Edgetech SENTRY-85 User manual

1

SENTRY™

OPERATORS MANUAL

Rev. D April 2016

COPYRIGHT NOTICE: Copyright 2016 Edgetech Instruments Inc. (ETI)

This work is protected under Title 17 of the US Code and is the sole property of ETI No part of this document may be copied

or otherwise reproduced, or stored in any electronic information retrieval system, except as specifically permitted under US

copyright law, without the prior written consent of ETI.

2

QUICK STARTUP GUIDE

Electrical and compressed Gas Hazards

The SENTRY is designed to detect low pressure or high dew point conditions within

compressed air or inert gas systems. It consists of a display control module and a

SMART, Multi-Sense Probe. Using the supplied ½ inch Male NPT pipe fitting, the

probe is inserted directly within the compressed air system header, accumulator

tank, or at the point of use. The SENTRY system continuously monitors both

pressure and dew point and provides a warning system to alert an operator should

there be a pressure loss or dryer failure.

The Sentry system comes fully prewired and requires only installation of the display

control module box and the probe. A power connection needs to be available within

3m (10ft).

There are two models available:

SENTRY-85: Combined strobe light and 85dB Audible Alarm.

SENTRY-100: Separate strobe light and 100dB Audible Alarm.

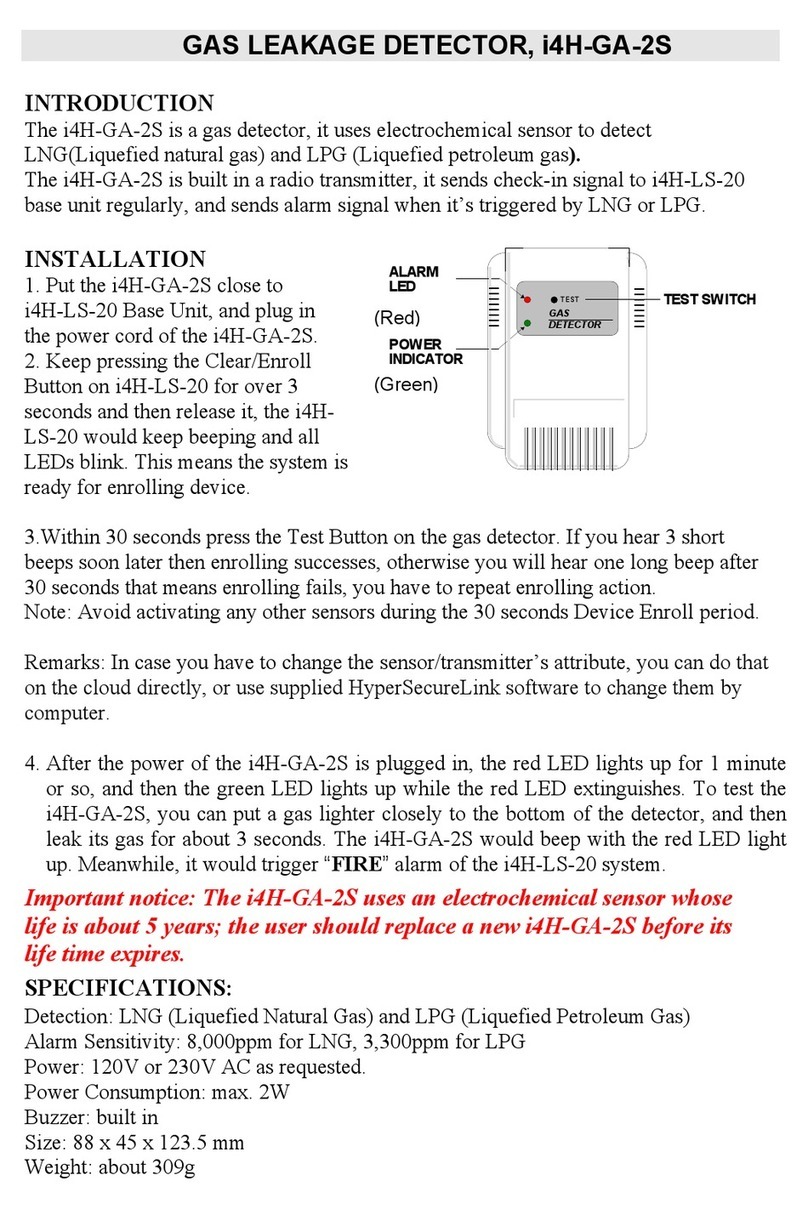

SENTRY-85

Compressed Air Monitor

Dew Point -10C

Pressure: 120 PSIG

SENTRY-100

Compressed Air Monitor

Dew Point -10C

Pressure: 120 PSIG

Alarm

Disable

Switch

Mute

Switch

HPP125 Sensor ProbeHPP125 Sensor Probe

3m Power Cord

1 m Signal Cable

3m Power Cord

1 m Signal Cable

Sentry 85 utilizes an Alarm disable switch which will deactivate both the Audible and

visual alarms.

Caution if the switch is left in the deactivate position there will be no alarm

function.

Sentry 100 utilizes an Alarm mute switch that will silence the Audible alarm.

Caution if the switch is left in the mute position only the visual alarm will be active.

3

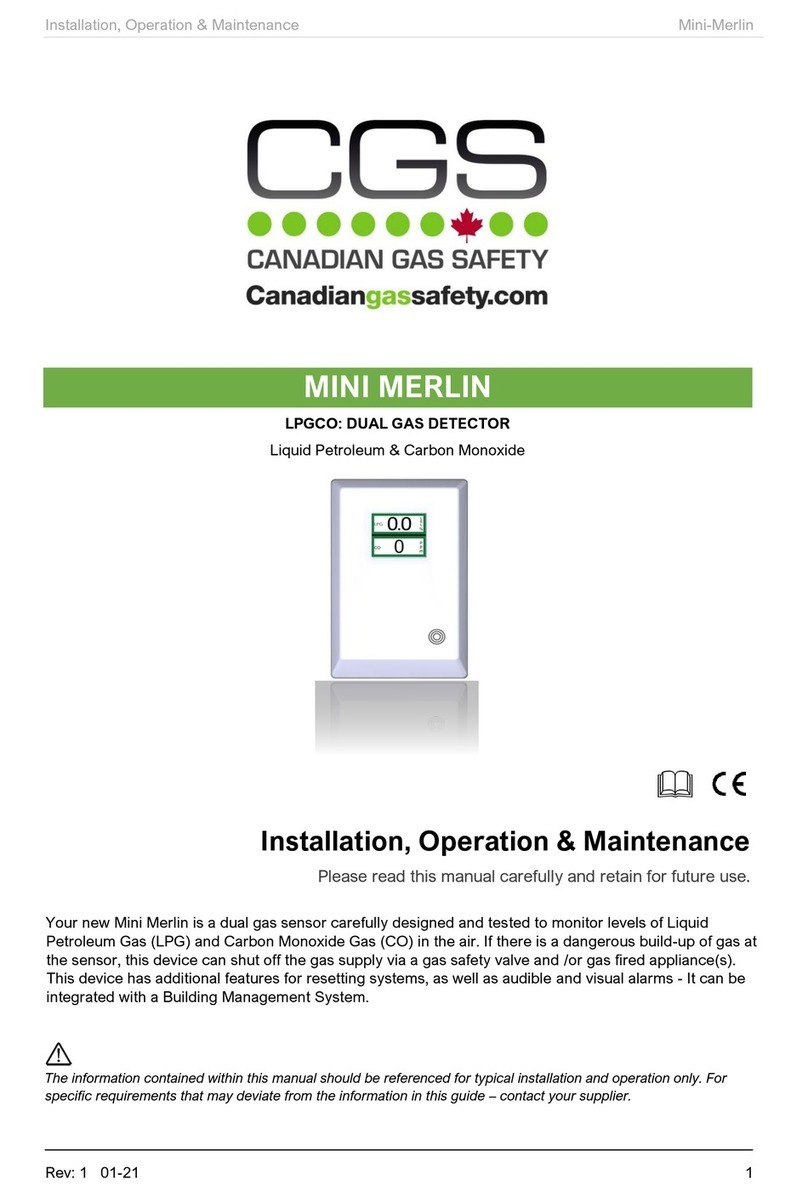

Mounting the Display and control box.

Both the Sentry 85 and Sentry 100 have the same mounting process.

RH 49.0% P 150 PSIG

T 23.7C DP 12.4C

4.53in (115.0mm)

5.12in (130.0mm)

5.12in (130.0mm)

4.53 in (115mm)

4.53in (115.0mm)

4.53 in (115mm)

COVER

REMOVED TO

SHOW

MOUNTING

HOLES

5.12in (130.0mm)

3.90in (99.0mm)

Dew Point -10C

Pressure: 120 PSIG

1.32 in

(34mm)

POWER

Signal

Cable

1.38 in

(35.1mm)

Optional

100dB HORN

1. Note the probe connection cable is 3ft long so the display must be

mounted within 3ft of the probe insertion point.

2. Remove the cover. The control box can be mounted with 4 screws

installed through the same holes as the cover mounting screws.

Electrical and compressed Gas Safety Hazards

The Sentry system delivered to you has been tested for safety, calibrated and

approved as shipped from the factory. Note the following precautions:

CAUTION

Do not modify the unit. Improper modification can damage the

product or lead to malfunction.

CAUTION

The transmitter body does not have user serviceable parts inside,

and is not designed to be opened. Opening the transmitter will

void the warranty.

4

ESD Protection

Electrostatic Discharge (ESD) can cause immediate or latent damage to

electronic circuits. Edgetech Instruments products are adequately protected

against ESD for their intended use. It is possible to damage the product,

however, by delivering electrostatic discharges when touching, removing, or

inserting any objects inside the equipment housing.

1. To make sure you are not delivering high static voltages yourself when handling

the replaceable sensor tip PCB.

2. Handle ESD sensitive components on a properly grounded and protected ESD

workbench.

3. When an ESD workbench is not available, ground yourself to the equipment

chassis with a wrist strap and a resistive connection cord.

4 If you are unable to take either of the above precautions, touch a conductive part

of the equipment chassis with your other hand before touching ESD sensitive

components.

5 Always hold component boards by the edges and avoid touching the

component contacts.

Using “Swagelok” fitting

1. How to install Swagelok fittings. Insert the HP125 probe to your selected

insertion depth. Avoid the area adjacent to and below the threaded tip cover

joint area

2. Tighten by hand until the nut is finger tight. Further tighten the nut until the

probe will not turn by hand and cannot be moved axially in the fitting.

a. Mark the nut at the at the 6-0-clock position

b. While holding the fitting body steady, tighten the nut one and one

quarter turns till the nut is in the 9-0-clock position.

c. Swagelok fittings may be disassembled and reassembled many times.

See Sentry Manual

Mounting the PROBE with CABLE.

Before mounting the probe into any system ensure the system is safe

to work on. Depressurize and verify that all the power connections are isolated

in the OFF position.

Installation should be carried out by trained technicians and following all local

safety protocols.

1. Ensure there is adequate cable length from the probe cable to make

connection to the control box.

2. Select Probe insertion position, ensure safe clearance around the probe

to avoid damage.

3. Check all pipe fittings and pipe boss dry assembly for fit up. Probe is

standard with ½” NPT fitting, optional ¾” NPT.

4. Insert pipe fittings using suitable sealing tape or sealing compound.

Mount the Probe in position to measure the desired gas.

5

5. Ensure the Probe is inserted to an adequate depth to obtain a good flow

of the sample gas around the tip sensor. Insertion depth: Max 6” (15cm)

Min 2.4” (6cm). The compression fitting should avoid the threaded tip

cover joint area.

6. Tighten the swage fitting till it grips the probe in place but at this stage do

not apply force.

7. Re check the probe position and measurement depth are correct, fully

tighten all pipe fittings

8. Slowly pressurize the system checking for any leaks. Do not quickly apply

pressure. If the probe is incorrectly fitted it will be projected out of the

fitting and can cause injury or damage.

Do not apply Power until all wiring is completed and checked

The Sentry unit is a standalone system and can now be powered up. If working

correctly 3 values will be displayed on the read out.

Additional customer connections

1. Two 4-20mA Analog Outputs: Pressure and Dew Point.

2. RS-232 Serial Interface.

3. One user accessible relay for remote low pressure/ high dew point

alarm.

TERMINAL TB1

ITEM

1, 2

ALARM Relay

6

4-20mA OUTPUT Pressure

7

4-20mA OUTPUT Dew Point

8

4-20mA COM.

11

RS232 RETURN

14

RS232 TX

15

RS232 RX

6

Notes:

Connect only the outputs desired.

Do not apply Power until all wiring is completed.

When the unit is powered up the display will show the Alarm set point (Pressure and

Dew point).

Default factory set Alarm points are Pressure 90PSIG and DewPoint -20F.

When the unit is powered up the display will show the 4-20mA range settings for

optional remote connections.

Default factory range is Pressure 0 to 400PSIG and Dew point -40 to 140F.

The Dew Point value is displayed as Dew Point at atmospheric pressure. The

system has imbedded intelligence that automatically corrects the DewPoint display

so it always corrected to the system pressure.

The pressure is displayed as PSIG.

The default display units are pressure in PSIG and DewPoint and temperature in

degree F.

Always turn the power off before disconnecting

or reconnecting the probe

7

TABLE OF CONTENTS Page

1.0 Quick Startup Guide 2

2.0 Commitment to Quality 9

3.0 Introduction 10

3.1 General Description 10

3.2 Standard Factory Configurations 10

3.2.1 Factory Default Output Ranges 11

3.3 Options and Accessories 11

4.0 Installation 12

4.1 Placement of Instrument 12

4.2 Mounting 12

4.2.1 Display Mounting 12

4.3.1 Probe Mounting 12

4.3 Electrical Wiring 13

4.3.1 Power Supply 13

4.3.2 Input/Output Wiring 14

5.0 Operation 15

5.1 Using the RS-232 Serial Port 15

5.2 Serial Port Setup 16

5.3 Programming via USB 16

5.4 Programming the Sentry 16

5.4.1 Changing between Metric & Imperial 17

5.4.2 Calibrating the 4-20mA ranges 17

5.4.3 Calibrating the Alarm relays 18

6.0 Maintenance 19

6.1 Routine Maintenance 19

6.1.1 Changing the Tip sensor 19

7.0 Specifications 20

8.0 Appendix 21

8.1 Warranty Statement 22

8.2 NIST Traceability 23

8.3 Mounting Dimensions 24

8.3.1 Wall Mount (plastic housing) 24

LIST OF ILLUSTRATIONS Page

3-1 Standard Configurations 10

4.1 HP125 probe dimensions 13

4-2 Terminal Strip Wiring 14

6-1 Tip sensor 19

8

LIST OF TABLES

4-1 Terminal Strip Wiring 13

4-2 Analog Output Switch Settings 14

5-1 Serial Cable Wiring 16

9

2.0 EDGETECH INSTRUMENTS INC.'S COMMITMENT TO

QUALITY

Thank you for purchasing one of our products. At Edgetech

Instruments, it is our policy to provide cost-effective products and

support services that meet or exceed your requirements, to deliver

them on time, and to continuously look for ways to improve both.

We all take great pride in the products which we manufacture 100%

in the USA.

We want you to be entirely satisfied with your instrument. The

information contained in this manual will get you started. It tells you

what you need to get your equipment up and running, and introduces

its many features.

We always enjoy hearing from the people who use our products.

Your experience with our products is an invaluable source of

information that we can use to continuously improve what we

manufacture. We encourage you to contact or visit us to discuss any

issues whatsoever that relate to our products or your application.

The Employees of Edgetech Instruments Inc.

10

3.0 INTRODUCTION

3.1 GENERAL DESCRIPTION

The Model Sentry Compressed air alarm system is, designed to continuously

measure the status of your compressed air system. The instrument is powered

universal power supply. It uses a RH polymer and pressure sensors to determine

the water vapor concentration in gas mixtures together with system pressure and

temperature measurements. Outputs include 4 to 20 mA (Factory default settings

unless specified otherwise when ordering), Two sets of analog outputs are supplied.

Additional outputs include an RS-232C serial port, as well as electrically isolated

relay contacts. The system is equipped with both visual and audible alarms to

ensure that operators are quickly notified if there is a problem with the compressed

air system.

3.2 STANDARD FACTORY CONFIGURATIONS

The Sentry is designed with a Standard configuration, as shown here.

In addition, you can consult the Factory for special configurations if needed.

The SENTRY is designed to detect low pressure or high dew point conditions within

compressed air or inert gas systems. It consists of a display control module and a

SMART, Multi-Sense Probe. Using the supplied ½ inch Male NPT pipe fitting, the

probe is inserted directly within the compressed air system header, accumulator

tank, or at the point of use. The SENTRY system continuously monitors both

pressure and dew point and provides a warning system to alert an operator should

there be a pressure loss or dryer failure.

The Sentry system comes fully prewired and requires only installation of the display

control module box and the probe. A power connection needs to be available within

3m (10ft).

There are two models available:

SENTRY-85: Combined strobe light and 85dB Audible Alarm.

SENTRY-100: Separate strobe light and 100dB Audible Alarm.

SENTRY-85

Compressed Air Monitor

Dew Point -10C

Pressure: 120 PSIG

SENTRY-100

Compressed Air Monitor

Dew Point -10C

Pressure: 120 PSIG

Alarm

Disable

Switch

Mute

Switch

HPP125 Sensor ProbeHPP125 Sensor Probe

3m Power Cord

1 m Signal Cable

3m Power Cord

1 m Signal Cable

11

3.2.1 FACTORY DEFAULT OUTPUT RANGES

These standard output measurement ranges apply to all instruments unless

specified otherwise when ordering. They correspond to 4 to 20 mA. There are 2

analogue outputs the factory defaults at selected. Analogue output 1 Dew Point.

Analogue output 2 is set for Pressure or %RH depending on probe tip selection.

Default factory set Alarm points are Pressure 90PSIG and DewPoint -20F

When the unit is powered up the display will show the 4-20mA range settings for

optional remote connections.

Default factory range is Pressure 0 to 400PSIG and Dew point -40 to 140F.

The Dew Point value is displayed as Dew Point at atmospheric pressure. The

system has imbedded intelligence that automatically corrects the DewPoint display

so it always corrected to the system pressure.

The pressure is displayed as PSIG.

The default display units are pressure in PSIG and DewPoint and temperature in

degree F.

Range Dew Point: -40°C to 90°C (-40°F to 194°F)

Pressure 0 to 400PSIG

% RH 0 to 99.9%

Air Temp: -40°C to 125°C

3.3 OPTIONS AND ACCESSORIES

The Sentry is designed to accept a small number of options and accessories to

expand its capabilities.

LDP - Low Dew Point Tip sensor to -60C DP.

CAM - Compressed Air Module to allow easy and safe access to the probe without

the need to turn off or depressurize the system to access the probe.

3/4NPT- Large pipe fitting adaptor ½ to ¾ NPT to replace probes that used a

3/4NPT penetration.

12

4.0 INSTALLATION

4.1 PLACEMENT OF INSTRUMENT

If possible, locate the Sentry in a clean area where the air to be measured is allowed

to freely move around the enclosure. Optimal performance of the instrument is

experienced when air is gently moving over sensor, providing a representative

sample for measurement. Choose a location where the display may be conveniently

observed. Depending on the location selected, it may be convenient to wire the

instrument prior to mounting.

4.2 MOUNTING

4.2.1 WALL MOUNT

Instruments with the plastic wall mount housing are mounted to a flat surface as

follows:

1. Remove the front cover. Using a flat screwdriver, carefully unscrew the

four slotted plastic screws.

2. Mounting screws (not provided) are inserted in the same holes as the

cover screws. They must have a head diameter that is small enough to fit

inside the clearance holes, but large enough to press against the collar

located at the bottom of the holes. No. 8 pan head or round head screws

are recommended.

3. Reinstall the front cover. Do not over-tighten the cover mounting

screws.

4.2.3 Mounting the PROBE with CABLE.

Before mounting the probe into any system ensure the system is safe

to work on. Depressurize and verify that all the power connections are isolated

in the OFF position.

Installation should be carried out by trained technicians and following all local

safety protocols.

1. Ensure there is adequate cable length from the probe cable to make

connection to the control box.

2. Select Probe insertion position, ensure safe clearance around the probe

to avoid damage.

3. Check all pipe fittings and pipe boss dry assembly for fit up. Probe is

standard with ½” NPT fitting, optional ¾” NPT.

4. Insert pipe fittings using suitable sealing tape or sealing compound.

Mount the Probe in position to measure the desired gas.

5. Ensure the Probe is inserted to an adequate depth to obtain a good flow

of the sample gas around the tip sensor. Insertion depth: Max 6” (15cm)

Min 2.4” (6cm). The compression fitting should avoid the threaded tip

cover joint area

13

6. Tighten the swage fitting till it grips the probe in place but at this stage do

not apply force.

7. Re check the probe position and measurement depth are correct, fully

tighten all pipe fittings

8. Slowly pressurize the system checking for any leaks. Do not quickly apply

pressure. If the probe is incorrectly fitted it will be projected out of the

fitting and can cause injury or damage.

Do not apply Power until all wiring is completed and checked

The Sentry unit is a standalone system and can now be powered up. If working

correctly 3 values will be displayed on the read out.

4.3 ELECTRICAL WIRING

4.3.1 POWER SUPPLY

The Sentry systems is delivered from the factory pre wired for both the HP125 Probe

and power. Simply install the probe to the pin connector and close the locking twist

collar.

The power supply is a universal power supply. All that is required is to have an outlet

within 10ft (3M) of the unit as this is the length of the standard power cord.

DO NOT APPLY POWER TO THE UNIT UNTIL THE INSTALLATION HAS BEEN

COMPLETED.

DO NOT APPLY POWER TO THE UNIT UNTIL THE INSTALLATION HAS BEEN

COMPLETED.

Additional customer connections

1. Two 4-20mA Analog Outputs: Pressure and Dew Point.

2. RS-232 Serial Interface.

3. One user accessible relay for remote low pressure/ high dew point

alarm.

4.

TERMINAL TB1

ITEM

1, 2

ALARM Relay

6

4-20mA OUTPUT Pressure

7

4-20mA OUTPUT Dew Point

8

4-20mA COM.

11

RS232 RETURN

14

RS232 TX

15

RS232 RX

14

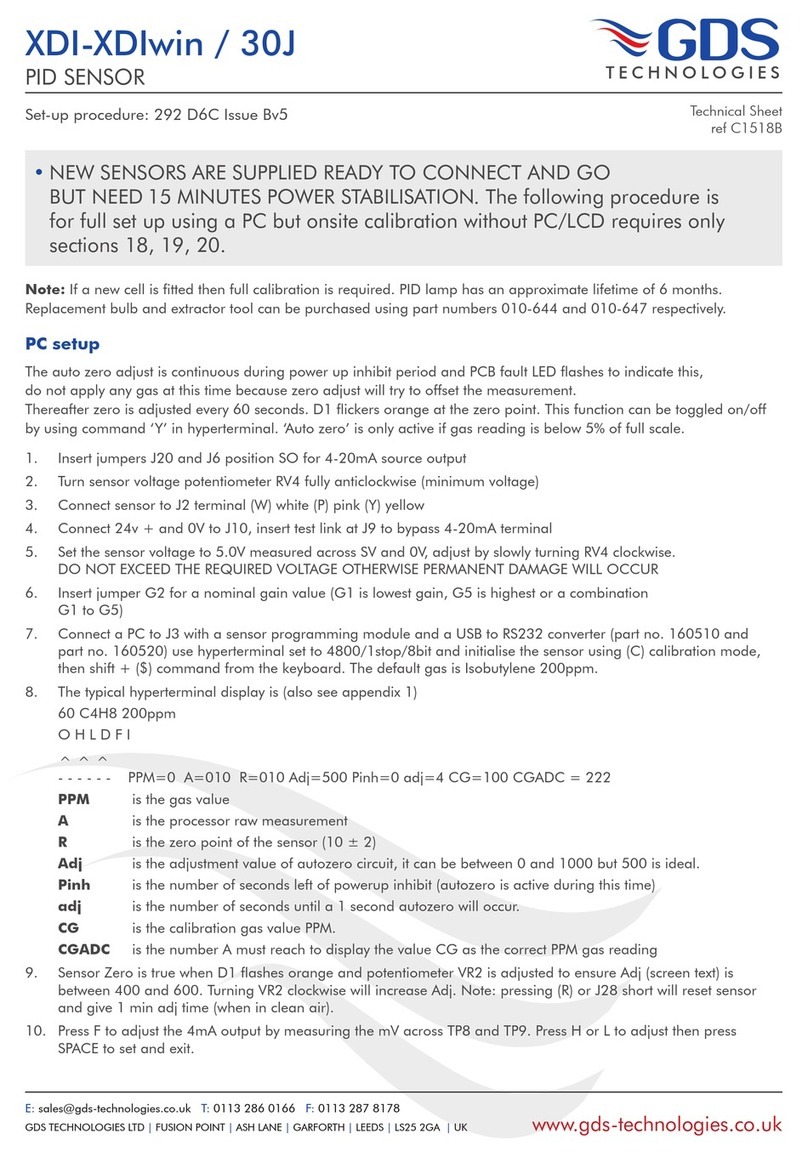

Figure 4-2 Terminal Strip Wiring

4.3.2 INPUT/OUTPUT WIRING

Wire the Analog Outputs as required. See 4.1 above for information on output

selection.

Connect the RS-232 Serial Output if desired. Only 2 wires are required if the output

is needed for transmitting information only. A third wire is added for bi-directional

communications with the serial port.

Connect the relays as needed. Used as upper or lower set point Alarm Relays. See

Section 5.4.3 for further information.

RS232 RTN

ANALOG OUT RTN

ANALOG OUT 1

ANALOG OUT 2

RS232 RX

RS232 TX

ALARM 2

CHASSIS GND

15

5.0 OPERATION

5.1 USING THE RS-232C SERIAL PORT TO REPROGRAM YOUR

SETTINGS

Note: If the Factory Default settings are satisfactory, there is no reason to perform

any programming.

The Sentry series air header system alarm is very versatile. Through the Serial Port,

the user may view current settings, change factory set parameters, or receive an

automatic update of system measurements and alarm status. Factory Set

parameters include:

Serial number of the Smart Sensor Tip

Version Software

Pressure set points: alarm engaged, disengaged

Dew Point set points: alarm engaged, disengaged

Units for Dew Point: degrees F or C

4-20mA output Pressure: Range Setting

4-20mA output Dew Point: Range Setting

5.2 SERIAL PORT SETUP

You will need a serial cable with a female DB-9 connector on one end, which will

mate to the serial port connector on your PC. ETI offers an RS-232 cable in our

accessories. If you do not have a serial port on your PC, jump to the next page “PC

with USB port only”. The open end of your RS-232 Serial cable will need the three

associated wires for Transmit / Receive / Return identified and exposed. These

wires are to be connected to Terminal Strip TB1 on the Sentry circuit board as

shown below:

Table 5-1 Serial Cable Wiring

Female DB-9 SERIAL CONNECTOR

TB1 TERMINAL STRIP

Pin 2

TX –Term. 14

Pin 3

RX –Term 15

Pin 5

RTN –Term. 11

Sentry terminal block:

SENTRY-100

Compressed Air Monitor

Dew Point -10C

Pressure: 120 PSIG

CUI VOF-65-24 POWER SUPPLY

SENTRY MAIN BOARD -TB1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

FEDERAL SIGNAL

PMC- STROBE/HORN

Flash Lite/ Pulse Horn

24 vdc output

- - + + RELAY 2

C NO

VAC POWER INPUT

L2 L1 GND RELAY 1

C NO

Chassis

GND

Analog

Out 2 +

Analog

Out 1 +

Analog

COM

RS-232

Tx Rx

24 VDC OUT

+ -

RS-232

RTN

No connection

No connection

Power Cord

NO

NC

C

“MUTE”

C 1

8" BLK

CUSTOMER

CUSTOMER

CUSTOMER

CUSTOMER

8" Red

WERMER 100 dB Horn

X2

X1

5" YEL

BLK

8" BLK

9" Red

6" BLK

5" ORG

7" ORG

Edgetech Instruments Inc.

Alarm Lite and Buzzer

Wiring of SENTRY 100/ ASHA2000

SK-03302016A 1 of 2

RJN April 5, 2016

Reference Only

16

5.3 PC with USB Port only:

If your PC does not have an available serial port, you can use the ETI accessory:

RSCBL (RS232 cable) plus the USB (USB to SERIAL Converter). The ETI kit

provides the 3 stripped RS232 wires, labeled and the wire ends properly tinned- to

be connected to the Sentry plus a USB converter jack to plug into your PC USB port.

Using a terminal emulation program, such as HyperTerminal or TERA TERM, set

your PC Com Port to:

BAUD: 19200

BITS 8

STOP BITS 1

PARITY NONE

FLOW CONTROL NONE

After connecting the serial cable, apply power to the Sentry. A window appears

showing warm-up and self-test data. Also included is Identification information

including probe serial number and version of software. If the sensor probe or the

smart sensor tip is not installed, a warning message will display. In this case, power

down the unit, install the tip/ probe, and re-power the Sentry.

After the self-checking and start-up period, the window will display information

similar to the photo shown on next page. This is the default condition. It indicates

the current settings:

Degrees F for Dew Point

Imperial Display

4-20mA output for Dew Point

4-20mA output for

Pressure

DewPoint Alarm

Settings: F or C,

set point on dewpoint

rise and setpoint on

dew point restore

Pressure Alarm

Settings: PSIG,

setpoint on pressure

loss and setpoint on

dew restore

And then it begins to

display the Sensor Serial Number followed by current measured values in a text

string, tab delimited.

5.4 PROGRAMMING THE SENTRY

If you do not see a window similar to the one shown above, you will not be able to

program this instrument.

17

Check your terminal emulation program, the power supply, and check the

interconnecting cable wiring as shown in Table 5 -1 above.

NOTE: WHEN PROGRAMMING ALPHABETIC CHARACTERS, USE UPPER

CASE ONLY.

To begin reprogramming, press the ESCape key on your computer keyboard. The

window will change to that shown below. To select the desired parameter, simply

select the first letter as shown.

You will find it quite intuitive once you try it. Several programming examples will be

shown here.

5.4.1Changing Between Metric and Imperial values

Units of Measurement:

To change the units of

measurement from

ENGLISH (Imperial) which

is standard (DegF, PSI) to

metric (DegC, Bar)- enter

“L”.

Enter “2” for English

(imperial) or “1” for Metric

as prompted. The entry

will be recognized and then

prompt to Enter or “X” to

exit.

5.4.2 Changing 4-20mA outputs

4-20mA Outputs: There are (2) 4-20mA outputs. These are factory set to

represent Pressure and DewPoint. To set the 4-20mA output ranges enter “S”.

Enter “1” for change output 1. Or enter “2” to change output 2.

To set Output 1, enter “1”.

You will be prompted to

enter which parameter to

represent output 1. In the

example above, output 1 is

set to represent DewPoint

in degrees F by entering

“5”. Next you are

prompted to enter the low

value. In the example

above, “-40” was entered

to represent 4 mA.

Then you are prompted to

enter the high value. In the example above, “140” was entered to represent 20mA.

The entry will be recognized and then prompt to enter “S” to save new settings or “X”

to exit.

18

To set Output 2, Enter “2

In the example, Output 2 is

set to represent pressure

by entering “7” when

prompted. Pressure is

represented in the Sentry

as PSIG units. You will be

prompted to enter a psig

value for the low setting.

In the example, 4 mA is set

to “0” psig and 20mA is set

to “400” psig.

5.4.3 RELAY OUTPUTS

Two relays, R1 and R2, are built into the Sentry

There are (2) ALARM LOGIC PARAMETERS. There are (2) Alarm Relays. One

relay is reserved for factory use, the second is a duplicate logic, but is available to

the customer. The Relay Alarms are factory set to represent Pressure Loss and

High DewPoint . The logic that turns the alarm on, is either pressure loss or high

dew point. Both relays follow the same logic. For each logic point (pressure and

dew point) a trip point and a reset to normal operation point is set.

For loss of pressure, the setpoint determines the pressure point when the alarm is

activated (Default is 95PSIG). Normal operation of the Sentry is not restored (alarm

off) until the return to normal operation point is achieved for both logic points

(pressure and dew point). The return to normal point is set to a higher pressure

point than the trigger point. The factory default is 5 psig higher than the trigger point

(Default100PSIG).

For high dew point, the setpoint determines the dew point when the alarm is

activated. Normal operation is not restored (alarm off) until the return to normal

operation point is achieved This second dew point is set to a lower dew point than

19

the trigger point. The factory default is 5 degrees below the trigger point. Both

conditions must be at return to normal operation before the alarm turns off.

To set the Alarm setpoints

enter “M”. The current

settings will be displayed.

Then follow the prompts to

enter the setpoints.

After you have made the

alarm setting, enter S to

save or X

to exit.

6.0 MAINTENENACE

6.1 ROUTINE MAINTENANCE

The only maintenance required by the Sentry is periodic check to ensure the unit is

functioning. The rate of contamination of the tip filter, varies from user to user. It

depends upon flow rate of the gas being measured, the quantity of contaminants in

the gas.

The HP125 probe intelligent tip sensor does require yearly calibration. The Sentry

system can also have a replacement calibrated tip supplied to allow a fast onsite

change over for a new fully calibrated tip board with no down time.

SENSOR CIRCUIT BOARD

Inside the barrel of the Sensor probe, mounted directly at the tip, is the plug-in

sensor circuit board. This board has been calibrated at the Factory for a standard

output level. Since all boards have been calibrated for the same normalized level,

they may be replaced in the field without the requirement for recalibration, while

maintaining the full published system accuracy specification.

Figure 6-1 Exploded view showing the Sensor Circuit Board

6.1.1 REMOVING THE SENSOR CIRCUIT BOARD

Figure 7-1 shows the Sensor Circuit Board. It may be accessed by first unscrewing

the mesh filter. Then holding the sides of the sensor tip gently pull out in a straight

pulling motion. Do not move the tip from side to side as this can damage the

connectors.

For replacement Intelligent tip the Sentry uses the code HPP configuration

Always turn the power off before

disconnecting or reconnecting the probe

20

7.0 SPECIFICATIONS

Measurement Range:

Dew Point: -40°C to 95°C (-40°F to 140°F)

LDP Option -60°C to 95°C (-75°F to 140°F)

Ambient Temperature: -40°C to 125°C (-40°F to 140°F)

Equivalent %RH: 1% to 99.9%

Operating Temperature:

Sensor: -60°C to 125°C (-40°F to 149°F)

Control Unit: 0°C to 50°C (32°F to 122°F)

Pressure: 400 psig maximum (30bar)

Analog Outputs: 4 to 20 mA

Load: 4 to 20 mA : 400 ohms or lower

0 to 5/10VDC: 1K ohm or higher

Serial Outputs: RS-232C, bidirectional

Relay Outputs:

K1: Alarm 1

Contact Rating: Normally Open (Form A)

3A at 250VAC, or 30VDC

Remote Cables: 3 ft. standard

Power Supply: 110/220V 60/50Hz

This manual suits for next models

1

Table of contents

Popular Gas Detector manuals by other brands

ESYLUX

ESYLUX PROTECTOR CD 45 manual

Gas Clip Technologies

Gas Clip Technologies Multi Gas Clip quick start guide

BW Technologies

BW Technologies GasAlertQuattro 1 Quick reference guide

Bacharach

Bacharach MGS 550 user manual

Pilot Communications

Pilot Communications 2011319/716/12 Operation and maintenance manual

Honeywell

Honeywell BW Ultra Quick reference guide