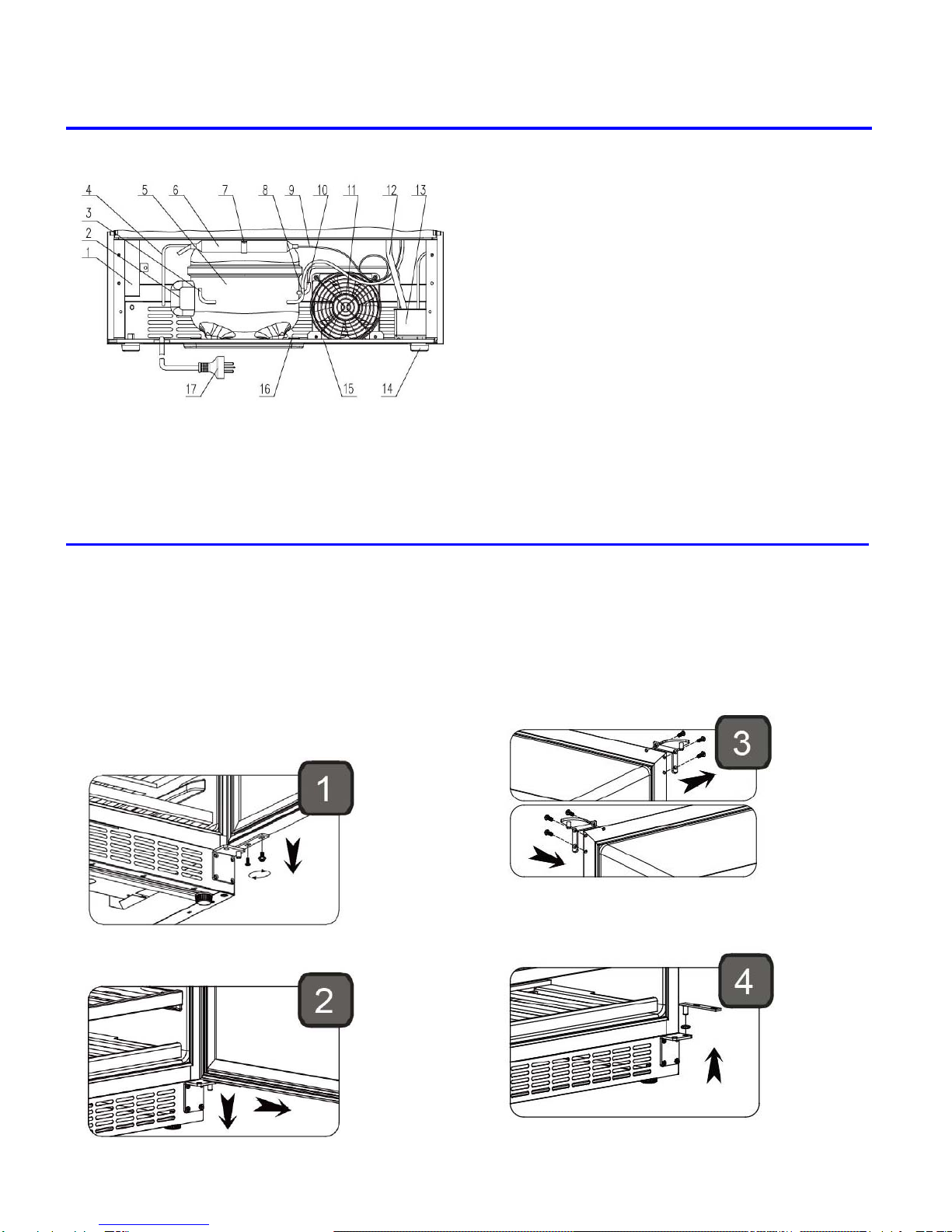

COMPRESSOR ROOM VIEW AND PARTS LIST…………………………………………………..…….……………….………..……....4

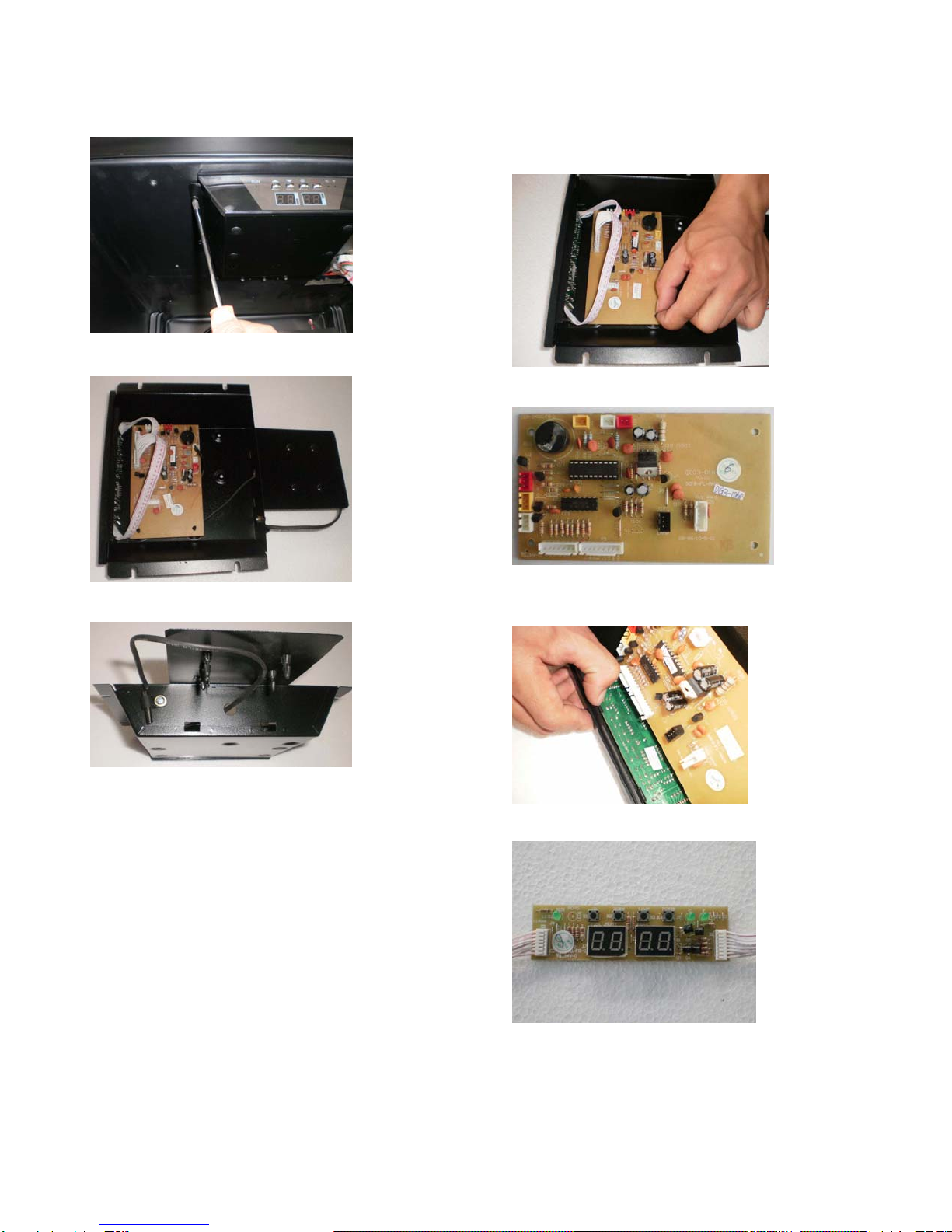

HOW TO REVERSE THE DOOR SWING……………………………………………………………………….……………………..…...4-5

HOW TO ATTACHING THE DOOR HANDLE…………………………………………………………….………………………………….5

HOW TO REMOVE THE SHELVES………………….…………………………………………………………..……..……………….…….6

HOW TO REPLACE THE MAIN PARTS………………………………………………………………………………..…………………6-11

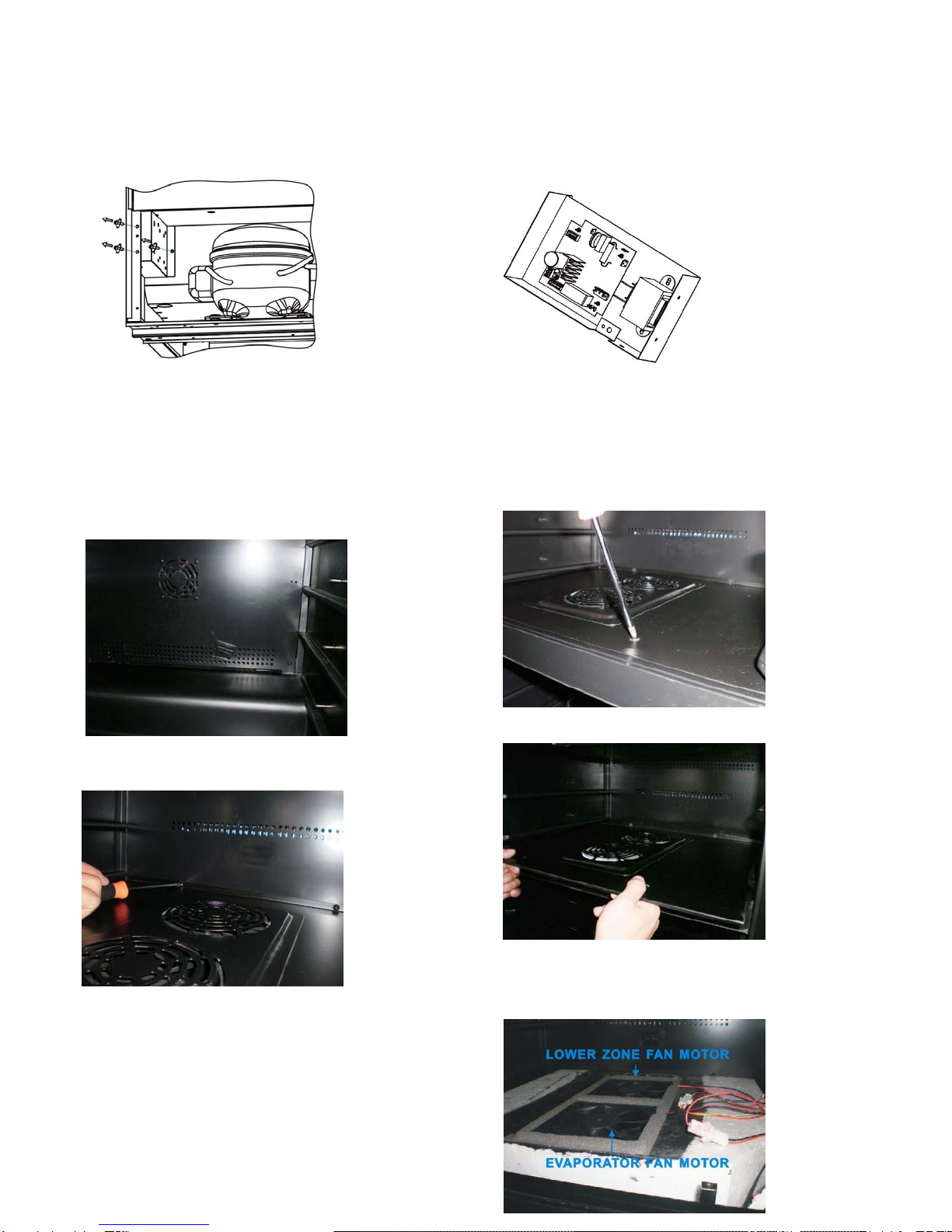

REPLACING THE CONTROL PCB , DISPLAY PCB ,UPPER ZONE SENSER & UPPER ZONE LED ASSEMBLY ….....…….…6-7

REPLACE THE POWER PCB & TRANSFORME…………………..…………………………………….…………...……………..…..…..8

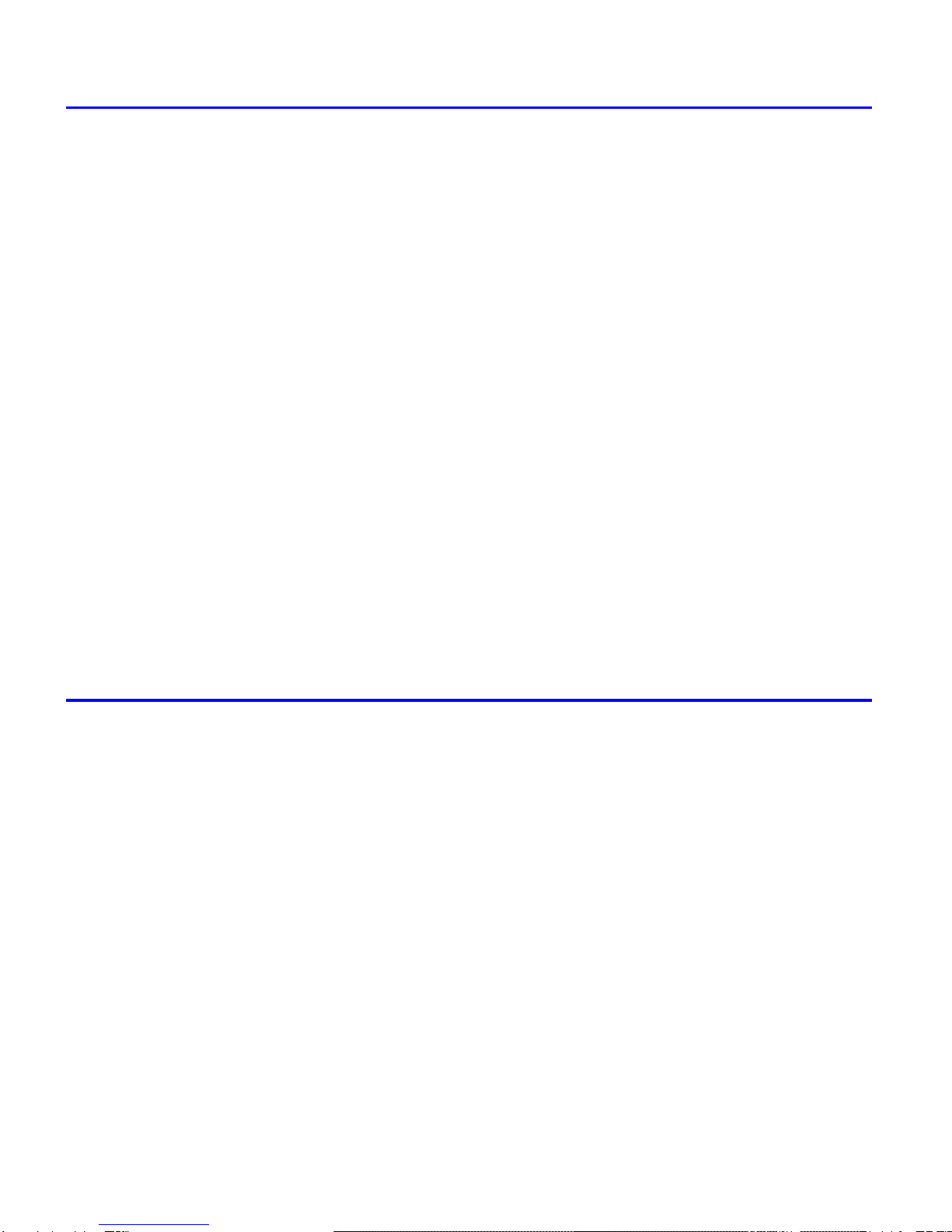

REPLACING THE LOWER ZONE LED LIGHT ASSEMBLY ,EVAPORATOR, PTC HEATER, FAN MOTORS & SENSORS….8-10

REPLACE THE CONDENSER FAN MOTOR ,COMPRESSOR STARTER & PROTECTOR………..………………………...…….. 11

ADJUSTMENT………………………………………………………………………………………………….…………..….………...….12-14

COOLING SYSTEM FAULTS……………..………...…………………………………………………………………….….…..…….……..12

PTC HEATER FAULTS……………..………...……………………………………………………………………..….……………….…12-13

NOISE OF WINE COOLLER……………..………...……………………………………………………………………………...………….13

EVAPORATOR FREEZING……...………………………………………………………………………………………..………………13-14

DESCRIPTION OF CONTROL PCB & POWER PCB………………………………………………………………………….….……….14

TROUBLESHOOTING…………………………………………………………………………………………………..……………………..15

TROUBLES SHOOTING GUIDE……………………………………………………………………………………..…..…………….….….15

SAFETY PRECAUTIONS

Please read the followingsbefore servicing your wine storage

1. Check if an electric leakage occurs in the set.

2. To prevent electric shock, unplug prior to servicing.

3. In case of testing with power on, wear rubber

gloves to prevent electric shock.

4. If you use any appliances, check regular current,

voltage and capacity.

5. Don't touch metal products in cold freezer with wet

hand. It may cause frostbite.

6. Prevent water flowing to electric elements in

mechanical parts.

7. When servicing evaporator part, wear cotton

gloves without fail. It is to prevent wound by

sharp fin of evaporator.

8. Leave a breakage of refrigerating cycle to a

heavy service center. The gas in cycle inside

may soil ambient air.

9. Never clean appliance parts with flammable fluids.

The fumes can create a fire hazard or explosion.