EG&G ORTEC 260 User manual

too

MIDLAND

ROAD.

OAK

RIDGE

TENNESSEE,

37830

AREA

CODE

(615)

483-8451

TWX

810-572-1078

INSTRUCTION

MANUAL

260

TIME

PICKOFF

UNIT

AN

COMPANY

INSTRUCTION

MANUAL

260

TIME

PICKOFF

UNIT

S^al

No.

Purchaser

Date

Issued

ORTEC

INCORPORATED

P.

0.

BOX

0

OAK

RIDGE,

TENNESSEE

37830

Telephone

(615)

483-8451

TWX

810-572-1078

@

ORTEC

Incorporated

1966

Printed

In

U«S«Aa

TABLE

OF

CONTENTS

Page

WARRANTY

PHOTOGRAPH

1.

DESCRIPTION

1-1

2.

SPECIFICATIONS

2-1

3.

INSTALLATION

INSTRUCTIONS

3-1

4.

OPERATING

INSTRUCTIONS

4-1

4.1

Initial

Checkout

and

Familiarization

4-

1

4.2

Application

Notes

4-

1

5.

CIRCUIT

DESCRIPTION

5-1

6.

MAINTENANCE

INSTRUCTIONS

6-1

6.1

Testing

Performance

6-

1

6.2

Calibration

Adjustments

6-

1

6.3

Suggestions

for

Troubleshooting

6-

1

SCHEMATIC

ORTEC

260

Time

Pickoff

260-Sl

LIST

OF

FIGURES

AND

ILLUSTRATIONS

Page

Figure

2-1.

Plof

of

ORTEC

260

Threshold

SensiH

vify

vs

Det-ector

Capacity

2-2

Figure

2-2.

Typical

Block

Diagram

for

Timing

With

Semiconductor

Detectors

2-3

Figure

4-1.

Pileup

Reduction

With

260

and

404

4

-2

Figure

4-2.

A

Method

of

Pulse

Shape

Discrimination

4-3

Figure

4-3.

Charged-Porticle

Identification

by

Time-of-Flight

4-4

Figure

4-4.

Beam

Pulse

Time

Pickoff

System

(T

=

O)

for

Pulsed

Accelerators

4-5

A

NEW

STANDARD

TWO-YEAR

WARRANTY

FOR

ORTEC

ELECTRONIC

INSTRUMENTS

ORTEC

warrants

its

nuclear

instrument

products

to

be

free

from

defects

in

workmanship

and

materials,

other

than

vacuum

tubes

and

semiconductors,

for

a

period

of

twenty-four

months

from

date

of

shipment,

provided

that

the

equipment

has

been

used

in

a

proper

manner

and

not

subjected

to

abuse.

Repairs

or

replacement,

at

ORTEC

option,

will

be

made

without

charge

at

the

ORTEC

factory.

Shipping

expense

will

be

to

the

account

of

the

customer

except

in

cases

of

defects

discovered

upon

initial

operation.

Warranties

of

vacuum

tubes

and

semiconductors,

as

made

by

their

manufacturers,

will

be

extended

to

our

customers

only

to

the

extent

of

the

manufacturers'

liability

to

ORTEC.

Specially

selected

vacuum

tubes

or

semiconductors

cannot

be

warranted.

ORTEC

reserves

the

right

to

modify

the

design

of

its

products

without

incurring

responsibility

for

modification

of

previously

manufactured

units.

Since

installation

conditions

are

beyond

our

control,

ORTEC

does

not

assume

any

risks

or

liabilities

associated

with

methods

of

installation

other

than

specified

in

the

instructions,

or

installation

results.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

ORTEC

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

REPAIR

SERVICE

ORTEC

instruments

not

in

warranty

may

be

returned

to

the

factory

for

repairs

or

checkout

at

modest

expense

to

the

customer.

Standard

procedure

requires

that

returned

instruments

pass

the

same

quality

control

tests

as

those

used

for

new

production

instruments.

Please

contact

the

factory

for

instructions

before

shipping

equipment.

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

ORTEC

of

the

circumstances

so

that

we

may

assist

in

damage

claims

and

in

providing

replacement

equipment

if

necessary.

'I

'

4".'

TIME

PICKOFF

UNIT

[--

>

I—DETfcCTOR

PRbAMP

MODEL

260

I

I

I

II

I

1

-1

}

INSTRUCTION

MANUAL

ORTEC

260

TIME

PICKOFF

UNIT

1.

DESCRIPTION

The

ORTEC

260

Time

Pickoff

Unit-

is

designed

to

obtain

a

timing

signal

directly

from

a

semiconductor

detector

without

significantly

altering

the

energy

resolution

qualities

of

the

detector-linear-amplifier

system.

It

consists

of

a

pulse

transformer,

a

wide-band

transistor

amplifier,

a

tunnel

diode

discriminator,

and

a

line

driver

buffer.

The

unit

is

connected

in

series

between

a

detector

and

a

charge-sensitive

preamplifier;

i.e.,

the

pulse

current

from

the

detector

flows

through

the

primary

of

the

pulse

transformer

en

route

to

the

preamplifier.

The

260

derives

its

power

and

discriminator

control

bias

from

a

remote

location

via

a

shielded

multiconductor

cable.

The

necessary

power

and

control

bias

are

provided

by

a

403A

Time

Pickoff

Control

.

All

signal

input

and

output

connections

are

of

a

BNC

type.

The

260

may

be

used

in

conjunction

with

photomultipliers

to

obtain

timing

signals

frpm

either

the

anode

or

dynode

simply

by

reversing

the

order

of

connections

to

the

transformer

primary.

This

unit

provides

the

necessary

functions

of

amplification

and

low

amplitude

triggering

required

for

signal

leading

edge

time

measurements

with

low

gain

(10-stage)

photomultipliers.

(Refer

to

section

4.2(2).)

The

260

may

also

be

used

in

conjunction

with

electrostatic-inductive

pickup

to

derive

a

timing

pulse

corresponding

to

T

=

0

for

pulsed

accelerators.

(Refer

to

section

4.2

(4).)

The

physical

dimensions

of

the

unit

are

6

x

4

x

1.7

(4.45

x

10.2

x

15.30cm).

I

(

*

2

-

1

I

2.

SPECIFICATIONS

2.1

Input

Polarily-

2.2

Input

Signal

Amplitude-

2.3

Sensitivity

2.4

Time

Pickoff

Effect

on

Energy

Resolution

■Either

positive

or

negative

by

reversing

the

order

of

connections

to

the

input

transformer

primary.

Connect

negative

input

to

BNC

(CN-1)

labeled

DET.,

and

posi

tive

input

to

BNC

(CN-2)

labeled

PREAMP.

-Dependent

on

input

impedance

of

ORTEC

260

amplifier,

which

may

be

changed

by

simple

plug-in

of

a

resistor.

Signal

input

to

the

amplifier

should

not

exceed

2V|

i.e.,

I2

Rj

^2V,

1^

=

1

.5

I2;

therefore,

I]

(max)

^.5/Rj.

I]

and

I2

refer

to

the

primary

and

secondary

pulse

transformer

currents.

-See

figure

1.

-Refer

to

table

1.

2.5

Energy

Variation

Effect

on

Time

Resolution

2.6

Threshold

Range-

2.7

Output

2.8

Power

Requirements-

2.9

Signal

Connections

2.10

Transformer

Insulation—

-Refer

to

table

2.

-s

15.1

-Negative

500

mV

(voltage

drive,

Zq~5

ohms),

Tj.

^

1.2

nsec.

Pulse

width

~10

nsec

(variable)

-+

12V

at

40

mA

or

-

12V

at

40

mA,

plus

discriminator

bios

current.

All

power

is

provided

by

a

Time

Pickoff

Control

Unit

(ORTEC

403A)

via

a

multiconductor

shielded

cable.

-BNC

type

-1

kV

Table

1.

Time

Pickoff

Effect

on

Energy

Resolution

(RC

Mode)

(Typical

Measurement)

Detector

Pulser

Width

Pulser

Width

Capacity

Without

Time

Pickoff

With

Time

Pickoff

(pF)

(keV)

(keV)

0

5.9

7.3

20

6.05

7.8

50

7.35

8.9

100

8.85

11.0

200

12.1

14.7

Note:

The

detector

capacity

indicated

is

in

addition

to

approximately

25

pF

cable

capacity.

2-2

I

Table

2.

Signal

Energy

Effect

on

Pickoff

Output

Time

(Typical

Measurement)

Signal

Amplitude

Time

Shift

Jitter

(FWHM)

(MeV,

Si

Detector)

(nsec)

(psec)

0.25

(Threshold)

0

150

0.5

1.2

86

1.25

1.9

73

2.5

2.5

68

5.0

2.7

62

Note:

The

pulse

generator

used

is

a

mercury-switch,

delay-line

type

(T^

<0.3

nsec).

600

LU

-J

3

O-

s

CM

U

UJ

H-

o

>

<D

>-

o

CSC

LU

z

LU

Q

_J

o

X

OO

LU

CC

X

400

200

c

)

.

ORTEC

*0017

0

100

200

500

SIMULATED

DETECTOR

CAPACITY

Figure

2-1

Plot

of

ORTEC

260

Threshold

Sensitivity

vs

Detector

Capacity

2-3

2-0=

son

I

1

CHARGE

TERMINATOR

CHARGE-SENSITIVE

PREAMPLIFIER

LINEAR

AMPLIFIER

DETECTOR

I

ANALYZER,

ETC,

PARTICLE

BEAM

PREAMP

DET.

POWER

a

CONTROL

BIAS

ORTEC

200172

OUTPUT

>—a

PRECISION

PULSE

GEN

FA^OUJ_^F^^R

7

outputs}

INPUT

A

403A

TIMING

SIGNALS

Figure

2-2

Typical

Block

Diagram

for

Timing

Wifh

Semiconductor

Detectors

3

-

1

3.

INSTALLATION

INSTRUCTIONS

3.1

CAUTION:

Before

applying

a

pulser

or

connecHng

to

a

photomultiplier,

refer

to

section

2.2.

3.2

Connect

the

260

between

the

detector

and

charge-sensitive

preamplifier

input

as

indicated

by

the

arrows

at

the

two

input

BNC

connectors.

The

inputs

are

indicated

for

electron

signal

collection.

(See

block

diagram,

figure

2.)

3.3

Connect

a

precision

pulse

generator

via

a

charge

terminator

in

parallel

with

the

de

tector

as

shown

in

the

block

diagram

(figure

2).

3.4

Connect

the

power

coble

between

260

and

403A

Time

Pickoff

Control

Unit.

3.5

Connect

50-ohm

coaxial

cable

from

260

output

to

input

of

fanout

buffer

of

Time

Pickoff

Control,

to

scope

input,

or

to

other

time

monitoring

point.

The

coaxial

cable

should

be

terminated

at

the

receiving

end.

3.6

Control

of

the

260

Time

Pickoff

is

now

handled

completely

by

the

403A

Time

Pickoff

Control

Unit.

3.7

Set

the

Control

Unit

discriminator

level

(R9)

at

1000.

3.8

Turn

on

Control

Unit

power.

3.9

The

discriminator

level

may

now

be

adjusted

to

the

energy

level

desired.

The

dis

criminator

should

trigger

on

amplifier

noise

when

the

level

is

set

very

near

zero.

4-

1

4.

OPERATING

INSTRUCTIONS

4.1

Initial

Checkout

and

Familiarization

(1)

Connect

the

unit

as

described

in

the

installation

instructions

(section

3).

(The

detector

need

not

be

connected

for

checkout.)

In

some

applications,

it

may

be

desirable

to

replace

the

charge-sensitive

preamplifier

by

a

fixed-capacity,

delay-line

terminating

impedance,

or

short-circuit

terminator.

Use

a

pulser

such

as

the

ORTEC

204

or

419

Precision

Pulse

Generator

or

any

mercury

switch

delay-

line

pulser

with

a

rise

time

of

less

than

2

nanoseconds.

If

a

delay-line

pulser

is

used,

set

the

pulse

width

to

2-10

nanoseconds,

and

use

a

terminating

impedance

in

place

of

the

charge-sensitive

preamplifier.

(2)

Adjust

the

pulser

amplitude

to

the

equivalent

of

~10

mV

into

100

ohms

before

connecting

to

the

260.

(Refer

to

section

2.2.)

(3)

Connect

pulser,

turn

on

power

to

Time

Pickoff

Control,

and

adjust

the

discriminator

level

to

obtain

an

output

pulse.

If

a

precision

pulse

generator

is

used,

it

may

be

calibrated

in

energy

and

then

the

pulser

becomes

an

energy

reference

to

both

the

energy

analysis

system

and

the

discriminator

of

the

260.

4.2

Application

Notes

Refer

to

the

next

four

pages

for

four

different

applications

using

this

equipment.

4-2

APPLICATION

NOTES

(1)

Inspecfion

and

Pileup

Reduction

Figure

3

is

a

block

diogrom

of

the

experimental

setup

for

removing

from

a

spectrum

those

pulses

which

have

the

wrong

amplitude

because

of

multiple

pulses

arriving

in

a

detector

within

a

period

of

time

corresponding

to

the

linear

amplifier

resolving

time.

This

is

especial

ly

important

when

pulse

height

analysis

is

performed

on

a

complicated

spectrum

containing

many

pulse

amplitudes

and

widely

varying

relative

rates.

Inspection

by

this

method

reduces

the

relative

pileup

time

from

3.3

microseconds

for

a

double-del

ay-line

clipped

amplifier

with

1-microsecond

clipping

lines

to

approximately

250

nanoseconds.

This

is

a

reduction

factor

of

approximately

12

in

the

number

of

counts

in

any

random

sum

or

difference

peak.

DETECTOR

I'

-OAOltr

CHARGE

SENSITIVE

LINEAR

PREAMP

427

LINEAR

DELAY

INPUT

MULTICHANNEL

ANALYZER

POWER

4

CONTROL

BIAS

Zo=

I

403A

50

ohm

-Lfl

)

i—jFAN

OUT

BUFFER

FAST

AMP

260

TIME

PICKOFF

INSPECT

^NGLES

J

TIMING

CIRCUIT

(TPHC,

COINC.,

ETC.)

SINGLES

SCALER

LINEAR

SIGNAl

LINEAR

(DELAYED)

TIME

PICKOFF

OUTPUT

INHWIT

PULSE

UNEAR

SIGNAl

LINEAR

(OaAYED)

TIME

PICKOFF

OUTPUT

INHIBIT

PULSE

r/

1

i/

(-

\\

V

•

-x

1

1..

..J

1

Figure

4-1

Pileup

Reduction

With

260

and

404A

4-3

APPLICATION

NOTES

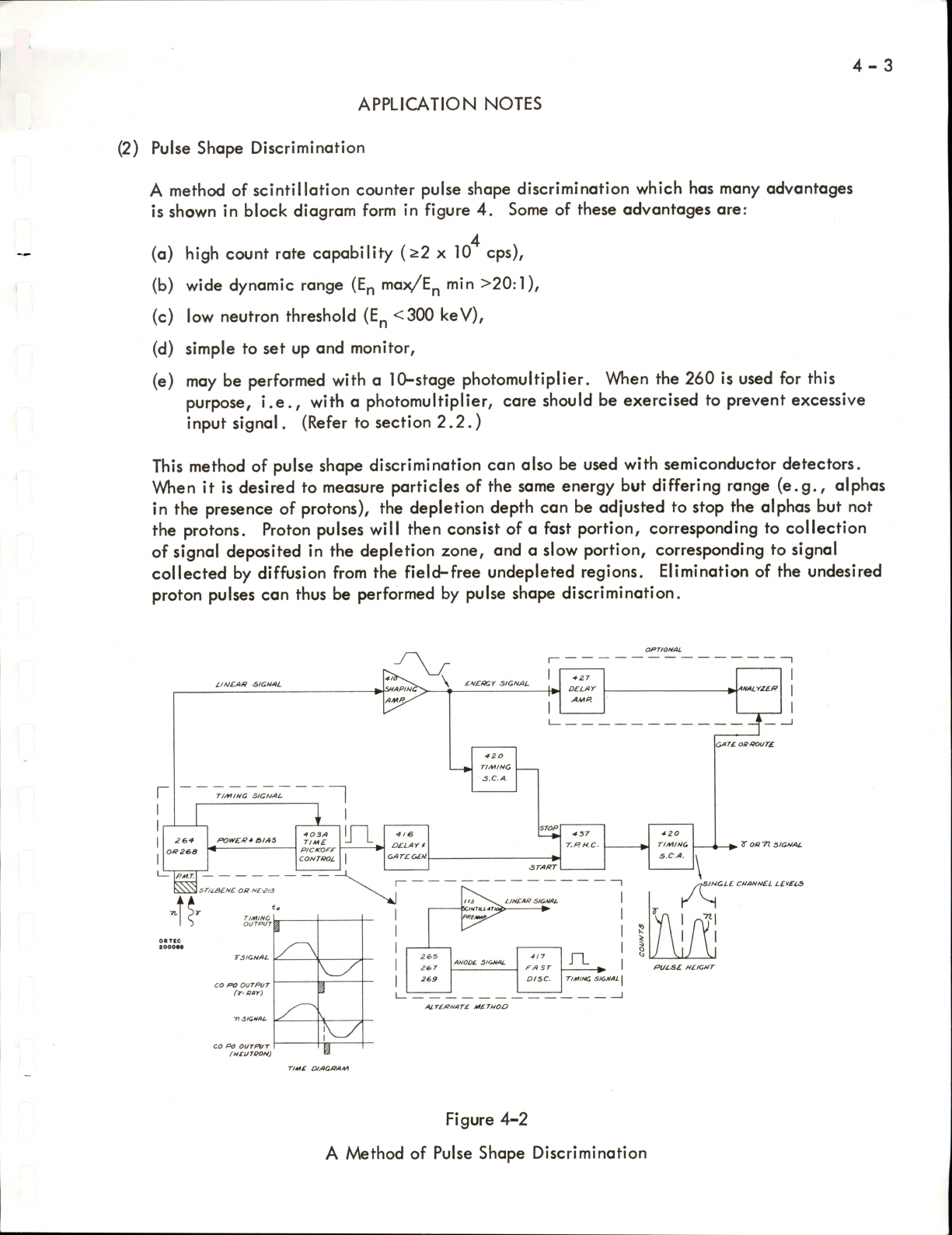

(2)

Pulse

Shape

Discrimination

A

method

of

scintillation

counter

pulse

shape

discrimination

which

has

many

advantages

is

shown

in

block

diagram

form

in

figure

4.

Some

of

these

advantages

are:

4

(a)

high

count

rate

capability

(s2

x

10

cps),

(b)

wide

dynamic

range

ma^v^E^

min

>20:1),

(c)

low

neutron

threshold

(E^^

<300

keV),

(d)

simple

to

set

up

and

monitor,

(e)

may

be

performed

with

a

10-stage

photomultiplier.

When

the

260

is

used

for

this

purpose,

i.e.,

with

a

photomultiplier,

care

should

be

exercised

to

prevent

excessive

input

signal.

(Refer

to

section

2.2.)

This

method

of

pulse

shape

discrimination

can

also

be

used

with

semiconductor

detectors.

When

it

is

desired

to

measure

particles

of

the

same

energy

but

differing

range

(e.g.,

alphas

in

the

presence

of

protons),

the

depletion

depth

can

be

adjusted

to

stop

the

alphas

but

not

the

protons.

Proton

pulses

will

then

consist

of

a

fast

portion,

corresponding

to

collection

of

signal

deposited

in

the

depletion

zone,

and

a

slow

portion,

corresponding

to

signal

collected

by

diffusion

from

the

field-free

undepleted

regions.

Elimination

of

the

undesired

proton

pulses

can

thus

be

performed

by

pulse

shape

discrimination.

£N£l9Cf

SIGNAL

LIN£AR

SIGNAL

VIAPIN

AMP.

AMP.

4

20

TIMING

S.C.A

TIMING

SIGNAL

4

OS

A

TIME

P/CKOPr

CONTROL

26-4

OP

see

POWER*

eiAS

DELAY

4

PM.T.

ST/lBENE

op

NC-^/S

XlHTIUMi

TS/GNAL

ANODC

SIGNAL

PA

ST

DISC.

TIMING

SIGNAL

CO

PO

OUTPUT

(r-

PAY)

ALTERNATE

METNOO

T>

SIGNAL

GATE

OP

ROUTE

4S7

4Z0

T.RH.C.

3.C.A.

OP

"71

SIGNAL

711

PULSE

NEIGNT

CO

PO

OUTPUT

(NCUTPON)

TIME

DIAGRAM

Figure

4-2

A

Method

of

Pulse

Shape

Discrimination

4-

4

APPLICATION

NOTES

(3)

Charged-Particle

Identification

by

Time-of-Flight

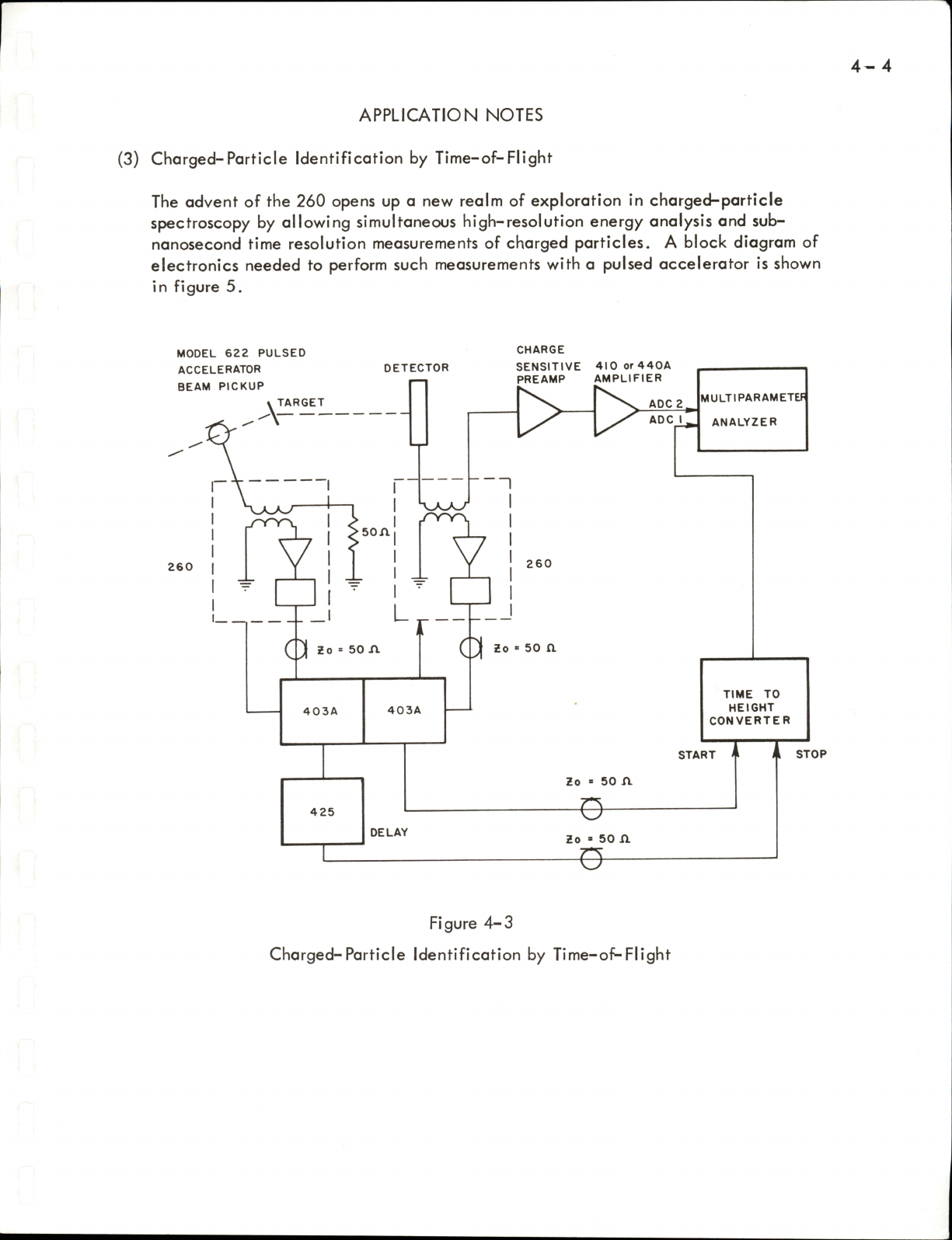

The

advent

of

the

260

opens

up

a

new

realm

of

exploration

in

charged-particle

spectroscopy

by

allowing

simultaneous

high-resolution

energy

analysis

and

sub-

nanosecond

time

resolution

measurements

of

charged

particles,

A

block

diagram

of

electronics

needed

to

perform

such

measurements

with

a

pulsed

accelerator

is

shown

in

figure

5.

MODEL

622

PULSED

CHARGE

DETECTOR

ADC

2

ADC

I

50A

260

260

Zo

'

SO

A

Ho

=

50

A

STOP

START

Ho

•

50

A

DELAY

Ho

•

50

A

425

TIME

TO

HEIGHT

CONVERTER

MULTIPARAMETEF

ANALYZER

403A

403A

Figure

4-3

Charged-Particle

Identification

by

Time-of-Flight

4-5

APPLICATION

NOTES

(4)

Beam

Pulse

Time

Pickoff

for

Pulsed

Accelerators

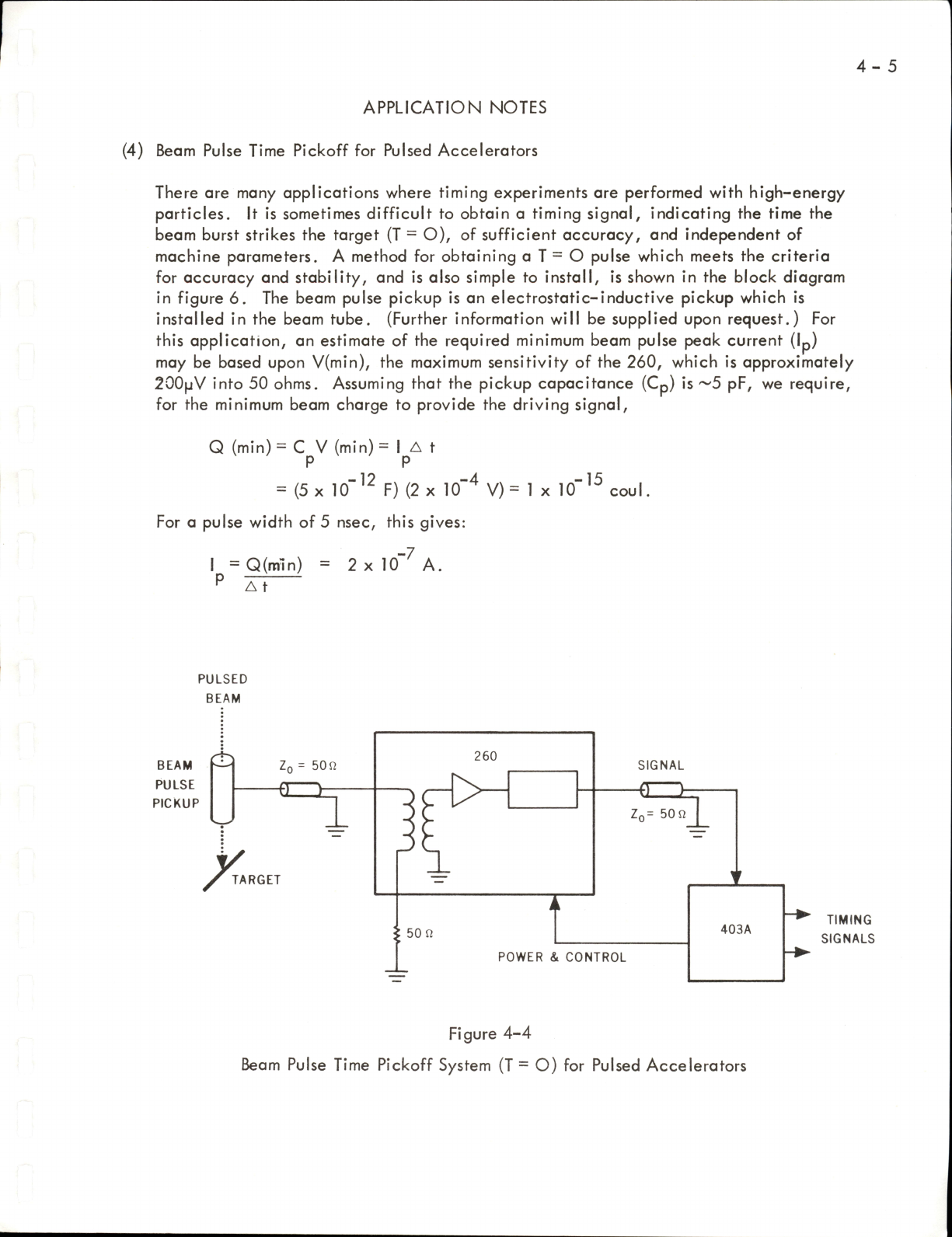

There

are

many

applications

where

timing

experiments

are

performed

with

high-energy

particles.

It

is

sometimes

difficult

to

obtain

a

timing

signal,

indicating

the

time

the

beam

burst

strikes

the

target

(T

=

O),

of

sufficient

accuracy,

and

independent

of

machine

parameters.

A

method

for

obtaining

a

T

=

O

pulse

which

meets

the

criteria

for

accuracy

and

stability,

and

is

also

simple

to

install,

is

shown

in

the

block

diagram

in

figure

6.

The

beam

pulse

pickup

is

an

electrostatic-inductive

pickup

which

is

installed

in

the

beam

tube.

(Further

information

will

be

supplied

upon

request.)

For

this

application,

an

estimate

of

the

required

minimum

beam

pulse

peak

current

(Ip)

may

be

based

upon

V(min),

the

maximum

sensitivity

of

the

260,

which

is

approximately

200pV

into

50

ohms.

Assuming

that

the

pickup

capacitance

(Cp)

is

~5

pF,

we

require,

for

the

minimum

beam

charge

to

provide

the

driving

signal,

Q

(min)

=

C

V

(min)

=

I

A

t

P

P

=

(5

X

10"^^

F)

(2

X

10""^

V)

=

1

X

10"^^

coul.

For

a

pulse

width

of

5

nsec,

this

gives:

I

=Q(raln)

=

2x10"^

A.

p

Z1—

PULSED

BEAM

BEAM

PULSE

PICKUP

SIGNAL

G=)

Zo=

son

A

TARGET

POWER

&

CONTROL

TIMING

SIGNALS

Figure

4-4

Beam

Pulse

Time

Pickoff

System

(T

=

O)

for

Pulsed

Accelerators

5-

1

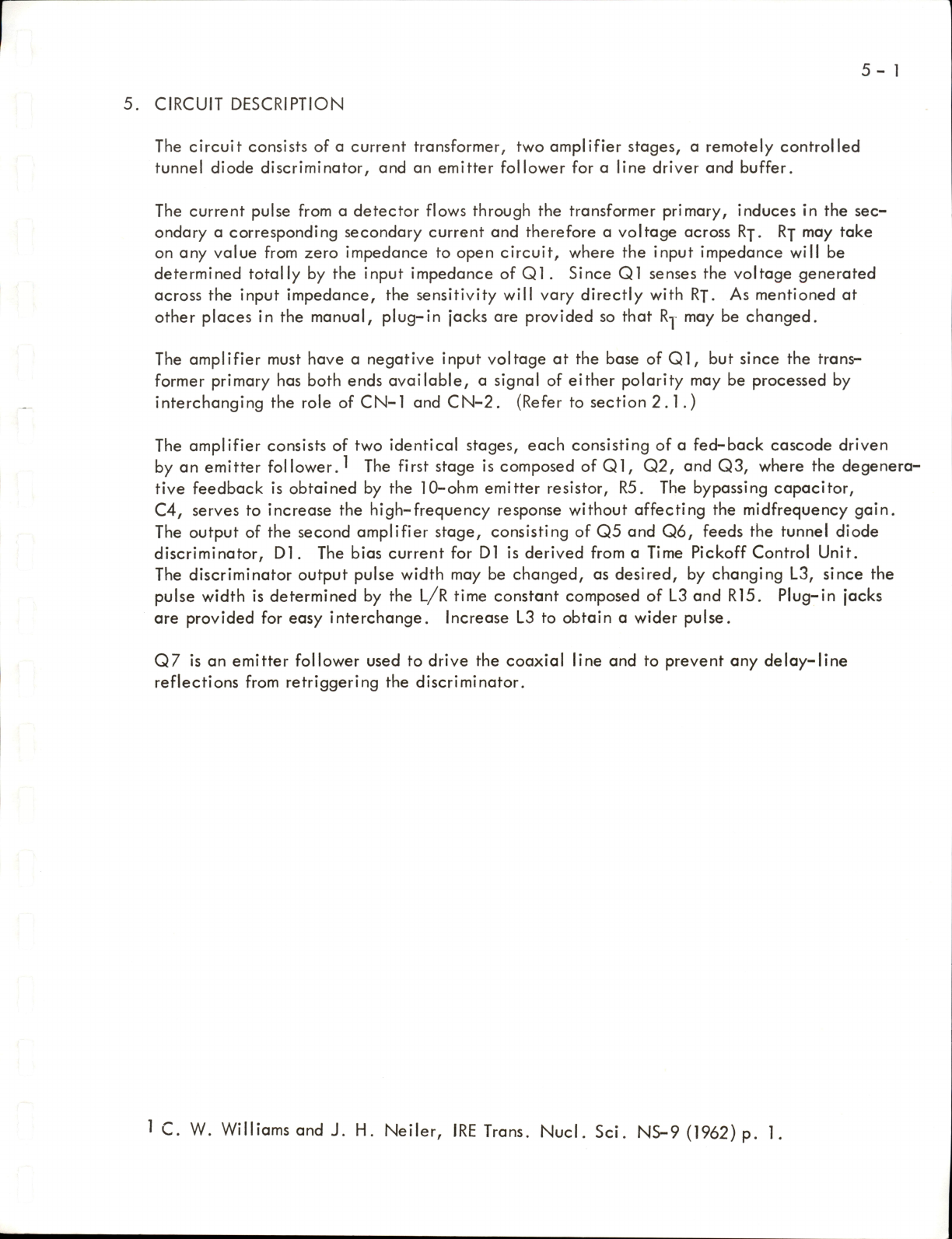

5.

CIRCUIT

DESCRIPTION

The

circuit

consists

of

a

current

transformer,

two

amplifier

stages,

a

remotely

controlled

tunnel

diode

discriminator,

and

an

emitter

follower

for

a

line

driver

and

buffer.

The

current

pulse

from

a

detector

flows

through

the

transformer

primary,

induces

in

the

sec

ondary

a

corresponding

secondary

current

and

therefore

a

voltage

across

Rj.

Rj

may

take

on

any

value

from

zero

impedance

to

open

circuit,

where

the

input

impedance

will

be

determined

total

ly

by

the

input

impedance

of

Q1

.

Since

Q1

senses

the

voltage

generated

across

the

input

impedance,

the

sensitivity

will

vary

directly

with

Rj.

As

mentioned

at

other

places

in

the

manual,

plug-in

jacks

are

provided

so

that

Ry

may

be

changed.

The

amplifier

must

have

a

negative

input

voltage

at

the

base

of

Ql,

but

since

the

trans

former

primary

has

both

ends

available,

a

signal

of

either

polarity

may

be

processed

by

interchanging

the

role

of

CN-1

and

CN-2.

(Refer

to

section

2.1.)

The

amplifier

consists

of

two

identical

stages,

each

consisting

of

a

fed-back

cascode

driven

by

an

emitter

follower.^

The

first

stage

is

composed

of

Ql,

Q2,

and

Q3,

where

the

degenera

tive

feedback

is

obtained

by

the

10-ohm

emitter

resistor,

R5.

The

bypassing

capacitor,

C4,

serves

to

increase

the

high-frequency

response

without

affecting

the

midfrequency

gain.

The

output

of

the

second

amplifier

stage,

consisting

of

Q5

and

Q6,

feeds

the

tunnel

diode

discriminator,

Dl.

The

bias

current

for

D1

is

derived

from

a

Time

Pickoff

Control

Unit.

The

discriminator

output

pulse

width

may

be

changed,

as

desired,

by

changing

L3,

since

the

pulse

width

is

determined

by

the

L/R

time

constant

composed

of

L3

and

R15.

Plug-in

jacks

are

provided

for

easy

interchange.

Increase

L3

to

obtain

a

wider

pulse.

Q7

is

an

emitter

follower

used

to

drive

the

coaxial

line

and

to

prevent

any

delay-line

reflections

from

retriggering

the

discriminator.

'

C.

W.

Williams

and

J.

H.

Neiler,

IRE

Trans.

Nucl.

Sci.

NS-9

(1962)

p.

1.

6

-

1

6.

MAINTENANCE

INSTRUCTIONS

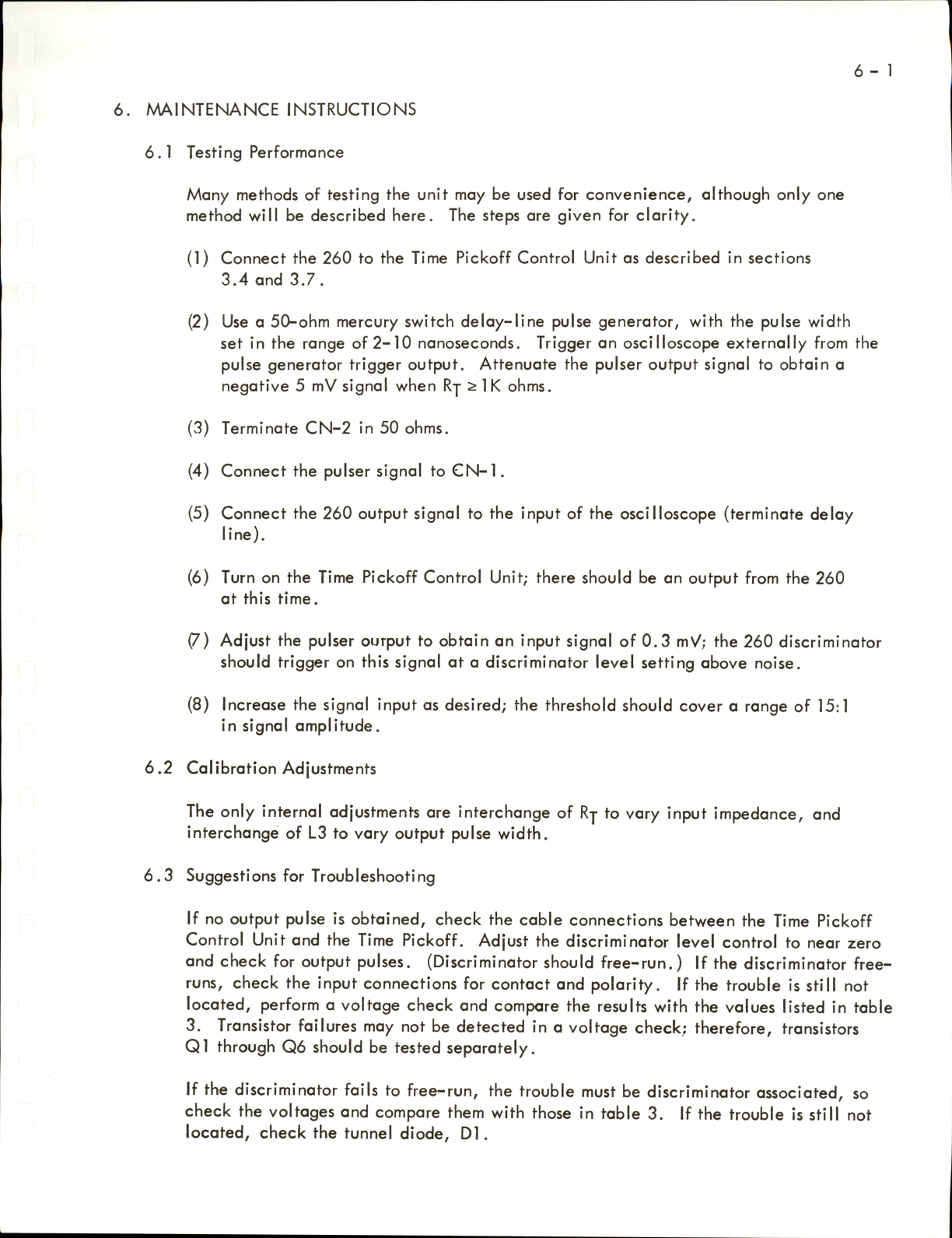

6.1

Testing

Performance

Many

methods

of

testing

the

unit

may

be

used

for

convenience,

although

only

one

method

will

be

described

here.

The

steps

are

given

for

clarity.

(1)

Connect

the

260

to

the

Time

PIckoff

Control

Unit

as

described

In

sections

3.4

and

3.7.

(2)

Use

a

50-ohm

mercury

switch

delay-line

pulse

generator,

with

the

pulse

width

set

In

the

range

of

2-10

nanoseconds.

Trigger

an

oscilloscope

externally

from

the

pulse

generator

trigger

output.

Attenuate

the

pulser

output

signal

to

obtain

a

negative

5

mV

signal

when

Rj

s

IK

ohms.

(3)

Terminate

CN-2

In

50

ohms.

(4)

Connect

the

pulser

signal

to

CN-1.

(5)

Connect

the

260

output

signal

to

the

Input

of

the

oscilloscope

(terminate

delay

line).

(6)

Turn

on

the

Time

PIckoff

Control

Unit;

there

should

be

an

output

from

the

260

at

this

time.

(7)

Adjust

the

pulser

ourput

to

obtain

an

Input

signal

of

0.3

mV;

the

260

discriminator

should

trigger

on

this

signal

at

a

discriminator

level

setting

above

noise.

(8)

Increase

the

signal

Input

as

desired;

the

threshold

should

cover

a

range

of

15:1

In

signal

amplitude.

6.2

Calibration

Adjustments

The

only

Internal

adjustments

are

Interchange

of

Rj

to

vary

Input

Impedance,

and

Interchange

of

L3

to

vary

output

pulse

width.

6.3

Suggestions

for

Troubleshooting

If

no

output

pulse

Is

obtained,

check

the

cable

connections

between

the

Time

PIckoff

Control

Unit

and

the

Time

PIckoff.

Adjust

the

discriminator

level

control

to

near

zero

and

check

for

output

pulses.

(Discriminator

should

free-run.)

If

the

discriminator

free-

runs,

check

the

Input

connections

for

contact

and

polarity.

If

the

trouble

Is

still

not

located,

perform

a

voltage

check

and

compare

the

results

with

the

values

listed

In

table

3.

Transistor

failures

may

not

be

detected

In

a

voltage

check;

therefore,

transistors

Q1

through

Q6

should

be

tested

separately.

If

the

discriminator

falls

to

free-run,

the

trouble

must

be

discriminator

associated,

so

check

the

voltages

and

compare

them

with

those

In

table

3.

If

the

trouble

Is

still

not

located,

check

the

tunnel

diode,

D1.

6-2

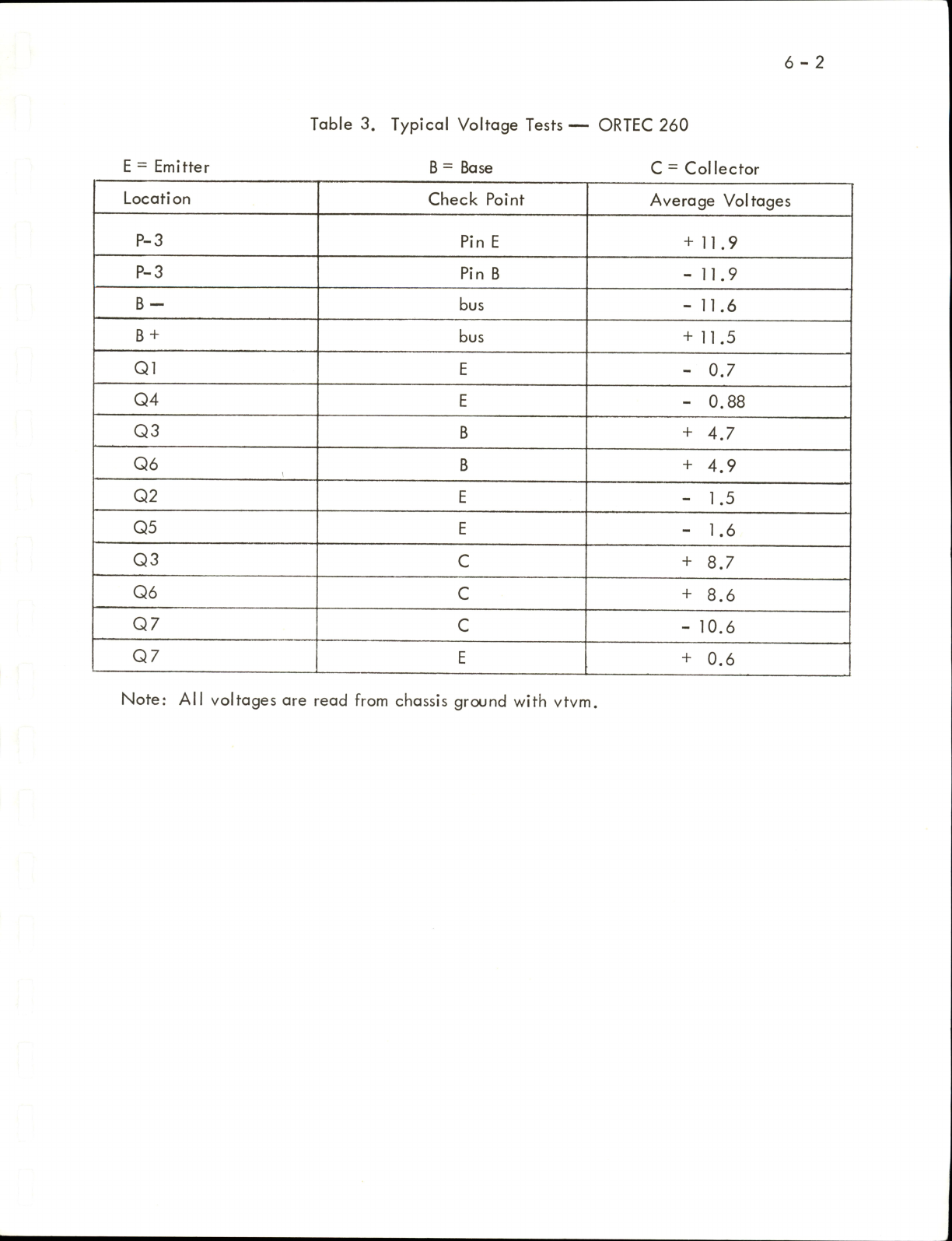

E

-

Emitter

Table

3.

Typical

Voltage

Tests

B

=

Base

ORTEC

260

C

=

Collector

Location

Check

Point

Average

Voltages

P-3

Pin

E

+

11

.9

P-3

Pin

B

-

11.9

B-

bus

-

11.6

B

+

bus

+

11

.5

Q1

E

-

0.7

Q4

E

-

0.88

Q3

B

+

4.7

Q6

B

+

4.9

Q2

E

-

1

.5

Q5

E

-

1.6

Q3

C

+

8.7

Q6

C

+

8.6

Q7

C

-

10.6

Q7

E

+

0.6

Note:

All

voltages

are

read

from

chassis

ground

with

vtvm.

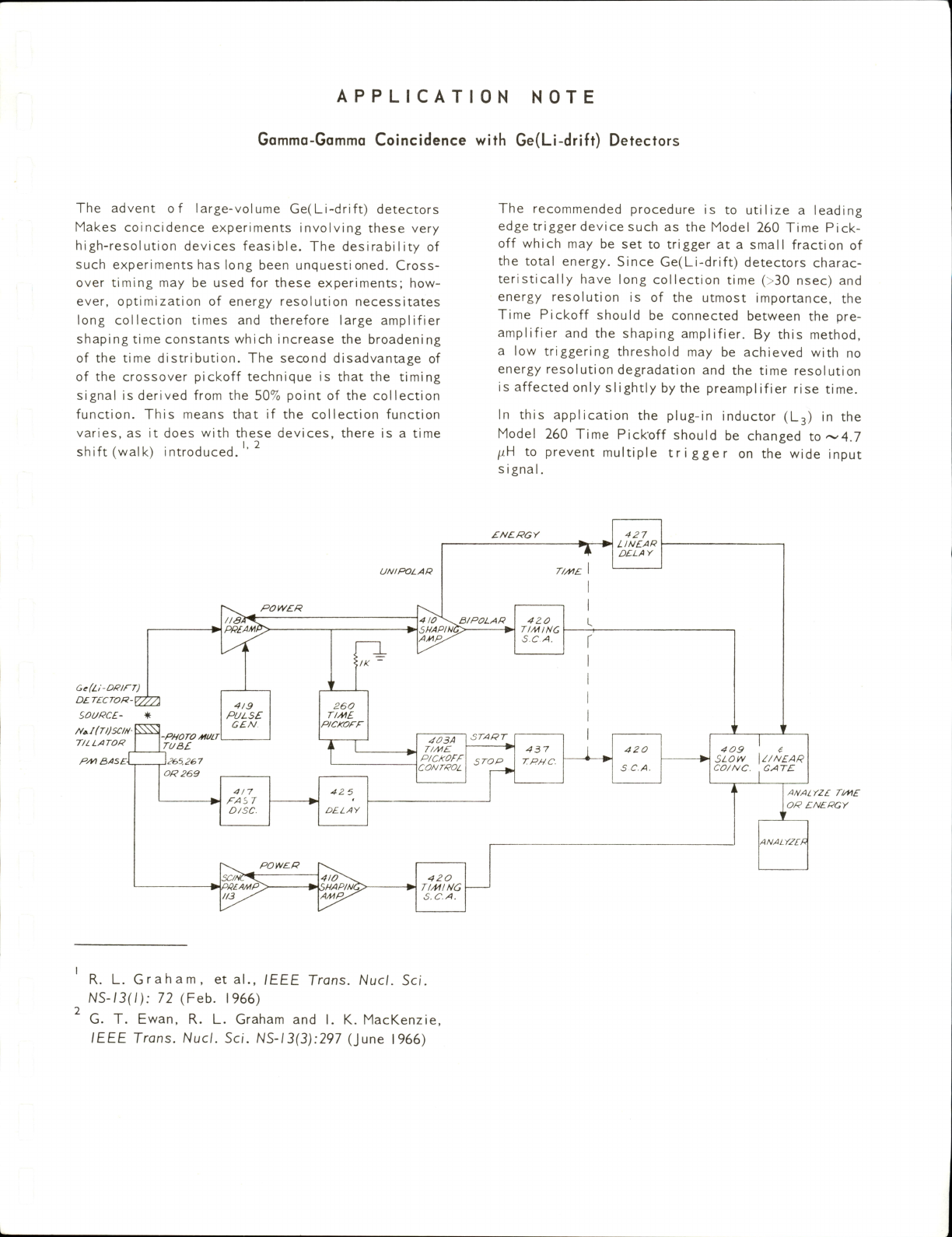

APPLICATION

NOTE

Gamma-Gamma

Coincidence

with

Ge(Li-drift)

Detectors

The

advent

of

large-volume

Ge(Li-drift)

detectors

Makes

coincidence

experiments

involving

these

very

high-resolution

devices

feasible.

The

desirabi

l

ity

of

such

experiments

has

long

been

unquestioned.

Cross

over

timing

may

be

used

for

these

experiments;

how

ever,

optimization

of

energy

resolution

necessitates

long

col

lection

times

and

therefore

large

ampl

ifier

shaping

time

constants

which

increase

the

broadening

of

the

time

distribution.

The

second

disadvantage

of

of

the

crossover

pickoff

technique

is

that

the

timing

signal

is

derived

from

the

50%

point

of

the

col

lection

function.

This

means

that

if

the

collection

function

varies,

as

it

does

with

these

devices,

there

is

a

time

shift

(walk)

introduced.

''^

The

recommended

procedure

is

to

uti

l

ize

a

leading

edge

trigger

device

such

as

the

Model

260

Time

Pick-

off

which

may

be

set

to

trigger

at

a

smal

l

fraction

of

the

total

energy.

Since

Ge(Li-drift)

detectors

charac

teristical

ly

have

long

col

lection

time

(>30

nsec)

and

energy

resolution

is

of

the

utmost

importance,

the

Time

Pickoff

should

be

connected

between

the

pre

ampl

ifier

and

the

shaping

ampl

ifier.

By

this

method,

a

low

triggering

threshold

may

be

achieved

with

no

energy

resolution

degradation

and

the

time

resolution

is

affected

only

slightly

by

the

preampl

ifier

rise

time.

In

this

appl

ication

the

plug-in

inductor

(L3)

in

the

Model

260

Time

Pick'off

should

be

changed

to~4.7

fxH

to

prevent

multiple

trigger

on

the

wide

input

signal.

Ge(Li'DPirT)

DLTCCTOR-YZm

SOURCE-

*

N».l(TI)SaN'^^

rULATOR

P/A

QASE^,

POWER

/IS>

PREAM/

r^r

—

-PHOTO

MULT

TUBE

~\

Ee5.2e7

ENERGY

rZ/HE

427

LINEAR

DELAY

A

POLAR

SHAPihiG:?——►

APR,

420

TIMING

S.CA.

4/9

260

Pulse

T/ME

GEN

P/CKOFF

4/7

PAST

O/SC.

42

6

RELAY

403A

T/ME

P/CNOFF

CONTROL

STOP

437

T.PPC.

4ZO

SC.A.

409

,

^

SLOW

\Z/NEAR

CO/NC.

GATE

r]

A

PfiEAMP

POWER

410

SHAPIM

AMP.

420

TIMING

S.C.A.

NALYZE

T/ME

OR

ENERGY

R.

L.

Graham,

et

al.,

IEEE

Trans.

Nucl.

Sci.

NS-I3(I):

12

(Feb.

1966)

G.

T.

Ewan,

R.

L.

Graham

and

i.

K.

MacKenzie,

IEEE

Trans.

Nucl.

Sci.

NS-I3(3):297

(June

1966)

Table of contents

Other EG&G Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Hayward

Hayward TLC SERIES Programming and users manual

MOBILE-ALERTS

MOBILE-ALERTS pro Series quick reference

Bushnell

Bushnell Yardage Pro 20-0750 user guide

JUMO

JUMO flowTRANS MAG S01 operating manual

Symmetricom

Symmetricom TimeAnalyzer 7500 user guide

Kamstrup

Kamstrup MULTICAL 402 Installation and user guide