EG&G ORTEC 553 Service manual

n

Model

553

Timing

Single-Channel

Analyzer

Operating

and

Service

Manual

Model

553

Tinning

Single-Channel

Analyzer

Operating

and

Service

Manual

This

manual

applies

to

instruments

marked

"Rev

18"

on

rear

panel

Printed

in

U.S.A.

ORTEC

Part

No.

733460

2661

0.2C

1087

standard

Warranty

for

EG&G

ORTEC

Nuclear

Electronic

Instruments

EG&G

ORTEC

warrants

that

the

items

will

be

delivered

free

from

defects

in

material

or

workmanship.

EG&G

ORTEC

makes

no

other

warranties,

express

or

implied,

and

specifically

NO

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

A

PARTICULAR

PURPOSE.

EG&G

ORTEC's

exclusive

liability

is

limited

to

repairing

or

replacing

at

EG&G

ORTEC's

option,

items

found

by

EG&G

ORTEC

to

be

defective

in

workmanship

or

materials

within

two

years

from

the

date

of

delivery.

EG&G

ORTEC's

liability

on

any

claim

of

any

kind,

including

negligence,

loss

or

damages

arising

out

of,

connected

with,

or

from

the

performance

or

breach

thereof,

or

from

the

manufacture,

sale,

delivery,

resale,

repair,

oruseof

any

item

or

services

covered

by

this

agree

ment

or

purchase

order,

shall

in

no

case

exceed

the

price

allocable

to

the

item

orservicefurnishedorany

part

thereof

that

gives

rise

to

the

claim.

In

the

event

EG&G

ORTEC

fails

to

manufacture

or

deliver

items

called

for

in

this

agreement

or

pur

chase

order,

EG&G

ORTEC's

exclusive

liability

and

buyer's

exclusive

remedy

shall

be

release

of

the

buyer

from

the

obliga

tion

to

pay

the

purchase

price.

In

no

event

shall

EG&G

ORTEC

be

liable

for

special

or

consequential

damages.

Quality

Control

Before

being

approved

for

shipment,

each

EG&G

ORTEO

nuclear

electronic

instrument

must

pass

a

stringent

set

of

quality

control

tests

designed

to

expose

any

flaws

in

materials

or

workmanship.

Permanent

records

of

these

tests

are

maintained

for

use

in

warrany

repair

and

as

a

source

of

statistical

information

for

design

improvements.

Repair

Service

If

it

becomes

necessary

to

return

this

instrument

for

repair,

it

is

essential

that

Customer

Services

be

contacted

in

advance

of

its

return

so

that

a

Return

Authorization

Number

can

be

assigned

to

the

unit.

Also,

EG&G

ORTEC

must

be

informed,

either

in

writing,

by

telephone

[(615)

482-4411

]

or

by

telex

(55-7450)

of

the

nature

of

the

fault

of

the

instrument

being

re

turned

and

of

the

model,

serial,

and

revision

("Rev"

on

rear

panel)

numbers.

Failure

to

do

so

may

cause

unnecessary

delays

in

getting

the

unit

repaired.

The

EG&G

ORTEC

standard

procedure

requires

that

instruments

returned

for

repair

pass

the

same

quality

control

tests

that

are

used

for

new-production

instruments.

Instruments

that

are

returned

should

be

packed

so

that

they

will

withstand

normal

transit

handling

and

must

be

shipped

PREPAID

via

Air

Parcel-

Post

or

United

Parcel

Service

to

the

nearest

EG&G

ORTEC

repair

center.

(In

the

case

where

the

instrument

did

not

function

upon

pur

chase,

EG&G

ORTEC

will

pay

shipment

costs

both

ways.)

The

address

label

and

the

package

should

include

the

Return

Authorization

Number

assigned.

Instruments

being

returned

that

are

damaged

in

transit

due

to

inadequate

packing

will

be

repaired

at

the

sender's

expense,

and

it

will

be

the

sender's

responsibility

to

make

claim

with

the

shipper.

Instruments

not

in

warranty

will

be

repaired

at

the

standard

charge

unless

they

have

been

grossly

misused

or

mishandled,

in

which

case

the

user

will

be

notified

prior

to

the

repair

being

done.

A

quotation

will

be

sent

with

the

notification.

Damage

in

Transit

Shipments

should

be

examined

immediately

upon

receipt

for

evidence

of

external

or

concealed

damage.

The

carrier

making

delivery

should

be

notified

immediately

of

any

such

damage,

since

the

carrier

is

normally

liable

for

damage

in

shipment.

Packing

materials,

waybills,

and

other

such

documentation

should

be

preserved

in

order

to

establish

claims.

After

such

notification

to

the

carrier,

please

notify

EG&G

ORTEC

of

the

circumstances

so

that

assistance

can

be

provided

in

making

damage

claims

and

in

providing

replacement

equipment

if

necessary.

CONTENTS

Page

WARRANTY

ii

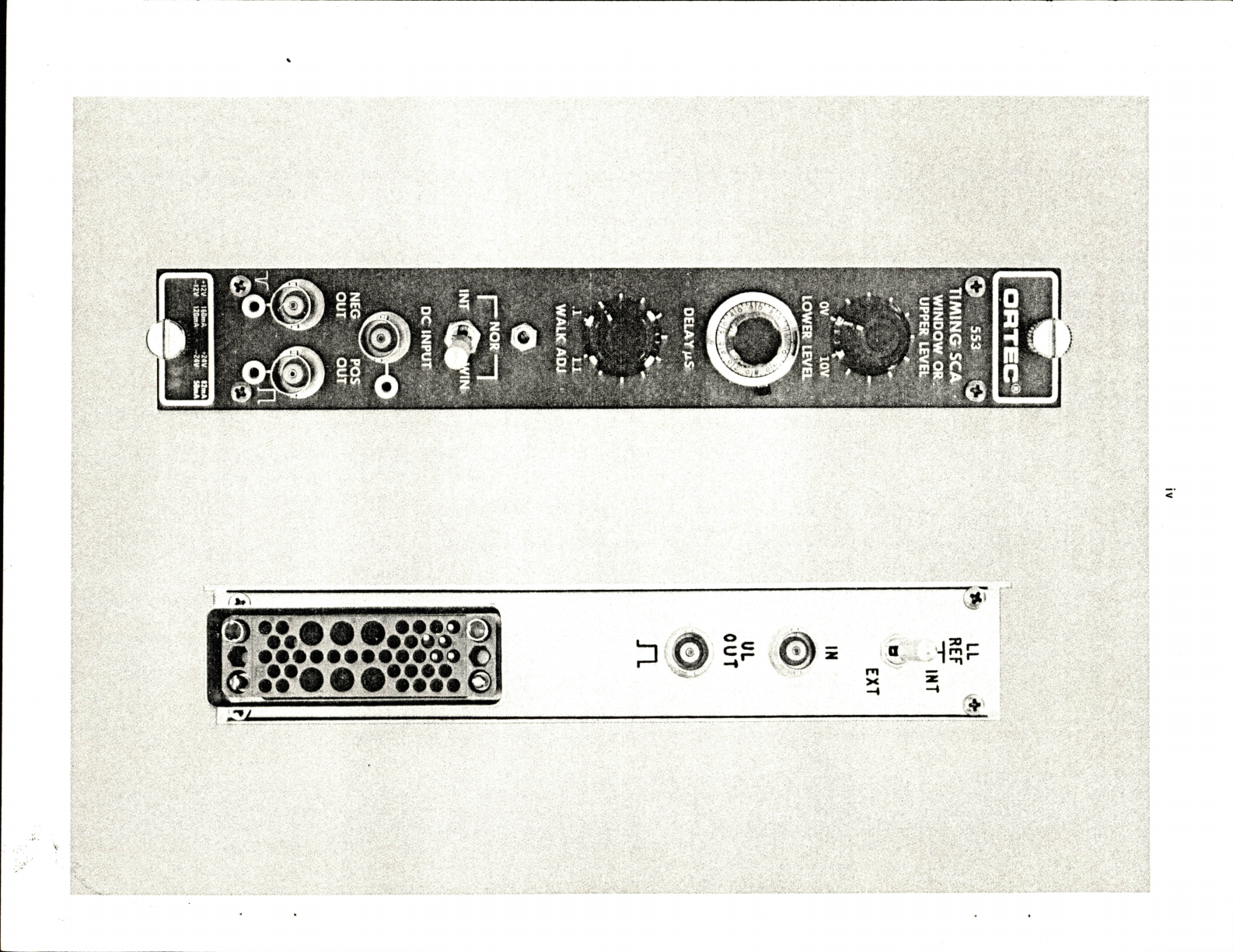

PHOTOGRAPHS

iv

1.

DESGRIPTiON

1

1.1.

Purpose

1

1.2.

Modes

of

Operation

1

1.3.

Output

Pulse

Timing

1

1.4.

Lower

Level

Reference

1

2.

SPECIFICATIONS

2

2.1.

Performance

2

2.2.

Controls

2

2.3.

Inputs

2

2.4.

Outputs

2

2.5.

Related

Equipment

2

2.6.

Electrical

and

Mecfianical

2

3.

INSTALLATION

3

3.1.

Connection

to

Power

3

3.2.

Connection

from

Linear

Amplifier

3

3.3.

Output

Connections

3

3.4.

Lower

Level

Reference

Input

3

4.

OPERATING

INSTRUCTIONS

4

5.

CIRCUIT

DESCRIPTION

5

5.1.

General

5

5.2.

Integrated

Circuits

5

5.3.

Lower

Level

Bias

5

5.4.

Upper

Level

Bias

6

5.5.

Input

Circuit

6

5.6.

Lower

Level

Discriminator

6

5.7.

Upper

Level

Discriminator

6

5.8.

Constant

Fraction

Circuit

6

5.9.

SCAGate

7

5.10.

Reset

Circuit

7

5.11.

Delay

Circuit

7

5.12.

DC

Power

7

6.

MAINTENANCE

AND

CALIBRATION

8

6.1.

General

8

6.2.

Calibration

8

6.3.

Factory

Repair

8

6.4.

Tabulated

Test

Point

Voltages

8

Block

Diagram

553-0101-B1

and

Schematic

553-0201-S1

ILLUSTRATIONS

Fig.

4.1.

Timing

Relationships

for

Input

and

Output

Pulses

4

Fig.

5.1.

Simplified

Block

Diagram

of

the

553

Timing

SCA

5

IV

's

-

n't-v

4.;

'

'«V

*

3

•

'

.v^'.

f'

'

'

,

}

'

'

■

>

'

^

„/

,

-••«'

fe

s-,'W

r

-,

.

f

^.

,

.

__

.

,

__

•«

^

'V-,

*

-

:

'-

»

%

y.>^-^.

.

;

..i

t

',f

^'.

^

,,

*

■'•*•

'

.

.

•*.

*.

.

, ,

"

,

,

,

;

.

,

'

.

■

'

,

.

..

,.

...1^

ISSsfU

.

-"-.1

iimm-mmy

LOWER-

LEVEL

DElAYjiS^V

,-—1,-

-

.1

'

Ll

WALK^AOL

.'.i^y,

^NOR—1^

INF

DC

INPUT

.

NEG

,.^

POS

OUT

^

sOUr

I

SSKSli^B&SE^

ilEB

LL

REF

INT

EXT

IN

UL

OUT

v4l'/

n

©g©

•52Sj

5''v*Si

wSMSyyyisy0Ws0SfiySiM&

:fcw,.

Ai

ORTEC

553

TIMING

SINGLE-CHANNEL

ANALYZER

1.

DESCRIPTION

1.1.

PURPOSE

The

ORTEC

553

Timing

Single-Channel

Analyzer

pro

vides

a

versatile

group

of

related

signal

derivation

func

tions.

It

can

be

used

as

either

a

single-channel

analyzer

or

as

an

Integral

discriminator.

The

principal

output,

furnished

as

both

a

NIM-standard

fast

negative

signal

and

a

NIM-standard

slow

positive

signal,

can

be

used

for

accurate

timing

information.

In

addition,

a

separate

NIM-

standard

slow

positive

output

is

furnished

separately

for

each

response

by

the

upper

level

discriminator

in

the

module.

The

output

signal

is

internally

generated

and

its

timing

relative

to

that

of

the

input

signal

is

derived

accurately,

using

a

time

recognition

technique

called

Constant-

Fraction

Discrimination.

This

technique

provides

unex

celled

timing

on

either

unipolar

or

bipolar

signals

which

displaces

<±3

ns

for

an

input

amplitude

variation

as

great

as

100:1.

This

eliminates

the

degradation

of

time

resolu

tion

for

varying

input

amplitudes

that

is

characteristic

of

leading-edge

time

recognition.

The

553

accepts

either

unipolar

or

bipolar

input

pulses

having

either

PC

or

delay-line

pulse-shaping

waveforms.

It

examines

the

amplitude

of

each

input

pulse

and

generates

appropriate

output

pulses

separately

for

SCA

and

ULD

responses.

The

SCA

output

is

delayed

from

the

time

of

recognition

(at

50%

of

full

amplitude

on

the

trailing

edge

of

the

input

positive

waveform).

The

delay

is

adjusted

on

the

front

panel

between

100

ns

and

1.1

ns

so

that

the

output

time

can

be

normalized

to

its

application.

The

instrument

is

designed

to

meet

the

recommended

interchangeability

standards

of

ERDA

Report

TID-20893

(Rev).

An

ORTEC

401/402

Series

Bin

and

Power

Supply

provides

all

the

necessary

power

through

the

rear

panel

power

connector.

All

signal

levels

and

impedances

are

compatible

with

other

ORTEC

NIM

modules.

1.2.

MODES

OF

OPERATION

The

553

has

a

front

panel

switch

that

selects

the

integral

mode

of

operation

or

either

of

two

types

of

differential

single-channel

analysis

modes.

For

Normal

operation,

each

of

the

discriminator

levels

is

adjusted

independ

ently

through

the

full

dynamic

range

of

0

to

10

V.

For

Window

operation,

the

range

of

the

lower

level

control

is

0

to

10

V

and

the

range

of

the

upper

level

(or

window)

control

is

the

adjusted

lower

level

plus

0

to

1

V.

Integral

Mode

Operation

In

the

integral

mode,

the

553

generates

an

output

through

both

the

Pos

Out

and

Neg

Out

connectors

on

the

front

panel

if

the

input

pulse

amplitude

exceeds

the

adjusted

lower

level

threshold;

the

range

is

0

to

10

V.

Normal

Mode

Operation

In

the

normal

mode,

the

553

generates

an

output

through

both

the

Pos

Out

and

Neg

Out

connectors

on

the

front

panel

if

the

input

pulse

amplitude

exceeds

the

adjusted

lower

level

but

does

not

exceed

the

adjusted

upper

level

threshold.

In

this

mode,

each

threshold

is

adjusted

independently

in

the

range

of

0

to

10

V,

and

the

upper

level

must

be

set

higher

than

the

lower

level

to

permit

the

SCA

outputs

to

be

generated.

Window

Mode

Operation

In

the

window

mode,

the

553

generates

an

output

through

both

the

Pos

Out

and

Neg

Out

connectors

on

the

front

panel

if

the

input

pulse

amplitude

exceeds

the

adjusted

lower

level

threshold,

but

by

an

amount

that

is

less

than

the

adjusted

window

width.

The

range

of

the

lower

level

control

is

0

to

10

V,

and

the

range

of

the

upper

level

control

is

0

to

1

V

above

the

lower

level.

This

mode

is

especially

adapted

to

high-

resolution

spectroscopy

because

the

very

narrow

win

dows

that

are

required

can

be

obtained

easily

and

reproducibly.

1.3.

OUTPUT

PULSE

TIMING

The

Pos

Out

and

Neg

Out

pulses

from

the

553

are

generated

at

a

delay

(with

internal

strobe)

following

the

precise

constant-fraction

time

recognition,

which

occurs

at

50%

of

the

peak

amplitude

on

the

trailing

edge

of

the

input

pulse.

The

delay

interval

is

adjustable

through

a

range

of

0.1

to

1.1

^iS.

The

front

panel

Delay

control

is

a

1-turn

potentiometer

that

is

marked

in

linear

increments

to

read

the

adjusted

delay

directly.

For

any

mode

of

operation,

a

signal

is

furnished

through

the

UL

Out

connector

on

the

rear

panel

when

the

upper

level

discriminator

is

triggered

on

the

leading

edge

of

the

input

signal.

Each

of

these

outputs

is

a

NIM-standard

positive

signal

that

can

be

used

for

any

desired

external

application.

1.4.

LOWER

LEVEL

REFERENCE

A

rear

panel

2-position

locking

toggle

switch

selects

either

the

front

panel

Lower

Level

control

or

the

voltage

signal

applied

through

the

rear

panel

LL

Ref

connector

as

the

reference

level

for

the

lower

level

discriminator.

This

permits

flexibility

in

operation,

where

an

external

reference

source

can

furnish

the

lower

level

threshold

from

a

stepped-

or

sliding-voltage

source

to

automati

cally

sweep

the

SCA

response

through

a

spectral

range

of

0

to

10

V.

The

selected

source

for

the

Lower

Level

Reference

is

effective

for

all

three

operating

modes.

2.

SPECIFICATIONS

2.1.

PERFORMANCE

Dynamic

Range

100:1.

Pulse-Pair

Resolving

Time

Output

pulse

width

plus

Delay

(as

selected

by

the

front

panel

Delay

control),

plus

100

ns

for

negative

NIM

output

or

plus

200

ns

for

positive

NIM

output.

Minimum

resolving

time

for

negative

output,

220

ns;

for

positive

output,

800

ns.

Threshold

Temperature

instability

<0.015%/°

C

of

full

scale,

0

to

50°C

using

a

NIM

class

A

power

supply

(referenced

to

-12

V).

Discriminator

Noniinearity

<±0.25%

of

full

scale

(inte

gral)

for

LL

discriminator.

Delay

Temperature

instability

<0.04%/°C

of

full

scale,

0

to

50°

C.

Delay

Noniinearity

<±2%.

Window

Width

Constancy

<0.1%

variation

of

full-scale

window

width

over

the

linear

0-

to

10-V

range.

Minimum

input

Threshold

50

mV

for

Lower

Level

dis

criminator.

Time

Shift

vs

Pulse

Height

(Walk)

Walk

(ns)

Dynamic

Range

10:1

50:1

100:1

System

System

A

B

±1.0

±2.5

±3.0

±2.0

±4.0

±8.0

System

A:

Using

an

ORTEC

460

Amplifier,

single

delay-l

ine

mode,

integrate

^0.1

ms

with

delay

line

1

mS-

System

B:

Using

an

ORTEC

471

or

472A

Amplifier,

unipolar

output

with

0.5

fiS

shaping

time,

input

from

ORTEC

419

Pulser.

2.2.

CONTROLS

Lower

Level

Front

panel

10-turn

potentiometer

adjust

able

from

0

to

10

V;

when

the

rear

panel

LL

Ref

mode

switch

is

set

on

Int,

determines

the

threshold

setting

for

the

Lower

Level

discriminator.

When

the

LL

Ref

mode

switch

on

the

rear

panel

is

in

the

Ext

position,

this

control

is

ineffective.

Window

or

Upper

Level

Front

panel

1-turn

potenti

ometer

determines

the

window

width

(0

to

+1

V)

in

the

Window

mode

or

the

Upper

Level

(0

to

+10

V)

threshold

in

the

Normal

mode.

This

control

is

disabled

in

the

Integral

mode.

Int/Nor/Win

Front

panel

3-position

locking

toggle

switch

selects

one

of

three

operating

modes.

Integral

LL

sets

a

single-discriminator

threshold

(0

to

+10

V)

and

UL

response

is

ignored

for

SCA

outputs.

Normal

UL

and

LL

are

independently

adjustable

lev

els

(0

to

+10

V);

differential

mode

operation.

Window

LL

sets

the

baseline

level

(0

to

+10

V)

and

UL

sets

the

window

width

(0

to

+1

V);

differential

mode

operation.

Delay

Front

panel

1-turn

potentiometer

for

continuous

adjustment

of

output

delay

over

a

0.1

to

1.1

fis

range.

Walk

Adjust

Front

panel

screwdriver

adjustment

for

precise

setting

of

walk

compensation.

LL

Ref

Mode

Rear

panel

two-position

locking

toggle

switch

selects

either

the

front

panel

LL

potentiometer

or

the

voltage

signal

applied

to

the

rear

panel

LL

Ref

Ext

connector

as

the

LL

discriminator

reference

threshold.

2.3.

INPUTS

Signal

Input

Front

panel

dc-coupled

BNC

connector

accepts

positive

unipolar

or

bipolar

signal,

0

to

+10

V

linear

range,

±12

V

maximum;

width,

^100

ns;

lOOOfl

input

impedance.

LL

Ref

Ext

When

the

rear

panel

LL

Ref

mode

switch

is

on

Ext,

the

rear

panel

LL

Ref

Ext

BNC

connector

accepts

the

Lower

Level

biasing

(an

input

of

0

to

-10

V

on

this

connector

corresponds

to

a

range

of

0

to

10

V

for

the

Lower

Level

discriminator

setting).

Input

protected

to

±24

V.

2.4.

OUTPUTS

Pos

Out

Front

panel

BNC

connector

provides

positive

NIM-standard

output,

nominally

+5

V;

<20

ns

rise

time,

500

ns

wide;

<10n

output

impedance.

Output

occurs

at

the

mid-point

of

the

linear

input

trailing

edge

plus

the

output

Delay

as

selected

by

the

front

panel

control.

Neg

Out

Front

panel

BNC

connector

provides

negative

NIM-standard

output,

nominally

-16

mA

(800

mV

on

50fi

load);

width,

<20

ns;

rise

time,

<5

ns.

Output

occurs

at

the

mid-point

of

the

linear

input

trailing

edge

plus

the

output

Delay

as

selected

by

the

front

panel

control.

UL

Out

Rear

panel

BNC

connector

provides

NIM-

standard

output,

nominally

+5

V,

500

ns

wide;

<10n

output

impedance.

Output

occurs

as

leading

edge

of

linear

input

crosses

the

UL

threshold.

2.5.

RELATED

EQUIPMENT

The

553

is

compatible

with

all

ORTEC

amplifiers

and

other

amplifiers

having

a

0-

to

10-V

positive,

linear

output

range.

2.6.

ELECTRICAL

AND

MECHANICAL

Power

Required

+24

V,

82

mA;

+12

V,

160

mA;

-24

V,

50

mA;

-12

V,

120

mA.

Dimensions

NIM-standard

single-width

module

(1.35

by

8.714

in.)

per

TID-20893

(Rev).

3.

INSTALLATION

The

553

must

be

used

in

conjunction

with

an

ORTEC

401/402

Series

Bin

and

Power

Supply

or

equivalent,

which

is

intended

for

rack

mounting.

Therefore

if

vacuum

tube

equipment

or

any

other

source

of

heat

is

operating

in

the

same

rack,

there

must

be

sufficient

cooling

air

circulating

to

prevent

any

localized

heating

of

the

transistorized

and

integrated

circuits

used through

out

the

553.

The

temperature

of

equipment

mounted

in

racks

can

easily

exceed

the

maximum

unless

precau

tions

are

taken;

the

553

should

not

be

subjected

to

temperatures

in

excess

of

120°F

(50°C).

3.1.

CONNECTION

TO

POWER

Turn

off

the

Bin

Power

Supply

when

inserting

or

remov

ing

modules.

The

ORTEC

NIM

modules

are

designed

so

that

it

is

not

possible

to

overload

a

properly

operating

power

supply

with

a

full

complement

of

modules

in

the

bin.

Since,

however,

this

may

not

be

true

when

the

bin

contains

modules

other

than

those

of

ORTEC

design,

power

supply

voltages

should

be

checked

after

the

modules

have

been

inserted.

The

401/402

has

test

points

on

the

power

supply

control

panel

to

monitor

dc

voltages.

When

using

the

553

outside

the

401/402

Bin

and

Power

Supply,

be

sure

that

the

power

extension

cable

that

is

used

properly

accounts

for

the

power

supply

grounding

circuits

that

are

provided

according

to

the

recommended

ERDA

standards

outlined

in

TID-20893

(Rev).

Both

high-

quality

and

power-return

ground

connections

are

pro

vided

to

ensure

proper

reference

voltage

feedback

into

the

power

supply,

and

these

must

be

preserved

in

remote

cable

installations.

Be

careful

also

to

avoid

ground

loops

when

the

module

is

operated

outside

the

bin.

3.2.

CONNECTION

FROM

LINEAR

AMPLIFIER

The

553

can

be

used

for

the

analog

signals

that

are

furnished

from

a

linear

amplifier.

The

BNC

on

the

front

panel

accepts

input

signals

through

a

dc-coupled

path.

The

input

circuit

accepts

positive

unipolar

pulses

or

bipolar

pulses

(the

positive

lobe

will

be

analyzed)

into

an

input

impedance

of

^lOOOfl.

When

long

cables

(more

than

about

4

ft)

are

used

to

connect

the

amplifier

output

to

the

553

input,

cable

termination

may

be

necessary

in

order

to

prevent

reflections;

match

the

cable

impedance

with

a

terminator

at

the

553

input

in

such

cases.

3.3.

OUTPUT

CONNECTIONS

The

logic

output

pulses

that

are

generated

when

input

pulses

satisfy

the

amplitude

and

logic

requirements

of

the

553

are

available

through

both

front

and

rear

panel

BNC

connectors.

NIM-standard

fast

negative

signals

are

available

through

the

front

panel

Neg

Out

BNC.

NIM-

standard

slow

positive

signals

are

available

through

the

front

panel

Pos

Out

connector.

When

the

553

is

set

for

either

differential

single-channel

mode

(normal

or

window),

the

logic

output

pulse

means

that

an

input

pulse

amplitude

is

sufficient

to

trigger

the

lower

level

discriminator

without

also

triggering

the

upper

level

discriminator.

When

the

553

is

set

for

its

integral

mode

of

operation,

the

logic

output

means

that

an

input

pulse

amplitude

is

sufficient

to

trigger

the

lower

level

discriminator;

triggering

of

the

upper

level

discrimi

nator

does

not

affect

the

output.

The

time

when

both

SCA

logic

output

signals

are

made

available

is

the

result

of

an

internal

strobe.

The

strobe

originates

from

the

constant-fraction

trigger,

at

50%

amplitude

on

the

decay

of

the

positive

input

pulse.

This

strobes

a

delay

circuit,

with

the

delay

interval

adjusted

with

a

front

panel

control

between

0.1

and

1.1

^s,

and

the

outputs

occur

at

the

end

of

the

delay

interval.

A

logic

output

is

available

through

the

rear

panel

to

indicate

when,

on

the

leading

edge

of

an

input

pulse,

the

UL

discriminator

is

triggered.

These

responses

can

be

used

to

monitor

the

discriminator

levels

during

adjust

ment,

to

be

counted

in

external

sealers,

to

provide

subgroup

routing

in

a

multichannel

analyzer,

or

for

any

other

applications

as

desired.

Each

logic

output

for

UL

Out

is

a

NIM-standard

slow

positive

pulse

that

is

com

patible

with

all

ORTEC

counters,

counting

rate

meters,

and

other

instruments.

The

output

impedance

through

each

output

path

is

sufficiently

low

to

drive

as

many

as

ten

paralleled

lOOOH

inputs.

3.4.

LOWER

LEVEL

REFERENCE

INPUT

If

the

LL

Ref

toggle

switch

on

the

rear

panel

of

the

553

is

set

at

Ext,

the

reference

level

for

the

lower

level

discrimi

nator

must

be

furnished

through

the

adjacent

LL

Ref

In

BNC

connector;

the

10-turn

Lower

Level

control

on

the

front

panel

is

disconnected.

An

input

of

0

to

-10

V

through

this

connector

corresponds

directly

to

a

range

of

0

to

+10

V

for

the

lower

level

discriminator

threshold.

If

an

input

is

connected

to

the

LL

Ref

connector

and

the

switch

selects

Int,

the

signal

through

the

connector

is

ignored.

4.

OPERATING

INSTRUCTIONS

After

the

553

has

been

connected

into

a

system

accord

ing

to

the

installation

information

in

Section

3,

the

operating

mode

can

be

selected

and

the

discriminator

thresholds

can

be

adjusted

as

required

for

each

appli

cation.

Figure

4.1

illustrates

the

timing

relationships

that

will

be

effective

in

the

553

for

each

of

three

possible

input

pulse

amplitudes.

The

first

two

pulses

exceed

the

lower

level

threshold

without

also

exceeding

the

upper

level,

and

the

third

pulse

exceeds

both

threshold

levels.

Superimposed

in

each

of

these

input

pulses

in

Fig.

4.1

is

an

internally-

generated

signal

that

rises

to

50%

of

the

input

peak

amplitude

and

is

stretched

at

that

level.

When

the

input

pulse

decays

through

the

50%

level,

the

CF

discriminator

resets

and,

when

delayed

by

a

fixed

interval,

triggers

the

SCA

outputs

if

the

analysis

criteria

have

been

satisfied.

The

delay

interval

can

be

adjusted

within

the

range

of

0.1

to

1.1

(us

using

a

front

panel

control.

If

the

pulses

of

Fig.

4.1

were

furnished

to

a

553

that

was

set

for

its

Normal

or

Window

(differential)

mode,

time-significant

SCA

output

pulses

would

be

generated

for

each

of

the

first

two

input

pulses

but

none

would

be

generated

for

the

third

be

cause

its

amplitude

was

greater

than

the

upper

level

threshold.

If

the

pulses

were

furnished

to

a

553

that

was

set

for

its

Integral

mode,

a

time-significant

output

pulse

pair

would

be

generated

for

each

of

the

three

input

pulses.

In

either

mode

of

operation,

a

ULD

output

will

result

when

the

corresponding

discriminator

threshold

is

exceeded

by

the

input

pulse

amplitude.

The

adjusted

lower

level

threshold

is

furnished

either

from

the

front

panel

Lower

Level

control

or

from

an

external

source

through

the

rear

panel

LL

Ref

connector;

the

alternate

selection

is

made

with

the

rear

panel

LL

Ref

toggle

switch

-

either

Int

for

the

front

panel

control

or

Ext

for

the

rear

panel

8NC.

In

either

case,

the

range

is

from

0

to

+10

V,

measured

from

chassis

ground,

of

the

input

signal.

The

adjusted

upper

level

threshold

is

determined

by

the

setting

of

the

front

panel

Upper

Level

or

Window

control

and

by

the

front

panel

mode

selector

toggle

switch.

When

the

switch

is

set

at

either

Int

or

Nor,

the

range

of

the

variable

control

is

from

0

to

+10

V,

measured

from

chassis

ground.

When

the

toggle

switch

is

set

at

Win,

the

range

of

the

variable

control

is

0

to

+1

V,

measured

above

the

adjusted

lower

level

threshold.

For

optimum

time-significant

SCA

output

timing,

the

front

panel

Walk

Adj

must

be

trimmed

to

the

combined

effects

of

the

input

shaping

and

its

time

constants

and

of

the

expected

dynamic

range

of

operation.

Using

a

dupli

cate

of

the

minimum

and

maximum

amplitudes

for

shaped

input

pulses,

set

the

control

to

provide

the

minimum

walk

(variation

of

time

of

occurrence

vs

input

amplitude).

ULD

CF

TRIGGER

Delay

adjusted

in

range

of

0.1

to

1.1

jjs

—•

(DIFF)

SCA

POS

OUT

(DIFF)

SCA

NEC

OUT

(INT)

SCA

POS

OUT

rL_

(INT)

SCA

NEG

OUT

Y

Hh

-Ih

Hh

■ih

n

Fig.

4.1.

Timing

Relationships

for

Input

and

Output

Pulses.

5.

CIRCUIT

DESCRIPTION

5.1.

GENERAL

Refer

to

schematic

diagram

553-0201-S1

included

at

the

back

of

the

manual.

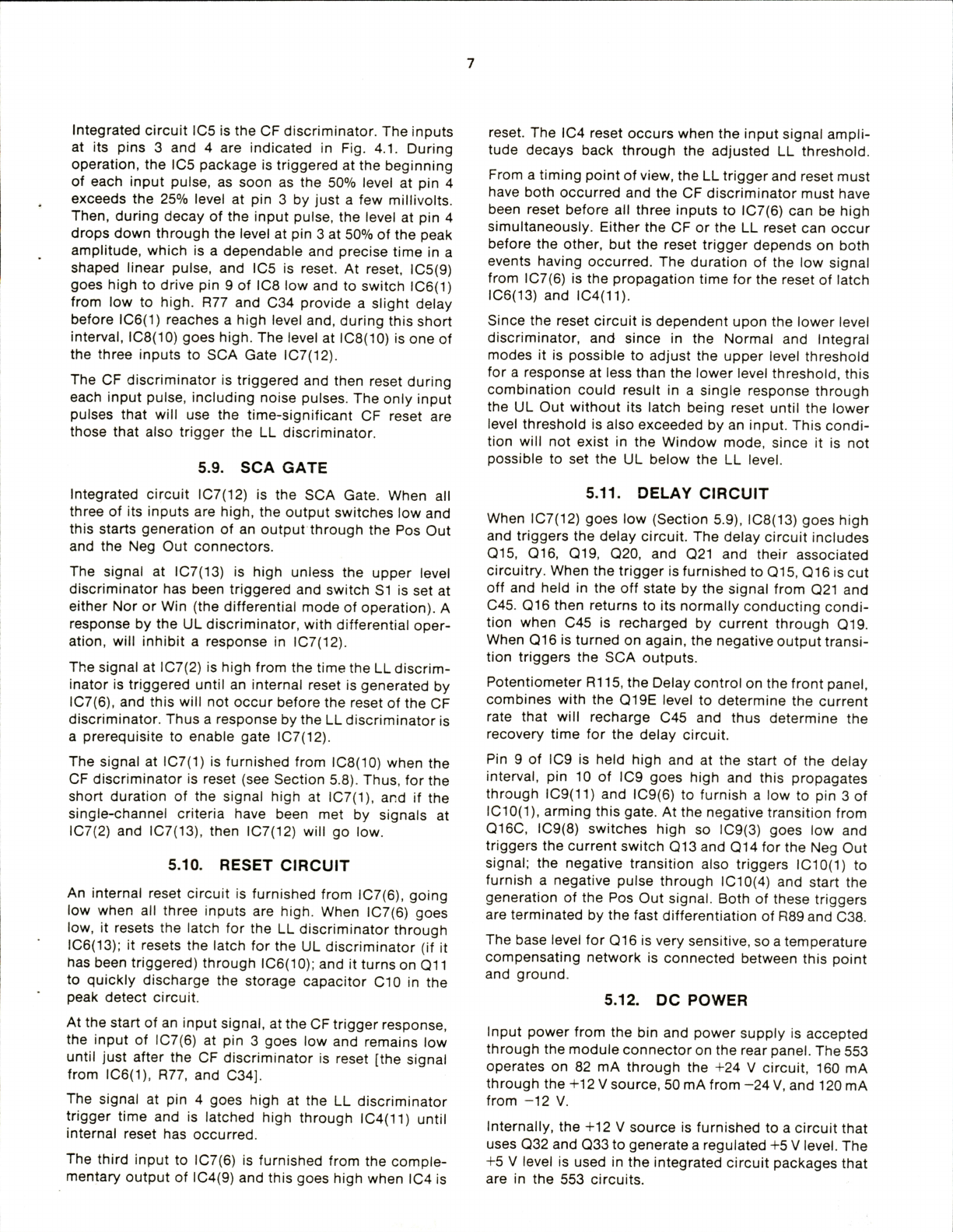

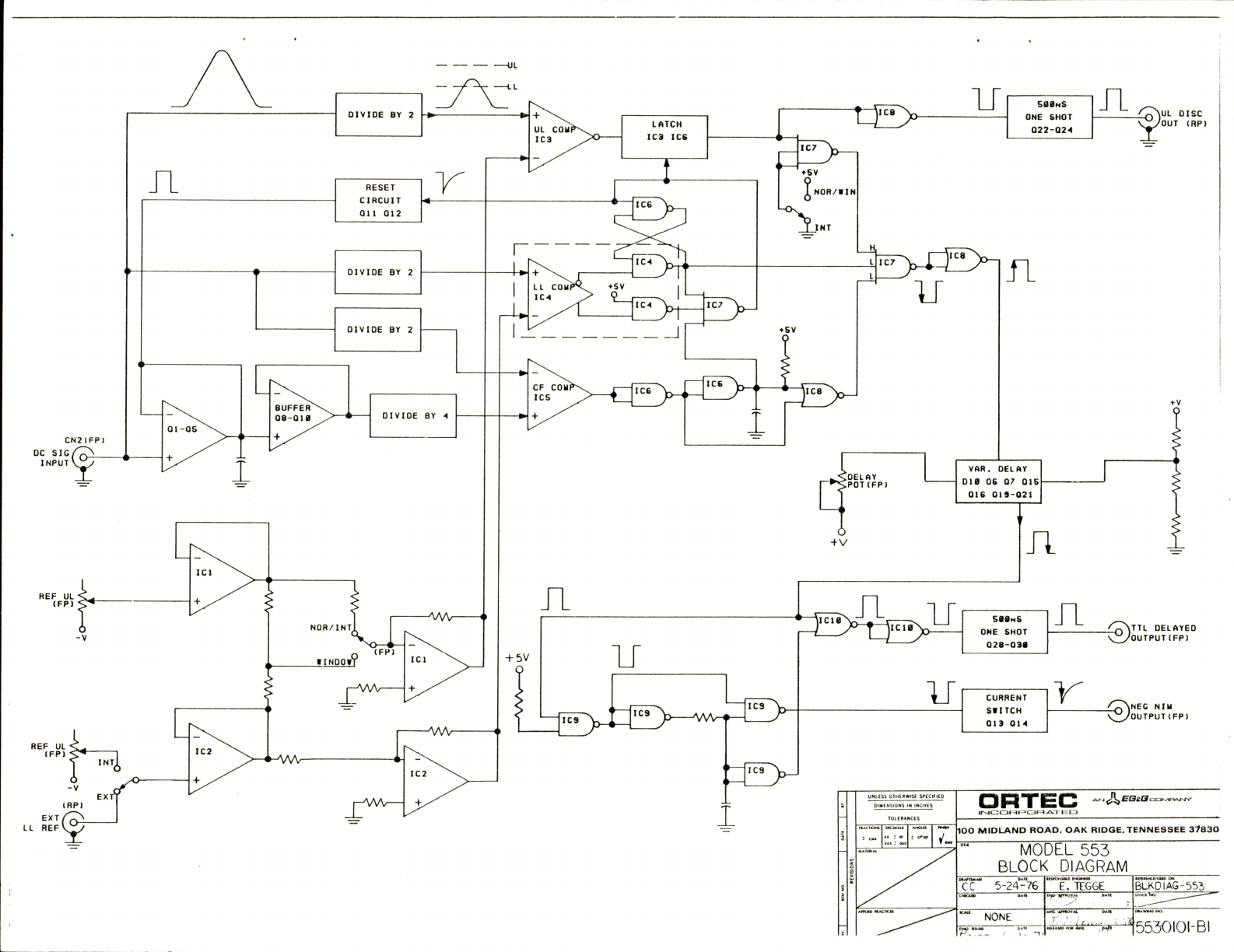

Figure

5.1

is

a

simplified

block

diagram

of

the

553

Timing

SCA.

It

shows

that

each

input

pulse

is

furnished

to

three

internal

discriminators

and

also

through

an

attenuate

and

peak

stretch

circuit.

The

three

discriminators

are

UL

(upper

level),

LL

(lower

level),

and

CP

(constant

frac

tion).

Each

discriminator

independently

triggers

a

re

sponse

when

the

amplitude

of

its

noninverted

input

exceeds

the

amplitude

of

its

inverted

input.

The

response

of

the

UL

and

LL

discriminators

is

latched

until

an

internal

reset

occurs.

The

CP

discriminator

is

reset

again

when

the

input

conditions

are

reversed.

Reference

levels

for

the

UL

and

LL

discriminators

are

set

independently

for

either

Integral

or

Normal

mode

opera

tion.

For

Window

operation,

the

threshold

for

the

UL

discriminator

is

based

on

the

LL

setting

instead

of

ground.

The

CP

discriminator

is

triggered

at

the

onset

of

each

input

pulse,

whether

its

amplitude

is

sufficient

to

trigger

either

of

the

other

two

discriminators

or

not.

Then

the

CP

discriminator

is

reset

when

the

amplitude

of

the

input

pulse

decays

through

its

50%

level

because

the

attenuate

and

peak

stretch

circuit

has

generated

and

maintained

this

50%

level

by

that

time

and

furnished

it

as

the

discriminator

reference

level.

The

SCA

gate

is

triggered

when

the

CP

discriminator

is

reset

if,

at

that

time,

the

LL

discriminator

has

been

triggered

and

the

UL

discriminator

either

has

not

been

triggered

(for

differential

operation)

or

is

ignored

(for

integral

operation).

Thus

the

gate

responds

to

both

logical

conditions

and

input-pulse

time

significance.

If

the

SCA

gate

responds,

it

strobes

a

delay

circuit

that

then

generates

the

SCA

outputs

at

the

end

of

the

delay

interval.

5.2.

INTEGRATED

CIRCUITS

The

nomenclature

used

to

identify

integrated

circuit

packages

in

this

manual

is

defined

below

for

the

example

IC5(4)

where

IC

=

integrated

circuit,

5

=

reference

designation,

(4)

=

pin

number.

Any

portion

of

an

IC

package

can

be

designated

by

its

output

pin

number:

in

this

example,

the

portion

of

IC5

that

includes

pin

4

as

an

output

is

identified

uniquely.

5.3.

LOWER

LEVEL

BIAS

The

threshold

for

the

lower

level

discriminator

is

ad

justed

with

the

front

panel

Lower

Level

control,

R43,

or

is

OUTPUT

T

Int

GENERATOR

UL

DISC

Nor/Win

DC

In

Int/Nor

LL

DISC

DELAY

OUTPUT

GENERATOR

CF

DISC

ATTENUATE

and

PEAK

STRETCH

CURRENT

SWITCH

UL

Out

-0

-0

Pos

Out

-0

Neg

Out

Fig.

5.1.

Simplified

Block

Diagram

of

tfie

553

Timing

SCA.

furnished

as

a

dc

level

through

CN3

on

the

rear

panel.

Switch

84

on

the

rear

panel

selects

which

of

these

sources

is

effective

for

bias

control.

For

the

internal

bias

circuit,

R47

is

a

potentiometer

mounted

on

the

printed

circuit

that

adjusts

the

minimum

level

for

the

front

panel

control.

The

actual

range

of

R43

is,

then,

from

a

few

millivolts

to

about

—5

V.

The

adjusted

level

is

buffered

through

IC2(7)

and

inverted

through

operational

amplifier

IC2{1),

with

a

gain

of

unity,

and

furnished

to

the

inverting

input

of

IC4,

the

lower

level

discriminator.

For

the

external

bias

circuit,

a

dc

level

between

0

and

-10

V

can

be

furnished

through

CN3

and

divided

by

R44

and

R45.

The

result

that

is

selected

with

switch

84

is

then

furnished

through

the

same

buffering

and

coupling

network

to

the

lower

level

discriminator.

5.4.

UPPER

LEVEL

BIAS

The

threshold

for

the

upper

level

discriminator

is

ad

justed

with

the

front

panel

Window

or

Upper

Level

control,

R38.

The

range

for

this

control

is

0

to

-5

V.

The

adjusted

level

is

buffered

through

IC1(7)

and

furnished

through

either

R55

or

R52,

through

operational

amplifier

IC1(1),

and

to

the

inverting

input

of

upper

level

discrimi

nator

IC3.

When

switch

81

is

set

at

either

Integrate

or

Normal,

the

gain

of

IC1{1)

for

this

adjusted

bias

signal

is

1.0;

when

the

switch

selects

Window,

the

gain

is

reduced

to

0.1

and

the

effective

range

of

the

Window

control

is

thus

reduced

by

a

factor

of

10.

Also,

when

the

switch

selects

Window,

the

level

that

is

furnished

from

IC2(7)

for

the

lower

level

discriminator

is

also

furnished

through

R50

and

IC1(1).

Thus

the

adjusted

lower

level

becomes,

effectively,

the

base

above

which

the

upper

level

is

added,

and

the

result

is

a

window

of

0

to

1

V

between

the

lower

level

and

upper

level

thresholds

(referred

to

the

input

pulse

amplitude).

The

gain

for

the

level

from

IC2(7)

through

IC1(1)

is

unity.

5.5.

INPUT

CIRCUIT

The

analog

input

signal

is

furnished

through

CN2

on

the

front

panel.

The

signal

is

then

furnished

to

dividers

R3-

R4

and

R147-R148,

and

50%

of

the

input

amplitude

is

applied

to

the

noninverting

inputs

of

both

the

UL

and

LL

discriminators,

IC3

and

104.

The

input

range

of

0

to

+10

V,

divided

by

two

for

an

effective

range

of

0

to

+5

V

at

the

discriminator

inputs,

is

directly

equivalent

to

the

range

of

threshold

levels

described

in

8ections

5.2

and

5.3.

The

input

signal,

through

the

front

panel

dc-coupled

circuit,

can

be

monitored

at

test

point

TP1

on

the

front

panel.

5.6.

LOWER

LEVEL

DISCRIMINATOR

Integrated

circuit

package

104

is

the

lower

level

discrimi

nator.

As

long

as

the

input

level

at

its

pin

3

does

not

exceed

the

level

at

pin

4,

the

output

at

its

pin

9

is

high.

When

the

amplitude

of

the

input

signal,

at

pin

3,

in

creases

above

the

threshold

level

at

pin

4,

104

triggers

and

reverses

the

levels

at

its

pins

9

and

11.

When

104(11)

goes

high,

106(13)

goes

low

and

latches

104(11)

in

the

high

state

until

a

reset

is

furnished

from

107(6).

The

reset

will

be

furnished

when

the

discriminator

returns

to

quies

cent

and

the

OF

discriminator

is

also

reset;

these

condi

tions

occur

on

the

trailing

edge

of

the

input

pulse.

Until

latch

106(13)

and

104(11)

is

reset,

the

high

level

to

pin

2

of

80A

gate

107(12)

arms

the

gate

to

permit

response

if

its

pins

1

and

13

go

high.

8ee

8ection

5.9,

80A

Gate.

5.7.

UPPER

LEVEL

DISCRIMINATOR

Integrated

circuit

package

103

is

the

upper

level

discrim

inator.

It

is

identical

to

104,

discussed

in

8ection

5.6,

except

that

its

output

at

pin

9

is

not

used.

If

the

amplitude

at

pin

3

increases

above

the

threshold

level

at

pin

4,

103

triggers

and

switches

the

output

at

103(11)

to

its

high

state.

This

output

at

pin

11

latches

through

106(10)

until

a

reset

is

furnished

from

107(6).

The

reset

will

be

furnished

when

both

the

lower

level

and

OF

discriminators

have

been

reset,

as

discussed

in

8ection

5.6.

At

the

trigger

time

on

the

leading

edge

of

the

input

signal,

when

103(11)

goes

high,

an

output

through

0N4,

the

UL

Out

connector,

is

generated

through

108(1),

022,

023,

and

024.

The

positive

output

pulse

has

a

width

of

about

500

ns.

If

switch

81

is

set

at

Int,

the

output

of

gate

107(8)

will

remain

high

whether

the

upper

level

discriminator

is

triggered

or

not.

But

if

the

switch

selects

either

Normal

or

Window

(for

differential

single-channel

operation),

a

response

in

103

will

furnish

a

low

signal

from

107(8)

to

inhibit

a

response

in

107(12)

and

prevent

an

80A

output

signal

from

being

generated.

5.8.

CONSTANT

FRACTION

CIRCUIT

The

input

signal

is

furnished

through

R2

into

a

peak

detect

circuit,

formed

by

Q1

through

Q5

and

O10.

During

the

rise

time

of

the

input

pulse,

the

capacitor

is

charged.

The

reverse

current

path

is

cut

off,

so

the

peak

amplitude

of

the

input

pulse

remains

on

O10

until

it

is

discharged

at

a

later

time.

The

peak

amplitude

of

the

input

pulse

is

furnished

through

a

unity-gain

buffer

amplifier,

Q8,

Q9,

and Q10.

The

front

panel

Walk

Adj

control,

R36,

provides

a

fine

adjustment

of

the

offset

of

this

amplifier

and

is

adjusted

for

its

dynamic

function

to

minimize

walk

in

the

time-

significant

output

pulses.

The

output

of

the

buffer

ampli

fier

is

furnished

through

R33

and

R31,

a

divide-by-4

attenuator.

From

this

circuit,

25%

of

the

peak

amplitude

of

the

signal

input

pulse

is

furnished

to

the

inverting

input

of

105.

Integrated

circuit

ICS

is

the

OF

discriminator.

The

inputs

at

its

pins

3

and

4

are

indicated

in

Fig.

4.1.

During

operation,

the

ICS

package

is

triggered

at

the

beginning

of

each

input

pulse,

as

soon

as

the

S0%

level

at

pin

4

exceeds

the

2S%

level

at

pin

3

by

just

a

few

millivolts.

Then,

during

decay

of

the

input

pulse,

the

level

at

pin

4

drops

down

through

the

level

at

pin

3

at

S0%

of

the

peak

amplitude,

which

is

a

dependable

and

precise

time

in

a

shaped

linear

pulse,

and

ICS

is

reset.

At

reset,

ICS(9)

goes

high

to

drive

pin

9

of

ICS

low

and

to

switch

IC6(1)

from

low

to

high.

R77

and

C34

provide

a

slight

delay

before

IC6(1)

reaches

a

high

level

and,

during

this

short

interval,

IC8(10)

goes

high.

The

level

at

IC8(10)

Is

one

of

the

three

inputs

to

SCA

Gate

IC7(12).

The

CF

discriminator

is

triggered

and

then

reset

during

each

input

pulse,

including

noise

pulses.

The

only

input

pulses

that

will

use

the

time-significant

CF

reset

are

those

that

also

trigger

the

LL

discriminator.

5.9.

SCA

GATE

Integrated

circuit

IC7(12)

is

the

SCA

Gate.

When

all

three

of

its

inputs

are

high,

the

output

switches

low

and

this

starts

generation

of

an

output

through

the

Pos

Out

and

the

Neg

Out

connectors.

The

signal

at

107(13)

is

high

unless

the

upper

level

discriminator

has

been

triggered

and

switch

81

is

set

at

either

Nor

or

Win

(the

differential

mode

of

operation).

A

response

by

the

UL

discriminator,

with

differential

oper

ation,

will

inhibit

a

response

in

IC7(12).

The

signal

at

IC7(2)

is

high

from

the

time

the

LL

discrim

inator

is

triggered

until

an

internal

reset

is

generated

by

IC7(6),

and

this

will

not

occur

before

the

reset

of

the

CF

discriminator.

Thus

a

response

by

the

LL

discriminator

is

a

prerequisite

to

enable

gate

IC7(12).

The

signal

at

IC7(1)

is

furnished

from

IC8(10)

when

the

CF

discriminator

is

reset

(see

Section

5.8).

Thus,

for

the

short

duration

of

the

signal

high

at

IC7(1),

and

if

the

single-channel

criteria

have

been

met

by

signals

at

IC7(2)

and

IC7(13),

then

IC7(12)

will

go

low.

5.10.

RESET

CIRCUIT

An

internal

reset

circuit

is

furnished

from

IC7(6),

going

low

when

all

three

inputs

are

high.

When

IC7(6)

goes

low,

it

resets

the

latch

for

the

LL

discriminator

through

IC6(13):

it

resets

the

latch

for

the

UL

discriminator

(if

it

has

been

triggered)

through

IC6(10);

and

it

turns

on

Q11

to

quickly

discharge

the

storage

capacitor

CIO

in

the

peak

detect

circuit.

At

the

start

of

an

input

signal,

at

the

CF

trigger

response,

the

input

of

IC7(6)

at

pin

3

goes

low

and

remains

low

until

just

after

the

CF

discriminator

is

reset

[the

signal

from

IC6(1),

R77,

and

C34].

The

signal

at

pin

4

goes

high

at

the

LL

discriminator

trigger

time

and

is

latched

high

through

IC4(11)

until

internal

reset

has

occurred.

The

third

input

to

IC7(6)

is

furnished

from

the

comple

mentary

output

of

IC4(9)

and

this

goes

high

when

IC4

is

reset.

The

IC4

reset

occurs

when

the

input

signal

ampli

tude

decays

back

through

the

adjusted

LL

threshold.

From

a

timing

point

of

view,

the

LL

trigger

and

reset

must

have

both

occurred

and

the

CF

discriminator

must

have

been

reset

before

all

three

inputs

to

IC7(6)

can

be

high

simultaneously.

Either

the

CF

or

the

LL

reset

can

occur

before

the

other,

but

the

reset

trigger

depends

on

both

events

having

occurred.

The

duration

of

the

low

signal

from

IC7(6)

is

the

propagation

time

for

the

reset

of

latch

IC6(13)

and

IC4(11).

Since

the

reset

circuit

is

dependent

upon

the

lower

level

discriminator,

and

since

in

the

Normal

and

Integral

modes

it

is

possible

to

adjust

the

upper

level

threshold

for

a

response

at

less

than

the

lower

level

threshold,

this

combination

could

result

in

a

single

response

through

the

UL

Out

without

its

latch

being

reset

until

the

lower

level

threshold

is

also

exceeded

by

an

input.

This

condi

tion

will

not

exist

in

the

Window

mode,

since

it

is

not

possible

to

set

the

UL

below

the

LL

level.

5.11.

DELAY

CIRCUIT

When

IC7(12)

goes

low

(Section

5.9),

IC8(13)

goes

high

and

triggers

the

delay

circuit.

The

delay

circuit

includes

Q15, Q16, Q19,

Q20,

and

Q21

and

their

associated

circuitry.

When

the

trigger

is

furnished

to

Q15,

Q16

is

cut

off

and

held

in

the

off

state

by

the

signal

from

Q21

and

C45.

Q16

then

returns

to

its

normally

conducting

condi

tion

when

C45

is

recharged

by

current

through

Q19.

When

Q16

is

turned

on

again,

the

negative

output

transi

tion

triggers

the

SCA

outputs.

Potentiometer

R115,

the

Delay

control

on

the

front

panel,

combines

with

the

Q19E

level

to

determine

the

current

rate

that

will

recharge

045

and

thus

determine

the

recovery

time

for

the

delay

circuit.

Pin

9

of

109

is

held

high

and

at

the

start

of

the

delay

interval,

pin

10

of

109

goes

high

and

this

propagates

through

109(11)

and

109(6)

to

furnish

a

low

to

pin

3

of

1010(1),

arming

this

gate.

At

the

negative

transition

from

Q160,

109(8)

switches

high

so

109(3)

goes

low

and

triggers

the

current

switch

Q13

and

Q14

for

the

Neg

Out

signal;

the

negative

transition

also

triggers

1010(1)

to

furnish

a

negative

pulse

through

1010(4)

and

start

the

generation

of

the

Pos

Out

signal.

Both

of

these

triggers

are

terminated

by

the

fast

differentiation

of

R89

and

038.

The

base

level

for

016

is

very

sensitive,

so

a

temperature

compensating

network

is

connected

between

this

point

and

ground.

5.12.

DC

POWER

Input

power

from

the

bin

and

power

supply

is

accepted

through

the

module

connector

on

the

rear

panel.

The

553

operates

on

82

mA

through

the

-1-24

V

circuit,

160

mA

through

the

-1-12

V

source,

50

mA

from

-24

V,

and

120

mA

from

-12

V.

Internally,

the

+12

V

source

is

furnished

to

a

circuit

that

uses

Q32

and

Q33

to

generate

a

regulated

+5

V

level.

The

+5

V

level

is

used

in

the

integrated

circuit

packages

that

are

in

the

553

circuits.

6.

MAINTENANCE

AND

CALIBRATION

6.1.

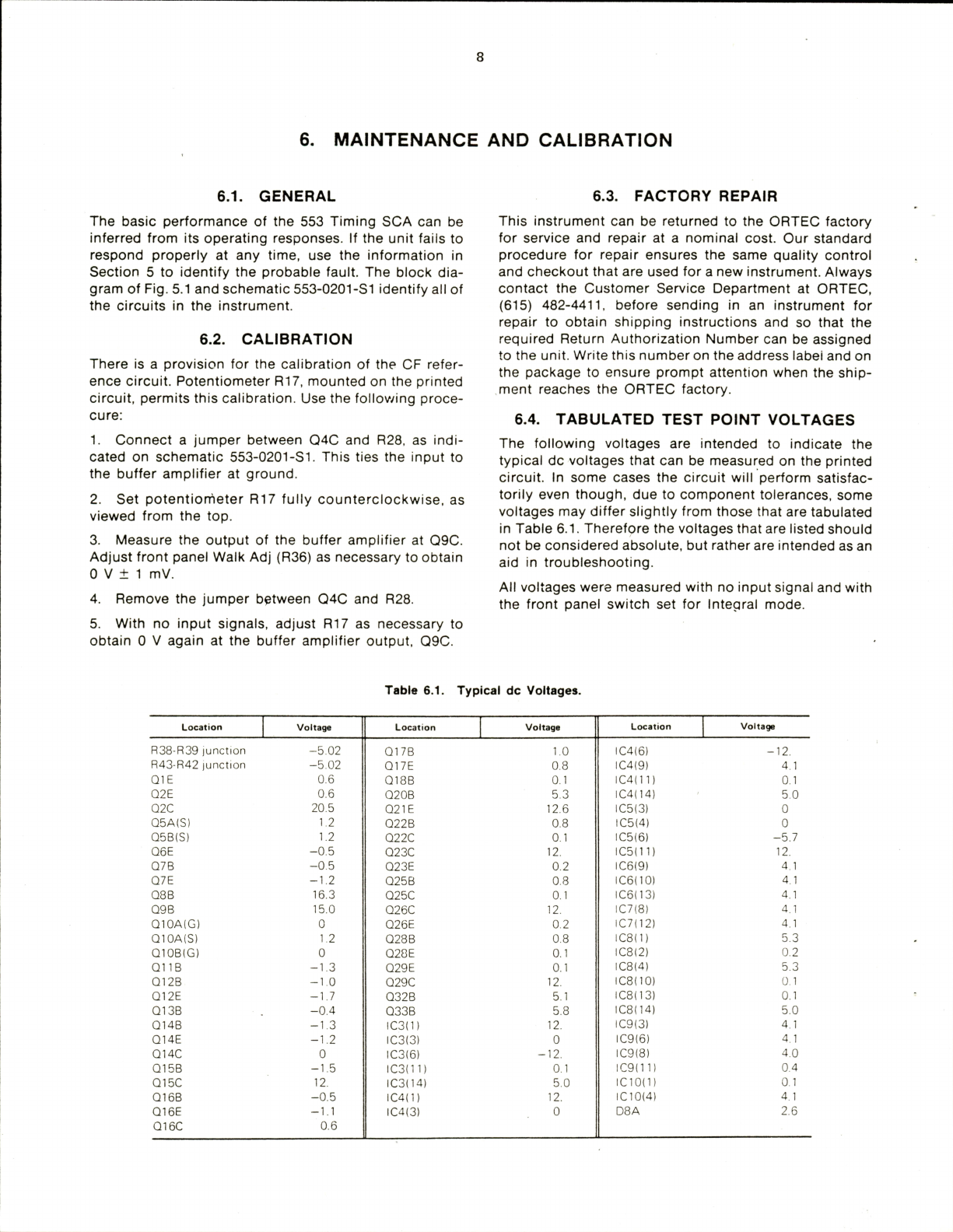

GENERAL

The

basic

performance

of

the

553

Timing

SCA

can

be

inferred

from

its

operating

responses.

If

the

unit

faiis

to

respond

properly

at

any

time,

use

the

information

in

Section

5

to

identify

the

probable

fault.

The

block

dia

gram

of

Fig.

5.1

and

schematic

553-0201-31

identify

all

of

the

circuits

in

the

instrument.

6.2.

CALIBRATION

There

is

a

provision

for

the

calibration

of

the

CF

refer

ence

circuit.

Potentiometer

R17,

mounted

on

the

printed

circuit,

permits

this

calibration.

Use

the

follov/ing

proce-

cure:

1.

Connect

a

jumper

between

Q4C

and

R28,

as

indi

cated

on

schematic

553-0201-81.

This

ties

the

input

to

the

buffer

amplifier

at

ground.

2.

Set

potentiorheter

R17

fully

counterclockwise,

as

viewed

from

the

top.

3.

Measure

the

output

of

the

buffer

amplifier

at

Q9C.

Adjust

front

panel

Walk

Adj

(R36)

as

necessary

to

obtain

0

V

±

1

mV.

4.

Remove

the

jumper

between

Q4G

and

R28.

5.

With

no

input

signals,

adjust

R17

as

necessary

to

obtain

0

V

again

at

the

buffer