4

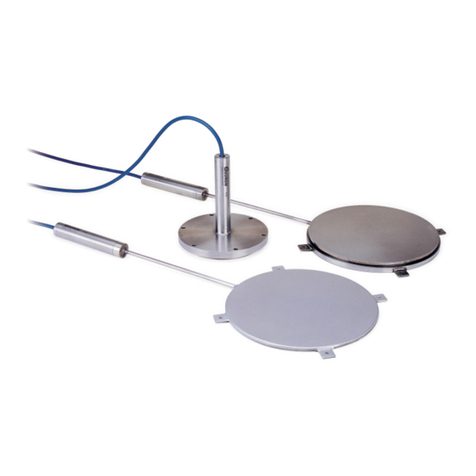

3) Select further sections of access tube and/or telescoping couplings. Position the spider

anchors along the sections of access tubing in their desired locations. The spider

anchors are attached to the access tube as shown in Figure 2.

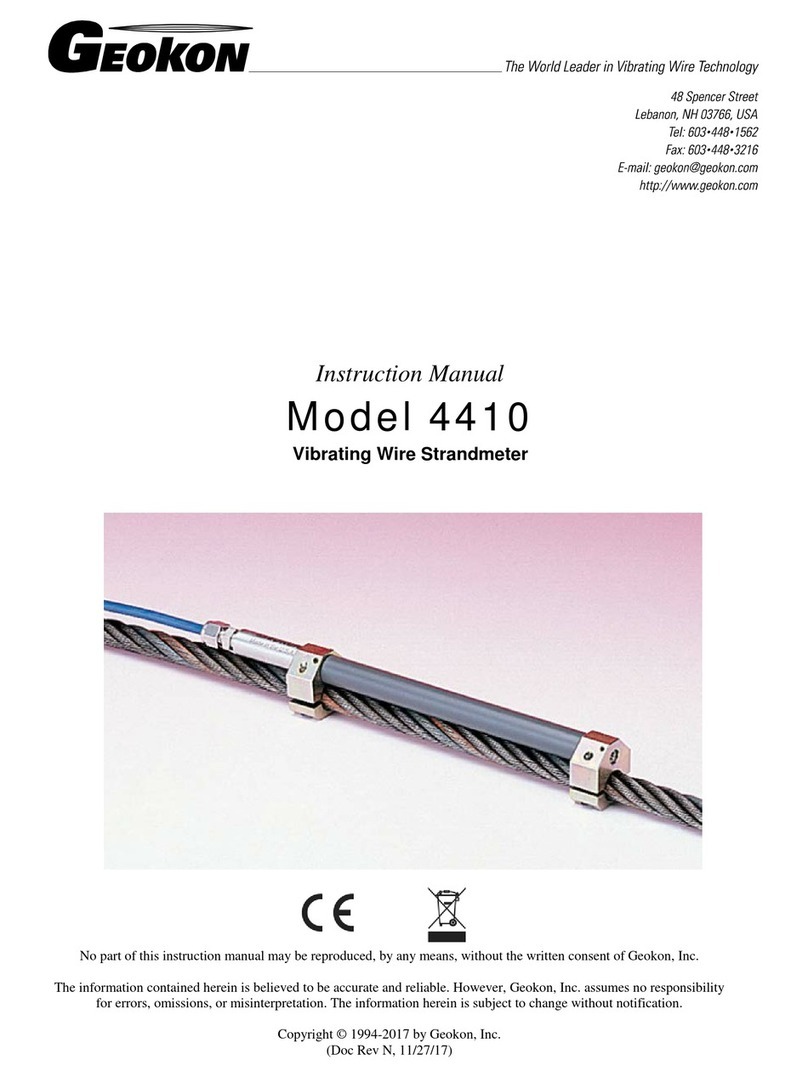

Figure 2 - Anchor Assembly / Securing the Leaf Springs

4) Use the chains supplied to restrain the ends of the leaf springs). The pull-pin passes

though the links of the chain holding the leaf springs snug against the access tube. Use

3/4 inch electricians tape (two turns) around the pull pin above and below the anchor,

(see Figure 2). This holds the anchor pull-pin in place and makes it more difficult to

pull the pin out, thus reducing the risk of prematurely tripping the anchor during

installation.) It also holds the spider anchor in place preventing it from sliding up the

access tube during installation.

5) Leaving the pull cable coiled, connect the loop on the end of the cable to the anchor

pull-pin by clipping the hook through the eye of the pull cable.

6) Wrap a single layer of masking tape around the cable about 30 cm above the hook.

This also will make it difficult for the pull-pin to be pulled prematurely.

7) Tape identification tags onto each end of the pull cables, e.g., use “#1” for the top

anchor, “#2” for the next anchor, etc. Colored tapes can tapes can also be used for

identification if identification tags are not available.

2.2.2 Installing the Access Tube Anchor String

1) Begin assembling the access tube string and pushing it into the borehole. If the hole is

to be grouted after the string is placed, then the tremie pipe should be taped to the end

of the access tube. Tape heavily enough to prevent the Tremie pipe from coming

loose as it is pushed into the hole but not so heavy that it cannot be pulled loose

deliberately at the start of grouting. If the borehole is already filled with grout or

water, it will be necessary to fill the access tube with water to overcome the buoyancy

forces.

2) When sections with spider anchors are added to the string, the pull-cables should be

uncoiled and fed smoothly into the borehole along with the access tubing. Do not

allow any of the pull-cables be snagged, tangled, or pulled on, which could cause

premature triggering of the anchors. It may be advisable to have more than one

person in charge of the pull-cables and tremie pipe.

3) Once the access tube has been lowered to the bottom of the borehole, it will be

necessary to make sure that all the telescoping couplings are fully extended to

accommodate the anticipated settlements. (If heave is being measured, the couplings