EG&G ORTEC 463 Service manual

A

r\i

EGkG

c

o

rs/i

F=>/\

f\i

^

Model

463

Constant

Fraction

Discriminator

Vice

Manual

jfi*

I'-'I*

iiiypiiiiimiiiiyliiiPiilliiiiiiiiiiiiiiiiiilii

iiiiiiiiiiiiiiBii;yiiiiiyii)iiiiiiiifflillfllllllliliiy

.;-,■■

■.:■

-y-t

■■■:■-'%;■:■

:

■'.fii.

.

M

■Mlki

Model

463

Constant

Fraction

Discriminator

Operating

and

Service

Manual

Printed

in

U.S.A.

©

ORTEC

Incorporated

1971

1127

03C

0771

01

TABLE

OF

CONTENTS

Page

WARRANTY

^

PHOTOGRAPH

1.

GENERAL

^

2.

SPECIFICATIONS

1

3.

INSTALLATION

2

3.1

General

2

3.2

Connection

to

Power

2

3.3

Input

Connection

2

3.4

Output

Connections

2

4.

OPERATION

3

5.

CIRCUIT

DESCRIPTION

3

6.

MAINTENANCE

4

6.1

General

4

6.2

Level

Discriminator

Zero

Adjustment

4

6.3

Negative

Output

Pulse

Shape

and

Amplitude

Adjustment

4

6.4

Walk

Adjustment

5

7.

APPLICATIONS

7

7.1

Timing

with

Fast

Scintillators

7

7.2

Timing

with

Large

Ge(Li)

Detectors

7

7.3

Timing

with

Surface

Barrier

Detectors

9

7.4

Timing

with

High-Resolution

Low-Energy

Photon

Spectrometers

10

7.5

Timing

with

Nal(TI)

Scintillators

11

BIBLIOGRAPHY

12

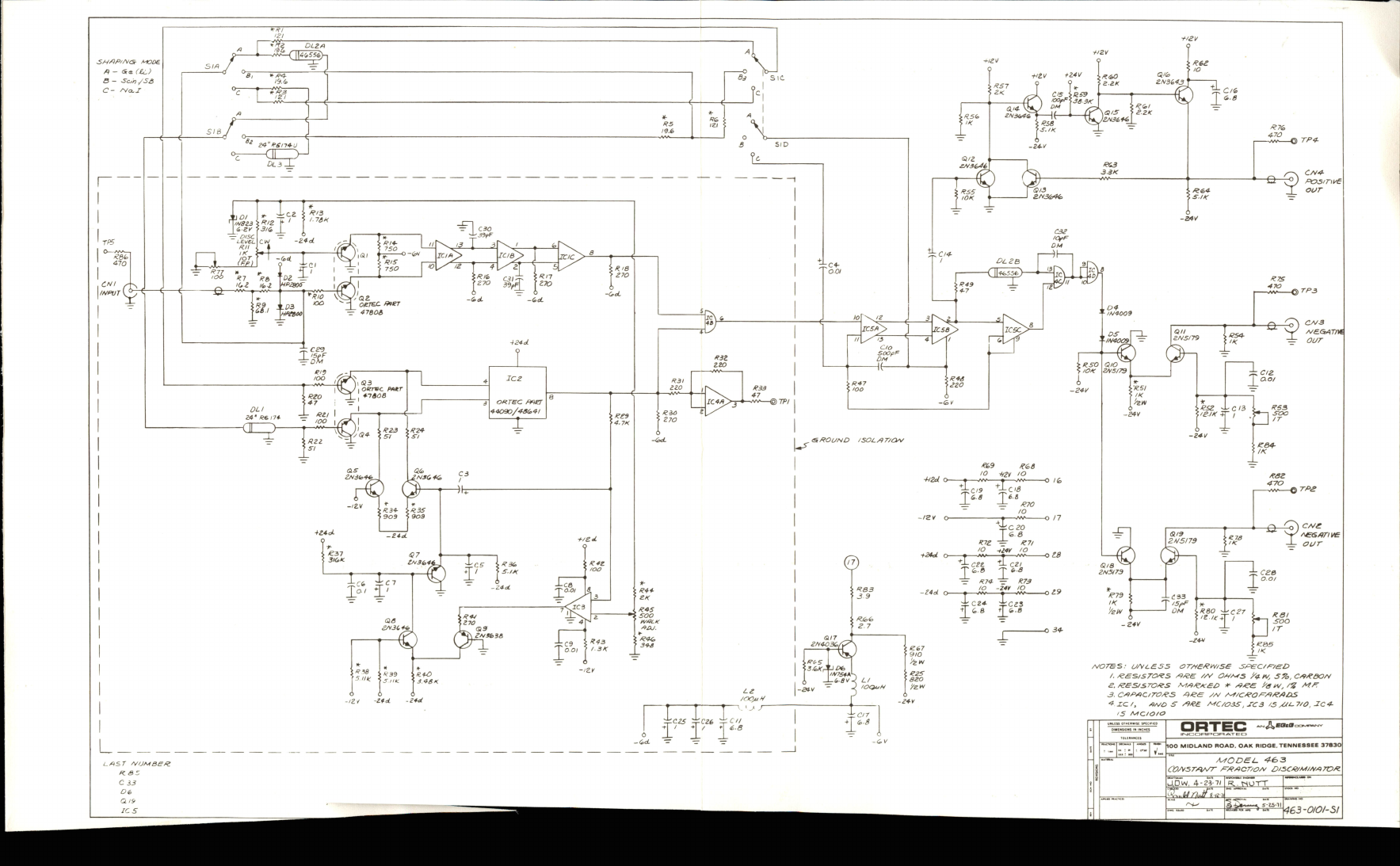

SCHEMATIC

463-0101-S1

ORTEC

463

Schematic

IV

LIST

OF

FIGURES

Page

4

Fig.

5.1.

Ideal

Pulse

Shapes

Illustrating

the

Constant

Fraction

Discriminator

Operation

Fig.

5.2.

Signal

Shapes

Illustrating

Detection

of

the

Zero-Crossing

Point

of

Constant

Fraction

Signal

Fig.

6.1.

Block

Diagram

of

System

for

Walk

Test

of

the

ORTEC

463

in

the

Ge(Li)

Mode

5

Fig.

6.2.

Block

Diagram

of

System

for

Walk

Test

of

the

ORTEC

463

in

the

Scint/SB

Mode

5

Fig.

6.3.

Effect

of

Walk

Adjustment

in

the

ORTEC

463

6

Fig.

7.1.

A

System

for

Gamma-Gamma

Lifetime

Measurement

7

Fig.

7.2.

Timing

Over

a

Narrow

Dynamic

Range

with

the

System

of

Fig.

7.1

8

Fig.

7.3.

Timing

Over

a

Wide

Dynamic

Range

with

the

System

of

Fig.

7.1

8

Fig.

7.4.

Gamma-Gamma

Coincidence

System

Using

Plastic

Scintillator

and

a

Large

Ge(Li)

Coaxial

Detector

®

Fig.

7.5.

Time

Resolution

of

a

Ge(Li)

Detector

as

a

Function

of

Energy

9

Fig.

7.6.

Typical

Timing

Spectrum

with

Wide

Dynamic

Range

Using

the

System

of

Fig.

7.4

9

Fig.

7.7.

System

for

Testing

Time

Resolution

of

the

ORTEC

130

Surface

Barrier

System

9

Fig.

7.8.

Typical

Timing

Spectrum

for

a

100-Atm

Surface

Barrier

Detector

Using

the

System

of

Fig.

7.7

Fig.

7.9.

Typical

Timing

Spectrum

for

a

1950-/.im

Surface

Barrier

Detector

Using

the

System

of

Fig.

7.7

Fig.

7.10.

Fast

Coincidence

System

Using

a

Ge(Li)

6-mm

Low

Energy

Photon

Spectrometer

11

Fig.

7.11.

Time

Resolution

vs

Energy

for

a

6-mm

Low

Energy

Photon

Spectrometer

11

Fig.

7.12.

Spectrum

of

the

Lifetime

of

the

14-keV

State

in

the

Decay

of

^

''Co.

11

10

10

STANDARD

WARRANTY

FOR

ORTEC

INSTRUMENTS

ORTEC

warrants

its

instruments

other

than

preampl

ifier

FET

input

transistors,

vacuum

tubes,

fuses,

and

batteries

to

be

free

from

defects

in

workmanship

and

materials

for

a

period

of

twelve

months

from

date

of

shipment

provided

that

the

equipment

has

been

used

in

a

proper

manner

and

not

subjected

to

abuse.

Repairs

or

replace

ment,

at

ORTEC

option,

will

be

made

on

in-warranty

instruments,

without

charge,

at

the

ORTEC

factory.

Shipping

expense

wi

ll

be

to

the

account

of

the

customer

except

in

cases

of

defects

discovered

upon

initial

operation.

Warranties

of

vacuum

tubes

and

semiconductors

made

by

their

manufacturers

wil

l

be

extended

to

our

customers

only

to

the

extent

of

the

manufacturers'

l

iabil

ity

to

ORTEC.

Specially

selected

vacuum

tubes

or

semiconductors

cannot

be

warranted.

ORTEC

reserves

the

right

to

modify

the

design

of

its

products

without

incurring

responsibil

ity

for

modification

of

previously

manufactured

units.

Since

in

stallation

conditions

are

beyond

our

control,

ORTEC

does

not

assume

any

risks

or

l

iabil

ities

associated

with

methods

of

installation

or

with

instal

lation

results.

QUALITY

CONTROL

Before

being

approved

for

shipment,

each

ORTEC

in

strument

must

pass

a

stringent

set

of

qual

ity

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warranty

repair

and

as

a

source

of

statistical

information

for

design

improvements.

ORTEC

must

be

informed

in

writing

of

the

nature

of

the

fault

of

the

instrument

being

returned

and

of

the

model

and

serial

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

Our

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

wil

l

withstand

normal

transit

handl

ing

and

must

be

shipped

PREPAID

via

Air

Parcel

Postor

United

Parcel

Service

to

the

nearest

ORTEC

repair

center.

Instru

ments

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibil

ity

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

wi

l l

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

wi

ll

be

notified

prior

to

the

repair

being

done.

A

quotation

wi

l

l

be

sent

with

the

notification.

DAMAGE

IN

TRANSIT

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normal

ly

liable

for

damage

in

shipment.

Packing

materials,

waybil

ls,

and

other

such

documentation

should

be

preserved

in

order

to

establ

ish

claims.

After

such

notification

to

the

carrier,

please

notify

ORTEC

of

the

circumstances

so

that

we

may

assist

in

dam

age

claims

and

in

providing

replacement

equipment

if

necessary.

Wmi?.

ORTEC

<!•

MODEL

463

❖

CONSTANT

FRACTION

DISC

SHAPING

MODE

^INT

'S8

DISC

LEVEL

50rnV-5V

irJPijT

(O-lOV)

50-TL

■

.v••V-<^.;v.v•/.■•/,.V

-.

iv

"//•

■•'

•■''►)

'•'

,

■•;

'-^

';;7/.;:',

"

L-OUTPUT-J

ORTEC

463

CONSTANT

FRACTION

DISCRIMINATOR

1.

GENERAL

The

ORTEC

463

Constant

Fraction

Discriminator

provides

logic

outputs

that

are

used

for

precise

timing

signals.

Fast

logic

outputs

are

derived

from

input

pulses

from

almost

any

style

of

nuclear

detector.

The

Constant

Fraction

technique

of

obtaining

timing

signals

ensures

accuracy

and

precision

through

a

wide

dynamic

range

of

input

signals.

The

detai

ls

of

shaping

are

all

selected

properly

by

a

front

panel

switch

that

is

marked

for

the

four

most

common

types

of

detectors

in

current

use.

The

types

of

detectors

with

which

the

463

can

be

used

are

Ge(Li),

Nal

(TI),

fast

plastic

scintil

lators,

and

surface

barrier,

identified

on

the

463

by

a

front

panel

selector

switch,

with

the

last

two

detectors

marked

"Scint"

and

"SB".

Because

of

the

signal

shapes

from

a

Ge(Li)

detector,

an

ORTEC

454

Timing

Filter

Ampl

ifier

should

be

included

between

the

preamplifier

and

the

463

when

this

type

of

detector

is

used

as

a

pulse

source.

The

use

of

a

454

is

also

advantageous

when

detector

signals

require

amplification.

This

easi

ly

used

single-width

module

virtually

eliminates

timing

walk

caused

by

amplitude

(energy)

and

also

pulse

shape

variations.

When

used

with

the

ORTEC

454

Timing

Ampl

ifier,

it

generates

a

walk-free

timing

signal

that

can

be

obtained

from

any

detector

over

a

100:1

dynamic

range

of

pulse

heights.

The

adjustments

and

selections

are

simple.

Just

set

the

input

discriminator

to

the

lowest

energy

level

of

interest,

select

the

appropriate

detector

switch

setting,

and

connect

the

input

and

output

cables,

and

it

is

ready

to

operate.

The

463

then

provides

the

most

stable

timing

signal,

suitable

for

even

the

most

sophisticated

time

spectroscopy

measure

ment.

For

convenience,

monitor

test

points

are

included

for

inspection

of

input

and

output

signals

and

of

the

special

ly

shaped

internal

signal

that

is

used

to

derive

the

walk-free

timing

signal

.

The

selections

of

the

compatible

delay

and

attenuation

are

made

automatically

by

the

switch

selection

of

the

detector

type.

The

benefits

of

this

modern

Constant

Fraction

technique

are

obtained

without

any

necessity

for

calculations

and

experimentations.

2.

SPECIFICATIONS

PERFORMANCE

INPUT

PULSE

CHARACTERISTICS

Accepts

negative

pulses

to

10

V

without

saturation:

protected

to

100

V

for

duty

cycle

of

10%;

f^^l

nsec.

REFLECTIONS

Typically

<10%

for

0-to

10-V

ampl

itude

range

and

rise

time

>1

nsec.

LOWER

LEVEL

DISCRIMINATOR

Temperature

Drift

<0.5

mV/°C,

0

to

50°C.

Integral

Nonllnearity

<±0.3%.

WALK

AND

DYNAMIC

RANGE

Ge(LI)

Mode

<±2

nsec

for

range

of

100

mV

to

10

V

with

40-nsec

tf.

Scint/SB

Mode

<+150

psec

for

range

of

100

mV

to

10

V

(using

signal

from

Naton-136

and

RCA-8575

PM

tube).

Nal

Mode

<+0.5

nsec

for

range

of

100

mV

to

10

V

with

5-nsec

t/-.

DELAY

TEMPERATURE

STABILITY

<10

psec/°C,

0

to

50°C,

for

TV

input

signal

with

<2-nsec

tr-

CONTROLS

SHAPING

MODE

3-position

selector

switch

selects

delay

and

fraction

for

optimum

Constant

Fraction

timing

signal

derivation

according

to

the

type

of

detector:

Ge(Li)

Selects

12-nsec

delay

and

compatible

fraction

for

optimum

shaping

of

signals

from

Ge(Li)

detectors.

Sclnt/SB

Selects

'v2-nsec

delay

and

compatible

fraction

for

optimum

shaping

of

signals

from

fast

plastic

scin

tillators

or

from

surface

barrier

detectors.

Nal

Selects

'V4-nsec

delay

and

compatible

fraction

for

optimum

shaping

of

signals

from

Nal(TI)

and

simi

lar

scintil

lators;

also

selects

an

internal

dead

time

of

lisec

from

the

leading

edge

of

the

input

signal

to

prevent

multiple

triggering

on

slow

decay

waveforms.

DISC.

LEVEL

10-turn

precision

locking

potentiometer

adjusts

trigger

level

of

the

lower

level

discriminator;

range

-50

mV

to

-5

V.

INPUT

Type

BNC

connector

on

front

panel

accepts

input

signals

from

preampl

ifier

or

from

shaping

amplifier;

dc-coupied

and

basel

ine

restored;

normal

range

from

Disc

Level

to

-10

V;

Z|n

50n.

OUTPUTS

NEC

Two

NIM-standard

Fast

Negative

logic

output

signals

generated

separately

and

furnished

through

two

type

BNC

connectors

on

front

panel

;

nominal

-16

mA

(800

mV

on

50fl

load),

width

<10

nsec,

f;-<2.5

nsec.

PCS

NIM-standard

Slow

Positive

logic

output

signal

furnished

through

type

BNC

connector

on

front

panel;

nominal

-i-5

V,

width

500

nsec,

tf

<25

nsec;

Zq

<10J2.

ELECTRICAL

AND

MECHANICAL

POWER

REQUIREMENTS

+24

V,

25

mA;

+12

V,

28

mA;

-24

V,90

mA;

-12

V,

170

mA.

WEIGHT

(SHIPPING)

4.5

lb

(2

kg).

WEIGHT

(NET)

2.5

lb

(1.1

kg).

DIMENSIONS

NIM-standard

single-width

module

(1.35

by

8.714

in.)

per

TID-20893

(Rev.).

3.

INSTALLATION

3.1.

GENERAL

The

463

is

used

in

conjunction

with

an

ORTEC

401/402

Bin

and

Power

Supply,

which

is

intended

for

rack

mount

ing.

Therefore

if

vacuum

tube

equipment

is

operated

in

the

same

rack,

there

must

be

sufficient

cool

ing

with

circulating

air

to

prevent

any

local

ized

heating

of

the

al

l-transistorized

circuitry

used

throughout

the

463.

The

temperature

of

equipment

mounted

in

racks

can

easily

exceed

the

recom

mended

maximum

l

imit

of

120°F

(50°C)

unless

these

precautions

are

taken.

3.2.

CONNECTION

TO

POWER

Always

turn

off

power

for

the

Power

Supply

before

inserting

or

removing

modules.

The

ORTEC

400

Series

of

modular

instruments

is

designed

so

that

the

Power

Supply

cannot

be

overloaded

when

there

is

a

ful

l

comple

ment

of

modules

in

the

Bin.

Since,

however,

this

may

not

be

true

when

the

Bin

contains

modules

other

than

those

of

ORTEC

design,

use

the

convenient

test

points

on

the

front

panel

of

the

401/402

to

check

each

Power

Supply

voltage

level

after

all

modules

have

been

inserted.

3.3.

INPUT

CONNECTION

The

Input

circuit

of

the

463

is

designed

for

use

with

50T2

cable.

The

input

impedance

is

50T2;

so

no

external

terminator

is

required

for

this

connection.

The

input

can

come

from

a

detector

or

photomultipl

ier

directly,

provided

that

the

negative

input

pulse

wi

l

l

have

sufficient

ampl

itude

to

exceed

a

Disc

Level

setting

in

the

463.

When

an

ampl

itude

requires

ampl

ification

or

when

additional

pulse

shaping

is

required

[such

as

with

Ge(Li)

coaxial

detectors]

,

an

ORTEC

454

Timing

Filter

Ampl

ifier

can

be

used

between

the

detector

and

the

input

to

the

463.

3.4.

OUTPUT

CONNECTIONS

There

are

three

outputs

on

the

463,

and

all

connectors

are

located

on

the

front

panel

.

Two

of

these

are

NIM-

standard

Fast

Negative

pulses

that

are

generated

sepa

rately

and

are

therefore

completely

isolated.

The

third

is

a

NIM-standard

Slow

Positive

pulse.

Al

l

three

pulses

are

furnished

for

each

input

pulse

that

exceeds

the

Disc

Level

setting.

The

Fast

Negative

output

pulses

are

intended

for

timing

appl

ications

such

as

the

Start

and

Stop

inputs

to

a

time

to

pulse

height

converter.

Either

or

both

may

be

used

and

the

alternate

connector

does

not

need

to

be

terminated

when

it

is

not

being

used.

Since

the

NIM-standard

Fast

Negative

pulse

is

a

current

pulse

and

since

it

is

intended

for

use

with

a

50r2

load,

you

should

use

50T2

cable

to

connect

it

to

the

point

where

it

wi

ll

be

used

and

that

point

must

be

terminated

in

50n.

Normal

ly

the

instrument

that

receives

the

pulse

will

have

a

50J2

input

impedance;

if

it

does

not,

use

an

external

termination

at

the

receiving

end

of

the

cable.

The

NIM-standard

Slow

Positive

output

pulses

can

be

used

for

coincidence

work

or

can

be

counted

directly

in

a

sealer

or

ratemeter.

It

is

normal

to

use

93Q

cable

to

transfer

this

voltage

pulse

that

is

furnished

through

the

output

impedance

of

<10J2.

For

cable

lengths

longer

than

2

meters

{^7

ft)

it

is

recommended

that

the

cable

be

terminated

in

its

characteristic

impedance.

This

output

can

also

drive

a

terminated

50n

cable,

but

with

a

sl

ightly

reduced

ampl

itude.

4.

OPERATION

After

the

463

has

been

instal

led

and

interconnected

as

described

in

Section

3,

the

only

operating

functions

that

are

required

are

the

setting

of

the

Mode

switch

and

an

adjustment

of

the

Disc

Level

control

.

Normal

ly

the

Mode

switch

can

be

set

at

the

switch

position

that

corresponds

to

the

type

of

detector

being

used.

Set

the

switch

at

Ge(Li)

for

signals

from

a

germanium

coaxial

detector;

set

it

at

Scint/SB

if

the

detector

is

either

a

fast

plastic

scintil

lator

or

a

surface

barrier

type;

or

set

it

at

Nal

for

use

with

a

slower

type

of

scintil

lator.

If

the

input

signal

to

the

463

is

furnished

from

a

signal

source

having

a

rise

time

that

is

longer

than

20

nsec,

the

Ge(Li)

switch

position

may

provide

more

satisfactory

operation

than

the

Scint/SB

position.

See

Section

7,

"Applications,"

for

further

suggestions.

The

function

of

the

Disc

Level

adjustment

is

to

permit

selection

of

signals

of

interest

and

to

eliminate

response

to

smal

ler

signals.

The

proper

setting

of

this

control

depends

on

the

range

of

signal

ampl

itudes

that

are

furnished

into

the

input.

The

range

is

from

-50

mV

to

-5

V

with

the

precision

10-turn

potentiometer

used

for

precise

setting

and

excellent

resettability.

5.

CIRCUIT

DESCRIPTION

The

signal

,

in

a

range

of

0

to

-10

V,

is

applied

through

Input

connector

CN1

and

routed

to

a

50f2

T

attenuator

consisting

of

R7, R8,

and

R9.

The

output

from

the

T

attenuator

has

half

of

the

input

signal

amplitude

and

is

l

imited

to

approximately

-6

V

and

+0.8

V

by

diodes

D2

and

D3.

The

signal

from

the

T

attenuator

goes

to

the

base

of

Q2

and

to

the

Shaping

Mode

switch,

81.

Q1

and

02

form

a

matched

pair

to

translate

the

zero

basel

ine

and

furnish

it

and

the

signal

into

a

fast

differential

comparator,

101.

When

the

signal

at

the

base

of

02

exceeds

the

level

selected

by

the

Disc

Level

control,

R11,

the

output

at

pin

8

of

101

switches

from

its

high

state

of

^^-0.8

V

to

its

low

state

of

'V-I.B

V.

The

low

state

is

appl

ied

to

pin

5

of

I04B

to

enable

the

And

gate

for

the

zero-crossing

signal

that

wil

l

come

from

102.

The

second

connection

for

the

output

from

the

T

attenuator

is

through

Shaping

Mode

switch

SI

.

For

each

switch-selected

shaping

mode

the

signal

is

spl

it

and

routed

through

an

attenuation

network

and

R19

to

the

base

of

Q3

and

through

a

delay

cable

DL1

and

R21

to

the

base

of

Q4.

The

switched

routing

provides

a

shaping

that

is

optimum

for

each

mode

selection.

For

Ge(Li)

the

signal

to

Q3

goes

through

R1

while

the

signal

for

Q4

goes

through

R2

and

DL2A.

For

Scint/SB,

the

signal

to

Q3

passes

through

R6

whi

le

the

signal

to

Q4

passes

through

R5.

For

Nal

the

signal

to

Q3

goes

through

R3

and

the

signal

to

Q4

goes

through

R4

and

DL3.

The

shaped

signals

through

the

matched

pair,

Q3

and

Q4,

are

applied

to

comparator

IC2.

When

zero-crossing

occurs,

the

signal

at

pin

8

of

IC2

shifts

to

the

low

state

and

is

applied

to

the

And

gate

IC4B

at

pin

4;

this

is

the

gate

that

has

been

enabled

to

accept

the

signal

by

the

out

put

from

IC1

.

The

output

from

IC2

is

also

buffered

through

IC4A

to

permit

osci

lloscope

observation

at

TP1.

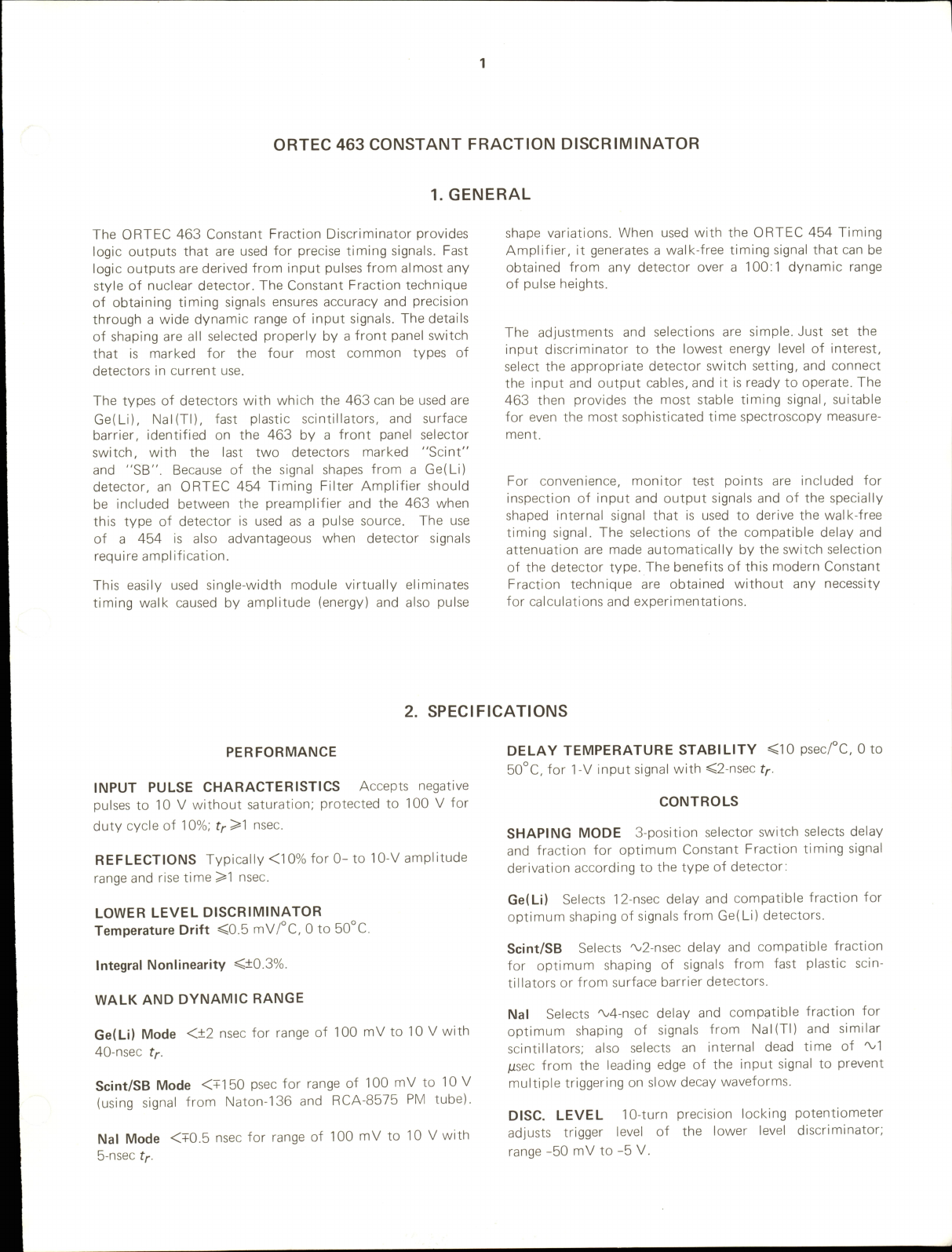

Waveforms

to

show

comparative

timing

of

the

signals

in

this

portion

of

the

463

are

shown

in

Figs.

5.1

and

5.2.

The

detection

of

the

zero-crossing

point

that

will

be

seen

at

TP1

is

the

waveform

in

Fig.

5.2

identified

as

the

Zero-Crossing

signal

from

pin

8

of

IC2.

This

signal

is

automatically

adjusted

so

that

the

zero-crossing

point

wil

l

always

occur

at

the

proper

time.

It

is

accompl

ished

by

making

the

signal

comparison

with

an

adjusted

dc

basel

ine

level

that

is

furnished

from

the

internal

Walk

Signal

Base

Q

Signal

Base

Q.

Signal

Base

Q

Zero

Cross

Signal

Pin

1

1C2A

Fig.

5.1.

Ideal

Pulse

Shapes

Illustrating

the

Constant

Fraction

Discriminator

Operation.

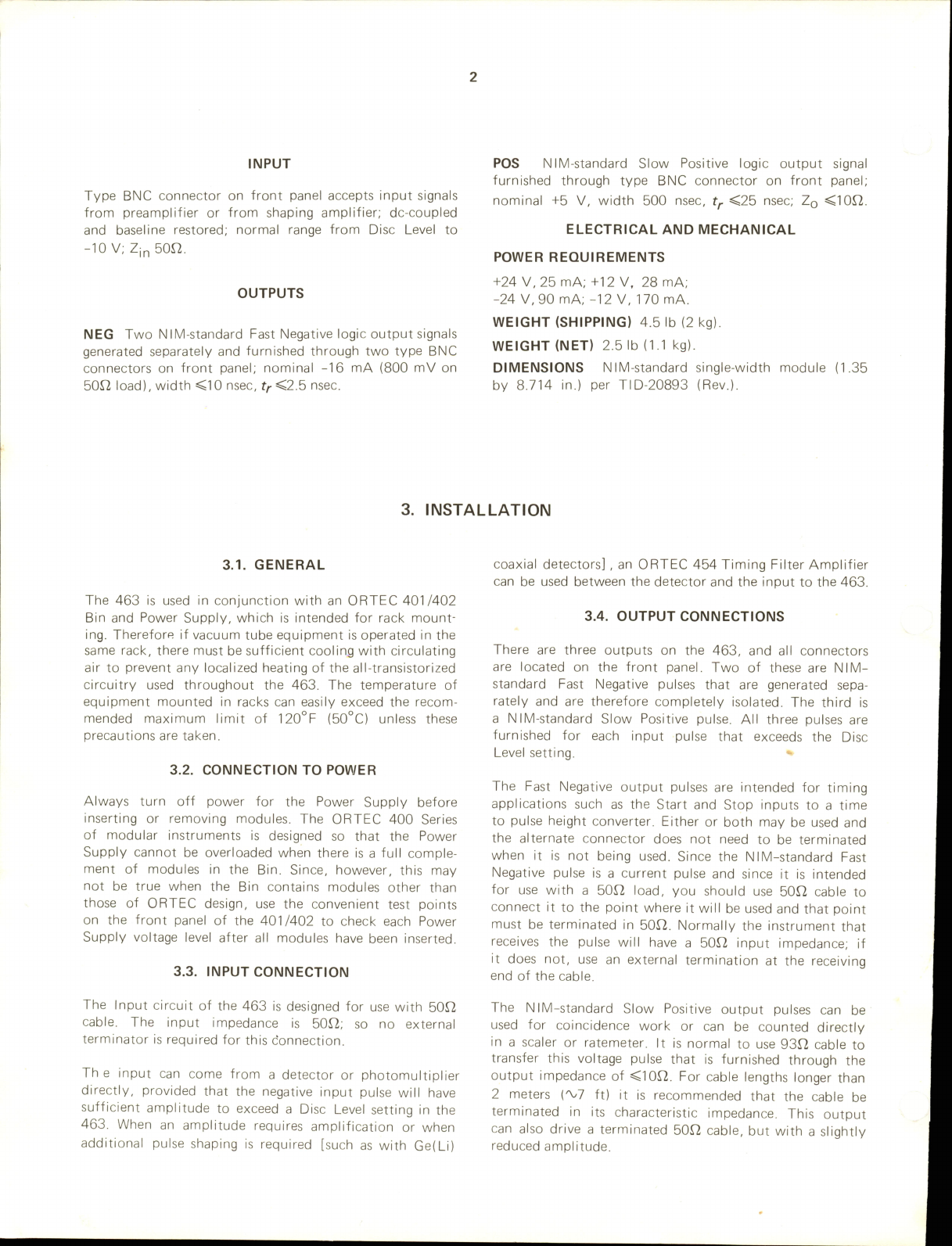

Level

Disc.

Output

-0.7V

(Pin

8.

IC1C)

Zero

Crossing

Signal

(Pin

8,

1C2C)

-1.5V

•0.7V

-0.7V

And

Output

Signal

(Pin

6,

IC4B}

Fig.

5.2.

Signal

Shapes

Illustrating

Detection

of

the

Zero-Crossing

Point

of

Constant

Fraction

Signal.

Adjust

potentiometer

R45,

This

comparison

is

made

by

ICS.

When

the

zero-crossing

basel

ine

goes

negative

with

respect

to

pin

2

of

ICS,

the

comparator

output

goes

from

its

low

to

its

high

state

of

'Vl

V.

At

this

time

Q9

is

conducting,

Q8

is

off,

and

C7

is

charged

slowly

toward

+24

V

by

current

through

R37.

This

positive

excursion

is

applied

through

Q7

to

the

base

of

Q6

to

increase

the

current

through

the

col

lector

of

Q6.

The

increasing

current

causes

the

of

QS

to

increase

and

provides

a

negative

offset

voltage

at

the

pin

4

input

of

IC2,

This

offset

is

ampl

ified

and

inverted

through

IC2

for

a

positive

excursion

back

to

pin

S

of

ICS

that

causes

ICS

to

change

back

to

its

low

state

and

to

thus

decrease

the

offset

voltage

at

pin

4

of

IC2.

This

negative

feedback

control

stabilizes

the

zero-crossing

point

against

drifts

due

to

power

supply

voltage

variations,

sl

ight

variations

in

the

input

dc

level,

or

aging

of

components.

After

the

internal

Walk

Adjust

is

performed

on

the

46S

at

the

factory,

no

further

adjustments

should

be

required

unless

components

are

interchanged

in

the

instrument.

The

detected

zero-crossing

signal

at

pin

6

of

IC4B

triggers

a

monostable,

IC5A

and

IC5B.

The

monostable

period

is

'VlOO

nsec

for

Ge(Li)

and

Scint/SB

selections

of

SI

and

is

increased

to

'Vl

fxsec

for

the

Nal

mode

selection.

The

longer

reset

time

used

for

the

Nal

mode

prevents

multiple

outputs

on

the

trail

ing

edge

of

the

Nal

signals.

The

positive-going

signal

at

the

pin

2

output

of

IC^B

triggers

a

positive

output

monostable,

Q12

to

Q16.

This

provides

a

positive

logic

signal

output

through

CN4.

The

positive

signal

from

pin

2

of

IC2B

is

also

routed

through

R49

and

DL2B

('vS-nsec

delay)

to

pin

IS

of

IC4C.

IC4C

sums

this

delayed

positive

signal

with

the

inverted

signal

from

pin

8

of

IC5C

for

a

positive

signal

at

pin

11

of

IC4C

with

a

width

equal

to

the

delay

of

DL2B

of

'V8

nsec.

This

shaped

signal

is

then

routed

to

two

current

switches

to

produce

the

two

negative

logic

signals

through

CN2

and

CNS.

Q10

and

Q11

form

the

current

switch

for

the

output

through

CNS,

and

Q18

and

Q19

form

the

current

switch

for

the

output

through

CN2.

Each

output

signal

is

approximately

20

mA

and

is

intended

to

drive

a

low

impedance

of

typically

50^2.

6.

MAINTENANCE

6.1.

GENERAL

The

ORTEC

46S

should

require

no

regular

maintenance

other

than

replacement

of

components

that

have

failed

due

to

age.

The

three

cal

ibrations

described

below

may

be

required

if

internal

components

are

replaced.

If

a

46S

is

suspected

of

malfunction,

disconnect

it

from

al

l

circuit

interconnections

and

check

the

voltages

at

the

check

points

l

isted

in

Table

6.1.

These

voltages

are

nominal

values

and

are

furnished

only

as

a

guide

for

troubleshooting

in

the

instrument.

The

values

have

been

measured

with

the

Shaping

Mode

switch

set

at

Scint/SB

and

with

the

Disc

Level

control

ful

ly

counterclockwise

at

0

dial

di

visions.

6.2.

LEVEL

DISCRIMINATOR

ZERO

ADJUSTMENT

Connect

a

source

of

-50-mV

pulses,

>10

nsec

wide,

to

the

463

Input.

Set

the

mode

switch

at

Scint/SB

and

adjust

the

Disc

Level

control

to

5

minor

divisions

for

50

mV.

Observe

the

Pos

output

of

the

463

with

an

oscilloscope

and

adjust

R77

on

the

bottom

of

the

463

for

half-firing.

Readjust

the

input

signal

to

-1

V

and

adjust

the

Disc

Level

control

to

again

obtain

half-firing.

The

Disc

Level

control

should

be

set

at

1

major

division

+10

minor

divisions.

If

the

Disc

Level

control

is

not

within

10

minor

divisions,

re

adjust

R77

and

repeat

the

procedure.

6.3.

NEGATIVE

OUTPUT

PULSE

SHAPE

AND

AMPLITUDE

ADJUSTMENT

Set

the

463

for

Its

Scint/SB

mode

with

the

Disc

Level

control

at

5

minor

divisions.

Connect

a

-TV

pulse

to

the

463

Input.

Observe

the

Neg

output

nearer

the

top

of

the

front

panel

with

an

oscil

loscope

that

is

capable

of

<3-nsec

rise

time.

Adjust

R81

(nearer

the

top

on

the

printed

circuit

board)

for

minimum

signal

width

and

maximum

ampl

itude.

Table

6.1.

Typical

Voltages

at

Suggested

Check

Points

Check

Point

Voltage

Check

Point

Voltage

Q1E

-0.658

IC3,

pin

7

+1.622

Q1B

-0.002

IC3,

pin

8

+10.78

Q2E

-0.663

IC4,

pin

8

-0.756

Q2B

-0.008

IC4,

pin

9

-1.646

IC1,

pin

3

-1.110

IC4,

pin

12

-0.937

IC1,pin4

-1.327

IC4,

pin

13

-1.414

IC1,

pin

1

-1.749

IC5,pin

11

-1.026

IC1,

pin

2

-0.709

IC5,

pin

3

-1.937

IC1,

pin

8

-1.756

IC5,

pin

4

-0.947

Q3E

-0.671

IC5,

pin

1

-1.158

Q3B

-0.009

IC5,

pin

2

-1.412

Q4E

-0.673

IC5,

pin

6

-1.024

Q4B

-0.009

Q10E

-2.704

IC2,

pin

1

-1.149

Q10B

-1.933

IC2,

pin

2

-1.146

Q18E

-2.705

IC2,

pin

12

-1.179

Q12B

-0.120

IC2,

pin

13

-1.146

Q12C

+3.509

IC2,

pin

8

-1.124

Q13B

-0.344

Q5E

-12.61

Q14E

+2.729

Q6E

-12.00

Q15B

+0.651

Q6B

-11.35

Q15C

+0.428

Q8E

-10.70

Q17E

-5.875

Q8B

-16.59

Q17B

-6.504

Q8C

-10.69

Q17C

-10.82

Q9E

+0.647

-6

-5.547

IC3,

pin

3

-1.147

-6d

-5.306

IC3,

pin

4

-6.183

The

width

should

be

<10

nsec

and

the

amplitude

should

be

>0.7

V

into

a

50f2

load.

A

slow

oscil

loscope

wil

l

distort

both

the

ampl

itude

and

the

width.

Move

the

oscilloscope

connection

to

observe

the

Neg

out

put

nearer

the

bottom

of

the

front

panel

.

Repeat

the

above

procedure

and

adjust

R53

(nearer

the

bottom

on

the

printed

circuit

board)

for

the

optimum

signal

through

this

output.

6.4.

WALK

ADJUSTMENT

If

the

463

is

suspected

of

having

excessive

walk,

test

it

for

conformance

to

operating

standards

with

the

following

steps.

The

tests

are

outl

ined

separately

for

each

of

the

3

operating

modes

of

the

463.

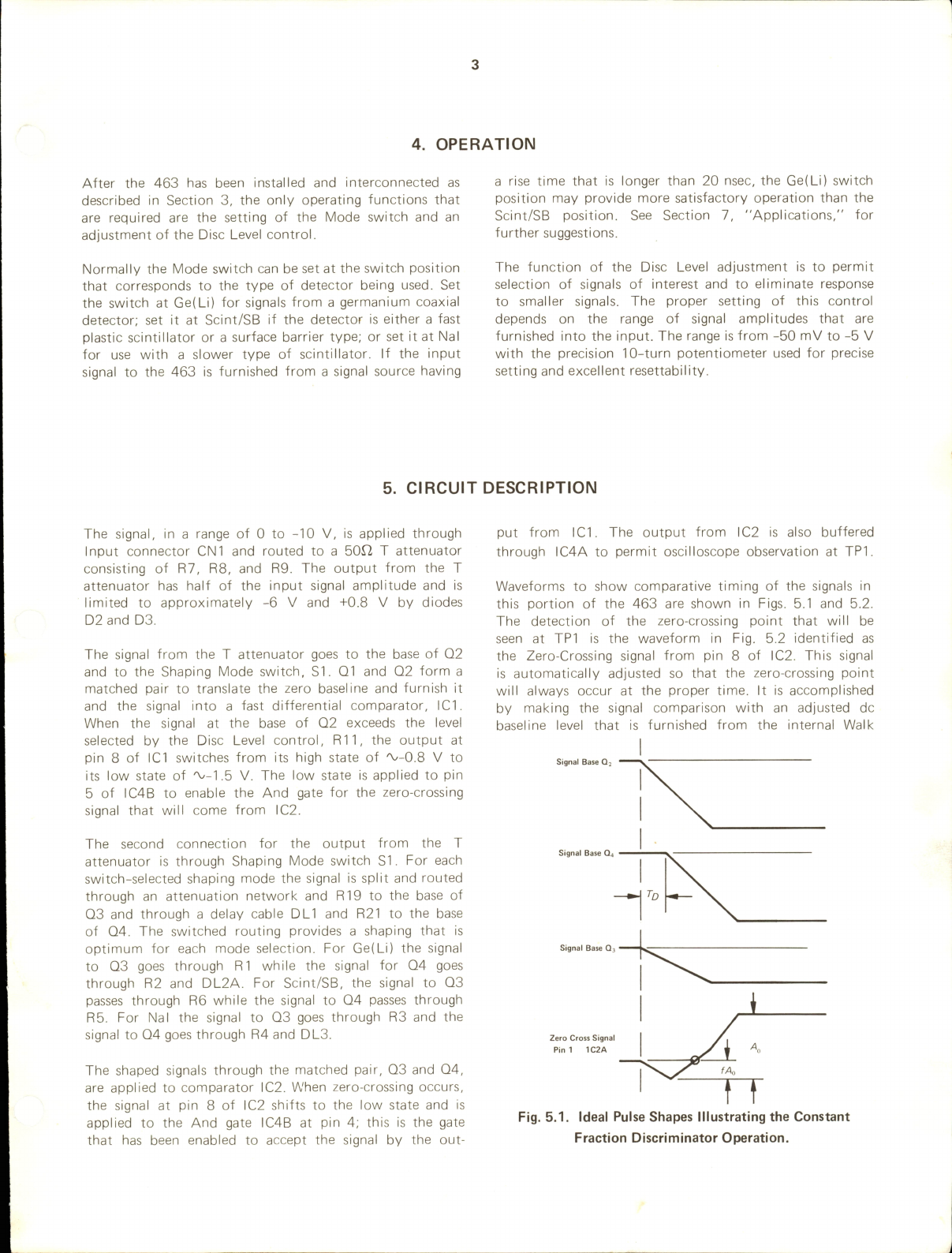

Ge(Li)

Mode

Figure

6.1

shows

a

system

tfiat

can

be

used

to

check

the

463

walk

in

the

Ge(Li)

mode.

A

slow

rise-time

pulse,

'VIOO

nsec,

with

a

maximum

ampl

itude

of

about

-10

V

is

appl

ied

to

the

463

Input.

When

the

Neg

output

is

observed,

it

should

not

move

more

than

+2

nsec

with

respect

to

the

trigger

applied

to

the

oscil

loscope

for

any

combinations

of

XI, X2, X5,

and

X10

attenuator

settings

on

the

448

Pulser.

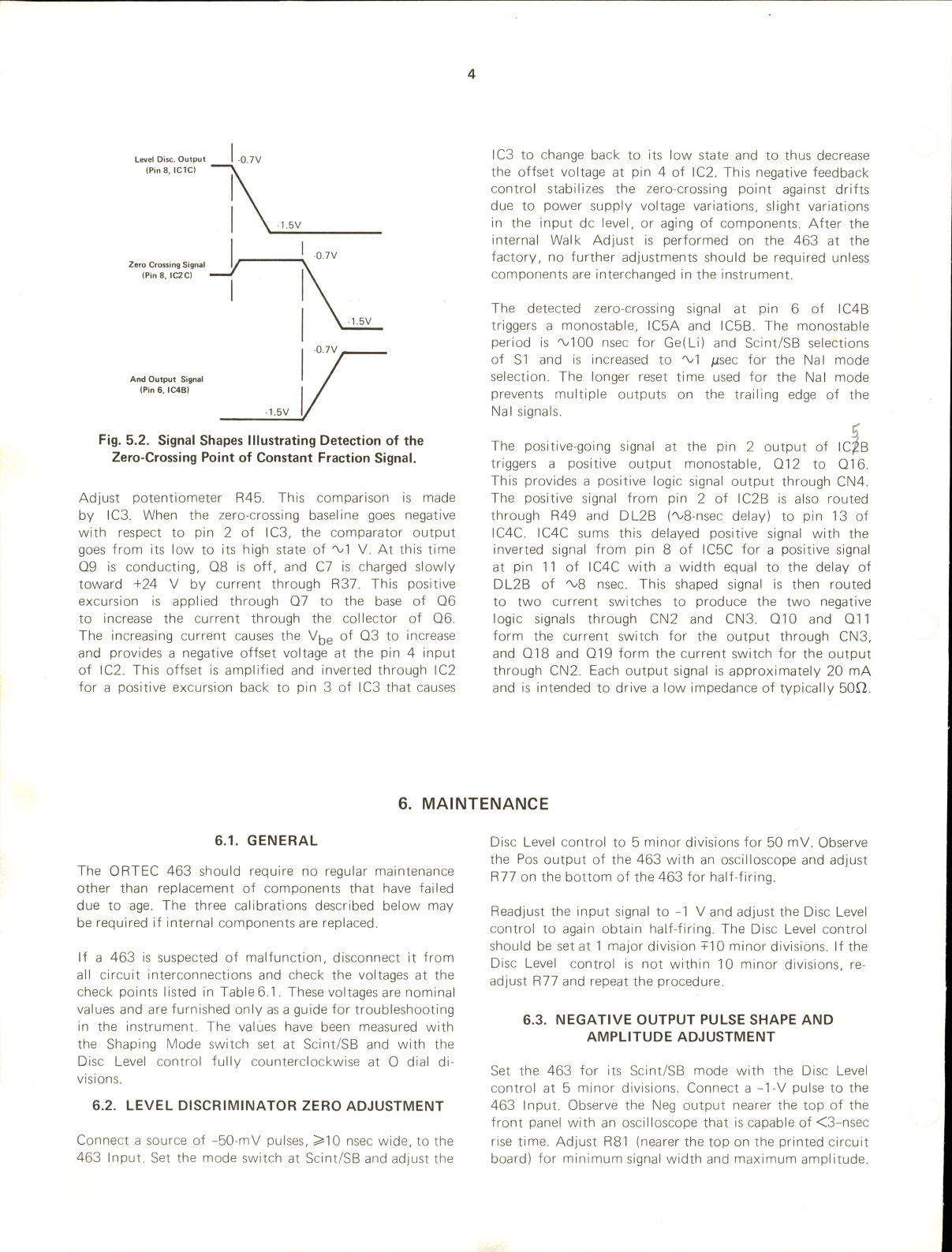

Scint/SB

Mode

Use

the

system

shown

in

the

block

diagram

of

Fig.

6.2

to

test

the

walk

of

the

463

in

its

Scint/SB

mode.

ORTEC

448

RESEARCH

PULSER

Negative

Polarity

RG-58

Cable

Direct

Output

loon

Attenuated

Output

ORTEC

454

TIMING

FILTER

AMPLIFIER

Coarse

Gain:

5

Fine

Gain:

2

lot:

100

nsec

Diff:

100

nsec

Input

Polarity:

Neg

TEKTRONIX

454

OSCILLOSCOPE

0.5

V/div

5

nsec/div

Ext

Trigger

ORTEC

463

CONSTANT

FRACTION

DISCRIMINATOR

Shaping

Mode:

Ge(Li)

Disc

Level:

5

(minor

div)

Fig.

6.1.

Block

Diagram

of

System

for

Walk

Test

of

the

ORTEC

463

In

the

Ge(LI)

Mode.

RG-58

Cable

RG-58

Cable

TRIGGER

50<>

TEKTRONIX

SO'i

ATTENUATOR

X2,X5,

X10

ORTEC

463

CONSTANT

FRACTION

DISCRIMINATOR

Shaping

Mode:

Ge(Li)

Disc

Level:

5

(minor

div)

TEKTRONIX

454

OSCILLOSCOPE

0.5

V/div

5

nsec/div

Ext

Trigger

Rep.

Rate:

Pulse

Width:

Amplitude:

Output

Polarity:

Neg.

1000

10

n

HP-8004

A

PULSER

sec

5

V

Fig.

6.2.

Block

Diagram

of

System

for

Walk

Test

of

the

ORTEC

463

In

the

Scint/SB

Mode.

For

any

combination

of

attenuator

settings

of

XI,X2,X5,

and

XI0

(but

not

for

XI00)

the

observed

walk

should

be

less

than

+0.15

of

a

minor

division

on

the

oscil

loscope.

A

more

precise

measurement

can

be

made

if

a

time

base

of

1

nsec/division

is

available.

This

time

base

is

available

on

Tektronix

454A

real

time

oscilloscopes

and

on

sampl

ing

oscilloscopes.

A

dynamic

range

of

only

50:1

has

been

suggested

because

the

FIP8004A

provides

a

maximum

output

ampl

itude

of

5

V.

If

a

pulser

is

available

with

a

rise

time

of

<2

nsec

and

an

ampl

itude

of

10

V,

the

463

walk

should

be

tested

for

the

range

of

10

V

to

100

mV.

Be

careful

when

making

this

measurement

to

consider

the

Tektronix

Attenuator

characteristics.

It

is

not

uncommon

for

an

insertion

delay

variation

of

+100

psec

to

exist

in

the

attenuator.

Verify

the

delay

consistency

of

the

attenuator

before

making

the

walk

test,

since

100

psec

is

equivalent

to

<1/8-inch

difference

in

signal

path

length

and

is

l

ikely

to

exist

for

most

attenuator

units.

Na!

Mode

This

test

is

identical

to

the

procedure

outl

ined

for

Scint/SB

mode

except

that

the

rise

time

of

the

signal

to

the

463

should

be

about

5

nsec

to

simulate

more

closely

the

signal

from

a

Nal

scinti

llator.

The

walk

should

not

exceed

+0.5

nsec

in

this

mode

for

a

range

of

input

pulse

heights

from

10

V

to

100

mV.

Walk

Correction

If

the

unit

fails

to

meet

the

walk

test

as

outl

ined

above,

a

correction

can

be

made.

This

adjustment

has

been

made

at

the

factory

and

should

not

normal

ly

be

necessary

unless

some

components

have

been

replaced

due

to

failure.

Use

the

fol

lowing

procedure:

1.

Connect

the

463

into

the

system

shown

in

Fig.

6.2

and

set

the

Tektronix

50J2

Attenuator

for

XI.

Move

the

cable

for

the

osci

l

loscope

input

signal

to

TPI

on

the

top

of

the

463

and

use

a

X10

attenuated

probe.

2.

Adjust

R45

clockwise

until

the

signal

is

similar

to

that

of

Fig.

6.3a.

3.

Adjust

R45

counterclockwise

until

the

signal

is

similar

to

that

of

Fig.

6.3b.

4.

Adjust

R45

clockwise

again

until

the

signal

at

TPI

is

correct

as

shown

in

Fig.

6.3c.

This

provides

a

first-order

adjustment

and

is

usual

ly

sufficient

for

proper

walk

characteristics.

If

a

finer

adjust

ment

is

necessary

to

minimize

the

walk,

use

the

exact

system

in

Fig.

6.2.

Set

the

attenuator

to

X50

and

adjust

R45

(less

than

+1

turn)

so

that

the

time

walk

is

zero.

After

this

adjustment

the

463

should

meet

the

walk

test

suggested

for

al

l

three

modes.

0

1 1

1

1

1

N

/

-

/

1

1

1

1

1

1 1

1

-tHT

rt

t

r

11

1 1

1

1

1 1

1

1

1 1

1

M

1 1

1 1 1

(a)

R45

Too

Far

Clockwise

(b)

R45

Too

Far

Counterclockwise

1

1

1 1

1

1

1

r

M

41

1

1

1 1

4444-

4444

1 1 1 1

Vert.

0.5

V

/div

Horiz.

5

nsec/div

1

1

(c)

Correct

Adjustment

Fig.

6.3.

Effect

of

Walk

Adjustment

In

the

ORTEC

463.

7.

APPLICATIONS

7.1.

TIMING

WITH

FAST

SCINTILLATORS

7.2.

TIMING

WITH

LARGE

Ge(Li)

DETECTORS

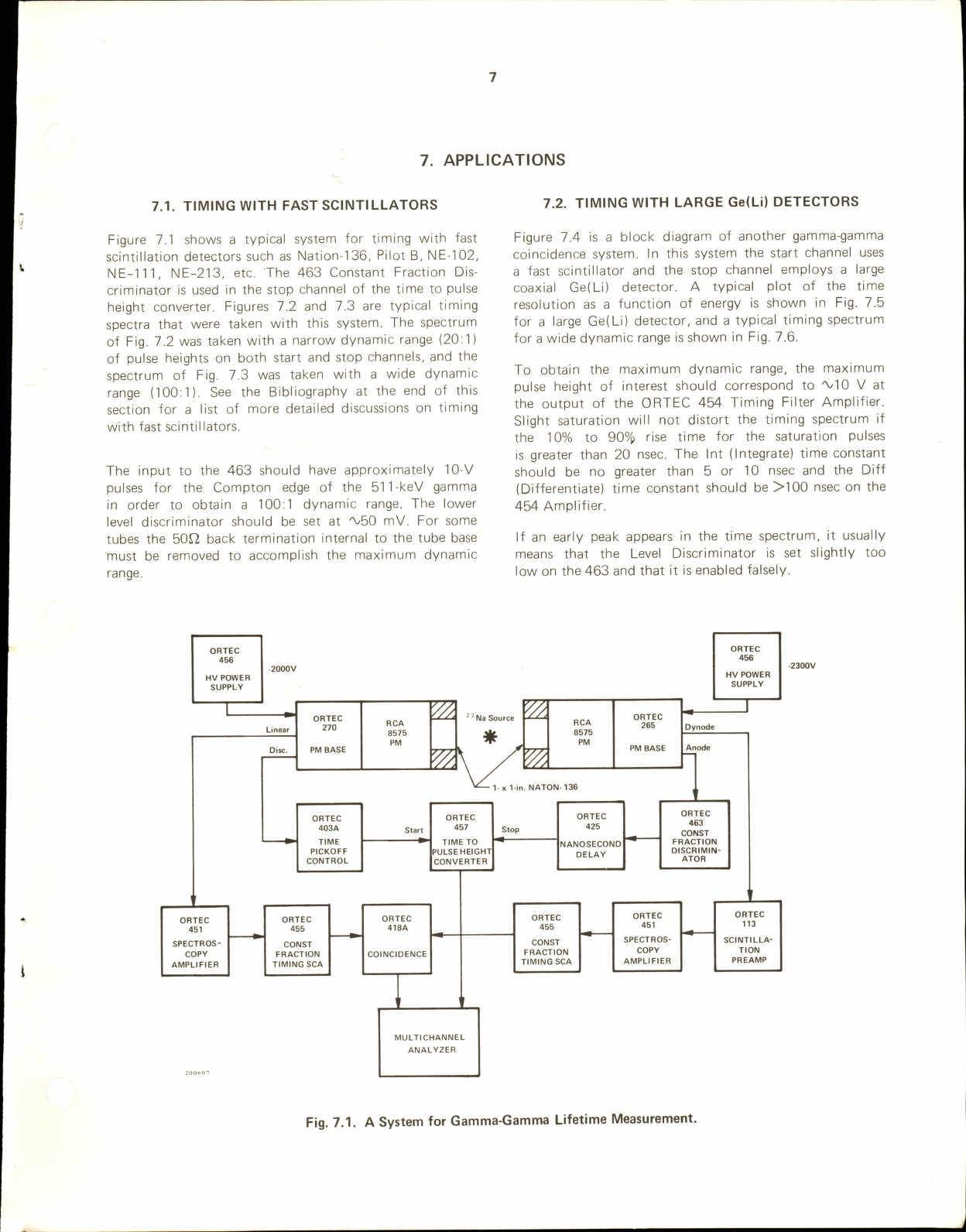

Figure

7.1

shows

a

typical

system

for

timing

with

fast

scintil

lation

detectors

such

as

Nation-136,

Pi

lot

B,

NE-102,

NE-111, NE-213,

etc.

The

463

Constant

Fraction

Dis

criminator

is

used

in

the

stop

channel

of

the

time

to

pulse

height

converter.

Figures

7.2

and

7.3

are

typical

timing

spectra

that

were

taken

with

this

system.

The

spectrum

of

Fig.

7.2

was

taken

with

a

narrow

dynamic

range

(20:1)

of

pulse

heights

on

both

start

and

stop

channels,

and

the

spectrum

of

Fig.

7.3

was

taken

with

a

wide

dynamic

range

(100:1).

See

the

Bibl

iography

at

the

end

of

this

section

for

a

l

ist

of

more

detailed

discussions

on

timing

with

fast

scintil

lators.

The

input

to

the

463

should

have

approximately

10-V

pulses

for

the

Compton

edge

of

the

51

TkeV

gamma

in

order

to

obtain

a

100:1

dynamic

range.

The

lower

level

discriminator

should

be

set

at

'V50

mV.

For

some

tubes

the

50^2

back

termination

internal

to

the

tube

base

must

be

removed

to

accomplish

the

maximum

dynamic

range.

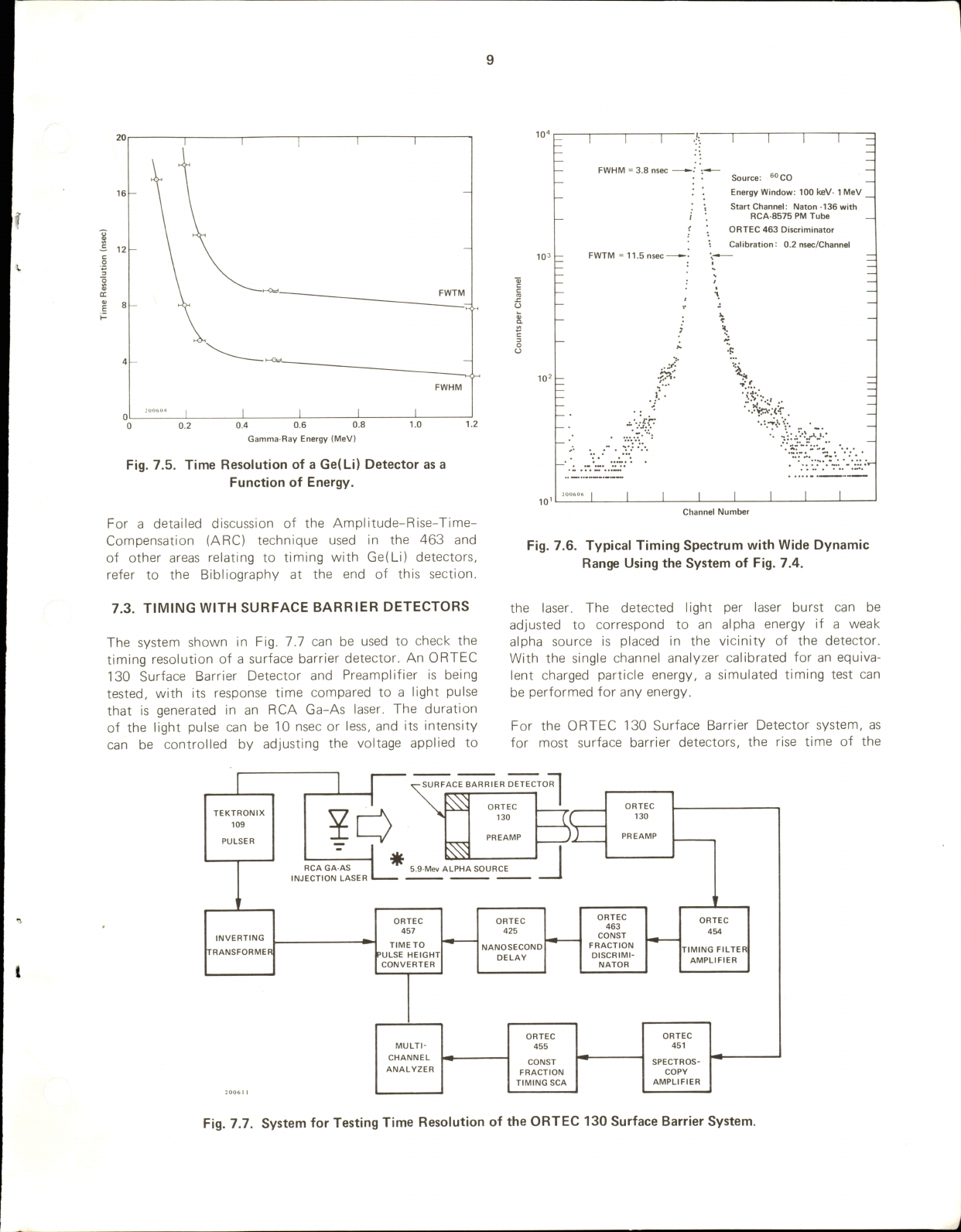

Figure

7.4

is

a

block

diagram

of

another

gamma-gamma

coincidence

system.

In

this

system

the

start

channel

uses

a

fast

scinti

llator

and

the

stop

channel

employs

a

large

coaxial

Ge(Li)

detector.

A

typical

plot

of

the

time

resolution

as

a

function

of

energy

is

shown

in

Fig.

7.5

for

a

large

Ge(Li)

detector,

and

a

typical

timing

spectrum

for

a

wide

dynamic

range

is

shown

in

Fig.

7.6.

To

obtain

the

maximum

dynamic

range,

the

maximum

pulse

height

of

interest

should

correspond

to

'ViO

V

at

the

output

of

the

ORTEC

454

Timing

Filter

Amplifier.

Sl

ight

saturation

wi

l l

not

distort

the

timing

spectrum

if

the

10%

to

90%

rise

time

for

the

saturation

pulses

is

greater

than

20

nsec.

The

Int

(Integrate)

time

constant

should

be

no

greater

than

5

or

10

nsec

and

the

Diff

(Differentiate)

time

constant

should

be

>100

nsec

on

the

454

Amplifier.

If

an

early

peak

appears

in

the

time

spectrum,

it

usual

ly

means

that

the

Level

Discriminator

is

set

slightly

too

low

on

the

463

and

that

it

is

enabled

falsely.

ORTEC

456

HV

POWER

SUPPLY

ORTEC

403A

TIME

PICKOFF

CONTROL

270

RCA

8575

PM

BASE

PM

Va

a

Source

*

Va

ORTEC

265

RCA

8575

PM

PM

BASE

l-x

1-in.

NATON-136

ORTEC

457

TIME

TO

PULSE

HEIGHT

CONVERTER

ORTEC

451

ORTEC

455

ORTEC

418A

SPECTROS-

CONST

COPY

FRACTION

COINCIDENCE

AMPLIFIER

TIMING

SCA

Stop

ORTEC

425

NANOSECOND

DELAY

ORTEC

455

CONST

FRACTION

TIMING

SCA

ORTEC

451

SPECTROS-

COPY

AMPLIFIER

MULTICHANNEL

ANALYZER

ORTEC

456

HV

POWER

SUPPLY

Dynode

ORTEC

463

CONST

FRACTION

DISCRIMIN

ATOR

ORTEC

113

SCINTILLA

TION

PREAMP

Fig.

7.1.

A

System

for

Gamma-Gamma

Lifetime

Measurement.

40,000

Calibration:

17.5

psec/Channel

Duration

of

Run:

5

hr

Source:

■'

Na

Dynamic

Range:

20%

-

FWHM

380

psec-

&

2000

1000

600

400

Start

Channel:

1-

by

1-in.

Naton-136,

RCA-8575

PM

Tube,

ORTEC

270

CFPHT

Base.

Stop

Channel:

1-

by

1-in.

Naton-136,

RCA-8575

PM

Tube,

ORTEC

463

Constant

Fraction

Discriminator

FWTM

735

psec

340

360

Channel

Number

Fig.

7.2.

Timing

Over

a

Narrow

Dynamic

Range

with

the

System

of

Fig.

7.1.

Calibration:

87.5

psec/channel

Source:

^

^

Na

Dynamic

Range:

100:1

l^max

~

340

kev)

FWHM

=

480

psec

FWTM

=

1.15

nsec

Start

Channel:

1-

by

Tin.

Naton-136,

RCA-8575

PM

Tube

ORTEC

270

CFPHT

Base

Stop

Channel

:

1-

by

1-in.

Naton-136,

RCA-8575

PM

Tube

ORTEC

463

Constant

Fraction

Discriminator

330 335 340

Channel

Number

Fig.

7.3.

Timing

Over

a

Wide

Dynamic

Range

with

the

System

of

Fig.

7.1.

2-

by

2-in.

Naton

136

ORTEC

456

HV

POWER

SUPPLY

ORTEC

463

CONST

FRACTION

DISCRIMI

NATOR

ORTEC

RCA

265

8575

PM

BASE

PM

TUBE

ORTEC

120

Ge

Li

45CC

PREAMP

Na

Source

ORTEC

416A

GATE

AND

DELAY

GENERATOR

ORTEC

455

CONST

FRACTION

TIMING

SCA

ORTEC

452

SPECTROS-

COPY

AMPLIFIER

ORTEC

457

TIME

TO

PULSE

HEIGHT

CONVERTER

ORTEC

425

NANOSECOND

DELAY

ORTEC

463

CONST

FRACTION

DISCRIMI

NATOR

ORTEC

459

DETECTOR

BIAS

SUPPLY

ORTEC

454

TIMING

FILTER

AMPLIFIER

MULTI

CHANNEL

ANALYZER

Fig.

7.4.

Gamma-Gamma

Coincidence

System

Using

Plastic

Scintillator

and

a

Large

Ge(Li)

Coaxial

Detector.

0

0.2

0.4

0.6

0.8

1.0

Gamma-Ray

Energy

(MeV)

Fig.

7.5.

Time

Resolution

of

a

Ge(Li)

Detector

as

a

Function

of

Energy.

For

a

detai

led

discussion

of

the

Ampl

itude-Rise-Time-

Compensation

(ARC)

technique

used

in

the

463

and

of

other

areas

relating

to

timing

with

Ge(Li)

detectors,

refer

to

the

Bibl

iography

at

the

end

of

this

section.

FWHM

=3.8

nsec

-

FWTM

=11.5

nsec-

1—q

Source:

""CO

Energy

Window:

100

keV-1

MeV

Start

Channel:

Naton

-136

with

RCA-8575

PM

Tube

ORTEC

463

Discriminator

Calibration:

0.2

nsec/Channel

'•W.t

Channel

Number

Fig.

7.6.

Typical

Timing

Spectrum

with

Wide

Dynamic

Range

Using

the

System

of

Fig.

7.4.

7.3.

TIMING

WITH

SURFACE

BARRIER

DETECTORS

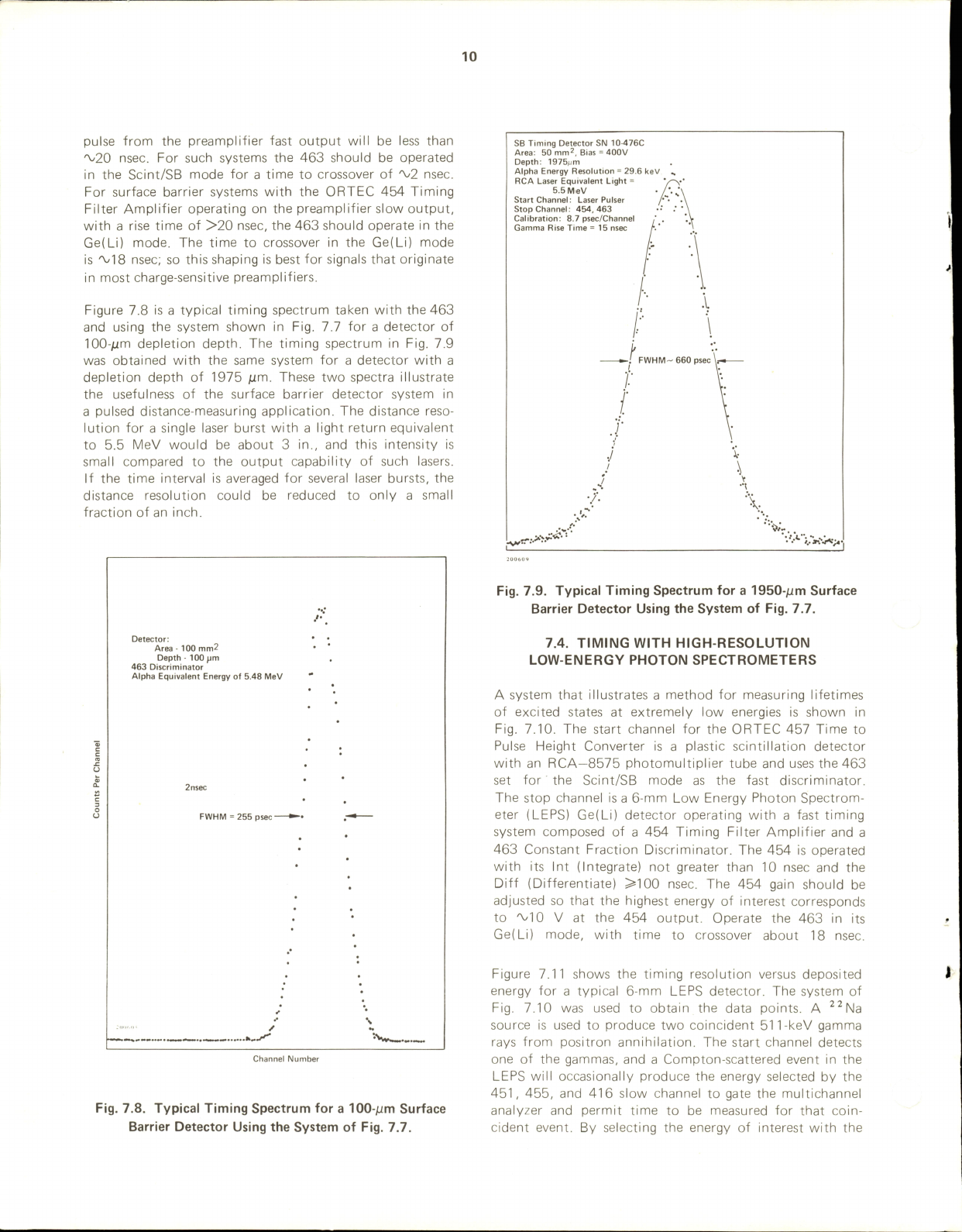

The

system

shown

in

Fig.

7.7

can

be

used

to

check

the

timing

resolution

of

a

surface

barrier

detector.

An

ORTEC

130

Surface

Barrier

Detector

and

Preampl

ifier

is

being

tested,

with

its

response

time

compared

to

a

l

ight

pulse

that

is

generated

in

an

RCA

Ga-As

laser.

The

duration

of

the

light

pulse

can

be

10

nsec

or

less,

and

its

intensity

can

be

controlled

by

adjusting

the

voltage

appl

ied

to

the

laser.

The

detected

light

per

laser

burst

can

be

adjusted

to

correspond

to

an

alpha

energy

if

a

weak

alpha

source

is

placed

in

the

vicinity

of

the

detector.

With

the

single

channel

analyzer

calibrated

for

an

equiva

lent

charged

particle

energy,

a

simulated

timing

test

can

be

performed

for

any

energy.

For

the

ORTEC

130

Surface

Barrier

Detector

system,

as

for

most

surface

barrier

detectors,

the

rise

time

of

the

TEKTRONIX

109

PULSER

RCA

GA-AS

INJECTION

LASER

ORTEC

457

TIMETO

PULSE

HEIGHT

CONVERTER

MULTI

CHANNEL

ANALYZER

SURFACE

BARRIER

DETECTOR

ORTEC

ORTEC

130

ZIC^

130

PREAMP

))

PREAMP

5.9-Mev

ALPHA

SOURCE

INVERTING

TRANSFORMER

ORTEC

425

NANOSECOND

DELAY

ORTEC

455

CONST

FRACTION

TIMING

SCA

ORTEC

463

CONST

FRACTION

DISCRIMI

NATOR

ORTEC

454

TIMING

FILTER

AMPLIFIER

ORTEC

451

SPECTROS-

COPY

AMPLIFIER

Fig.

7.7.

System

for

Testing

Time

Resolution

of

the

ORTEC

130

Surface

Barrier

System.

10

pulse

from

the

preamplifier

fast

output

wi

ll

be

less

than

'V20

nsec.

For

such

systems

the

463

should

be

operated

in

the

Scint/SB

mode

for

a

time

to

crossover

of

"^2

nsec.

For

surface

barrier

systems

with

the

ORTEC

454

Timing

Filter

Ampl

ifier

operating

on

the

preampl

ifier

slow

output,

with

a

rise

time

of

>20

nsec,

the

463

should

operate

in

the

Ge(Li)

mode.

The

time

to

crossover

in

the

Ge(Li)

mode

is

'V/IS

nsec;

so

this

shaping

is

best

for

signals

that

originate

in

most

charge-sensitive

preampl

ifiers.

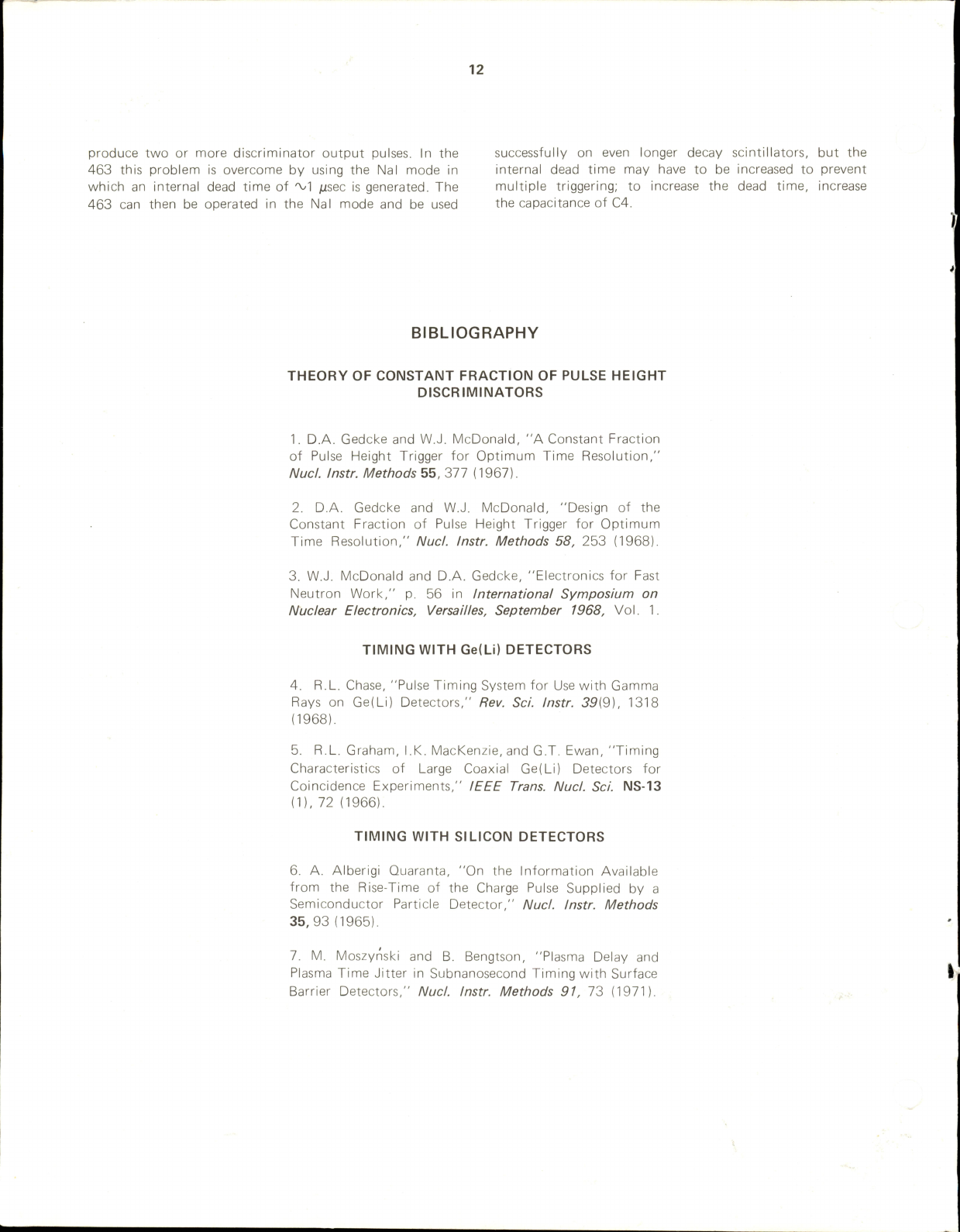

Figure

7.8

is

a

typical

timing

spectrum

taken

with

the

463

and

using

the

system

shown

in

Fig.

7.7

for

a

detector

of

100-/L(m

depletion

depth.

The

timing

spectrum

in

Fig.

7.9

was

obtained

with

the

same

system

for

a

detector

with

a

depletion

depth

of

1975

/jm.

These

two

spectra

illustrate

the

usefulness

of

the

surface

barrier

detector

system

in

a

pulsed

distance-measuring

appl

ication.

The

distance

reso

lution

for

a

single

laser

burst

with

a

light

return

equivalent

to

5.5

MeV

would

be

about

3

in.,

and

this

intensity

is

smal

l

compared

to

the

output

capabil

ity

of

such

lasers.

If

the

time

interval

is

averaged

for

several

laser

bursts,

the

distance

resolution

could

be

reduced

to

only

a

smal

l

fraction

of

an

inch.

/\

Detector:

•

•

Area

•

100

mm2

•

Depth

•

100

pm

,

463

Discriminator

Alpha

Equivalent

Energy

of

5.48

MeV

^

•

2

nsec

•

FWHM

=

255

psec

•

<

\

/

••

..

N-v

Channel

Number

SB

Timing

Detector

SN

10-4760

Area;

50

mm^.

Bias

=

400V

Depth:

1975Aim

Alpha

Energy

Resolution

=

29.6

keV

^

RCA

Laser

Equivalent

Light

=

y-y

5.5

MeV

•

/*.

Start

Channel:

Laser

Pulser

/•**•

i

Stop

Channel:

454,463

••

Calibration:

8.7

psec/Channel

Gamma

Rise

Time

=

15

nsec

FWHM'-'

660

psec

\

y

\

.•vC

Fig.

7.8.

Typical

Timing

Spectrum

for

a

100-/im

Surface

Barrier

Detector

Using

the

System

of

Fig.

7.7.

Fig.

7.9.

Typical

Timing

Spectrum

for

a

1950-/im

Surface

Barrier

Detector

Using

the

System

of

Fig.

7.7.

7.4.

TIMING

WITH

HIGH-RESOLUTION

LOW-ENERGY

PHOTON

SPECTROMETERS

A

system

that

i

llustrates

a

method

for

measuring

l

ifetimes

of

excited

states

at

extremely

low

energies

is

shown

in

Fig.

7.10.

The

start

channel

for

the

ORTEC

457

Time

to

Pulse

Fleight

Converter

is

a

plastic

scintillation

detector

with

an

RCA—8575

photomultiplier

tube

and

uses

the

463

set

for

the

Scint/SB

mode

as

the

fast

discriminator.

The

stop

channel

is

a

6-mm

Low

Energy

Photon

Spectrom

eter

(LEPS)

Ge(Li)

detector

operating

with

a

fast

timing

system

composed

of

a

454

Timing

Filter

Amplifier

and

a

463

Constant

Fraction

Discriminator.

The

454

is

operated

with

its

Int

(Integrate)

not

greater

than

10

nsec

and

the

□iff

(Differentiate)

>100

nsec.

The

454

gain

should

be

adjusted

so

that

the

highest

energy

of

interest

corresponds

to

'V'lO

V

at

the

454

output.

Operate

the

463

in

its

Ge(Li)

mode,

with

time

to

crossover

about

18

nsec.

Figure

7.11

shows

the

timing

resolution

versus

deposited

energy

for

a

typical

6-mm

LEPS

detector.

The

system

of

Fig.

7.10

was

used

to

obtain

the

data

points.

A

^^Na

source

is

used

to

produce

two

coincident

511-keV

gamma

rays

from

positron

annihilation.

The

start

channel

detects

one

of

the

gammas,

and

a

Compton-scattered

event

in

the

LEPS

wil

l

occasional

ly

produce

the

energy

selected

by

the

451,

455,

and

416

slow

channel

to

gate

the

multichannel

analyzer

and

permit

time

to

be

measured

for

that

coin

cident

event.

By

selecting

the

energy

of

interest

with

the

11

ORTEC

456

HV

POWER

SUPPLY

2-

by

2

in.

Naton

136

RCA

8575

/

ORTEC

124

265

/

*

Ge(Li)

PM

BASE

PM

TUBE

6-mm

PREAMP

^

*

Na

Source

ORTEC

463

CONST

FRACTION

DISCRIMI

NATOR

ORTEC

457

Stop

ORTEC

425

TIME

TO

PULSE

HEIGHT

CONVERTER

NANOSECOND

DELAY

i

ORTEC

442

ORTEC

416A

LINEAR

GATE

AND

STRETCHER

GATE

AND

DELAY

GENERATOR

ORTEC

463

CONST

FRACTION

DISCRIMI

NATOR

ORTEC

455