EDI 210E User manual

THIS MANUAL CONTAINS TECHNICAL INFORMATION FOR THE FOLLOWING SERIES

OF MODEL 210/2010/2018 SIGNAL MONITORS, PCB Issue G:

210E, 210ECL, 2010, 2010ECL, 2010ECLip, 2018ECL, 2018ECLip

REVISION: NOVEMBER 2014

pn 888-2010-002

- NOTE -

EDI ECCOM SOFTWARE MUST BE UPDATED TO VERSION 3.8.0 OR

GREATER FOR COMPATIBILITY WITH THIS FIRMWARE VERSION.

THE ECCOM SOFTWARE IS AVAILABLE FREE OF CHARGE AT

WWW.EDITRAFFIC.COM

210E - 210ECL - 2010ECL - 2018ECL

RMS Signal Monitor

Operations Manual

THE 210/2010/2018 SERIES SIGNAL MONITOR UNIT IS DESIGNED AND

MANUFACTURED IN THE USA BY EBERLE DESIGN INC., PHOENIX, ARIZONA, AN

ISO 9001:2008 REGISTERED COMPANY

INFORMATION CONTAINED HEREIN IS PROPRIETARY TECHNICAL INFORMATION

OF EBERLE DESIGN INC. PUBLICATION, REPRODUCTION OR USE IN WHOLE OR

PART IS NOT PERMITTED EXCEPT UNDER TERMS AGREED UPON IN WRITING.

©COPYRIGHT 2014 EDI

MAINTENANCE NOTE

EBERLE DESIGN INC. SIGNAL MONITORS HAVE BEEN

CAREFULLY INSPECTED AND TESTED TO ENSURE PROPER

OPERATION. IT IS RECOMMENDED THAT THE SIGNAL MONITOR

BE TESTED AT LEAST ANNUALLY TO ENSURE COMPLIANCE

WITH THE PROPER SPECIFICATIONS.

SECTION 4.1.2, SPECIAL FUNCTION INPUTS

SPECIAL FUNCTION #2 HAS BEEN DISABLED TO PROVIDE

COMPATIBILITY WITH THE MT-180 MONITOR TESTER.

RESISTOR R31 HAS BEEN REMOVED TO DISABLE THIS

CIRCUIT. IF SPECIAL FUNCTION #2 INPUT IS REQUIRED, R31

(150K OHMS, 1/2W) SHOULD BE INSTALLED.

- WARNING -

THE P1 RED INTERFACE CABLE SHOULD ALWAYS BE UNPLUGGED

BEFORE REMOVING THE UNIT FROM THE CABINET TO PREVENT

POTENTIAL EXPOSURE TO ELECTRICAL SHOCK.

- WARNING -

PIN 27 OF THE MAIN CONNECTOR PROVIDES THE CLOSED CONTACT OF

THE OUTPUT RELAY WHEN THE MONITOR IS IN THE NO-FAULT STATE.

WHEN THE MONITOR IS IN THE NO-FAULT STATE AND THE AUTO/FLASH

SWITCH IS IN THE FLASH POSITION, AC LINE VOLTAGE MAY BE PRESENT

ON PIN 27.

THIS PIN WAS PREVIOUSLY DEFINED AS A “NO-CONNECT’ PIN IN LEGACY

EQUIPMENT. TO PREVENT POTENTIAL EXPOSURE TO ELECTRICAL

SHOCK, BEFORE INSTALLING THIS MONITOR THE USER IS CAUTIONED

TO CHECK THAT THE CABINET WIRING IS COMPATIBLE WITH THE USE OF

THIS PIN AS A SOURCE OF AC LINE VOLTAGE.

Table of Contents

Section 1 BASIC FUNCTIONS .............................................................................................1

1.1 Model Description ......................................................................................................1

1.2 Basic Functions .........................................................................................................1

1.2.1 Conflict Monitoring ...........................................................................................1

1.2.2 24VDC Monitoring ............................................................................................1

1.2.3 Controller Watchdog Monitoring (WDT Error) ..................................................2

Section 2 EXTENDED FEATURES ......................................................................................3

2.1 Hardware Features ....................................................................................................3

2.2 Red Failure Monitoring ..............................................................................................3

2.2.1 Red Fail SSM Enable .......................................................................................3

2.2.2 Red Interface Cable Fault ................................................................................4

2.3 GYR-Dual Indication Monitoring ................................................................................4

2.3.1 GY-Dual Indication Monitoring .........................................................................4

2.4 Clearance (Short or Absent Yellow) Monitoring.........................................................4

2.5 AC Line Brown-out Detection ....................................................................................5

2.5.1 Minimum Flash Time ........................................................................................5

2.6 LEDguard®LED Field Signal Sensing .......................................................................5

2.7 Recurrent Pulse Detection.........................................................................................5

2.8 Exit Flash ...................................................................................................................6

2.9 Non-Volatile Fault Memory ........................................................................................6

2.10 PCA (Program Card Absent) Indication...................................................................6

2.11 Configuration Change Monitoring ............................................................................7

2.12 Internal MPU Watchdog...........................................................................................7

2.13 Reset Input Detection ..............................................................................................7

2.14 LED Test..................................................................................................................7

2.15 Memory Test............................................................................................................7

2.16 Watchdog Monitoring Disabled Indicator .................................................................8

2.17 Red Failure Monitor Disabled Indicator ...................................................................8

2.18 Diagnostic Display Mode (210E / 2010) ..................................................................8

2.18.1 No Fault Diagnostic Display ...........................................................................8

2.18.2 Fault Diagnostic Display.................................................................................8

2.19 Diagnostic Display Mode (210ECL / 2010ECL /2018ECL)......................................9

2.19.1 No Fault Diagnostic Display ...........................................................................9

2.19.2 Fault Diagnostic Display.................................................................................9

2.20 Flashing Yellow Arrow (FYA) Overview.................................................................10

2.20.1 FYA Mode ....................................................................................................10

2.20.2 FYAc (Compact) Mode.................................................................................13

Section 3 EVENT LOGGING FEATURES..........................................................................17

3.1 Basic Front Panel Fault Event Display ....................................................................17

3.2 Model 210ECL / 2010ECL /2018ECL Status/Event Reporting ................................17

3.2.1 BI Tran Systems 233 Program Monitor Status...............................................17

3.2.2 EDI ECcom Monitor Report............................................................................17

3.2.3 EDI ECcom Monitor Event Log Examples .....................................................18

Section 4 INSTALLATION ..................................................................................................21

4.1 Adapting Red Monitoring .........................................................................................21

4.1.1 Red Field Inputs .............................................................................................21

4.1.2 Special Function Preempt Inputs (SF1, SF2).................................................21

4.2 SSM Switch Programming.......................................................................................22

4.3 Program Card Programming....................................................................................22

4.3.1 Yellow Disable Jumpers .................................................................................22

4.4 Option Switch Programming ....................................................................................22

4.4.1 Red Fail Timing Switch ..................................................................................22

4.4.2 Recurrent Pulse (RP) Disable Switch (RP DISABLE)....................................22

4.4.3 WDT Timing Switch........................................................................................23

4.4.4 GY Enable Switch ..........................................................................................23

4.4.5 Polarity Switch................................................................................................23

4.4.6 LEDguard Switch ...........................................................................................23

4.4.7 RF SSM Switch ..............................................................................................23

4.4.8 FYA Mode Switch...........................................................................................23

4.5 Select Jumper Programming ...................................................................................23

4.5.1 Watchdog Latch Select (SEL1) ......................................................................23

4.5.2 Minimum Flash Enable Select (SEL2) ...........................................................24

4.5.3 Configuration Change Fault Select (SEL3) ....................................................24

4.5.4 Red Interface Cable Fault Select (SEL4) .......................................................24

4.5.5 AC Line Brown-out Select (SEL5)..................................................................24

4.5.6 EE Input Polarity Select (SEL9) .....................................................................24

4.5.7 FYA FlashRate Monitor disable (SEL15) .......................................................24

4.6 Watchdog Programming ..........................................................................................24

4.6.1 Watchdog Enable Switch ...............................................................................24

4.6.2 Watchdog Timing Option................................................................................24

Section 5 FRONT PANEL DESCRIPTION .........................................................................25

5.1 Indicators .................................................................................................................25

5.1.1 (G) AC POWER Indicator...............................................................................25

5.1.2 (Y) VDC FAILED Indicator .............................................................................25

5.1.3 (R) WDT ERROR Indicator ............................................................................25

5.1.4 CONFLICT Indicator ......................................................................................25

5.1.5 RED FAIL Indicator ........................................................................................25

5.1.6 DUAL IND Indicator........................................................................................25

5.1.7 CLEARANCE Indicator ..................................................................................25

5.1.8 PCA Indicator .................................................................................................26

5.1.9 DIAGNOSTIC Indicator ..................................................................................26

5.1.10 RP DETECT Indicator ..................................................................................26

5.1.11 COMM Indicator ...........................................................................................26

5.1.12 CHANNEL STATUS Indicators (210E / 2010) .............................................26

5.1.13 CHANNEL STATUS Indicators (210ECL / 2010ECL / 2018ECL)................26

5.2 Front Panel Controls................................................................................................26

5.2.1 RESET Button ................................................................................................26

5.3 Red Interface Connector (P1)..................................................................................27

Section 6 CIRCUIT OPERATION .......................................................................................28

6.1 Introduction ..............................................................................................................28

6.2 Main MPU Logic ......................................................................................................28

6.3 Serial Peripheral Interface (SPI) ..............................................................................28

6.4 Internal MPU Watchdog...........................................................................................28

6.5 EEprom Memory......................................................................................................28

6.6 24Vdc Logic Inputs ..................................................................................................28

6.7 Real Time Clock ......................................................................................................29

6.8 Display .....................................................................................................................29

6.9 Program Card and Switch Inputs.............................................................................29

6.10 RMS-Engine ..........................................................................................................29

6.11 Power Supply.........................................................................................................29

6.12 EIA-232 Communications Port ..............................................................................29

6.13 Ethernet Communications Port..............................................................................29

Section 7 TROUBLE SHOOTING.......................................................................................30

Section 8 SPECIFICATIONS ..............................................................................................32

8.1 Electrical ..................................................................................................................32

8.1.1 Power Requirements......................................................................................32

8.1.2 AC Voltage Monitors ......................................................................................32

8.1.3 DC Voltage Monitors ......................................................................................32

8.1.4 Outputs...........................................................................................................32

8.2 Timing Functions .....................................................................................................33

8.3 Mechanical...............................................................................................................33

8.4 Environmental..........................................................................................................33

Section 9 WIRING ASSIGNMENTS ...................................................................................34

9.1 Monitor Unit Connector (P6) ....................................................................................34

9.1.1 Sixteen Channel .............................................................................................34

9.1.2 Eighteen Channel...........................................................................................35

9.2 Program Card Connector.........................................................................................35

9.2.1 Sixteen Channel .............................................................................................35

9.2.2 Eighteen Channel...........................................................................................36

9.3 Red Interface Connector (P1)..................................................................................37

9.4 EIA-232 Connector (J1) ...........................................................................................37

9.4.1 EIA-232 Cable to a PC ...................................................................................38

9.4.2 EIA-232 Cable to a 170 Controller Unit..........................................................38

9.5 Ethernet LAN Port....................................................................................................38

9.5.1 Ethernet LAN Cable .......................................................................................38

9.6 16-Channel Program Card Diagram ........................................................................38

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 1

Section 1

BASIC FUNCTIONS

1.1 MODEL DESCRIPTION

The Signal Monitor consists of five models; the 210E, 210ECL, 2010, 2010ECL and

2018ECL. The model 210E is the base unit. The model 2010ECL and 2018ECL add an

EIA-232 serial port that gives the unit the capability to communicate with a Controller Unit

or PC based operational software for status and fault event data. The model 2010ECL and

2018ECL also add an enhanced event logging capability for full time stamped event

reporting. The model 2010, 2010ECL, and 2018ECL units are configured to be compatible

with the requirements of both the 170 Controller Unit and the 2070 Advanced Traffic

Controller. The model 210E and 210ECL units are compatible with the requirements of the

170 Controller Unit. The model 2018ECL is equivalent to the 2010ECL but provides

eighteen channels. The “ip” models replace the EIA-232 port with a 10/100 Mbps Ethernet

port. Where not specified otherwise, the information in this manual will apply to all models.

1.2 BASIC FUNCTIONS

The Signal Monitor is a device used in a traffic controller assembly to monitor traffic signals

at an intersection for conflicting proceed indications caused by malfunctions of the

controller, load switches, field wiring and loads, or miss-wiring of the cabinet. The Signal

Monitor also provides error sensing of the cabinet 24VDC supply and monitors the

controller Watchdog output. The Signal Monitor is directly interchangeable with a standard

model 210 Signal Monitor and complies with all specifications outlined in Chapter 4 (Model

210 Monitor Specifications) of the Caltrans Traffic Signal Control Equipment Specifications

(January 1989).

When triggered by the detection of a fault condition which exists longer than the minimum

period, the Signal Monitor will enter the fault mode causing the Output relay contacts to

close and enabling the Stop-Time output to the controller. The cabinet assembly should be

wired such that the closure of the Output relay contacts will cause an automatic switching

of the field signal outputs from normal operation to flashing operation. The Signal Monitor

will then display the appropriate fault indications and will remain in this fault mode until a

reset command is issued. The loss of AC Line power will not reset the fault mode (except

Diagnostic Fail). In the event of AC Line power loss the Signal Monitor will retain the status

of all fault and channel indicators and will display the correct fault and channel status upon

restoration of AC Line power.

1.2.1 CONFLICT MONITORING

The Signal Monitor is capable of monitoring 16 channels (2018ECL provides 18 channels).

Each channel consists of a Green, Yellow, and Red field signal output. A Program Card is

provided for assigning conflicting channels and inhibiting Yellow monitoring for required

channels. The Signal Monitor detects the presence of conflicting Green or Yellow signals

on the AC field terminations between any two or more channels assigned to conflict on the

Program Card. The monitoring circuitry is capable of detecting either full wave or positive

and negative half-wave field signal outputs at the specified voltage levels.

1.2.2 24VDC MONITORING

Sensing of the cabinet 24VDC supply is provided as specified in Section 4.2, Chapter 4 of

the Caltrans Traffic Signal Control Equipment Specifications. When the 24VDC input falls

below the specified voltage levels the Signal Monitor will enter the fault mode causing the

Output relay contacts to close and enabling the Stop-Time output to the controller. See

Section 8.1.3.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 2

1.2.3 CONTROLLER WATCHDOG MONITORING (WDT ERROR)

Sensing of the controller Watchdog output is provided as specified in Section 4.3 of the

Caltrans Traffic Signal Control Equipment Specifications. When a logic transition is not

sensed for the specified period (see Section 8.2) the Signal Monitor will enter the fault

mode causing the Output relay contacts to close and enabling the Stop-Time output to the

controller.

The WDT Latch option (see Section 4.5.1) determines whether this WDT Error fault mode

is latched through an AC Line brownout or not. If the WDT Latch option is not selected, an

AC Line brownout condition will reset the WDT ERROR fault mode when the AC Line is

restored. The WDT Error indicator will remain illuminated until a Reset command is issued

via the front panel RESET button or External Reset input. This indicates to the technician

that a WDT Error occurred but was cleared by an AC Line brownout. If the WDT LATCH

option is selected, the WDT Error fault mode is maintained until a Reset command is

applied.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 3

Section 2

EXTENDED FEATURES

The following extended features are provided on the Signal Monitor to provide additional

fault monitoring functions, to increase the reliability of the monitor operation, and enhance

the diagnostic capabilities offered to the service technician.

2.1 HARDWARE FEATURES

The 210/2010/2018 series Signal Monitor is a dual microprocessor based unit. All

monitoring functions and features are firmware programmable that permits upgrades or

modifications by simply replacing the EPROM device containing the firmware with the

upgraded version. Thus, most changes to the Signal Monitor specifications may be

accommodated without modifying the hardware.

Since all critical timing functions are accomplished by the microprocessor, the quartz

crystal based accuracy results in very precise and repeatable measurements. This

accuracy is maintained on functions from timing fault conditions to implementing a unique

firmware based digital sampling and filtering algorithm. This algorithm is applied to all AC

field signals to help eliminate false detection in a "noisy" AC line environment.

Input voltages are measured using a true Root Mean Squared (RMS) technique. A

dedicated microprocessor RMS- Engine controls the analog to digital (A/D) hardware which

samples each AC input voltage 32 times per cycle. The RMS-Engine then calculates the

true RMS voltage value producing accurate results which are very insensitive to changes in

frequency, phase, wave shape, and distortion. Voltage references are temperature

compensated for constant voltage levels within the operating temperature range.

A nonvolatile EEPROM device is utilized to retain fault status information and event logs in

the event of an AC Line power interruption. The correct fault indications will be displayed

upon restoration of AC Line power. This EEPROM device requires no battery back-up. The

time of day in the model “ECL” model is stored in a battery-backed real time clock circuit.

Should this battery fail, only current time of day and date information will be lost. No

monitor configuration programming is stored under battery power.

2.2 RED FAILURE MONITORING

The Signal Monitor is designed to adapt Red Failure Monitoring to a conventional controller

cabinet assembly. The simultaneous absence of active Green, Yellow, and Red field signal

voltages on a channel places the Signal Monitor into the fault mode causing the Output

relay contacts to close and enabling the Stop-Time output to the controller. Sixteen Red

signal inputs, a Red Enable input, and two Special Function preemption inputs (SF1, SF2)

are connected to the monitor via a front panel connector (P1) and ribbon cable assembly.

Chassis Ground may also be connected to the unit through pin P1-4. Jumper E1 must then

be inserted to complete the connection.

The Red Fail fault timing value is selected by the Red Fail timing Option switch labeled RF

2010. See Section 4.4.1.

This monitoring function is enabled by applying AC+ to the Red Enable input (P1-20).

Unused Red signal inputs must be tied to AC+ to prevent a Red Failure on those channels.

Red Failure monitoring is disabled for all channels when the Red Enable input is not active,

a Preemption input (SF1, SF2) is active, or the EE input (MC Coil) is active.

2.2.1 RED FAIL SSM ENABLE

The Red Fail function can also be enabled on a per channel basis using the SSM switches.

If the “RF SSM” option switch is in the On position (Section 4.4.7), then each channel will

be monitored for a Red Fail condition if the corresponding SSM switch is in the On position.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 4

Red Failure monitoring is disabled for all channels when the Red Enable input is not active,

a Preemption input (SF1, SF2) is active, or the EE input (MC Coil) is active.

2.2.2 RED INTERFACE CABLE FAULT

When inserted into the output file without the Red Interface cable assembly, the Signal

Monitor will operate as a standard 210 Signal Monitor. The Red Fail, Dual Indication, and

Clearance monitoring functions will be disabled. When the Red Cable Fault select option is

installed (see Section 4.5.4), operating without the Red Interface cable will cause the Signal

Monitor to enter the fault mode causing the Output relay contacts to close and enabling the

Stop-Time output to the controller. To indicate this fault mode the Red Fail indicator will be

illuminated with all channel indicators Off.

The cabinet should be wired such that the Red Enable input is only interrupted by the Load

Switch bus being de-energized. Red Fail preemption control to the monitor should use the

Special Function inputs #1 or #2.

2.3 GYR-DUAL INDICATION MONITORING

This monitoring function detects simultaneous indications of active Green and Yellow,

Green and Red, or Yellow and Red field signal outputs on the same channel. A GYR-Dual

Indication fault places the Signal Monitor into the fault mode causing the Output relay

contacts to close and enabling the Stop-Time output to the controller. GYR-Dual Indication

Monitoring is enabled concurrently with Clearance Monitoring on a per channel basis using

the SSM switches (see Section 4.2) and requires the controller cabinet assembly to be

adapted for Red Signal Monitoring. GYR-Dual Indication Monitoring is disabled for all

channels when the Red Enable input is not active or the EE input (MC Coil) is active.

An open or no load condition (i.e., burned-out bulb) may be detected as an active signal

due to load switch leakage current and may cause a Dual Indication fault. Dual Indication

Monitoring may also anticipate a possible Conflict in the event that a proceed signal on a

channel is constantly detected as active.

2.3.1 GY-DUAL INDICATION MONITORING

This monitoring function detects a simultaneous indication of active Green and Yellow field

signal outputs on the same channel. A GY-Dual Indication fault places the Signal Monitor

into the fault mode causing the Output relay contacts to close and enabling the Stop-Time

output to the controller. It does not require the controller cabinet assembly to be adapted for

Red Signal Monitoring, and is enabled by setting option switch SW3-4 labeled GY ENABLE

in the ON position (see Section 4.4.4). GY-Dual Indication Monitoring may be enabled

concurrently with GYR-Dual Indication Monitoring. When GY-Dual Indication Monitoring is

enabled, all channels will be individually monitored for simultaneous indications of active

Green and Yellow field signal outputs. Any channels which have been selected for GYR-

Dual Indication Monitoring will function as described above in Section 2.3.

This monitoring function is intended to accommodate Green and Yellow Dual Indication

Monitoring on a five section PPLT signal head. It is also useful if the controller cabinet

assembly is not adapted for Red Signal Monitoring as in the case of a standard 210 Signal

Monitor.

2.4 CLEARANCE (SHORT OR ABSENT YELLOW) MONITORING

This function detects the absence of a minimum period of active Yellow field signal output

during a Green to Yellow to Red sequence. Clearance (Sequence) Monitoring is enabled

concurrently with GYR-Dual Indication Monitoring on a per channel basis using the SSM

switches (see Section 4.2) and requires the controller cabinet assembly to be adapted for

Red Signal Monitoring. Clearance Monitoring is disabled for all channels when the Red

Enable input is not active or the EE input (MC Coil) is active.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 5

A Clearance (short or absent Yellow) fault condition will place the Signal Monitor into the

fault mode causing the Output relay contacts to close and enabling the Stop-Time output to

the controller. This occurs when a Red input signal to a channel is active following the

termination of an active Yellow input signal which is less than the minimum duration,

including zero (i.e. skipped).

2.5 AC LINE BROWN-OUT DETECTION

When the AC Line voltage is below the "drop-out" level the Signal Monitor will suspend all

fault monitoring functions, close the Output relay contacts, and enable the Stop-Time

output to the controller. The AC POWER indicator on the front panel will flash at a rate of

2Hz to indicate the brown-out status. When the AC Line voltage returns above the

"restore" level the monitor will resume normal operation and the AC POWER indicator on

the front panel will remain illuminated.

The AC Brownout dropout and restore voltage levels are selected by the AC Line Brown-

out Select jumper labeled SEL5. See Section 4.5.5.

AC Line Brown-out Detection is provided to prevent a dark intersection in the event a

brown-out causes the cabinet controller to release control of the intersection. If this occurs

and the intersection is not placed into flash, the monitor will detect a Red Failure (absence

of signal) or WDT Error and will require a manual reset. The "low AC Line Voltage" level

on the Controller Unit should be set at least 5 volts below the monitor drop-out level.

2.5.1 MINIMUM FLASH TIME

A Minimum Flash time option can be selected (see Section 4.5.2) which provides a flash

interval of at least 6 seconds and at most 10 seconds in duration following a power-up, an

AC Line interruption, or a brownout restore. During this interval the unit will suspend all fault

monitoring functions and close the Output relay contacts. The AC indicator on the front

panel will flash at a rate of 4Hz.

The minimum flash interval will be terminated after at least 6 seconds if the Watchdog input

has made 5 transitions between the True and False state and the AC Line voltage is

greater than the restore level.

2.6 LEDGUARD®LED FIELD SIGNAL SENSING

The Signal Monitor can be configured to use a technique called LEDguard®that is designed

to better monitor the characteristics of LED based signal loads (See Section 4.4.6). Each

field signal input is measured and compared to both a high threshold and a low threshold

value to determine On / Off status. This differs from conventional operation where the

active threshold is picked according to the color of the field signal. Once the high and low

On / Off thresholds (Section 8.1.2) have been determined using the input RMS voltage, the

individual fault monitor functions use the appropriate threshold to determine if a fault

condition exists.

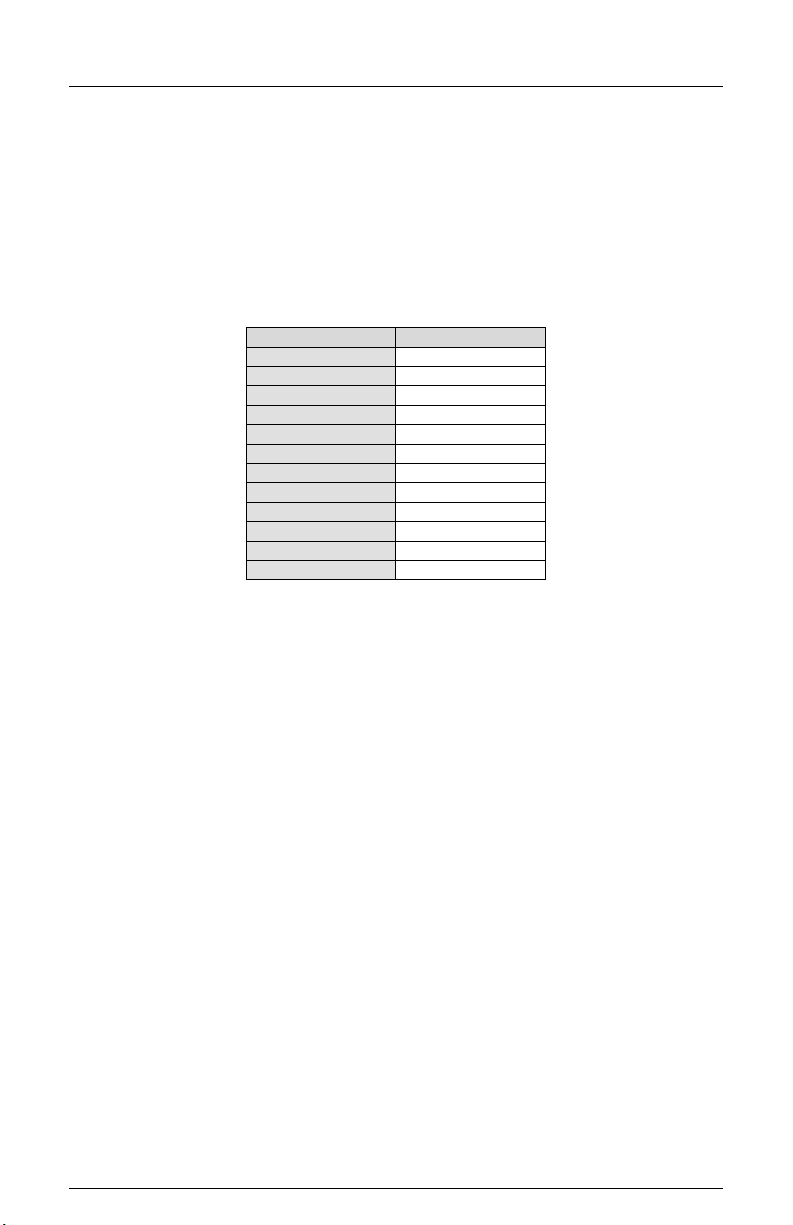

LEDguard®

Green/Walk

Yellow

Red/Dont Walk

Conflict

Low

Low

---

Red Fail

High

High

High

Dual Indication

Low

Low

Low

Clearance

Low

Low

High

2.7 RECURRENT PULSE DETECTION

This error detection function supplements the normal Conflict, Dual Indication, and Red Fail

monitoring algorithms for sensing faults that are intermittent or pulsing in nature. The RMS-

Engine is designed to filter out short term transients commonly found on the electrical

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 6

service and provide noise immunity against false signal detections. The Recurrent Pulse

detection function is designed to respond to fault conditions which are intermittent in nature

and do not meet the continuous timing requirements of the normal detection algorithms, yet

may still produce improper signal displays. These input conditions are differentiated by

their longer time constant and fault response times.

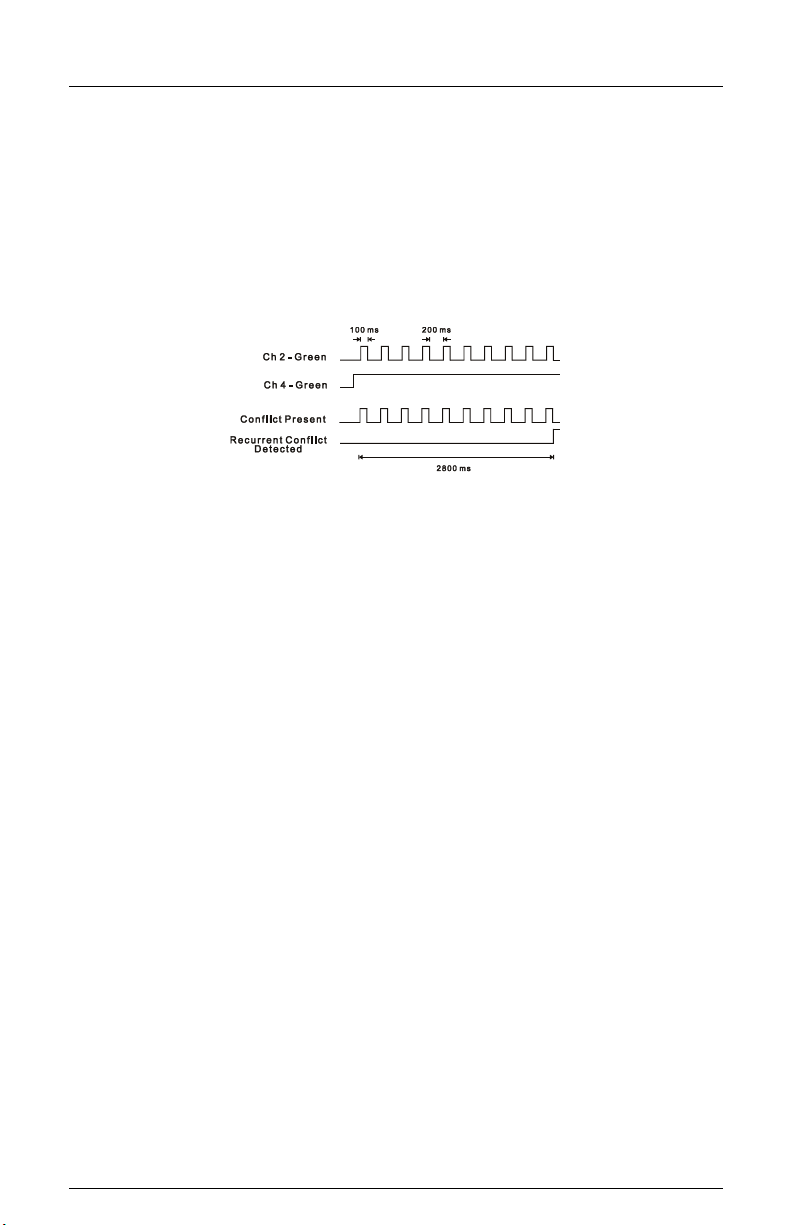

The figure below shows a simple example of a recurrent Conflict fault. Channel 2 Green is

detected active due to a malfunction of the load switch that caused the output to flicker On

for 100 ms approximately every 200 ms. Since normal Conflict detection requires a

continuous fault of at least 350 ms duration, this event could go undetected. The Recurrent

Pulse detection algorithm will combine these pulses into one event and trigger a Conflict

fault once the longer recurrent timing threshold is exceeded.

When triggered by a recurrent fault condition, the Signal Monitor will enter the fault mode,

transfer the Output relay contacts to the Fault position, enable the Stop-Time output to the

controller, and illuminate the appropriate CONFLICT, DUAL, or RED FAIL indicator along

with the RP DETECT indicator. The unit will remain in the fault mode until reset by the

Reset button or the External Reset input. Fault response times will vary depending on the

pulse width and frequency of the recurrent inputs, but will range from 1000 ms minimum to

10.4 seconds maximum. Recurrent Pulse detection can be disabled with the RP DISABLE

option switch (SW3-2), see Section 4.4.2.

2.8 EXIT FLASH

When the Signal Monitor series exits the flash state (Output relay de-energized) as a result

of a Reset command or AC Line brownout restore, the Stop Time output will go to the

inactive state 250 _+ 50 ms before the Output relay transfers to the energized state. This

transition will provide an early indication to the 2070 Controller Unit that the cabinet will

transfer from flash to signal operation.

2.9 NON-VOLATILE FAULT MEMORY

The Signal Monitor stores the fault and channel indicator status at the time the fault occurs

into a non-volatile EEPROM device. Should an AC Line power interruption occur while the

monitor is in the fault mode, then upon restoration of AC Line power, the Output relay and

Stop-Time output will remain in the fault mode and the correct fault and channel indicators

will be displayed.

The “ECL” models use a lifetime lithium battery to maintain the time of day clock. Should

this battery fail, only current time and date functions will be lost. No monitor configuration

parameters or event log data is stored under battery power.

2.10 PCA (PROGRAM CARD ABSENT) INDICATION

If the Program Card is absent or not seated properly in the edge connector, the Signal

Monitor will enter the fault mode causing the Output relay contacts to close and enabling

the Stop-Time output to the controller. The PCA indicator will illuminate to indicate this

condition. A manual or external Reset is required after the Program Card is properly

seated.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 7

2.11 CONFIGURATION CHANGE MONITORING

The Signal Monitor maintains an internally calculated CRC value of the current

configuration settings. These settings include the permissive diode matrix, SSM switches,

Yellow Disable switches, Option switches, SEL1 through SEL16 jumpers, and the

Watchdog Enable switch. On power-up, reset, and periodically during operation, the unit

will compare the current configuration settings with the previously stored value. If the

settings have changed, the Signal Monitor will automatically log the new setting.

When the Configuration Change Fault select option is enabled (see Section 4.5.3), any

change in the configuration parameters will cause the Signal Monitor to enter the fault

mode causing the Output relay contacts to close and enabling the Stop-Time output to the

controller. To indicate this fault mode the PCA indicator will flash at a 4 Hz rate.

Depressing the Reset button for three full seconds will clear this fault and log the new

configuration parameters.

If the Configuration Change Fault select jumper is not installed, the unit will not set the fault

mode but will still log the configuration change.

2.12 INTERNAL MPU WATCHDOG

The Signal Monitor generates an internal watchdog pulse from its microprocessor. This

occurs at least once per line cycle. If the internal hardware does not detect a watchdog

pulse within approximately 325 milliseconds, the Signal Monitor will enter the fault mode

causing the Output relay contacts to close and enabling the Stop-Time output to the

controller. The DIAGNOSTIC indicator on the front panel will illuminate to indicate a monitor

hardware and/or firmware failure.

This type of failure is configured as latching. With latching operation, only a loss of AC Line

will restore operation. If the microprocessor resumes operation the unit will not return to

normal operation. If non-latching operation is desired, jumper E5 (Latching MPU Fault) may

be removed.

2.13 RESET INPUT DETECTION

A reset command from either the front panel Reset button or External Reset input will

cause a one-time reset command to the monitor. If the reset command is maintained longer

than 500 milliseconds, the monitor will resume monitoring functions and the Reset

command will then provide input to the Diagnostic Display mode (see Section 2.18).

2.14 LED TEST

The monitor will illuminate all front panel indicators for 500 milliseconds when a Reset

command is issued by the front panel Reset button or External Reset Input. This function

provides a means to verify the operation of all front panel indicators.

2.15 MEMORY TEST

The Signal Monitor verifies the proper operation of the memory devices (RAM, EPROM, &

EEPROM) required to operate the monitor. This test is performed when AC Line power is

applied, a Reset Command is issued to the monitor, and periodically during operation. If a

memory error is detected, the Signal Monitor will attempt to update the front panel display

and then execute a STOP instruction. This will cause the Output relay contacts to close and

enable the Stop-Time output to the controller. The DIAGNOSTIC indicator on the front

panel will illuminate to indicate a monitor hardware and/or firmware failure. Due to the

nature of these hardware or firmware failures, other fault indicators that may be

concurrently illuminated may not be valid for trouble shooting purposes.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 8

2.16 WATCHDOG MONITORING DISABLED INDICATOR

When the WDT ENABLE switch is in the OFF position to disable Watchdog Monitoring of

the cabinet Controller, or the AC Line voltage is below the Watchdog disable level, the

Signal Monitor will flash the WDT ERROR indicator on the front panel once every 2

seconds. This function informs the service technician that the cabinet Controller Watchdog

monitoring function is disabled.

2.17 RED FAILURE MONITOR DISABLED INDICATOR

When the Red Fail Monitoring function is disabled because the Red Enable input is not

active or the EE input (MC Coil) is active or a Special Function input is active, the Signal

Monitor will flash the RED FAIL indicator on the front panel once every 2 seconds. This

function informs the service technician that Red Fail Monitoring function is disabled.

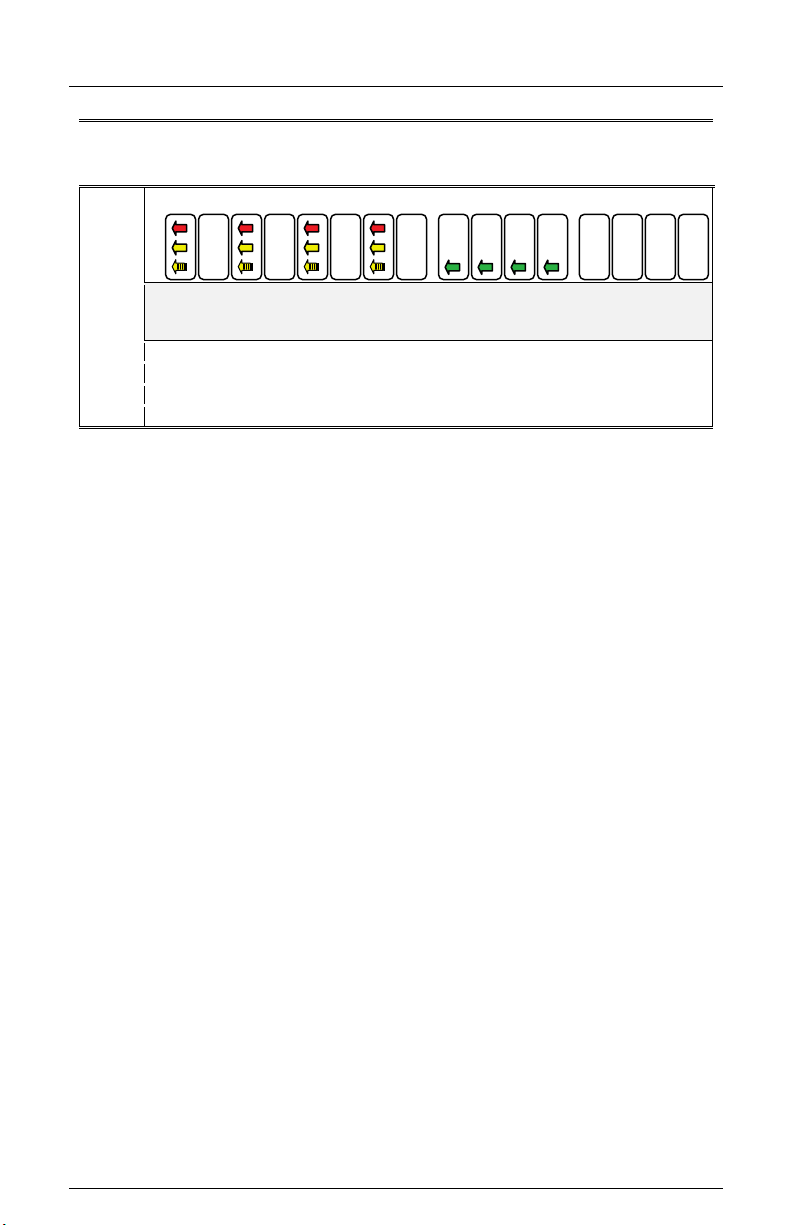

2.18 DIAGNOSTIC DISPLAY MODE (210E / 2010)

The 210E / 2010 models provide two means of displaying the individual Green, Yellow, and

Red field status. The No Fault Diagnostic Display mode shows the individual colors while

the monitor is not in the fault mode (intersection operating). The Fault Diagnostic Display

mode shows the individual colors that were active at the time the monitor triggered to the

fault mode (intersection in flash). The Fault Diagnostic Display mode also provides a review

of previous fault events.

2.18.1 NO FAULT DIAGNOSTIC DISPLAY

When the 210E / 2010 model is not in the fault state, the unit can display the active Green,

Yellow, and Red field status individually. To enter this display mode depress and hold the

Reset button. Each time the Reset button is activated and held, the next set of colors will

be displayed on the channel status indicators. The display will continue to show the

selected color as long as the Reset button is activated. This mode only affects the monitor

display and normal fault processing will continue to occur. The sequence is as follows:

Reset Fault Status LEDs Channel Status LEDs

#1 (G) AC POWER LED flashes Green field status 1-16

#2 (Y) VDC FAILED LED flashes Yellow field status 1-16

#3 (R) WDT ERROR LED flashes Red field status 1-16

... (repeats back to top)

2.18.2 FAULT DIAGNOSTIC DISPLAY

Once the 210E / 2010 model has been triggered by a fault, the Green, Yellow, and Red

field input status active at the time of the current fault and the two previous faults may be

displayed individually. This status is not reset by an AC Line power interruption. To enter

this display mode remove the Program Card. The sequence is as follows:

Reset Event PCA LED Fault Status LEDs Channel Status LEDs

--- #1 Single flash Current Fault Status (newest) Current channel status

#1 #1 Single flash (G) AC POWER LED flashes Green field status 1-16

#2 #1 Single flash (Y) VDC FAILED LED flashes Yellow field status 1-16

#3 #1 Single flash (R) WDT ERROR LED flashes Red field status 1-16

#4 #2 Double flash Event #2 Fault Status Event #2 channel status

#5 #2 Double flash (G) AC POWER LED flashes Green field status 1-16

#6 #2 Double flash (Y) VDC FAILED LED flashes Yellow field status 1-16

#7 #2 Double flash (R) WDT ERROR LED flashes Red field status 1-16

#8 #3 Triple flash Event #3 Fault Status (oldest) Event #3 channel status

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 9

#9 #3 Triple flash (G) AC POWER LED flashes Green field status 1-16

#10 #3 Triple flash (Y) VDC FAILED LED flashes Yellow field status 1-16

#11 #3 Triple flash (R) WDT ERROR LED flashes Red field status 1-16

... (repeats back to top)

To enter this display mode remove the Program Card. Depressing the Reset button

advances the display mode from the normal mode to the Green field input display. The (G)

AC POWER LED will pulse ON once per second to indicate this mode. The channel display

LEDs will show the Green channels active at the time of the fault. The PCA LED will pulse

once per second to indicate the current fault (#1, newest).

Depressing the Reset button again advances the display mode from the Green display

mode to the Yellow field input display. The (Y) VDC FAIL LED will pulse ON once per

second to indicate this mode. The channel display LEDs will show the Yellow channels

active at the time of the fault.

Depressing the Reset button again advances the display mode from the Yellow display

mode to the Red field input display. The (R) WDT ERROR LED will pulse ON once per

second to indicate this mode. The channel display LEDs will show the Red channels active

at the time of the fault.

Depressing the Reset button again advances the display mode from the Red display mode

(of fault #1) to the fault display mode for fault #2. The PCA LED will pulse twice per second

to indicate the previous fault (#2). Additional button closures will cycle through the colors for

fault #2 and fault #3 (oldest). After the Red display for fault #3, the display will return to fault

#1.

To exit this display mode, replace the Program Card. If the Program Card is removed while

the model 210E unit has not been triggered by a fault, the fault status display mode will

show the Green, Yellow, and Red channels active when the Program Card was removed. If

a PCA fault is displayed during the review, the PCA LED will not flash during the Fault

Status display step to indicate the fault number.

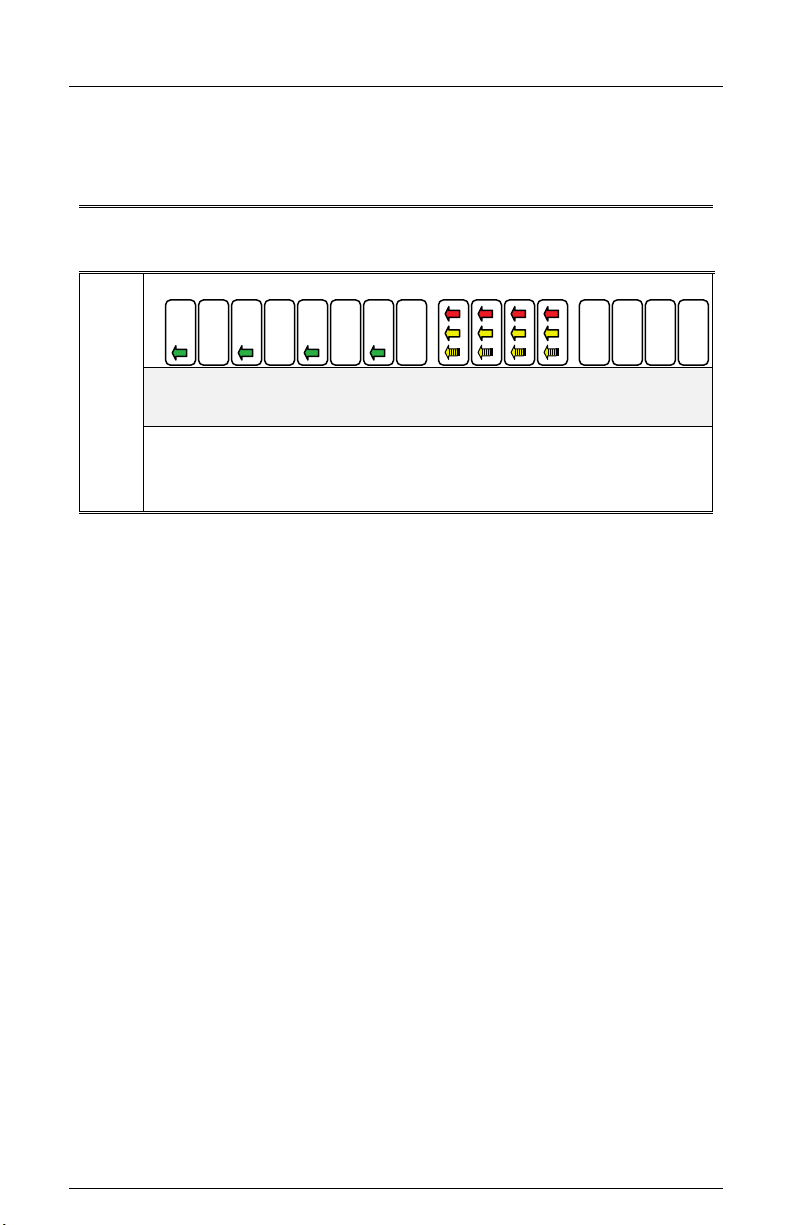

2.19 DIAGNOSTIC DISPLAY MODE (210ECL / 2010ECL /2018ECL)

The “ECL” models provide two means of displaying the individual Green, Yellow, and Red

field status. The No Fault Diagnostic Display mode shows the real time individual colors

while the monitor is not in the fault mode (intersection operating) using the three color LED

full intersection display. The Fault Diagnostic Display mode shows the individual colors

which were active at the time the monitor triggered to the fault mode (intersection in flash)

as well as the channel(s) which were involved in the fault. The Fault Diagnostic Display

mode also provides a review of previous fault events.

2.19.1 NO FAULT DIAGNOSTIC DISPLAY

When the “ECL” model is not in the fault state, the unit will continuously display the active

Green, Yellow, and Red field status simultaneously on a three color LED full intersection

display.

2.19.2 FAULT DIAGNOSTIC DISPLAY

Once the “ECL” model has been triggered by a fault the channel status display will

alternate between the field signals active at the time of the fault for 6 seconds, and the

channels which were involved in the fault (fault status) for 2 seconds. The channels

involved in the fault will flash their respective Green, Yellow, and Red indicators

simultaneously at a 4 Hz rate for the 2 second fault status interval. If the fault displayed is a

Recurrent Pulse Conflict, Recurrent Pulse Dual Indication, or a Recurrent Pulse Red Fail,

the RP DETECT indicator will then flash simultaneously at a 4 Hz rate with the input(s) that

had Recurrent Pulse status for an additional 2 seconds following the fault channel display.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 10

The two previous faults may be also be displayed individually. This status is not reset by

an AC Line power interruption. To enter this display mode remove the Program Card. The

sequence is as follows:

Reset Event PCA LED Fault Status LEDs Channel Status LEDs

--- #1 Single flash Current Fault Status (newest) Current RYG channel status

#1 #2 Double flash Event #2 Fault Status Event #2 RYG channel status

#2 #3 Triple flash Event #3 Fault Status (oldest) Event #3 RYG channel status

... (repeats back to top)

To enter this display mode remove the Program Card. The channel status display will

alternate between the channels which were involved in the fault (fault status) for 2 seconds,

and the field signals active at the time of the fault for 6 seconds. The channels involved in

the fault will flash their Green, Yellow, and Red indicators simultaneously at a 4 Hz rate for

the 2 second interval. The PCA LED will pulse once per second to indicate the current fault

(#1, newest).

Depressing the Reset button advances the display mode from the current fault ( #1) to the

fault display mode for fault #2. The PCA LED will pulse twice per second to indicate the

previous fault (#2).

Depressing the Reset button again advances the display mode from fault #2 to the fault

display mode for fault #3. The PCA LED will pulse three times per second to indicate the

previous fault (#3).

Depressing the Reset button again returns the display mode from fault #3 to the fault

display mode for fault #1.

To exit this display mode, replace the Program Card. If the Program Card is removed while

the model 210ECL unit has not been triggered by a fault, the fault status display mode will

show the Green, Yellow, and Red channels active when the Program Card was removed. If

a PCA fault is displayed during the review, the PCA LED will not flash during the Fault

Status display step to indicate the fault number.

2.20 FLASHING YELLOW ARROW (FYA) OVERVIEW

This unit is designed to monitor an intersection with up to four approaches using the four

section FYA movement outlined by the NCHRP Research Project 3-54 and NEMA TS-2

Amendment #4-2012 on Protected/Permissive signal displays with Flashing Yellow Arrows.

For monitoring purposes an FYA approach is defined as a four input “logical channel”

consisting of the solid Red Arrow, solid Yellow Arrow, flashing Yellow Arrow (permissive),

and solid Green Arrow (protected). The Signal Monitor combines two physical channels to

monitor each “logical” FYA approach.

Two cabinet configurations are supported depending on the number of load switches

provided and the capabilities of the Controller Unit. A Flashing Yellow Arrow approach is

actually monitored using two physical channels of the Signal Monitor. In the basic FYA

mode of the unit, one additional load switch is required for each FYA approach to be

monitored. Thus a cabinet providing four vehicle phases, four pedestrian phases, and four

FYA approaches would require sixteen load switches. The compact FYAc mode requires

the Controller Unit to remap the Yellow outputs of the pedestrian load switches to drive the

protected Green Arrow signals of the FYA approaches. In this mode the cabinet can

provide the four FYA approaches with the existing twelve position output assembly. See

Section 4.4.8 for FYA Mode programming.

2.20.1 FYA MODE

In the FYA mode (see Table 2-1), the cabinet must be wired such that for each FYA

approach, the solid Green protected Arrow is driven by a load switch monitored on

channels 1, 3, 5, and 7. The associated solid Red Arrow, solid Yellow Arrow, and flashing

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 11

Yellow Arrow (Overlap phase) must be driven by a load switch monitored on channels 9,

10, 11, and 12 respectively. The Signal Monitor associates channel 1 with 9, channel 3 with

10, channel 5 with 11, and channel 7 with 12, when FYA monitoring is enabled for that

respective approach. See Section 4.4.8 for FYA Mode programming.

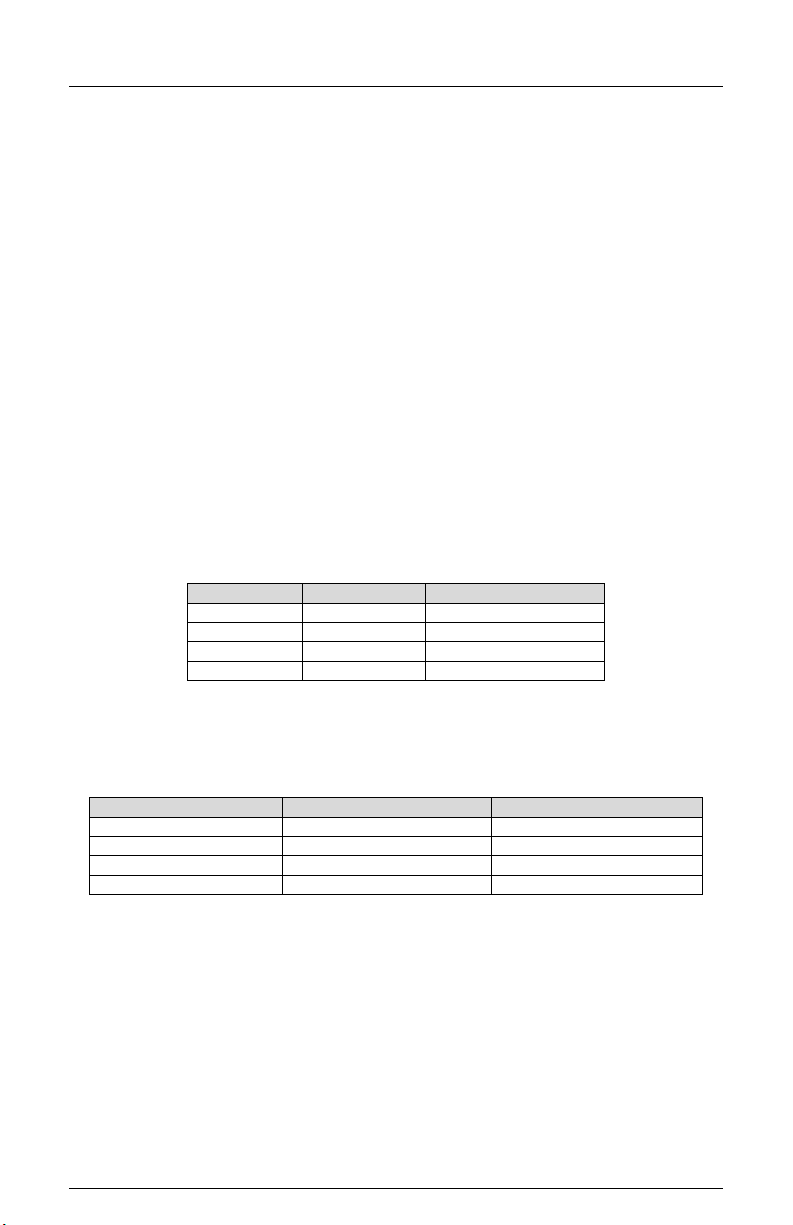

Table 2-1

FYA Mode Channel Configurations

FYA

Mode

Ch: 1 3 5 7 9 12 13 16

Protected Turn

Channels

(Ga)

Opposing

Through

Channels

Permissive Turn

Channels

(Ra, Ya, fYa)

Green Arrow Signal

Driver Source

1

2

9

1 Green

3

4

10

3 Green

5

6

11

5 Green

7

8

12

7 Green

2.20.1.1 FYA MONITORING FUNCTIONS

If a FYA channel pair is enabled for FYA operation, the Signal Monitor will monitor the FYA

logical channel pair for the following fault conditions:

2.20.1.1.1 CONFLICT

Channel conflicts are detected based on the Permissive programming jumpers on the

Program Card for each channel. This operation remains unchanged from normal operation

except for the solid Yellow arrow (FYA clearance) signal.

2.20.1.1.1.1 PROTECTED YELLOW CHANGE INTERVAL CONFLICT

The Signal Monitor will verify during the Yellow change interval of the Protected Turn

channel (Green arrow; channels 1,3,5,7) that no conflicting channels to the solid Yellow

arrow channel (clearance) are active. The conflicting channels are determined by the

Program Card compatibility programming of the Protected Turn channel (Green arrow;

channels 1,3,5,7) of the pair.

2.20.1.1.1.2 PERMISSIVE YELLOW CHANGE INTERVAL CONFLICT

During all other times the Signal Monitor will verify that no conflicting channels to the solid

Yellow arrow channel (clearance) are active as determined by the Program Card

compatibility programming of the Permissive Turn channel (flashing Yellow arrow;

Channels 9, 10,11, 12).

2.20.1.1.2 FLASH RATE DETECTION

When the FLASHRATE FAULT option is not disabled (see Section 4.5.7), the Signal

Monitor will monitor a flashing yellow arrow output for a lack of flashing operation. If any of

the enabled flashing yellow arrow signals on channels 9,10,11,12 remain active for more

than the FYA Flash Rate Fault time (Section 8.2), the Signal Monitor will enter the fault

mode, transfer the OUTPUT relay contacts to the Fault position, and display status. The

Signal Monitor will remain in the fault mode until the unit is reset by the RESET button or

the EXTERNAL RESET input.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 12

2.20.1.1.3 RED FAIL

A Red Fail fault will occur if the solid Red Arrow AND solid Yellow Arrow AND flashing

Yellow Arrow AND solid Green Arrow all remain inactive for the Red Fail fault response

time. The fault channel status will be indicated for both channels of the pair. The Red and

Yellow inputs for channels 1, 3, 5, and 7 do not affect the Red Fail condition for the FYA

channels 9, 10, 11, and 12.

2.20.1.1.4 DUAL INDICATION

A Dual Indication fault will occur if any two or more of the solid Red Arrow, solid Yellow

Arrow, flashing Yellow Arrow, or solid Green Arrow signal combinations are active

simultaneously for the Dual Indication fault response time. The fault channel status will be

indicated for the Overlap channel (9, 10, 11, 12). The fault channel status will also be

indicated for the solid Green Arrow channel (1, 3, 5, 7) IF the solid Green Arrow was active.

If the SSM switch is On for the solid Green Arrow channels (1, 3, 5, 7) then a Dual

Indication fault will occur if any two or more of the Red, Yellow, or solid Green Arrow inputs

(1, 3, 5, 7) are active simultaneously for the Dual Indication fault response time.

2.20.1.1.5 CLEARANCE

A Clearance fault will be detected if the FYA channel sequences from the solid Green

Arrow (1, 3, 5, 7) to the solid Red Arrow (9, 10, 11, 12) without a minimum clearance time

on the solid Yellow Arrow (9, 10, 11, 12), when SSM switch 9, 10, 11, 12 is On. The fault

channel status will be indicated for the Overlap channel (9, 10, 11, 12).

A Clearance fault will be detected if the FYA channel sequences from the flashing Yellow

Arrow (9, 10, 11, 12) to the solid Red Arrow (9, 10, 11, 12) without a minimum clearance

time on the solid Yellow Arrow (9, 10, 11, 12), when SSM switch 9, 10, 11, 12 is On. The

fault channel status will be indicated for the Overlap channel (9, 10, 11, 12).

A Clearance fault will be detected if the protected channel sequences from the solid Green

Arrow (1, 3, 5, 7) to the solid Red Arrow (1, 3, 5, 7) without a minimum clearance time on

the solid Yellow Arrow (1, 3, 5, 7). SSM switch 1, 3, 5, 7 is On. The fault channel status will

be indicated for the solid Green Arrow channel (1, 3, 5, 7).

2.20.1.2 FYA INSTALLATION

The cabinet must be wired such that for each FYA approach, the solid Green protected

Arrow is driven by a load switch monitored on channels 1, 3, 5, and 7. The associated solid

Red Arrow, solid Yellow Arrow, and flashing Yellow Arrow (Overlap phase) must be driven

by a load switch monitored on channels 9, 10, 11, and 12 respectively. The Signal Monitor

associates channel 1 with 9, channel 3 with 10, channel 5 with 11, and channel 7 with 12

when FYA monitoring is enabled for that respective approach.

- WARNING -

IF THE PERMISSIVE FLASHING YELLOW ARROW AND PROTECTED GREEN

ARROW CHANNEL ASSIGNMENTS ARE SWAPPED SUCH THAT THE FYA INPUT

IS MONITORED ON CHANNELS 1,3,5, AND 7:

1) The Flashrate Fault function monitors the enabled flashing Yellow Arrow input of

channels 9,10,11, and 12. The Flashrate Fault function must be disabled. See

Section 4.5.7.

2) Exit Flash into Start-up in all Yellow signals is not permitted.

3) Time of Day flash in all Yellow signals is not permitted.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 13

To enable channel pair for FYA operation, place the Option DIP Switch labeled “FYA x-y”

(where “x-y” is 1-9, 3-10, 5-11, or 7-12) in the On position. When the “FYA x-y” switch is in

the Off position, both channel x and y operate in standard fashion. See Section 4.4.8.1.

This Permissive Programming (Conflict Matrix) assignment example assumes standard

channel assignments for an eight phase quad intersection. The Permissive programming

for channels 1, 3, 5, and 7 (solid Green Arrow) are unchanged from conventional

programming for a protected left turn phase, with the addition of the jumpers for the

associated FYA overlap channels. The Permissive programming for overlap channels 9,

10, 11, and 12 (solid Yellow and flashing Yellow Arrow) must be set with similar

programming to the associated through phase. For example:

Primary Channel

Permissive With:

1

5, 6, 11

2

5, 6, 9, 11

3

7, 8, 12

4

7, 8, 10, 12

5

9

6

9, 11

7

10

8

10, 12

9

11

10

12

11

--

12

--

Note: This example is for illustrative purposes ONLY. Permissive Programming for

an application depends on actual intersection geometry, cabinet wiring, and

Controller programming.

2.20.1.3 RIGHT TURN OVERLAPS

Because the FYA operation uses channels 9 through 12 normally assigned to overlap

phases, a sixteen channel monitor does not provide enough channels for an eight phase

intersection with four pedestrian channels, four right turn overlaps, and four FYA

approaches. Right turn overlaps can still be implemented by driving the right turn signal

heads with the corresponding protected left turn load switch. In this case, the right turn

overlap will not be controlled independently. Consideration should be given for the SSM

switch being On for the channel 1, 3, 5, and 7 if used in this manner.

For right turn overlaps with no Yellow Arrow, consideration should be given to driving the

Green Arrow load switch input with the Phase On control.

2.20.2 FYAC (COMPACT) MODE

For each FYAc approach (see Table 2-2), each solid Green protected Arrow signal is

monitored on channels 9, 10, 11, and 12 (Green). The associated solid Red Arrow, solid

Yellow Arrow, and flashing Yellow Arrow is monitored on channels 1, 3, 5, and 7

respectively. The Signal Monitor associates channel 1 with 9, channel 3 with 10, channel 5

with 11, and channel 7 with 12, when FYAc monitoring is enabled for that respective

approach. See Section 4.4.8 for FYA Mode programming.

In the FYAc mode the Signal Monitor requires that the protected Green arrow signals be

driven by the unused Ped Yellow load switch outputs. This relies on a Caltrans cabinet

wiring requirement of connecting the Ped Yellow load switch outputs to monitor channels 9

and 10 as described in section 2.20.2.2. Using this scheme allows a standard twelve

position Output File to provide the necessary signals without the addition of an Auxiliary

File.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 14

Table 2-2

FYAC Channel Configurations

FYAC

Mode

Ch: 1 3 5 7 9 12 13 16

Protected Turn

Channels

(Ga)

Opposing

Through

Channels

Permissive Turn

Channels

(Ra, Ya, fYa)

Green Arrow Signal

Driver Source

9

2

1

13 Yellow

10

4

3

14 Yellow

11

6

5

15 Yellow

12

8

7

16 Yellow

2.20.2.1 FYAC MONITORING FUNCTIONS

If a FYA channel pair is enabled for FYAc operation, the Signal Monitor will monitor the

FYAc logical channel pair for the following fault conditions:

2.20.2.1.1 CONFLICT

Channel conflicts are detected based on the Permissive programming jumpers on the

Program Card for each channel. This operation remains unchanged from normal operation

except for the solid Yellow arrow (FYA clearance) signal.

2.20.2.1.1.1 PROTECTED YELLOW CHANGE INTERVAL CONFLICT

The Signal Monitor will verify during the Yellow change interval of the Protected Turn

channel (Green arrow; channels 9,10,11,12) that no conflicting channels to the solid Yellow

arrow channel (clearance) are active. The conflicting channels are determined by the

Program Card compatibility programming of the Protected Turn channel (Green arrow;

channels 9,10,11,12) of the pair.

2.20.2.1.1.2 PERMISSIVE YELLOW CHANGE INTERVAL CONFLICT

During all other times the Signal Monitor will verify that no conflicting channels to the solid

Yellow arrow channel (clearance) are active as determined by the Program Card

compatibility programming of the Permissive Turn channel (flashing Yellow arrow;

Channels 1,3,5,7).

2.20.2.1.2 FLASH RATE DETECTION

When the FLASHRATE FAULT option is not disabled (see Section 4.5.7), the Signal

Monitor will monitor a flashing yellow arrow output for a lack of flashing operation. If any of

the enabled flashing yellow arrow signals on channels 1,3,5,7 remain active for more than

the FYA Flash Rate Fault time (Section 8.2), the Signal Monitor will enter the fault mode,

transfer the OUTPUT relay contacts to the Fault position, and display status. The Signal

Monitor will remain in the fault mode until the unit is reset by the RESET button or the

EXTERNAL RESET input.

2.20.2.1.3 RED FAIL

A Red Fail fault will occur if the solid Red Arrow AND solid Yellow Arrow AND flashing

Yellow Arrow AND solid Green Arrow all remain inactive for the Red Fail fault response

time. The fault channel status will be indicated for both channels of the pair. The Red and

Yellow inputs (typically unused) for channels 9, 10, 11, and 12 do not affect the Red Fail

condition for the FYA channels 1, 3, 5, and 7.

210E / 210ECL / 2010 / 2010ECL / 2018ECL SERIES SIGNAL MONITOR

OPERATIONS MANUAL

Eberle Design Inc. Page 15

The SSM Switch for each channel must be in the ON position to enable Red Fail Monitoring

for that channel.

2.20.2.1.4 DUAL INDICATION

A Dual Indication fault will occur if any two or more of the solid Red Arrow, solid Yellow

Arrow, flashing Yellow Arrow, or solid Green Arrow signal combinations are active

simultaneously for the Dual Indication fault response time. The fault channel status will be

indicated for the FYAc channel (1, 3, 5, 7). The fault channel status will also be indicated

for the solid Green Arrow channel (9, 10, 11, 12) IF the solid Green Arrow was active.

2.20.2.1.5 CLEARANCE

A Clearance fault will be detected if the FYAc channel sequences from the solid Green

Arrow (9, 10, 11, 12) to the solid Red Arrow (1, 3, 5, 7) without a minimum clearance time

on the solid Yellow Arrow (1, 3, 5, 7), when SSM switch 1, 3, 5, 7 is On. The fault channel

status will be indicated for the FYAc channel (1, 3, 5, 7).

A Clearance fault will be detected if the FYAc channel sequences from the flashing Yellow

Arrow (1, 3, 5, 7) to the solid Red Arrow (1, 3, 5, 7) without a minimum clearance time on

the solid Yellow Arrow (1, 3, 5, 7), when SSM switch 1, 3, 5, 7 is On. The fault channel

status will be indicated for the FYAc channel (1, 3, 5, 7).

2.20.2.2 FYAC INSTALLATION

The cabinet must be wired such that the (unused) Ped Yellow load switch outputs are wired

to the Signal Monitor inputs as follows:

Phase

Load Switch #

Monitor Physical Input

Ped 2 Yellow

3

Ch 9 Green (pin 13)

Ped 4 Yellow

6

Ch 9 Yellow (pin 16)

Ped 6 Yellow

9

Ch 10 Green (pin R)

Ped 8 Yellow

12

Ch 10 Yellow (pin U)

The Controller unit must be configured to drive the protected Green arrow signals from the

Ped Yellow load switch outputs. If ANY channel pairs are enabled for FYAc operation, the

Signal Monitor will internally remap monitor Channel 9 and 10 physical inputs such that the

protected Green arrow signals will be monitored as Channels 9, 10, 11, and 12 as follows:

Monitor Physical Input

Monitor Logical Channel

Associated FYA Channel

Ch 9 Green

Ch 9 Green

Ch 1

Ch 9 Yellow

Ch 10 Green

Ch 3

Ch 10 Green

Ch 11 Green

Ch 5

Ch 10 Yellow

Ch 12 Green

Ch 7

The associated solid Red Arrow, solid Yellow Arrow, and flashing Yellow Arrow phases

must be driven by a load switch monitored on channels 1, 3, 5, and 7 respectively. The

Signal Monitor associates channel 1 with 9, channel 3 with 10, channel 5 with 11, and

channel 7 with 12 when FYA monitoring is enabled for that respective approach.

This manual suits for next models

6

Table of contents

Other EDI Measuring Instrument manuals