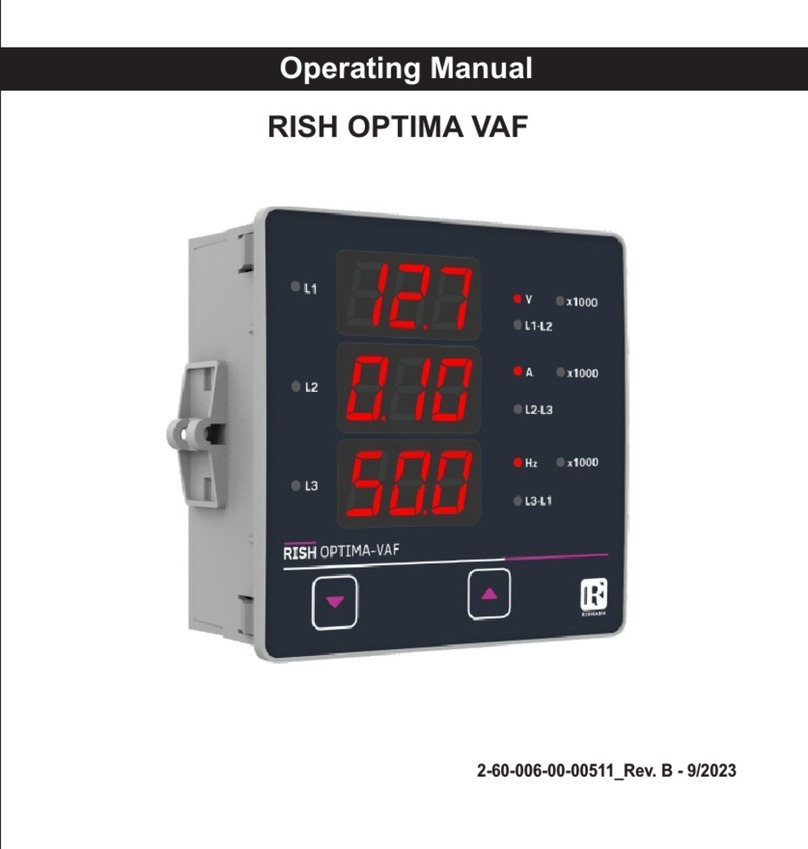

2. LCD Display

The meter displays more than 80 measurement parameters including Total Energies, Tariff, Partial

and also other important electrical parameters like Max Demand, Voltage, Current, Frequency,

Active, Power, Reactive Power, Apparent Power and Power Factor on individual screens. The

user can easily scroll and See System Parameter By Pressing Scroll key and By Pressing and

Holding Scroll key for 5 Seconds the user can see Tarrif & Demand Parameters on screen2. again

Pressing and Holding Scroll key for 5 Seconds it back to the Main Parameter Screen1. Refer Table

1 & Table 2 for list all the Measurement Parameters available on Display and MODBUS.

The LCD has bold seven segment digits with bright white backlit for display of measurement

parameters. Special symbols, units and bar graph are provided for effective display and easy

onsite configuration. Indications for current reversal, communication status, active tariff, digital

inputs and pulse outputs status are continuously available on screen. Measurement screen can

be set as automatic scrolling or manual scrolling.

2.2. LCD Display Symbols and Indications

2.1. Introduction

2.2.1 SO Output Indication

The meter has two opto-isolated pulse outputs that can be configured for any one of the Active, Reactive and

Apparent Energy parameter.

2.2.2 Communication Indication

The meter provides communication based on MODBUS protocol for remote data acquisition of measurement data

and configuration. If meter is properly communicating with host than it is indicated by symbol as shown:

This symbol indicates that the meter is communicating.

This symbol indicates that SO1 is energized.

This symbol indicates that SO2 is energized.

5