Edwards CXS User manual

P601-01-340

Issue B

Original Instructions

Instruction Manual

CXS Control Box

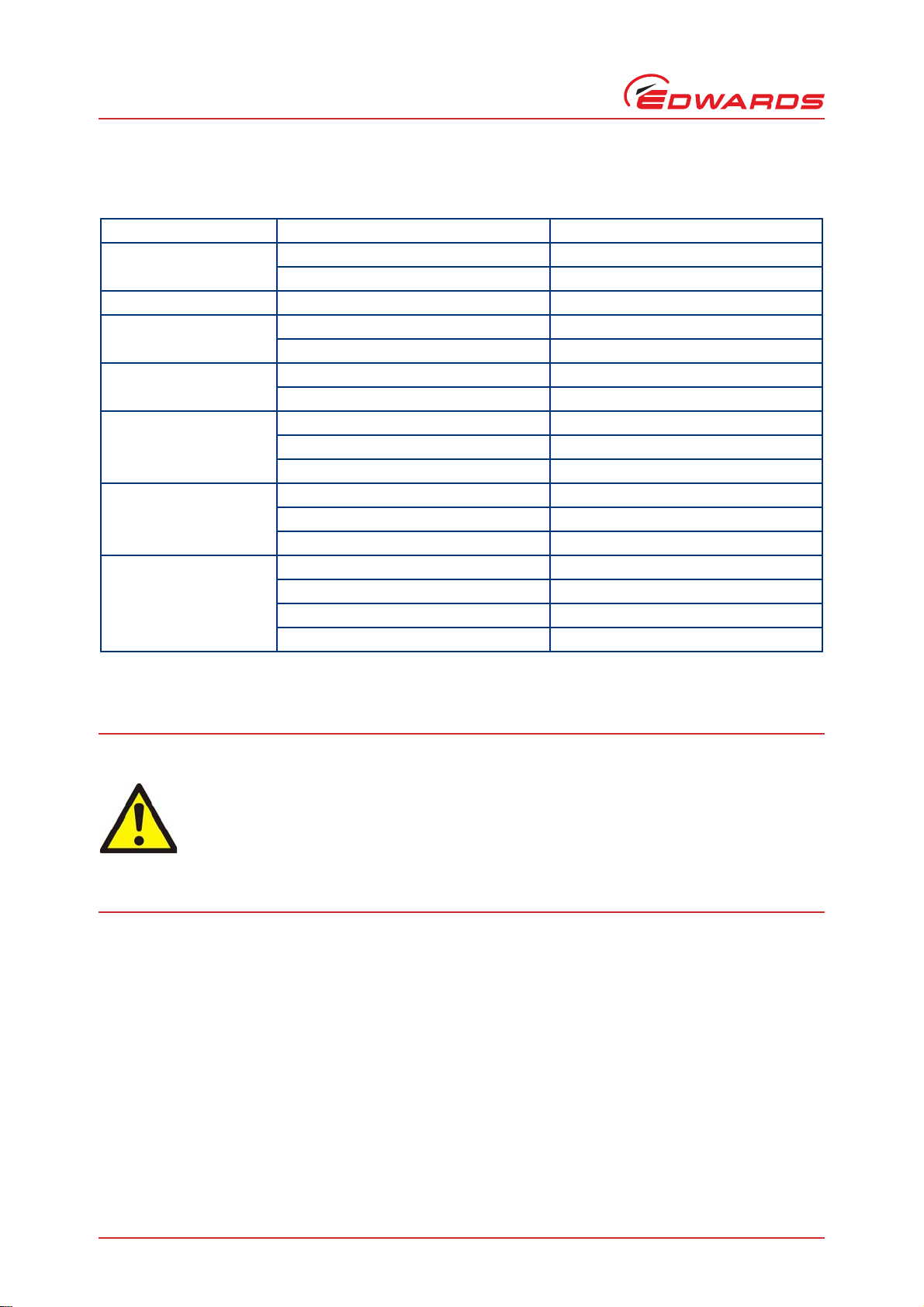

Description Item Number

CXS Control Box 7.5 kW M528-XX-XXX

CXS Control Box 7.5 kW - MK2 water circuit M529-XX-XXX

CXS Control Box 11 kW M538-XX-XXX

CXS Exd Control Box

Voltage

1 = High volt

2 = Low volt

M5 0

Booster Kit

0 = No EH Booster kit

1 = EH Booster kit

Amps

0 = No trip amps

1 = 1 trip amp

2 = 2 trip amps

3 = 3 trip amps

4 = 4 trip amps

Controls

0 = No control

1 = Ethernet

2 = Profibus

3 = MicroTIM

4 = Ethernet & Profibus

5 = Ethernet & MicroTIM

6 = Profibus & MicroTIM

7 = Ethernet & Profibus

& MicroTIM

Product Family Name

28 = 7.5 kW

29 = 7.5 kW MK2 water circuit

38 = 11 kW

© Edwards Limited 2018. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Instruction Manual for CXS Control Box

P601-01-340 Issue B

Note: Please note that the contents of this instruction manual will be embedded in the instruction manual for the

complete CXS system.

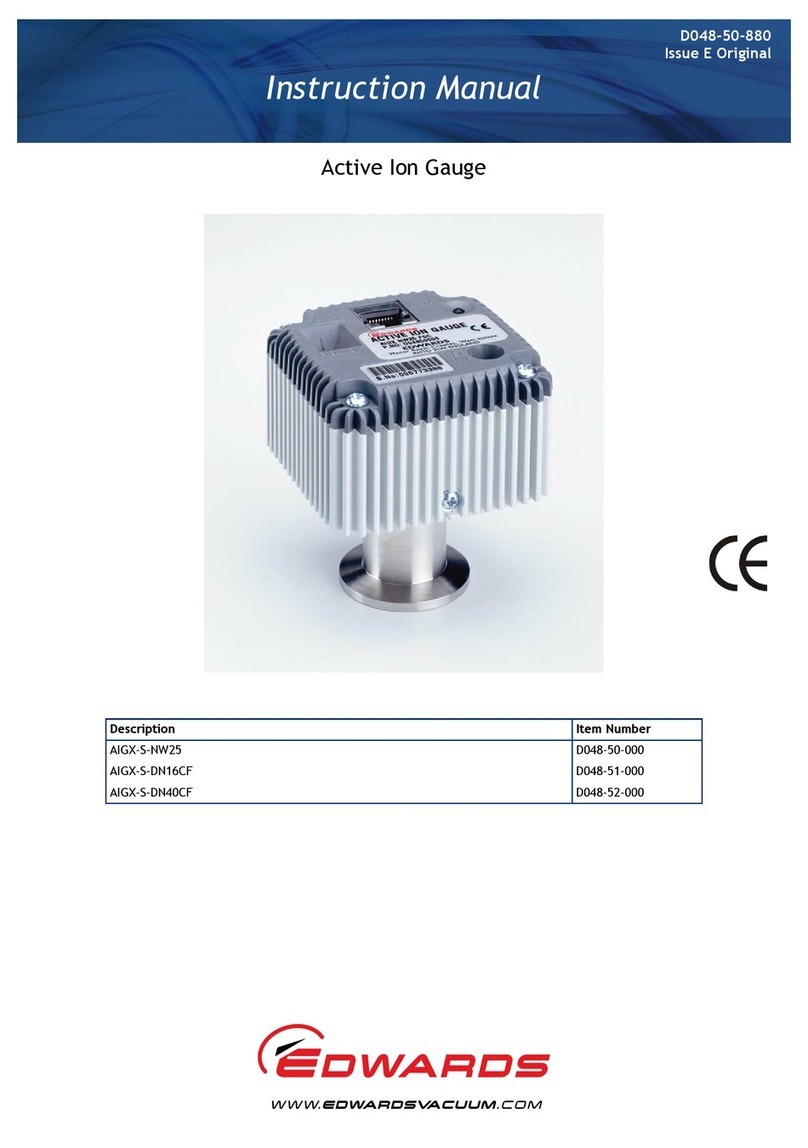

1 Instruction Manual for CXS Control Box

The CXS control box is a flame-proof Exd enclosure that forms part of the Edwards CXS chemical dry pump system.

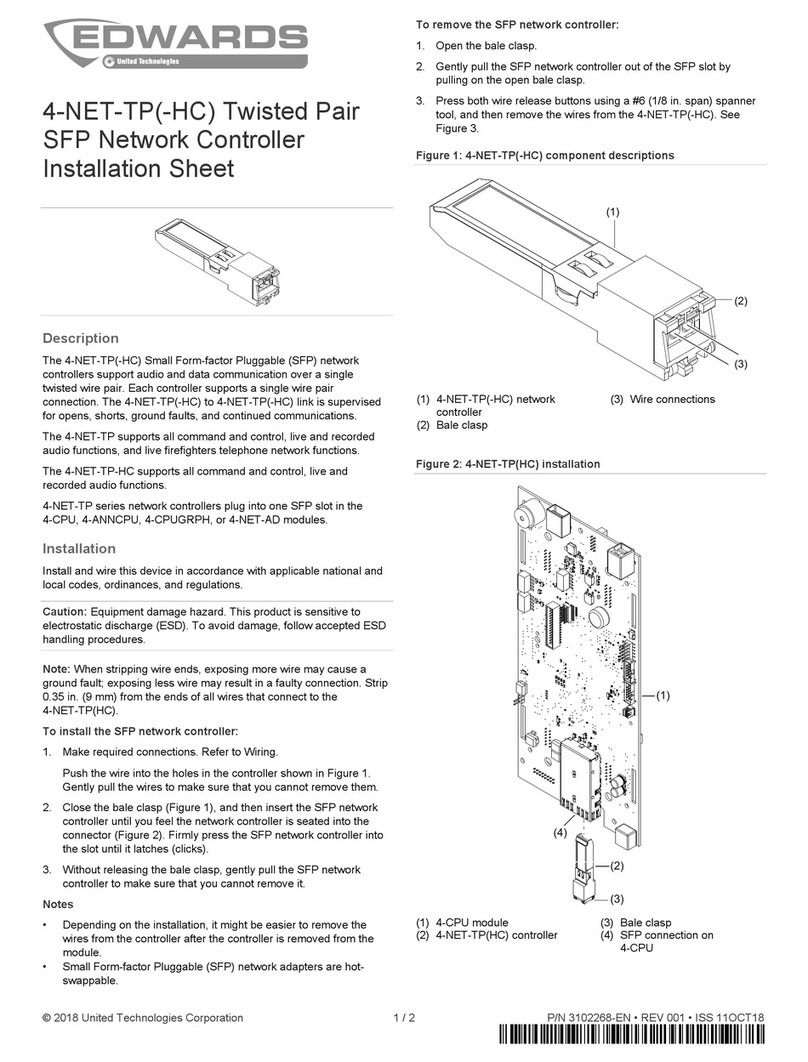

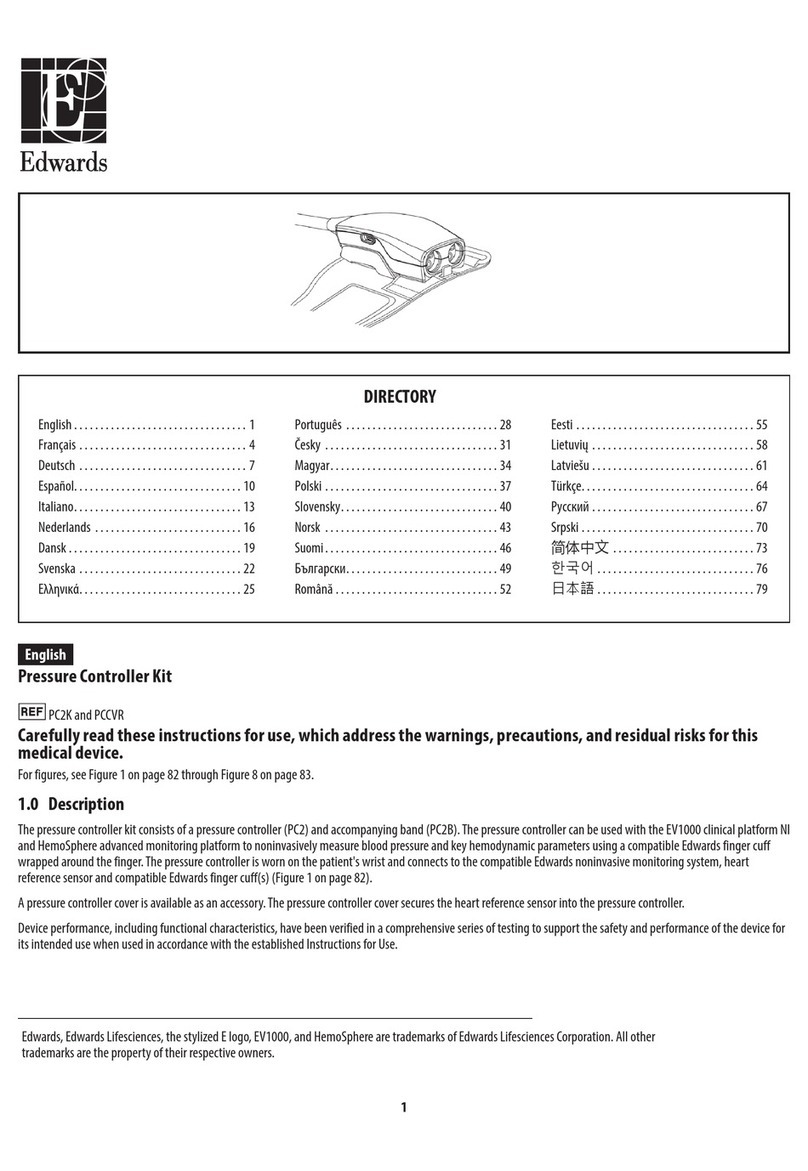

It houses the controls to operate and control the pump. Figures 1and 2show external views of the CXS control box.

Figure 1 - Control box front view

Figure 2 - Control box rear view

1. Top face

2. Customer 3PH supply in

3. PDT diagnostics port

4. Display module feedthrough

5. Front lid

1. Customer 3PH supply in

2. Booster 3PH out

3. Booster thermistor cable

4. Customer connections

5. CXS DP 3PH motor out

6. Pump facing side

7. Gland plate safety looms

8. Access plate motor terminations

P601-01-340 Issue B

Page 2 © Edwards Limited 2018. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Instruction Manual for CXS Control Box

Components must not be added to the control box. Some of the entries are for connection to the CXS pump, display

module or ancillaries (e.g. boosters) and must be closed with suitable fittings, i.e. either suitable rated stopping

plugs or cable and cable glands, as detailed below in Table 4.

The only entries allowed for connection to the user's equipment/services are marked with a # and must be closed

with suitable fittings as detailed below in Table 5.

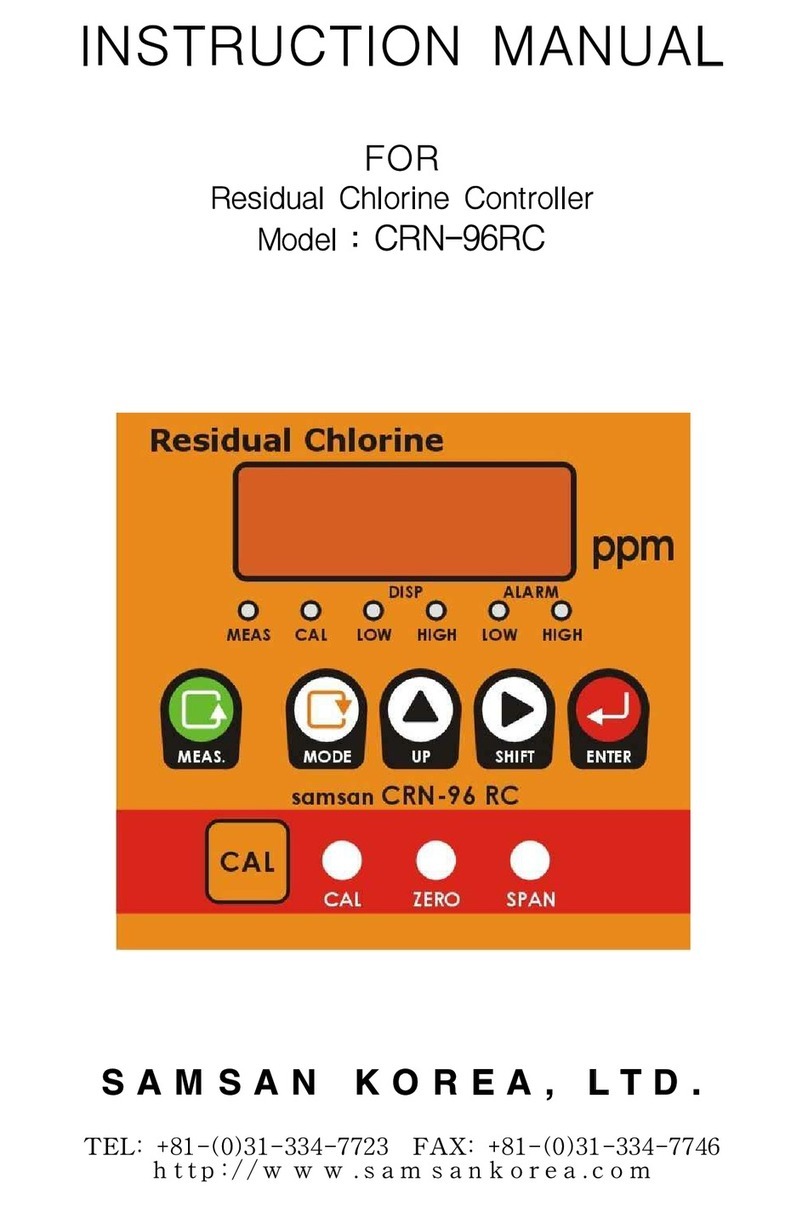

Figure 3 - Control box front view fasteners and holes

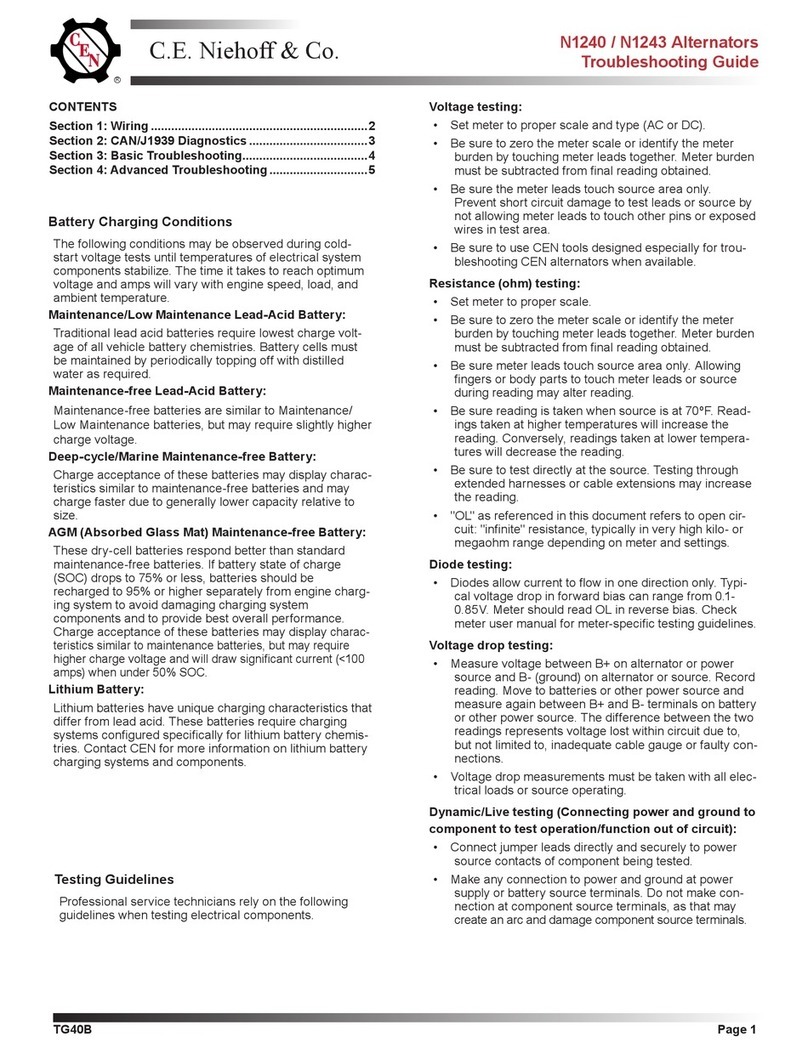

Figure 4 - Control box rear view fasteners and holes

1. ISO 4762 M8 x 1.25 x 40-12.9 ENP 27522-051 4 POSITIONS

2. Thread form ISO 965-1 M32 x 1.5-6H

3. Thread form ISO 965-1 M25 x 1.5-6H

4. Inspect cover joint to ensure maximum 40 µm gap

requirement is complied with

1. Thread form ISO 965-1 M20 x 1.5-6H

2. ISO 4762 M8 x 1.25 x 40-12.9 ENP 27522-051

4 POSITIONS

3. Thread form ISO 965-1 M32 x 1.5-6H

4. ISO 4762 M8 x 1.25 x 40-12.9 ENP 27522-051

4 POSITIONS

5. A maximum of 9 cable glands may be fitted on this

plate

6. Inspect plate-box joint to ensure max 40 µm gap

requirement is complied with

7. Thread form 1/2-20 UNF 2B BS1580 3 positions

8. Thread form ISO 965-1 M8 x 1.25-6H

© Edwards Limited 2018. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Certification of the CXS control box

P601-01-340 Issue B

Figure 5 - Control box top view fasteners and holes

2 Certification of the CXS control box

The CXS control box can be safely operated in Zone 1 atmospheres containing IIB gases with the temperature class

T4. The certified ambient conditions are as follows:

-20°C ≥Tamb ≥40°C for all non pump facing sides

-20°C ≥Tamb ≥70°C for the pump facing side

Explosion protection certification

II 2G Ex db IIBG T4 Gb

Table 1 - Rated operational voltage and current

The CXS control box complies with the following standards:

EN60079-0

EN60079-1

2.1 IP rating

The IP rating of the box is IP65 and is therefore suitable for outdoor use.

High Volt Low Volt

Rated operational voltage 380 - 460V 180 - 230V

Rated operational current CXS160 12 Amps 23 Amps

CXS160/EH500 15.2 Amps 29.1 Amps

CXS160/EH1200 17.9 Amps 34.9 Amps

CXS250 13 Amps 31 Amps

CXS250/EH1200 16.7 Amps 37.1 Amps

CXS250/EH2600 19.4 Amps 42.9 Amps

1. Thread form ISO 965-1 M20 x 1.5-6H

6 positions

2. Thread form ISO 965-1 M32 x 1.5-6H

P601-01-340 Issue B

Page 4 © Edwards Limited 2018. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Materials of construction

2.2 Cooling water data

Cooling water is required to cool the CXS pump system, including elements within the CXS control box. Refer to

Table 2 for the minimum requirement based on the control box certification.

Note: If the pump is operated at lower temperatures higher flow rates may be required for reliable operation.

Table 2 - Cooling water data

3 Materials of construction

Table 3 - Materials of construction

4 Instructions for use

In order to operate the CXS system the mains power supply must be connected to the control box.

The mains power connector and the interface connections must be made using the combination of tested cable glands

and cables listed in Table 4 or by using alternative cables (suitably electrically rated) along with certified Exd

compound glands.

Table 4 - Cable and cable glands for customer connection

Please refer to Figures 3, 4and 5for the type and size of thread.

The installation may only be performed by qualified personnel, which have been suitably trained for this purpose.

All suitable national regulations of the country of use have to be followed.

Any unused entry threads should be sealed with an appropriate Exd rated blanking plug.

4.1 Opening the control box

When opening the control box either by taking off the front lid or one of the cable gland plates or cover plates, you

must ensure that the flame-path surfaces are kept clean and scratch-free. Please refer to Figures 6to 10.

Minimum water supply 4 l/min

Cooling water temperature 5°C - 35°C

Control box Aluminium Alloy AISi7MgKT6

Cable gland plates and lid Aluminium Alloy AW-6082-T6

Where used Tested cable Tested gland

Mains in LAPP 1121377 Hawke, E1WF/25/M25 + Reducer ARB/M32/M25

Customer I/F LAPP 1135762 - 12 way PEPPERS E1WF/16/M20

LAPP 1135762 - 12 way Hawke A501-453-Os-uni

LAPP 1125025 - 25 way PEPPERS E1WF/20s/M20

LAPP 1125025 - 25 way Hawke A501-453-A-uni

LAPP 1135818 - 18 way PEPPERS E1WF/20s/M20

LAPP 0031052 - 16 way x 0.34 Hawke A501-453-A-uni

© Edwards Limited 2018. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Instructions for use

P601-01-340 Issue B

Figure 6 - Flame path on control box

Figure 7 - Flame path on lid facing control box

1. 21.3 mm minimum

2. 14 mm minimum

Note: Dimensions in mm

P601-01-340 Issue B

Page 6 © Edwards Limited 2018. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Instructions for use

Figure 8 - Control box pump facing side safety loom and terminal cover gland plates flame paths

Figure 9 - Safety loom gland plate flame path

Note: Dimensions in mm

Note: Dimensions in mm

© Edwards Limited 2018. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Instructions for use

P601-01-340 Issue B

Figure 10 - Terminal cover flame path

1. Unscrew the fasteners on the lid and/or cover/gland plates.

2. Open and remove the lid or plates carefully (the lid is hinged - it is advised not to remove it completely unless

necessary).

3. Store the lid and/or plates in a way to ensure that no damage will be made to the flame-path surfaces.

4. When fitting the lid and/or plates take special care that the flame-paths are not damaged.

5. Tighten the fasteners using the specified tightening torque.

6. Check the gaps between the gland plates and control box and lid and control box to the specification given in

Figure 4.

You must use the fasteners provided with the box or source replacements to the specification below. After

unscrewing the fasteners, keep them in a safe place and ensure they are clean and undamaged if re-using them.

Specification for replacement fasteners:

M8x1.25 6g 12.9 ENP ISO4762

The following table lists the cable/gland combinations that have been tested and approved, for use with the

connections to the CXS system and ancillaries (eg booster pump), in addition to the mains and interface combinations

listed in Section 4.1. These connections will be made by Edwards during the manufacture of the CXS system.

Connections must be made using the following combination of tested cable glands and cables or by using alternative

cables (suitably electrically rated) along with certified Exd compound glands.

WARNING

Any scratches or damage on the flame-path surfaces (refer to Figures 6to 10) will impair the

explosion protection of the CXS Exd control box. Handle all enclosure covers with care. If any

flame-path surface is damaged you must replace that part before re-using the enclosure.

Note: Dimensions in mm

P601-01-340 Issue B

Page 8 © Edwards Limited 2018. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Instructions for use

List of tested cable glands and cable combinations:

Table 5 - Certified cable glands and cable combinations

* Temperatures at the entry point for the motor cable can be as high as 77°C under rated conditions. If

another cable than the ones listed in Table 5 are chosen, this higher temperature rating has to be taken into

account.

Where used Cable Cable gland

Booster thermistor Lapp 0035004 PEPPERS E1WF/R/16/M20

Lapp 0035004 Hawke A501-453-uni-Os

Booster power Lapp 1121367 - 6mm CY Peppers E1WF/20/M20

Booster N2 supply Lapp 0010000 PEPPERS A3LF/16

Lapp 0010012 Hawke A501-421-A

Sensor cable Lapp 0010012 PEPPERS A3LF/20

Lapp 0010000 Hawke A501-421-Os

Display box interface/ Trip

amp loom/ Cat.2 loom/

PID loom

DEF STAN 61-12, 7-2-25 PEPPERS A3LF/20

DEF STAN 61-12, 7-2-25 Hawke A501-421-A

LAPP 0028051 16 x 0.34 PEPPERS A3LF/20s

CXS Motor power * LAPP 1119614 A3LF/25/M25

LAPP 0011169 A3LF/25/M25

LAPP 1121372 A3LF/25/M25

Solenoid Valve cable Lapp 1119103 PEPPERS A3LF/16

Lapp 1119103 Hawke A501-421-Os

DANFOSS H05 V2v2 -F 3G075 PEPPERS A3LF/16

DANFOSS H05 V2v2 -F 3G075 Hawke A501-421-Os

WARNING

Entries must be fitted with the gland/cable combinations detailed in this manual, or by using

alternative cables (suitably electrically rated) along with certified Exd compound glands,

otherwise the explosion protection can no longer be guaranteed.

All unused entries in the enclosure must be closed using certified Exd blanking/stopping plugs to

guarantee the explosion protection of the control box. If any entries are left open the explosion

protection of the control box can no longer be guaranteed. Refer to Figure 4 for information on

thread type on all entries.

© Edwards Limited 2018. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Servicing and Maintenance

P601-01-340 Issue B

5 Servicing and Maintenance

WARNING

Risk of electric shock. Ensure that the power supply to the control box is disconnected before you

start maintenance work.

WARNING

Risk of electric shock. Allow 15 minutes before you open the control box when it has been de-

energised.

WARNING

Risk of damage to equipment or injury to people. Ensure that only suitably trained and authorized

personnel perform work on the control box.

P601-01-340 Issue B

Page 10 © Edwards Limited 2018. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

This page has been intentionally left blank.

This page has been intentionally left blank.

This page has been intentionally left blank.

Return the equipment or components for service

Before you send your equipment to us for service or for any other reason, you must send us a

completed Declaration of Contamination of Vacuum Equipment and Components – Form HS2. The

HS2 form tells us if any substances found in the equipment are hazardous, which is important for

the safety of our employees and all other people involved in the service of your equipment. The

hazard information also lets us select the correct procedures to service your equipment.

We provide instructions for completing the form in the Declaration of Contamination of Vacuum

equipment and Components – Procedure HS1.

If you are returning a vacuum pump, note the following:

If a pump is configured to suit the application, make a record of the configuration before

returning the pump. All replacement pumps will be supplied with default factory settings.

Do not return a pump with accessories fitted. Remove all accessories and retain them for

future use.

The instruction in the returns procedure to drain all fluids does not apply to the lubricant in

pump oil reservoirs.

Download the latest documents from www.edwardsvacuum.com/HSForms/, follow the procedure in

HS1, fill in the electronic HS2 form, print it, sign it, and return the signed copy to Edwards.

Note: If we do not receive a completed HS2 form, we will not accept the return of the

equipment.

P80081000, Issue A

P800‐80‐000IssueT

edwardsvacuum.com

Other manuals for CXS

1

Table of contents

Other Edwards Controllers manuals

Edwards

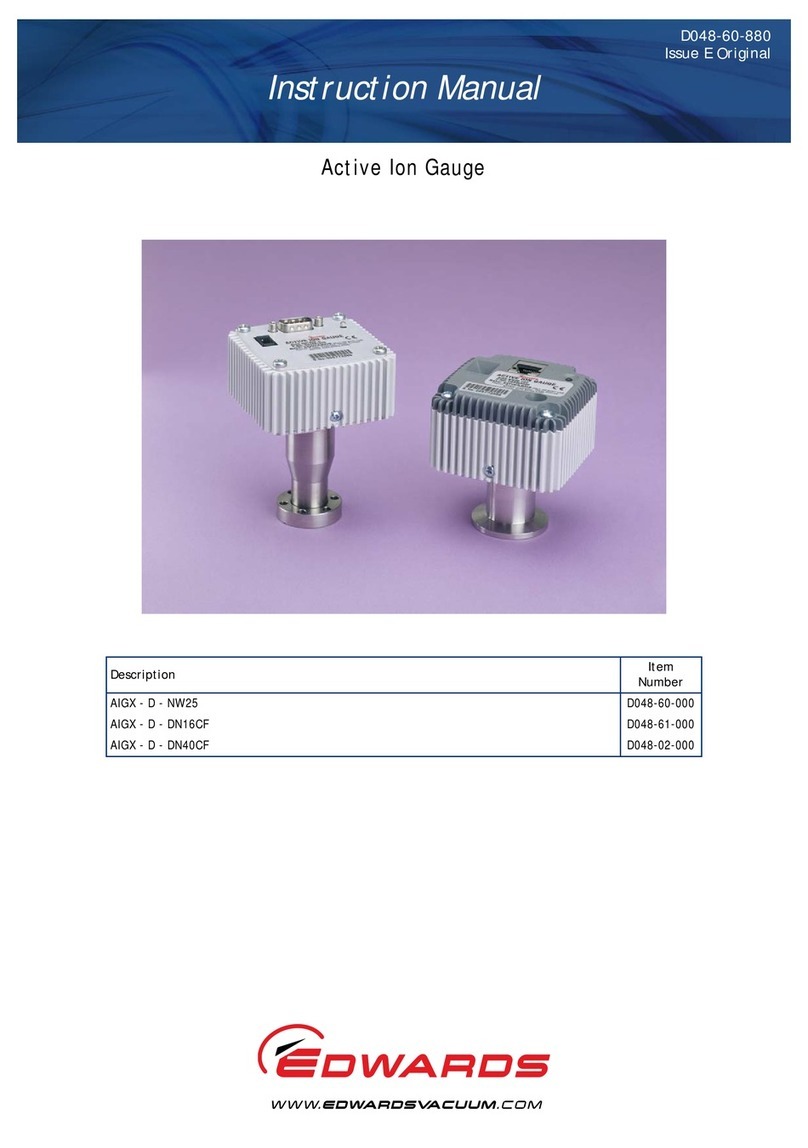

Edwards AIGX-S-NW25 User manual

Edwards

Edwards EXC120 User manual

Edwards

Edwards D395-92-000 User manual

Edwards

Edwards AIGX-D-NW25 User manual

Edwards

Edwards ASG2-1000-1/8 NPT User manual

Edwards

Edwards PGC202 User manual

Edwards

Edwards iTIM E73/A1/T1 User manual

Edwards

Edwards PGC201 User manual

Edwards

Edwards 4-NET-CAT Assembly instructions

Edwards

Edwards D397-00-000 User manual